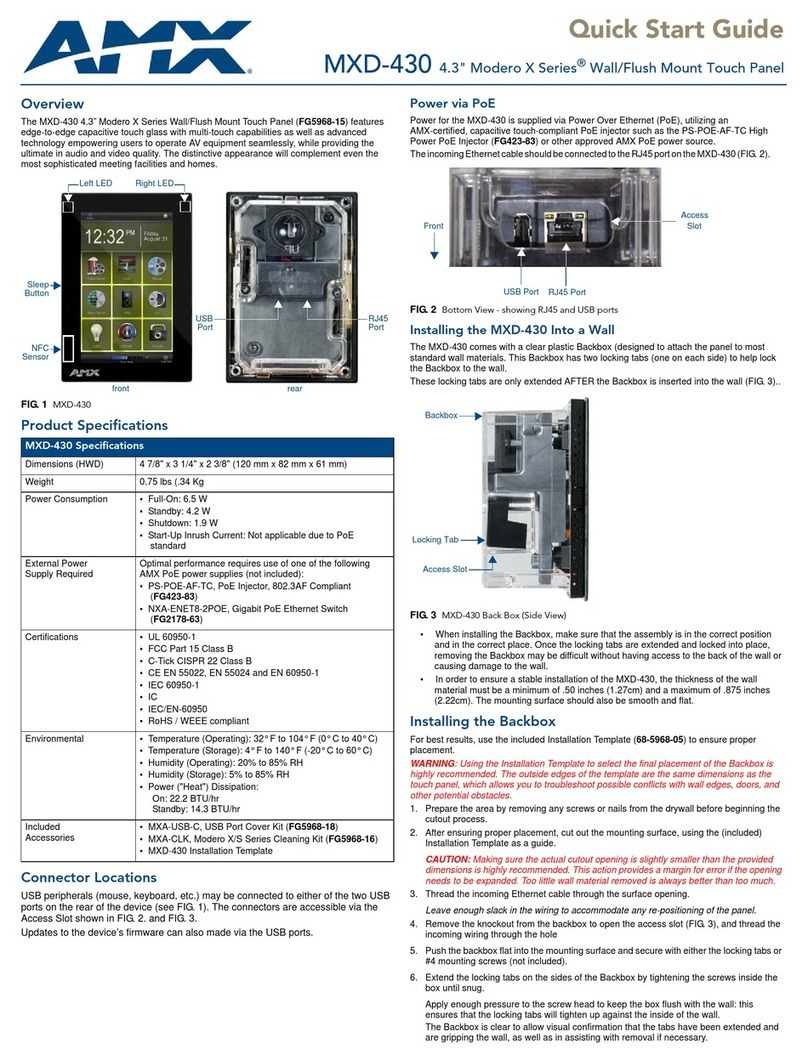

DO GUIDE

TSW-550/750/1050-TTK and TSW-550/750/1050-SMK

TableTop Kits and Swivel Mount Kit for TSW-550, TSW-750, and TSW-1050

The Crestron®TSW-550-TTK, TSW-750-TTK, and TSW-1050-TTK are functionally identical. For

simplicity within this guide, the term “TSW-550/750/1050-TTK” is used except where noted.

DO Prepare the TSW-550/750/1050-TTK

The TSW-550/750/1050-TTK comes with parts for routing device cabling through either the rear of

the unit or through the bottom for a neat appearance.

Route Cable through the Bottom of the TSW-550/750/1050-TTK

Out of the box, the TSW-550/750/1050-TTK comes with a plastic cover on the rear of the unit,

allowing the LAN cable to pass out through the bottom, such as when the TSW-550/750/1050-TTK is

attached to the TSW-550/750/1050-SMK Swivel Mount Kit (sold separately).

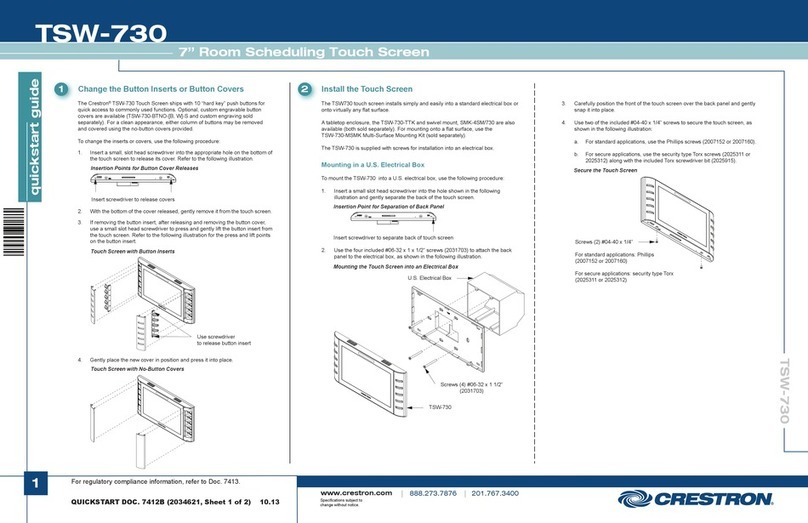

Route Cable through the Rear of the TSW-550/750/1050-TTK

For routing a single CAT5 cable through the rear of the TSW-550/750/1050-TTK, the plastic cover on

the rear must be replaced with the included strain relief. To replace the plastic cover with the strain

relief, perform the following procedure:

1. Remove the two screws on the bottom of the unit that hold the metal bracket inside the

TSW-550/750/1050-TTK. Then, remove the metal bracket.

2. With the metal bracket removed, pull downward on the plastic cover to remove it from the

TSW-550/750/1050-TTK.

3. Insert the LAN cable through the opening on the rear of the TSW-550/750/1050-TTK and attach

the strain relief to the cable.

4. Attach the strain relief by pushing it upward into the slot on the rear of the

TSW-550/750/1050-TTK.

NOTE: For added security in mounting the touch screen, refer to “DO Use the Security Option”

and follow that procedure from this point. For standard mounting, continue with the following

step.

5. Reinstall the metal bracket using the screws removed in step 1.

DO Mount the Touch Screen in

the TSW-550/750/1050-TTK

Connect the LAN cable to the touch screen and

gently pull excess cable out through the rear of

the TSW-550/750/1050-TTK to ensure the touch

screen is seated completely into the

TSW-550/750/1050-TTK and that the touch

screen’s magnets engage the metal bracket.

DO Assemble the

TSW-550/750/1050-SMK

Assemble the Swivel Mount

To assemble the swivel mount, perform the

following procedure:

1. Attach and secure the swivel mechanism tube

to the bottom of the TSW-550/750/1050-TTK

using the three 06-32 x 3/16” screws included

with the TSW-550/750/1050-TTK.

2. Remove the paper liner from the felt washer and attach the washer to the bottom of the swivel

mechanism tube.

3. If the cable is routed to exit through the bottom of the TSW-550/750/1050-TTK, feed the full

length of the cable through the swivel mechanism tube.

4. Use the included template to prepare the mounting surface. The center hole diameter for the

swivel mechanism tube should be 7/8” (22 mm) minimum, 15/16” (24 mm) maximum. Position the

template so the edge indicated as the front edge of the table or surface aligns with the desired

front position of the TSW-550/750/1050-TTK. Observe the dashed line indicating the front edge

of the TSW-550/750/1050-TTK to ensure the device does not overhang the mounting surface.

5. Using the six mounting holes on the swivel stop plate as a template, drill pilot holes in the

mounting surface. The holes should be 0.093” (2 mm) minimum diameter, 0.115” (3 mm)

maximum diameter, and no deeper than 0.35” (9 mm).

6. Attach the swivel stop plate to the bottom of the mounting surface using the six included 08-8B

x 1/2” screws.

7. Pass the swivel mechanism tube down through the mounting hole and swivel stop plate.

NOTE: The swivel stop plate has a permanently installed limiting screw to prevent the swivel

mechanism from spinning continuously in one direction and tangling the cable attached to the

touch screen.

8. Slide the included hardware up onto the swivel mechanism tube in the order indicated in the

illustration that follows.

NOTE: The keyed metal washer ts onto the swivel mechanism tube in one of two orientations:

facing toward or facing away from the permanently installed limiting screw in the swivel stop

plate. Orient the tab on the washer to face away from the permanently installed limiting screw.

9. Adjust the tightness of the 7/8”-14 nut to achieve the desired resistance in swivel assembly

motion. A at tool, such as a large at head screwdriver, may be used in the slot on the bottom

of the swivel mechanism tube to hold the tube still while tightening the nut.

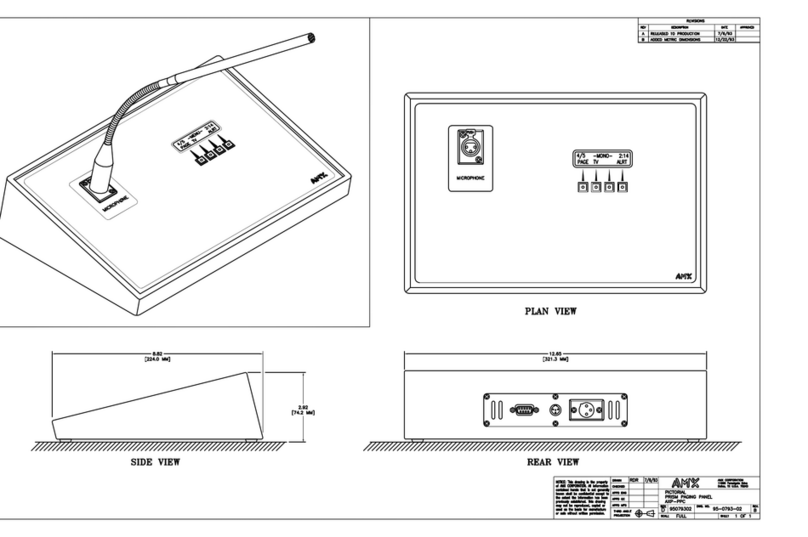

Metal Bracket

Plastic Cover Remove these screws

to release the metal bracket.

Pull downward on the

plastic cover to remove it.

Push the strain

relief upward to

attach it.

Cutout

TSW-750-TTK

Swivel Mechanism Tube

Screws (3) 06-32 x 3/16”

Felt Washer Swivel Mechanism Tube

Slot in Tube

Table or Mounting Surface (Front Edge)

Mounting Holes (6)

in Swivel Stop Plate

Swivel Stop Plate

Screws (2) 08-32 x 1/8”

Bottom Side of Table or Mounting Surface

Screws (6) 08-8B x 1/2”

Cork and Rubber Washer

Keyed Metal Washer

Rubber Washer

Steel Washer

Nut 7/8”-14

Mounting Hole

Permanently Installed

Limting Screw

DO Check the Box

QUANTITY PRODUCT COLOR PART NUMBER

Items for TSW-550/750/1050-TTK Only

1Plastic Strain Relief1Black 2033955

1Plastic Strain Relief2Gray 2033954

1Overlay Cutout Template 4517324

2 Screws, 04-20 x 5/8" 2007139

Items for TSW-550/750/1050-SMK Only

1Swivel Stop Plate 4504353

1 Keyed Metal Washer 4506321

1 Cork and Rubber Washer 2017614

1Rubber Washer 2017615

1Overlay Cutout Template 4517324

1Felt Washer 2024711

2 Screws, 08-32 x 1/8" 2017634

1Steel Washer 2017633

1Nut, 7/8"-14 2017632

6 Screws, 08-8B x 1/2" 2017784

3 Screws, 06-32 x 3/16" 2007202

1. This part ships with the TSW-550-TTK-B-S, TSW-750-TTK-B-S, and TSW-1050-TTK-B-S.

2. This part ships with the TSW-550-TTK-W-S, TSW-750-TTK-W-S, and TSW-1050-TTK-W-S