2 Specific installer safety instructions

Installation manual

6

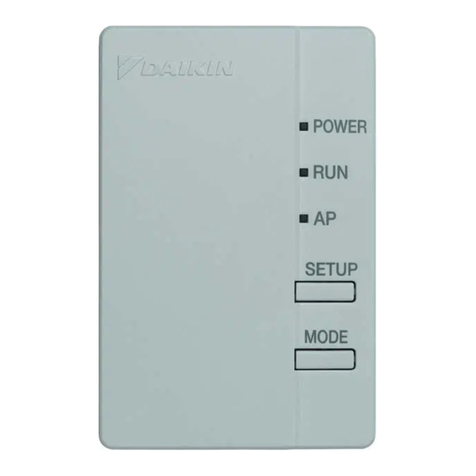

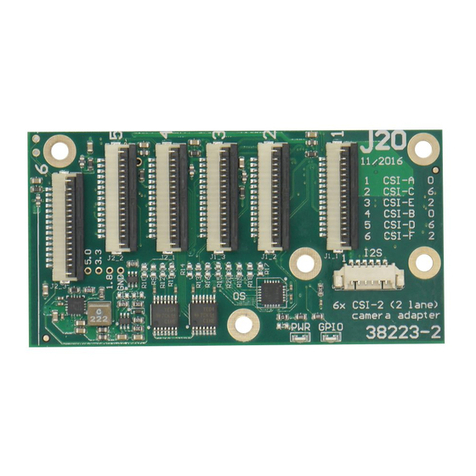

EKMBPP1

Modbus adapter

4P720139-1B – 2023.09

WARNING

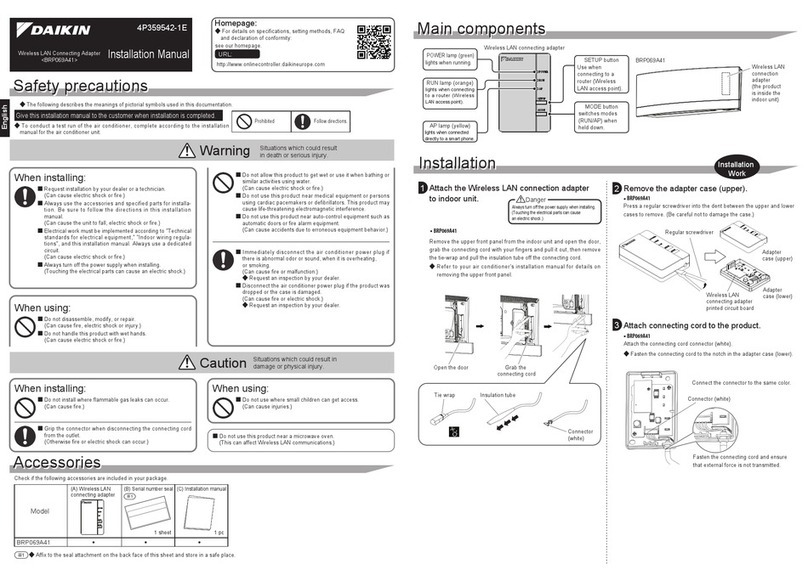

When applying this Modbus adapter (EKMBPP1), the

installation requirements described in the indoor and outdoor

unit installation manuals of the system to which this Modbus

adapter is connected, including any countermeasures, remain

applicable.

For systems NOT using R32 refrigerant, this Modbus adapter

can be the only (and main) remote controller connected. For

systems using R32 refrigerant, the installation of additional

remote controllers may be required.

Hand-over to the user (see "7 Hand-over to the user" [4 33])

DANGER

▪ Do NOT disassemble, modify, or repair the adapter. This

can cause fire, electrical shock, or injury.

▪ Do NOT allow the adapter to get wet or use it when bathing

or doing similar activities with water. This can cause

electrical shock or fire.

▪ Do NOT use the adapter near medical equipment, or

persons using cardiac pacemakers or defibrillators. This

can cause life-threatening electromagnetic interference.

▪ Do NOT use the adapter near auto-control equipment such

as automatic doors or fire alarm equipment. This can cause

accidents due to erroneous equipment behaviour.

▪ In case of abnormal odour or sound, overheating, or smoke

coming out of the adapter, immediately disconnect the

indoor unit from its power supply. Otherwise, this can lead

to fire or malfunction. If this happens, consult your dealer.

▪ In case you drop or damage the adapter, disconnect the

indoor unit from its power supply. Otherwise, this can lead

to fire or malfunction. If this happens, consult your dealer.