Crosswater WS2001RC User manual

Other Crosswater Plumbing Product manuals

Crosswater

Crosswater MPRO US-PRO418 User manual

Crosswater

Crosswater Arcade US-ARC600 User manual

Crosswater

Crosswater ATOLL SQUARE EXPOSED THERMO SHOWER VALVE... User manual

Crosswater

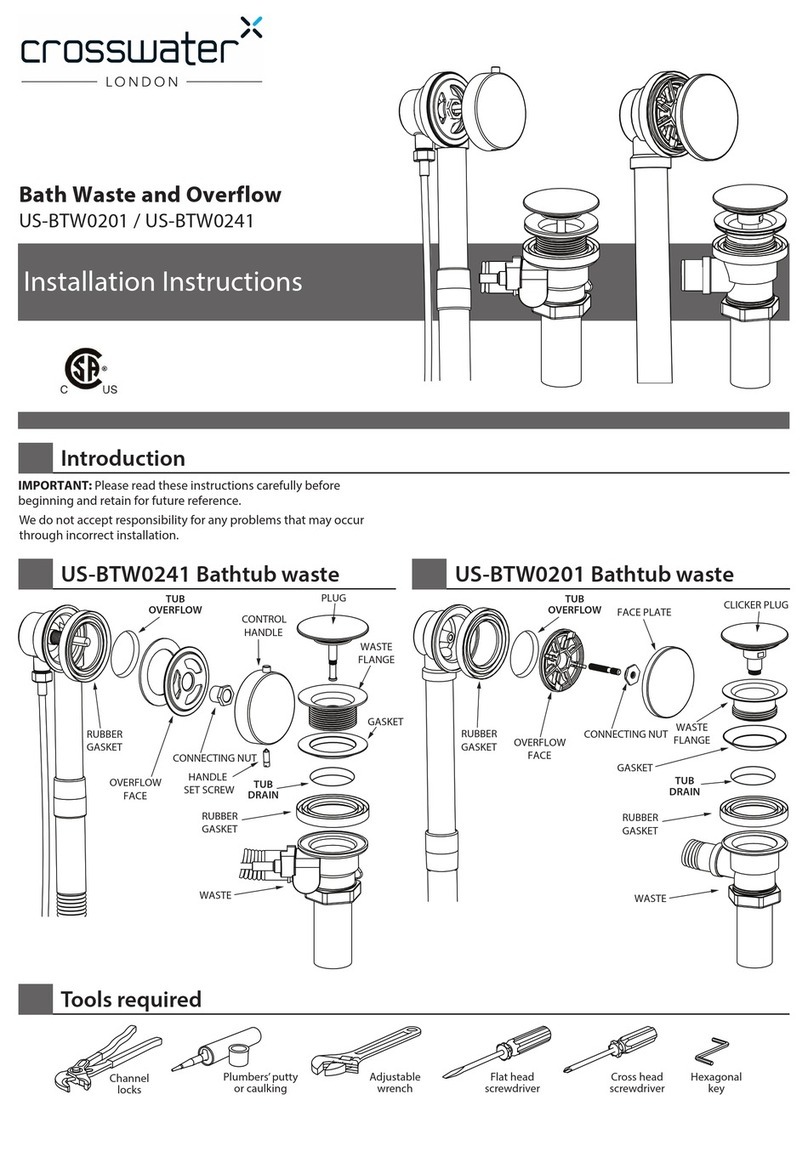

Crosswater US-BTW0201 User manual

Crosswater

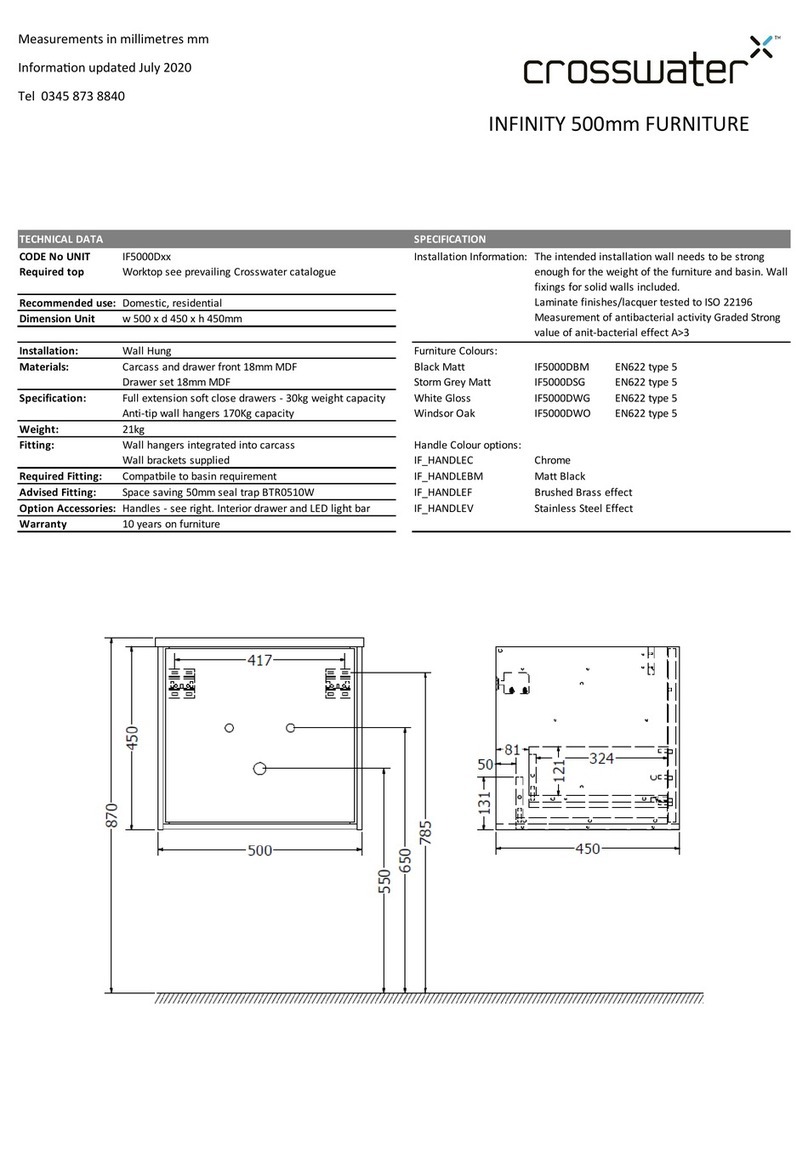

Crosswater INFINITY 500mm FURNITURE User manual

Crosswater

Crosswater 17-20-T User manual

Crosswater

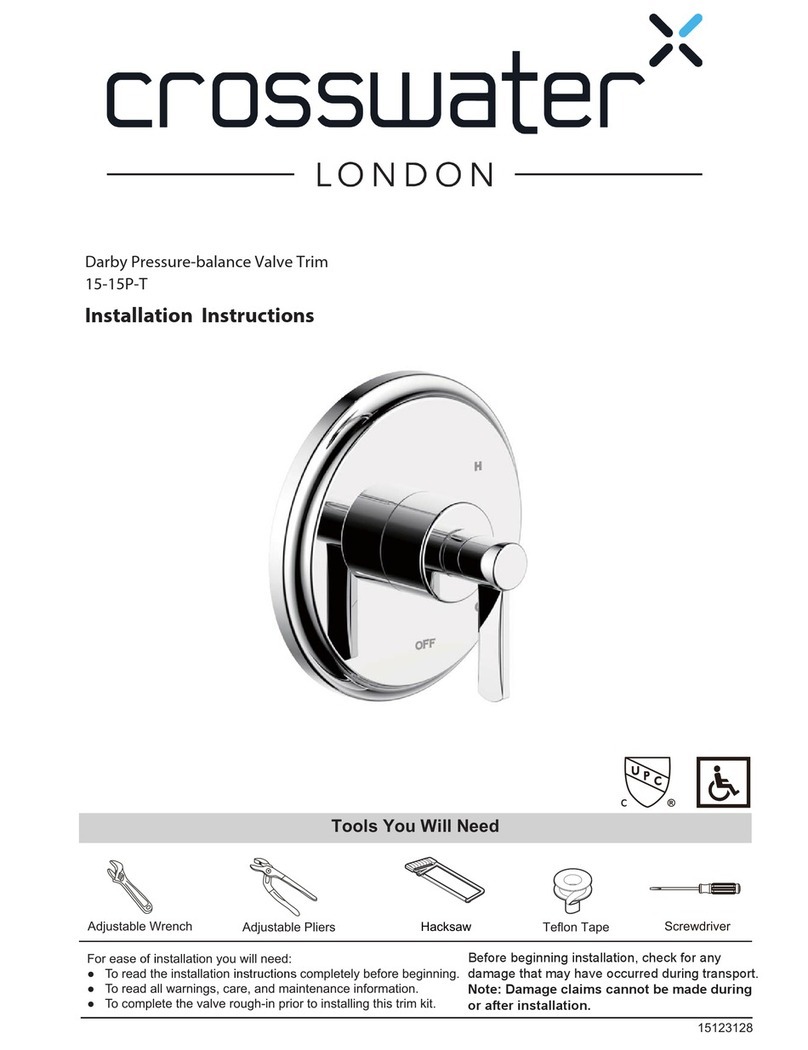

Crosswater Darby 15-15P-T User manual

Crosswater

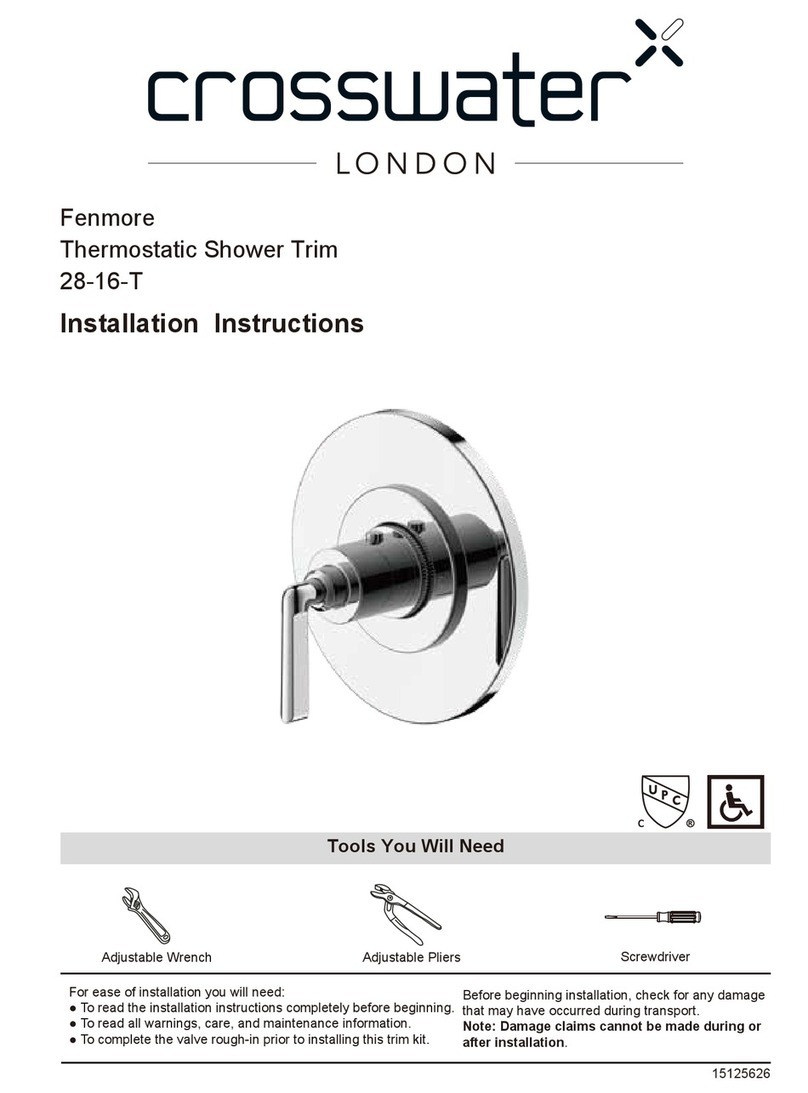

Crosswater 28-16-T User manual

Crosswater

Crosswater Darby 15-16-T User manual

Crosswater

Crosswater Berea 11-01 User manual

Crosswater

Crosswater KWC 10.441.004.000FL Manual

Crosswater

Crosswater US-AL7005CW User manual

Crosswater

Crosswater Leyden 14X-03-T User manual

Crosswater

Crosswater Smith SMI-UM1913-TSQ-WH User manual

Crosswater

Crosswater KWC DOMO 10.061.033.000 Quick guide

Crosswater

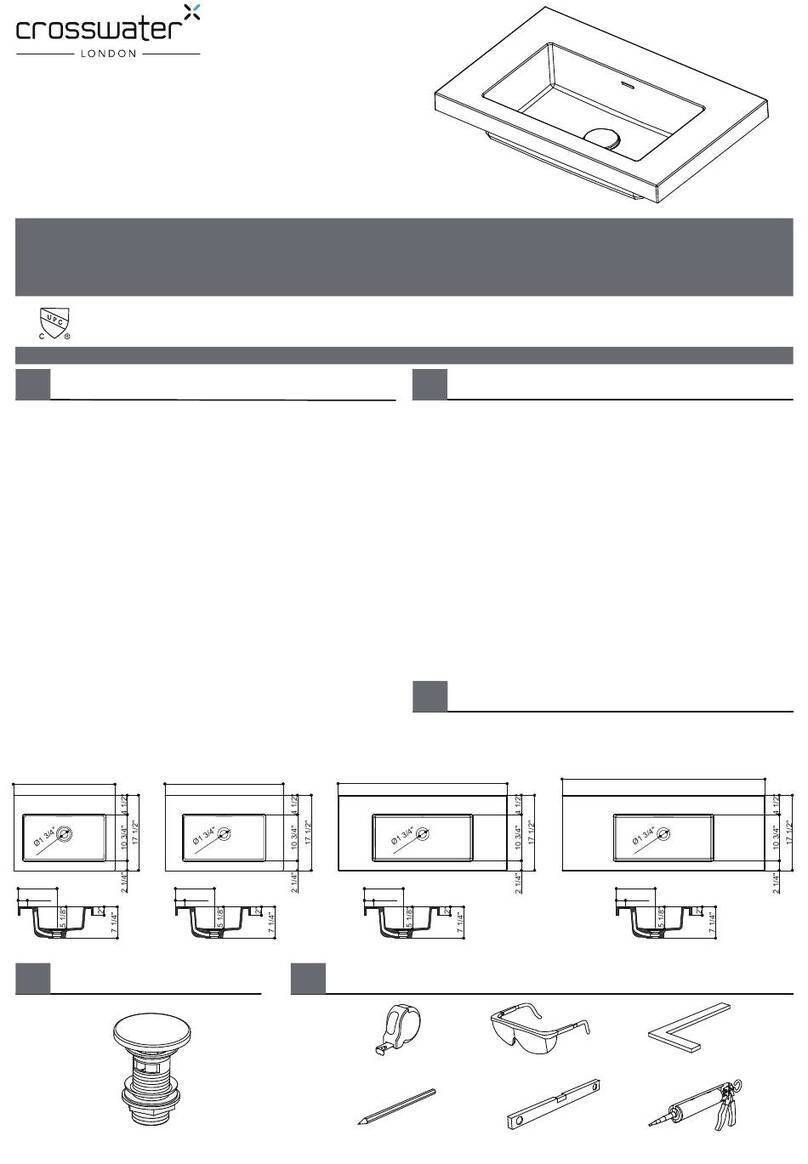

Crosswater Smith Basin 24 Top SMI-BT24-WH User manual

Crosswater

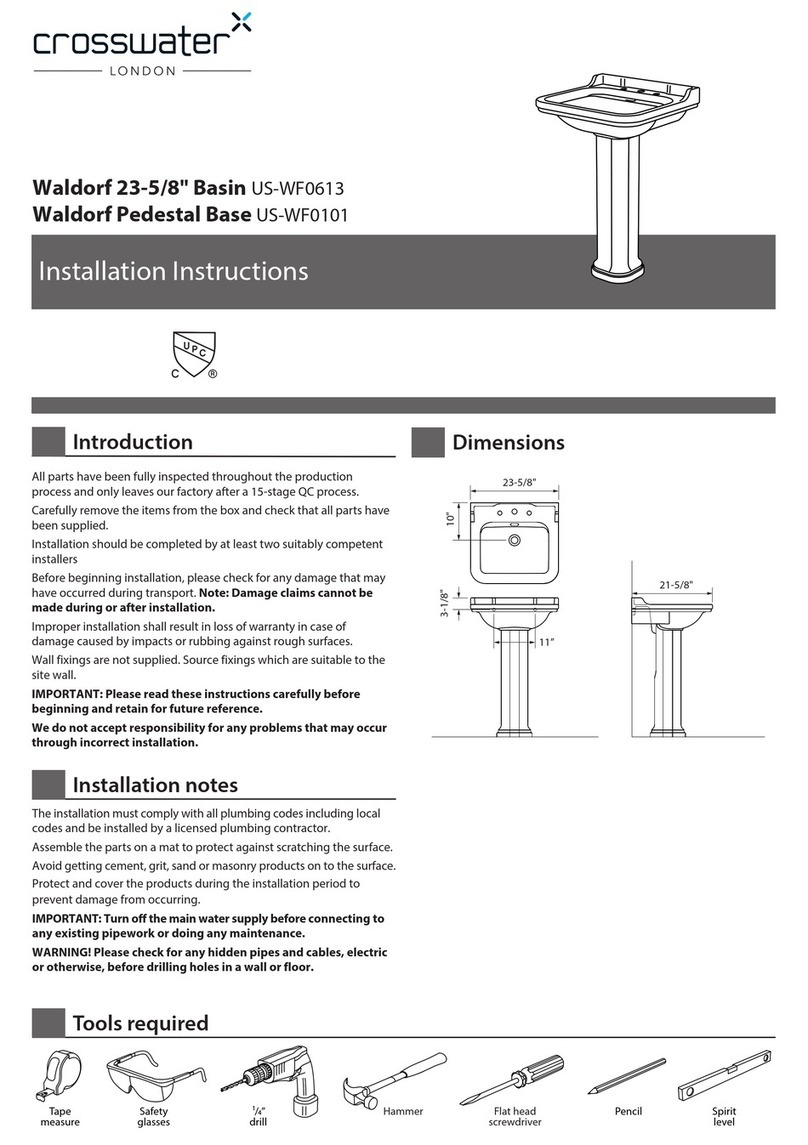

Crosswater Waldorf US-WF0613 User manual

Crosswater

Crosswater UNION US-UN399 User manual

Crosswater

Crosswater Belgravia US-BL422 User manual

Crosswater

Crosswater 1000 Series User manual

Popular Plumbing Product manuals by other brands

Weka

Weka 506.2020.00E ASSEMBLY, USER AND MAINTENANCE INSTRUCTIONS

American Standard

American Standard DetectLink 6072121 manual

Kohler

Kohler K-6228 Installation and care guide

Uponor

Uponor Contec TS Mounting instructions

Pfister

Pfister Selia 49-SL Quick installation guide

Fortis

Fortis VITRINA 6068700 quick start guide

Elkay

Elkay EDF15AC Installation, care & use manual

Hans Grohe

Hans Grohe AXOR Citterio E 36702000 Instructions for use/assembly instructions

baliv

baliv WT-140 manual

Kohler

Kohler Mira Eco Installation & user guide

BELLOSTA

BELLOSTA romina 0308/CC Installation instruction

Bristan

Bristan PS2 BAS C D2 Installation instructions & user guide