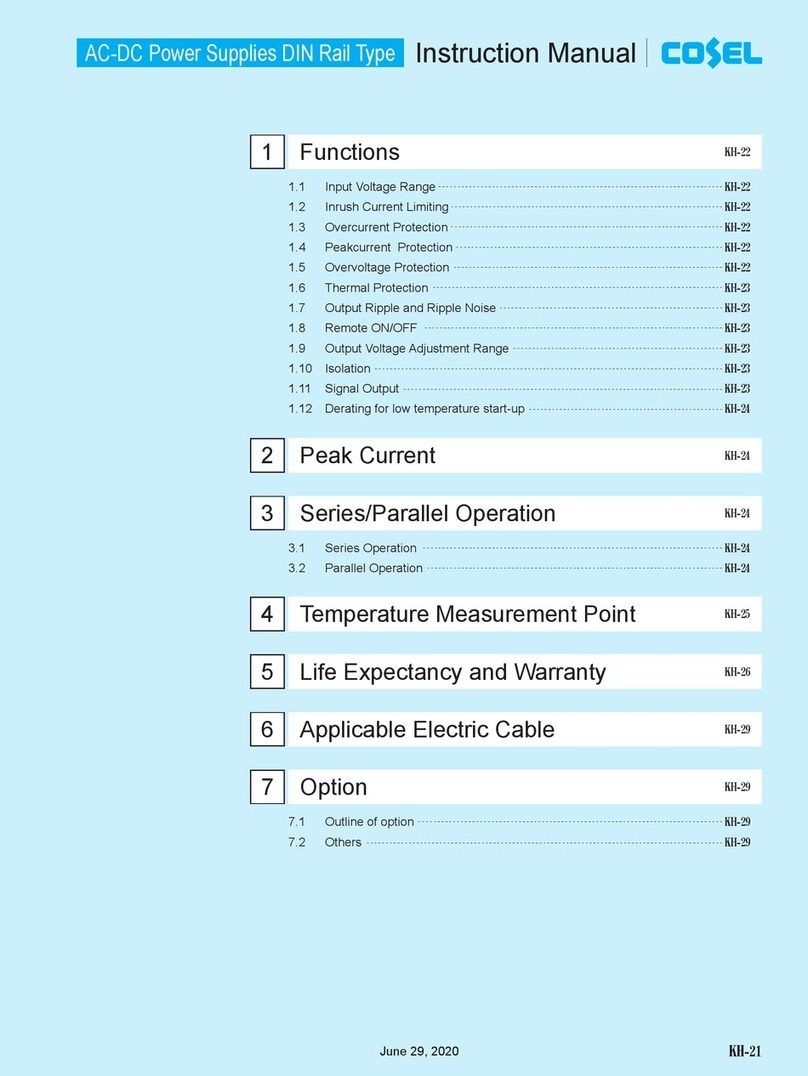

1.1 Input voltage range

¡The range is from AC85V to AC132V.

¡AC input voltage must have a range from AC85V to AC132V for

normal operation. If the wrong input is applied, the unit will not op-

erate properly and/or may be damaged.

¡In cases that conform with safety standard, input voltage range is

AC100-AC120V(50/60Hz).

1.2 Inrush current limiting

¡Inrush current limiting is built-in.

¡If a switch is being used for input, ensure that it is configured to

handle the input inrush current.

¿ LGA50A, LGA75A

¡If the unit is shut down, recycling AC line has to be done after

cooling down the unit since thermistor is used for the protection

from the inrush current.

¿ LGA100A, LGA150A, LGA240A

¡The SCR is used for protection from inrush current. When power

is turned ON/OFF repeatedly within a short period of time, it is

necessary to have enough time between power ON and OFF to

operate resistance circuit for inrush current.

1.3 Overcurrent protection

¡Overcurrent protection is built-in and comes into effect at over

105%(-H is 101% or more of the peak current) of the rated cur-

rent. Overcurrent protection prevents the unit from short circuit

and overcurrent condition of less than 15 seconds. The unit auto-

matically recovers when the fault condition is cleared.

¿

LGA50A-3R3-Y, LGA50A-5, LGA75A-3R3-Y,

LGA75A-5, LGA100A-3R3-Y, LGA100A-5-Y,

LGA150A-3R3-Y, LGA150A-5-Y

¡Intermittent current characteristics.

¡When the output voltage drops at overcurrent, the average output

current is reduced by intermittent operation of power supply.

1.4 Overvoltage protection

¡An overvoltage protection circuit is built-in. The AC input should

be shut down if overvoltage protection is in operation. The mini-

mum interval of AC recycling for recovery is 1.5 minutes (LGA240A

is 3minutes).

*The recovery time varies depending on input voltage.

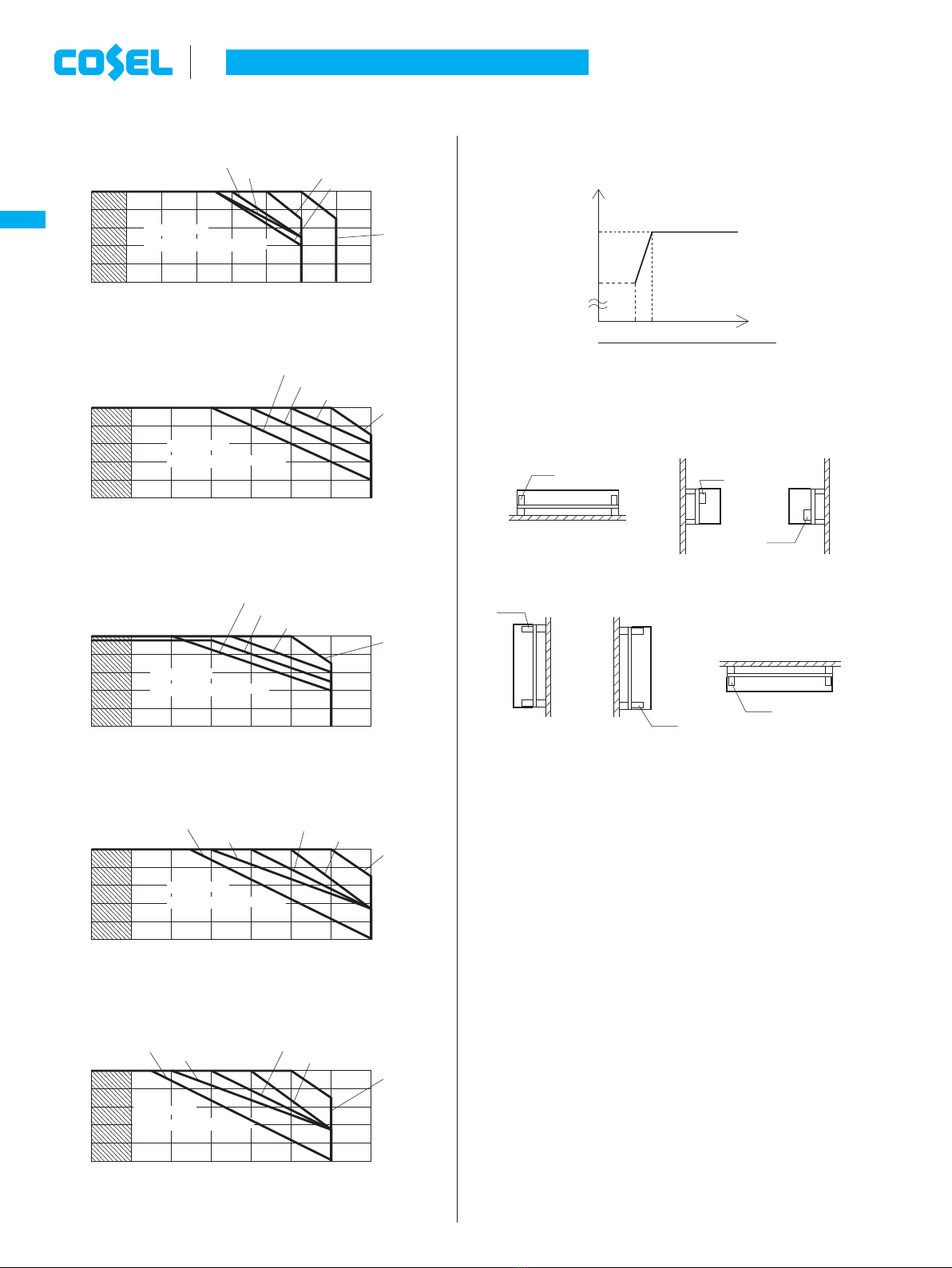

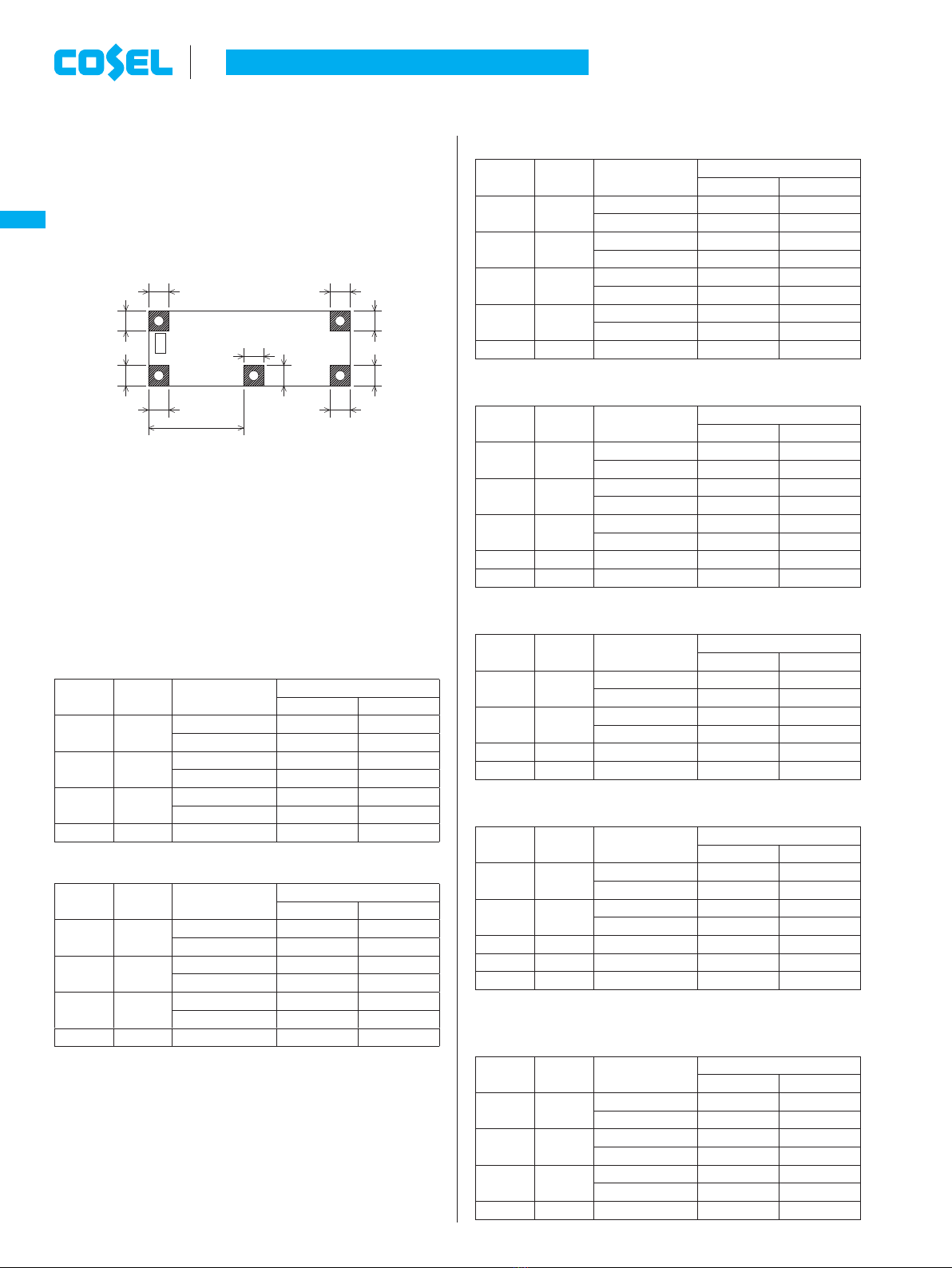

¡Series operation is available by connecting the outputs of two or

more power supplies with the same output voltage, as shown be-

low. Output current in series connection should be lower than the

lowest rated current in each unit.

¡Parallel operation is not possible.

¡Redundancy operation is available by wiring as shown below.

¡Even a slight difference in output voltage can affect the balance

between the values of I1and I2.

Please make sure that the value of I3does not exceed the rated

current of a power supply.

I3[the rated current value

1 Function Remarks:

Please avoid applying the over-rated voltage to the output termi-

nal. Power supply may operate incorrectly or fail.In case of oper-

ating a motor etc. , please install an external diode on the output

terminal to protect the unit.

1.5 Output voltage adjustment range

¡Adjustment of output voltage is possible by using potentiometer.

Please refer to instruction manual 5.1.

¡Option ”-Y” is recommended which can adjust the output voltatge.

1.6 Isolation

¡For a receiving inspection, such as Hi-Pot test, gradually increase

(decrease) the voltage for the start (shut down). Avoid using Hi-

Pot tester with the timer because it may generate voltage a few

times higher than the applied voltage, at ON/OFF of a timer.

2 Series Operation and

Parallel Operation

AC-DC Power Supplies Open Frame/ Enclosed Type

Instruction Manual

LGA-14

LGA

I2

I1I3

-

+

+

-

Load

Power

Supply

Power

Supply

Load

(a) (b)

Load Load

Power

Supply

+

-

Power

Supply

+

-

Power

Supply

+

-

+

-

Power

Supply

Fig.2.1 Examples of connecting in series operation

Fig.2.2 Example of redundancy operation

melga1.inddLGA-14me lga1 indd LGA-14 2015/06/1914:42:252015/06/19 14:42:25