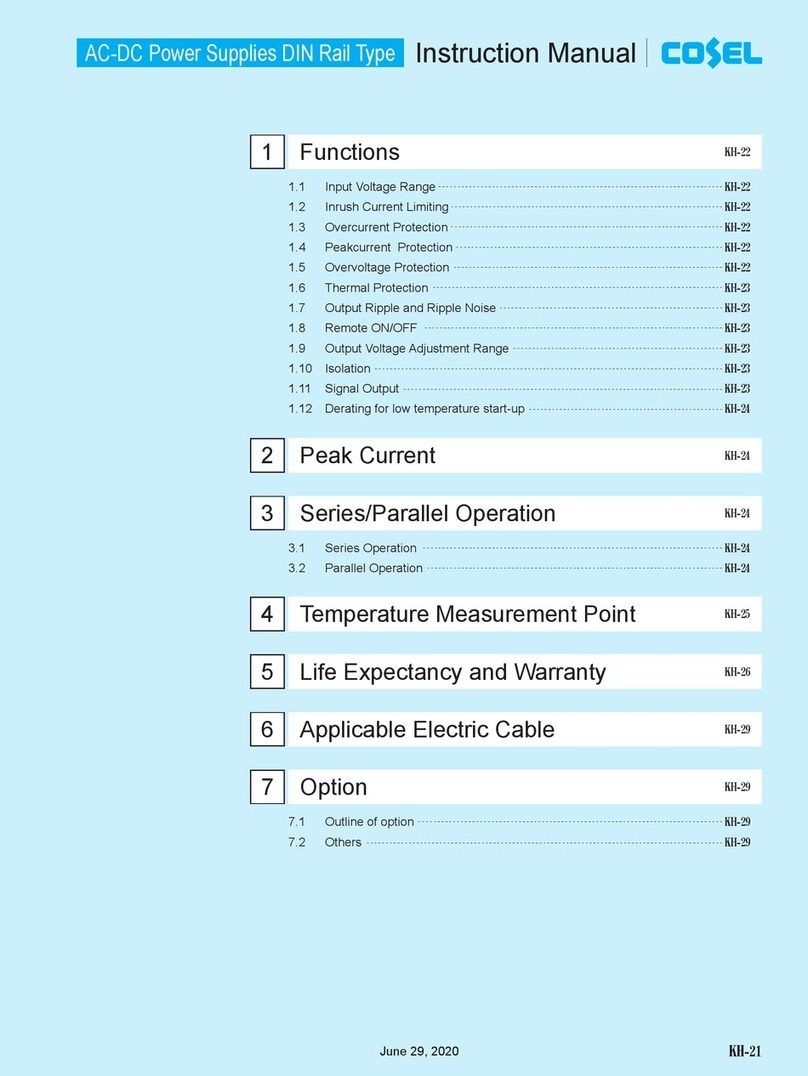

2.6 Thermal Protection

¡A thermal protection circuit is built-in.

The thermal protection circuit may be activated under following

conditions and shut down the output.

1

When a current and a temperature continue to exceed the val-

ues determined by the derating curve.

2

When a fan stops or air flow weakens by intake port or exhaust

port is blocked.

If the thermal protection circuit is activated, shut off the input volt-

age and eliminate all the overheating conditions. To recover the

output voltage, have enough time to cool down the unit before

turning on the input voltage again.

2.7 Output VoltageAdjustment Range

¡To increase an output voltage, turn a built-in potentiometer clock-

wise. To decrease the output voltage, turn it counterclockwise.

¡The power supplies have an external output voltage control func-

tion. The output voltage can be adjusted within a 110% range

from 90% by changing the voltage between the terminal TRM and

the terminal COM on CN1/CN2. You can decrease the voltage by

drawing a current from the TRM terminal.

You can calculate the output voltage in this case from formula 1

below.

Please note that the formula 1gives you only an estimate.

Please contact us if you need accurate numbers.

Please do not apply negative Voltage to TRM terminal.

There is more than one method to adjust the output voltage, in-

cluding the methods to use external resistors and external power

supplies. Since each method has different characteristic, please

contact us for details.

Output voltage = Xrated output voltage---1

The voltage between

TRM and COM

2.5 [V]

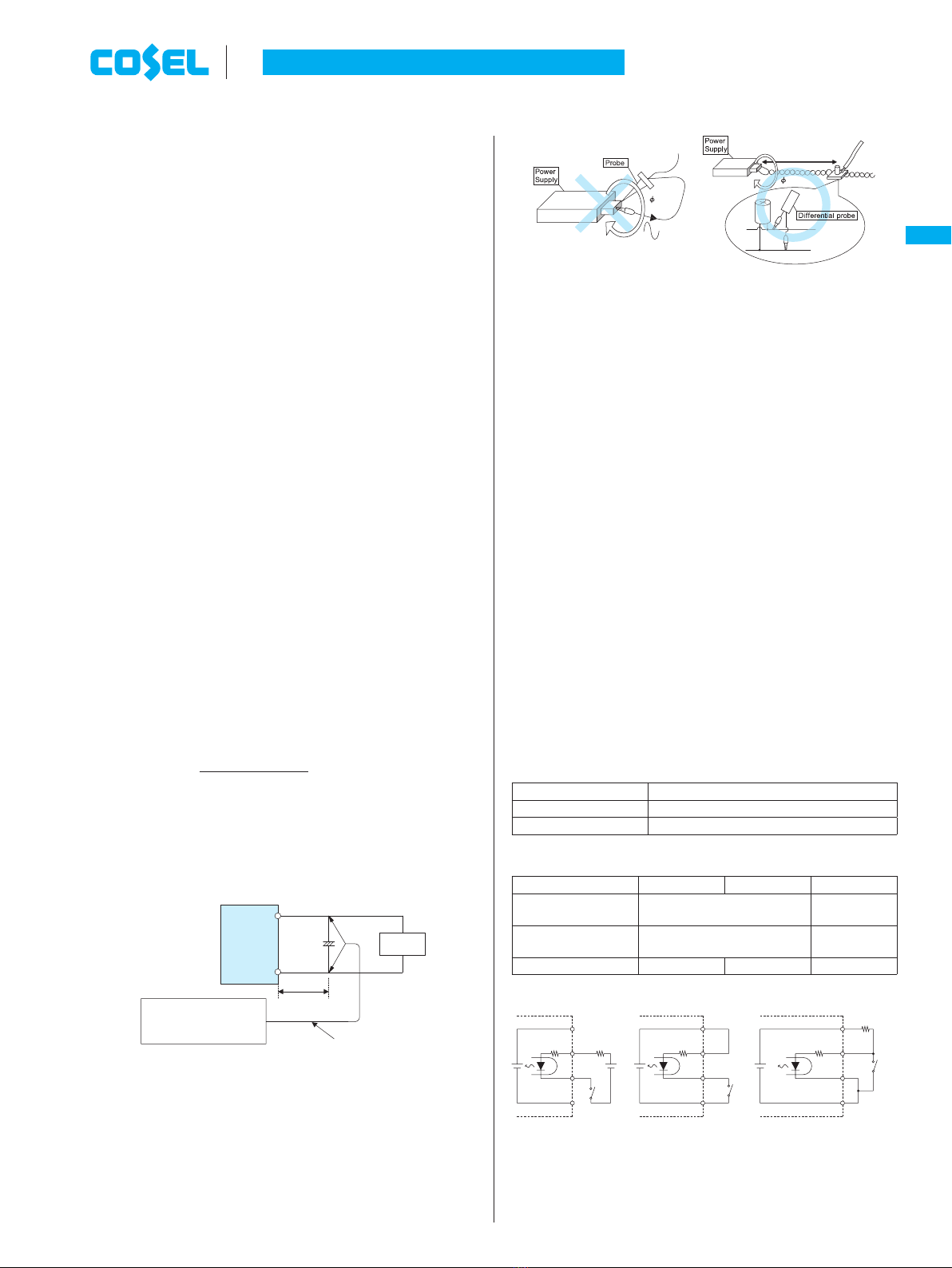

2.8 Output Ripple and Ripple Noise

¡Output ripple noise may be influenced by measurement environ-

ment, measuring method Fig.2.1 is recommended.

+Vout

-Vout

Load

150mm

C

1

Oscilloscope

Bw:500MHz

Differential probe

+

C1 : Aluminum electrolytic capacitor 22μF

Fig.2.1 Measuring method of Ripple and Ripple Noise

Remarks :

When GND cable of probe with flux of magnetic force from power

supply are crossing, ripple and ripple noise might not measure

correctly.

Please note the measuring environment.

150mm

Bad example Good example

Fig.2.2. Example of measuring output ripple and ripple noise

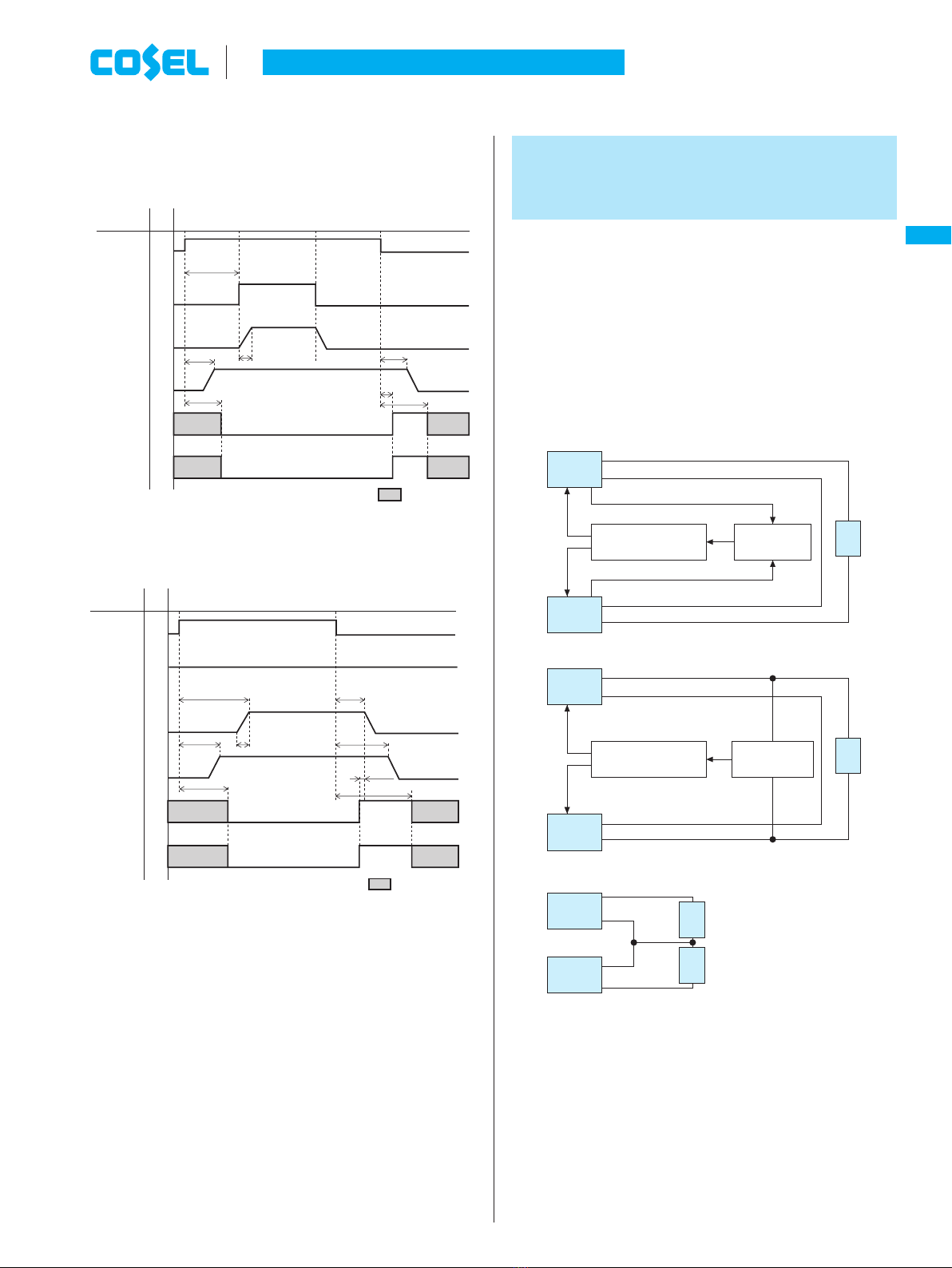

2.9 Remote ON/OFF

¡These models have a remote ON/OFF function.

¡You can operate the remote ON/OFF function by sending signals

to CN1/CN2. Please see Table 2.1 and Table 2.2 for specifica-

tions and Fig.2.3 for connecting examples.

¡Please note the followings when using the remote ON/OFF func-

tion.

1The output stops when a current flows to RC.

2The current flown to RC is a 20mA max.

3When the output voltage is turned off through the remote ON/OFF

circuit, the built-in fan slows down.

4If the output voltage is turned off through the remote ON/OFF

circuit, the WRN signals and the PG signals keep ”Low”.

5Description in this section is based on the assumption that you

will use one unit alone. If you are planning to use the units

in parallel operation or use multiple units for a single system,

please check necessary voltage and current values.

¡Please wire carefully. If you are wrongly, the internal components

of a unit may be damaged.

¡Remote ON/OFF circuits (RC and RCG) are isolated from input,

output, FG, AUX, WRN and PG.

Table 2.1 Specifications of remote ON/OFF (RC-RCG)

Output voltage Between RC and RCG

ON L level (0 to 0.5V) or open

OFF H level (4.5 to 12.5V)

Table 2.2 Specifications of remote ON/OFF (Case of Fig.2.3)

Connection method Fig.2.3 (a) Fig.2.3 (b) Fig.2.3 (c)

Power ON SW open

(0.1mA max) SW close

(0.5V max)

Power OFF SW close

(3mA min) SW open

(0.1mA max)

Base pin RCG AUXG RCG, AUXG

Ri=780WRi=780WRi=780W

RCG

RC RC RC

AUX AUX AUX

RCG

AUXG AUXG

RCG

AUXG

SW SW

SW

Rb=1kW

Vcc

Ra*1

(a) (b) (c)

12V

typ 12V

typ 12V

typ

Fig.2.3 Examples of connecting remote ON/OFF circuit

AC-DC Power Supplies Enclosed type Instruction Manual

FETA-7

FETA

mefeta1.indd7me feta1 indd 7 2013/09/0914:28:402013/09/09 14:28:40