Table of Contents

PNEG-250-PM Hi-Lo and PRO-1 Pan Feeder Parts 3

Contents

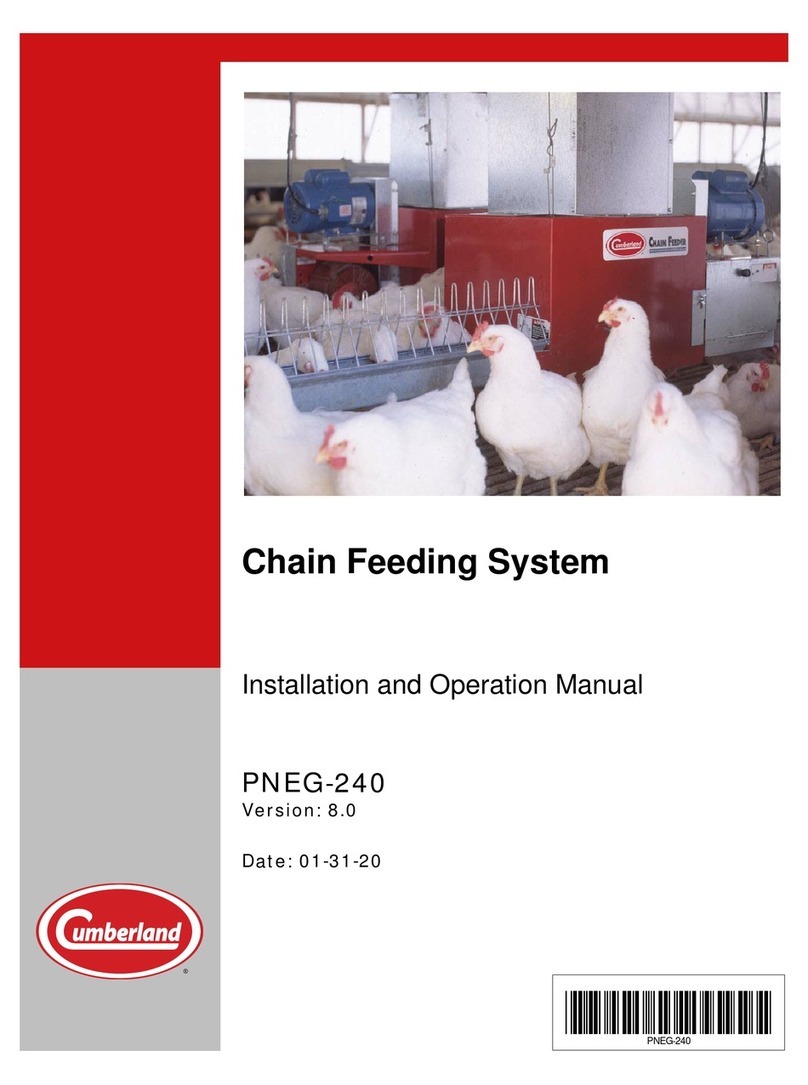

Chapter 1 Introduction ..........................................................................................................................................4

Chapter 2 Safety .....................................................................................................................................................5

Safety Guidelines ...................................................................................................................................5

Cautionary Symbols Definitions .............................................................................................................6

Safety Cautions ......................................................................................................................................7

Safety Sign-Off Sheet ..........................................................................................................................10

Chapter 3 Decals ..................................................................................................................................................11

Safety Decals and Placement ..............................................................................................................11

Chapter 4 Parts List .............................................................................................................................................14

Hi-Lo Pan Feeder (7098851 and 7101255) .........................................................................................16

Hi-Lo Plus Pan Feeder Parts (C2000702 and C2000703) ...................................................................17

Hi-Lo Plus Retrofit Kit Parts (C2000706) .............................................................................................18

PRO-1 Assembly ..................................................................................................................................19

“E” Feeder Assembly (Short Cone) (C2000416S and C2000423S) ....................................................20

Hi-Lo Center House Control Pan with Microswitch (7101534) .............................................................21

Hi-Lo End Control Pan with Microswitch (7101482) .............................................................................24

Electrical Box Assembly for Micro Control 3 Phase (07101483-3) ......................................................28

Electrical Box Assembly for Micro Control (7101483) ..........................................................................30

Housing Assembly, Center Control (Prox, Plunger) (C2000526) .........................................................32

Housing Assembly, End Control (Prox, Plunger) (C2000431) .............................................................33

End Control Assembly, Plunger (C2000434) .......................................................................................34

Electrical Box Assembly, (Center House Spinner) (C2000525) ...........................................................36

Housing Assembly, End Control (C2000430) ......................................................................................37

Hi-Lo Electrical Components (7100211) ..............................................................................................38

Hi-Lo Breeder i-Plus3 End Control Pan 1-3/4" (220V, 1 PH) (C2000668) ...........................................40

Hi-Lo i-Plus3 End Control Pan (220V, 1 PH) (C2000532) ...................................................................42

“E” Feeder i-Plus3 End Control Pan (220V, 1 PH) (C2000559) ...........................................................44

Hi-Lo i-Plus3 Center House Control Pan (220V, 1 PH) (C2000560) ....................................................46

“E” Feeder i-Plus3 Center House Control Pan (220V, 1 PH) (C2000562) ...........................................48

Center Control Assembly (Bolt-On), IR Sensor (220V, 1 PH) (C2000645) ..........................................50

“E” Feeder i-Plus3 (Bolt-On) Center House Control Pan (220V, 1 PH) (C2000683) ...........................52

Nutrapan i-Plus3 End Control Pan (220V, 1 PH) (C2000555) .............................................................54

Nutrapan i-Plus3 Center House Control Pan (220V, 1 PH) (C2000561) .............................................56

120 Lbs. Feed Hopper (7098232) ........................................................................................................58

200 Lbs. Feed Hopper (7098256) ........................................................................................................59

300 Lbs. Feed Hopper (7098715) ........................................................................................................60

400 Lbs. Feed Hopper (7099426) ........................................................................................................61

Single Boot Assembly ..........................................................................................................................62

Double Boot Assembly .........................................................................................................................63

Feed Level Control Switch (7051400) ..................................................................................................64

Flex-Flo Hopper Level Control Assembly .............................................................................................66

Flex-Flo Level Control Switch (FLX-3802) ...........................................................................................68

Winching and Miscellaneous Accessories ...........................................................................................70

Ceiling Unit Parts .................................................................................................................................74

Main Control Parts ...............................................................................................................................75

Winch Assembly Parts .........................................................................................................................76

650 Lbs. Hopper Scale Assembly (7100751) .......................................................................................78

650 Lbs. Hopper Scale Sub-Assembly (C2000297) ............................................................................79

Chapter 5 Warranty ..............................................................................................................................................81