Cross Technologies 2016-12 User manual

Other Cross Technologies Media Converter manuals

Cross Technologies

Cross Technologies 4115-41-212 User manual

Cross Technologies

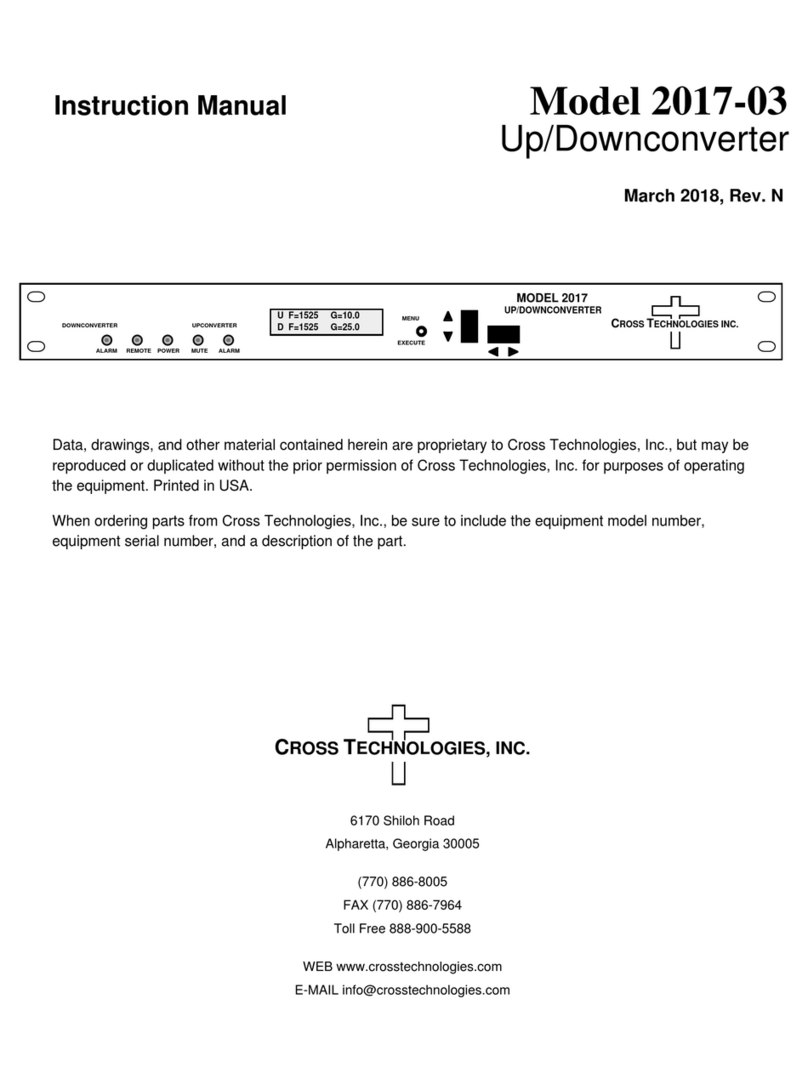

Cross Technologies 2017-03 User manual

Cross Technologies

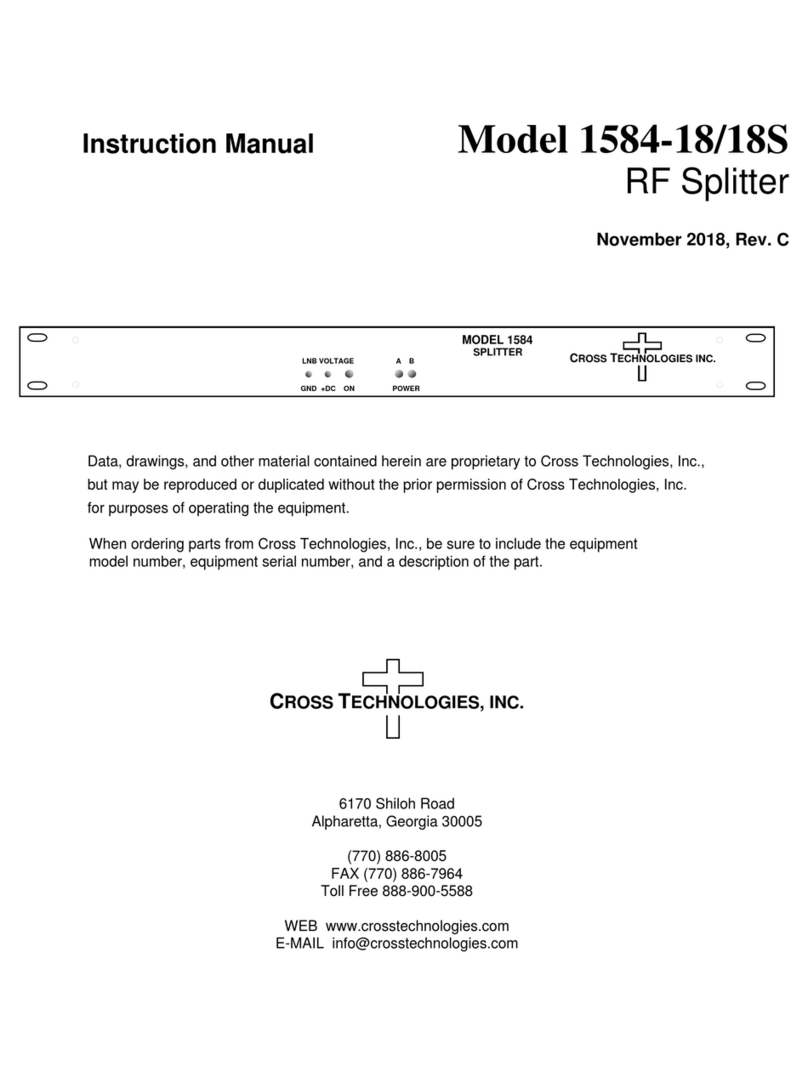

Cross Technologies 1584 User manual

Cross Technologies

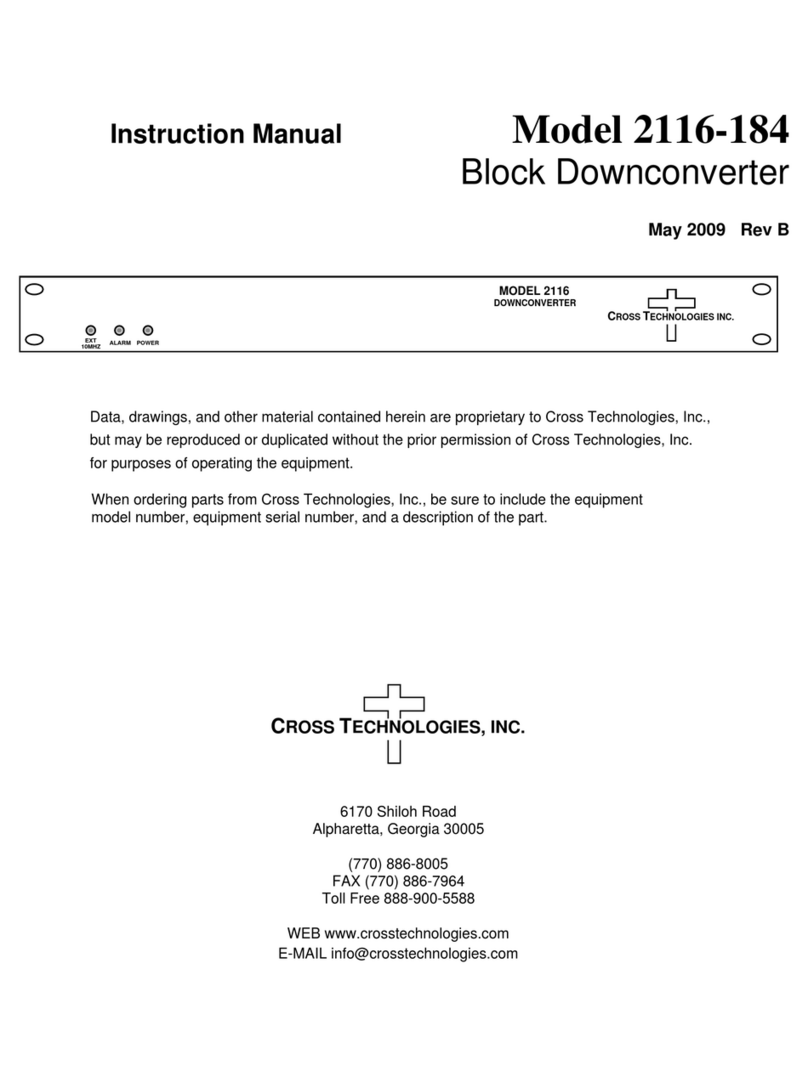

Cross Technologies 2116-184 User manual

Cross Technologies

Cross Technologies 1584-29 User manual

Cross Technologies

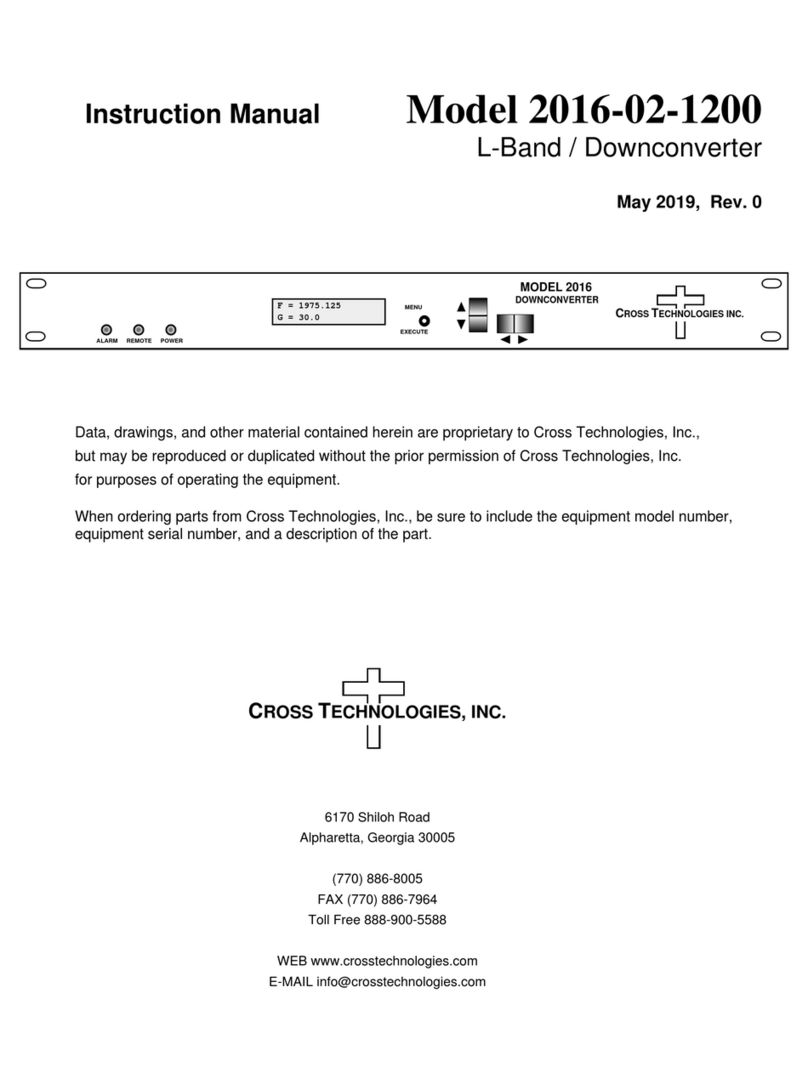

Cross Technologies 2016-02-1200 User manual

Cross Technologies

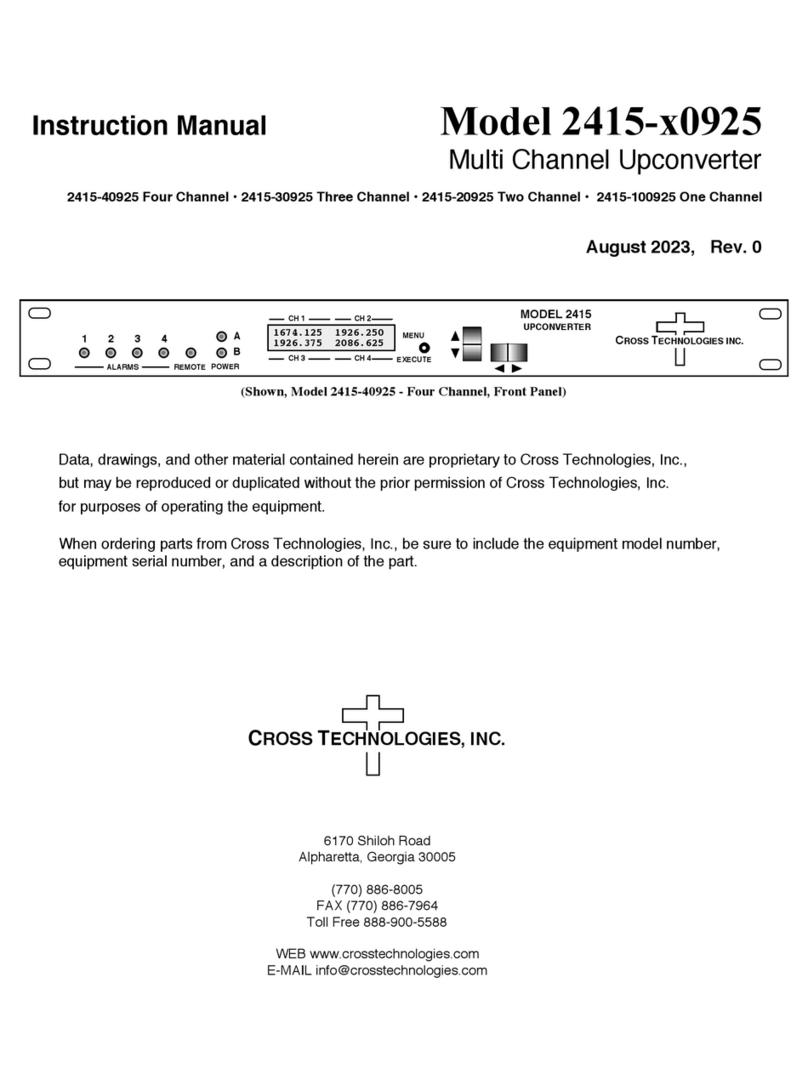

Cross Technologies 2415 0925 Series User manual

Cross Technologies

Cross Technologies 2017-1727-140 User manual

Cross Technologies

Cross Technologies 2005-10 User manual

Cross Technologies

Cross Technologies 2015-7075 User manual

Cross Technologies

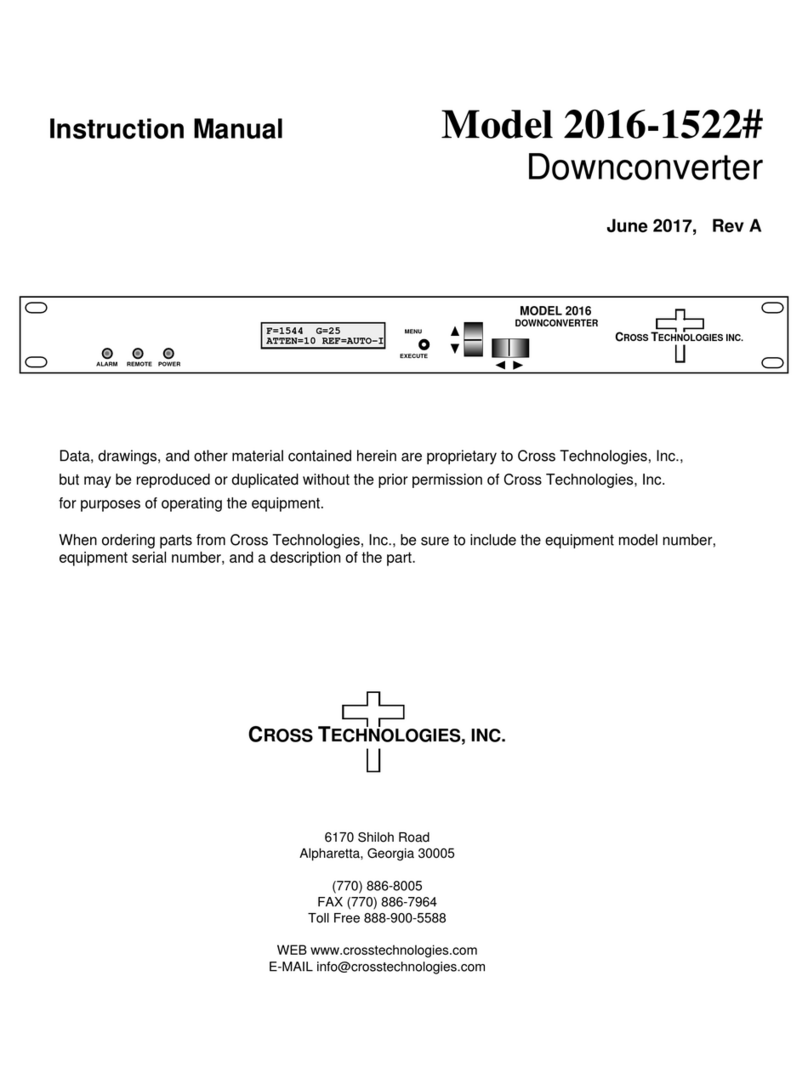

Cross Technologies 2016-1522 User manual

Cross Technologies

Cross Technologies 2016-05A User manual

Cross Technologies

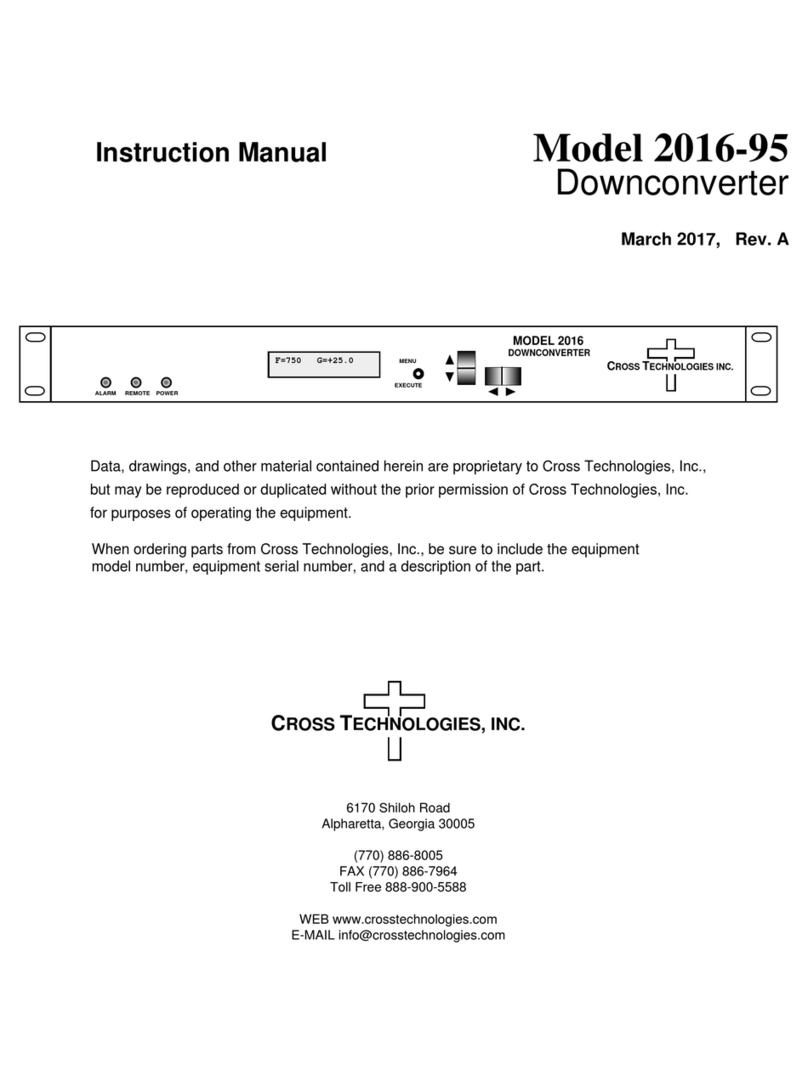

Cross Technologies 2016-95 User manual

Cross Technologies

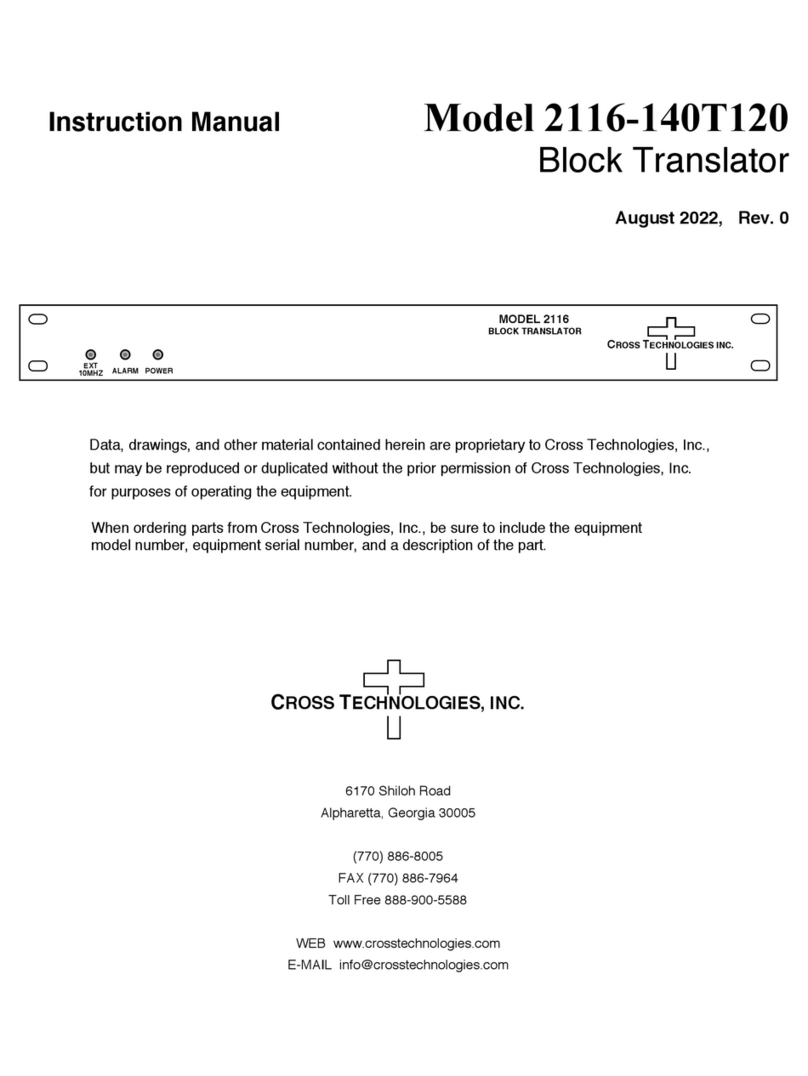

Cross Technologies 2116-140T120 User manual

Cross Technologies

Cross Technologies 2117-8485 User manual

Cross Technologies

Cross Technologies 2099-10 User manual

Cross Technologies

Cross Technologies 3115-21-109 User manual

Cross Technologies

Cross Technologies 2117-7172 User manual

Cross Technologies

Cross Technologies 2016-8085 User manual

Cross Technologies

Cross Technologies 4116-31-2831 User manual

Popular Media Converter manuals by other brands

Omnitron Systems Technology

Omnitron Systems Technology 10/100 Media Converter miConverter user manual

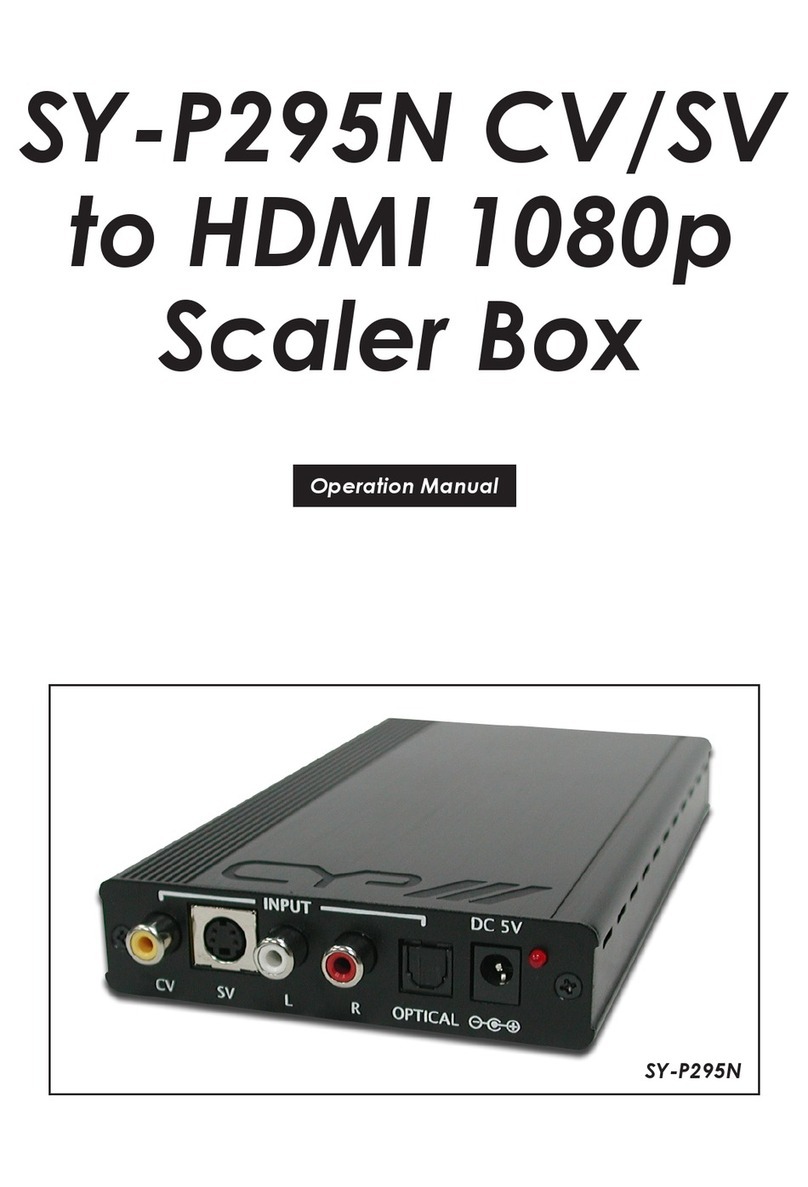

CYP

CYP SY-P295N Operation manual

Genelec

Genelec AD9200A operating manual

Flight Display Systems

Flight Display Systems FDSDI-HDMI Installation and operation manual

Hubner

Hubner FGH 14 Operating and assembly instructions

Perle

Perle SMI Media Converter installation guide