Danfoss MBT 9110 User manual

Other Danfoss Transmitter manuals

Danfoss

Danfoss MBS 32 User manual

Danfoss

Danfoss MBS 1700 User manual

Danfoss

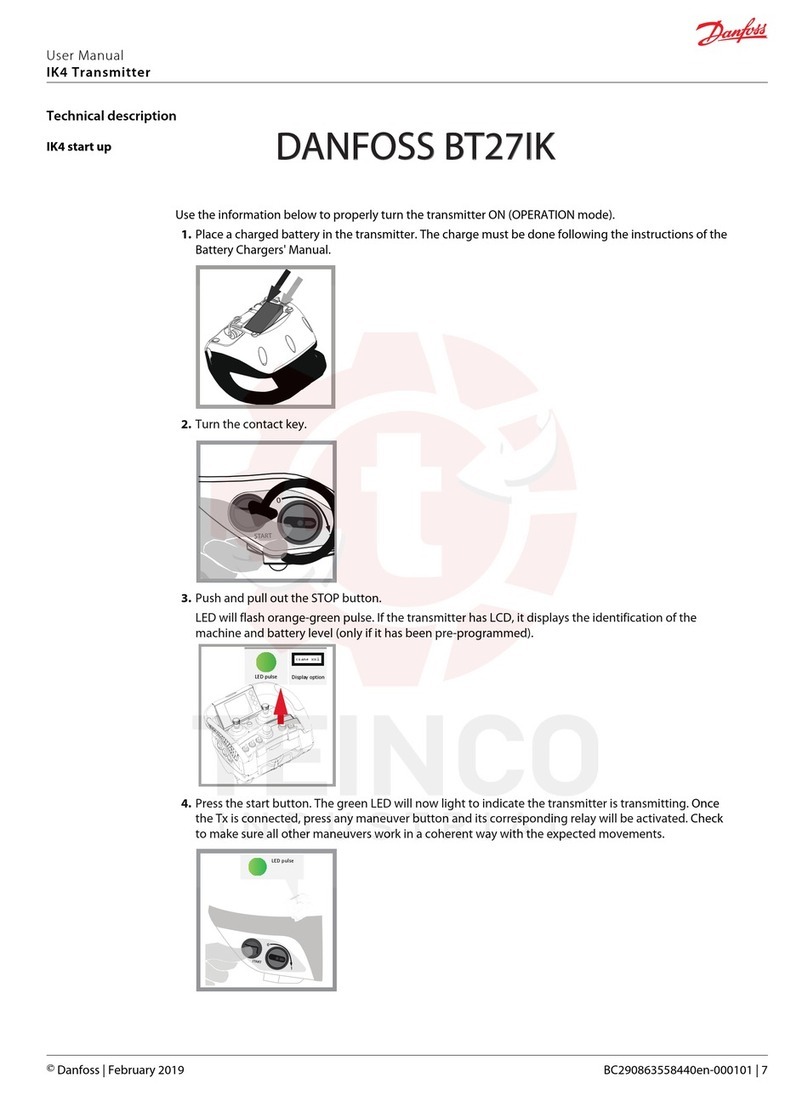

Danfoss BT27IK User manual

Danfoss

Danfoss IKORE B User manual

Danfoss

Danfoss AKS 32 User manual

Danfoss

Danfoss Ikargo1 User manual

Danfoss

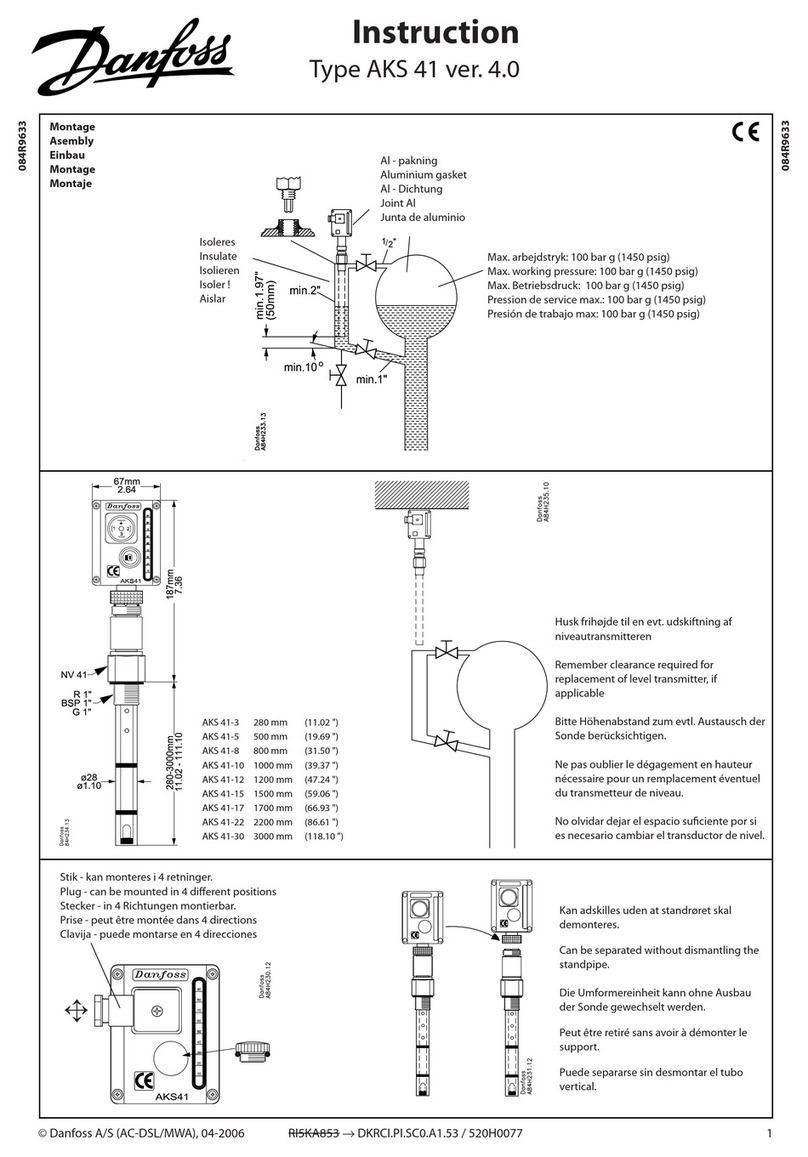

Danfoss AKS 41 User manual

Danfoss

Danfoss MBS 32R User manual

Danfoss

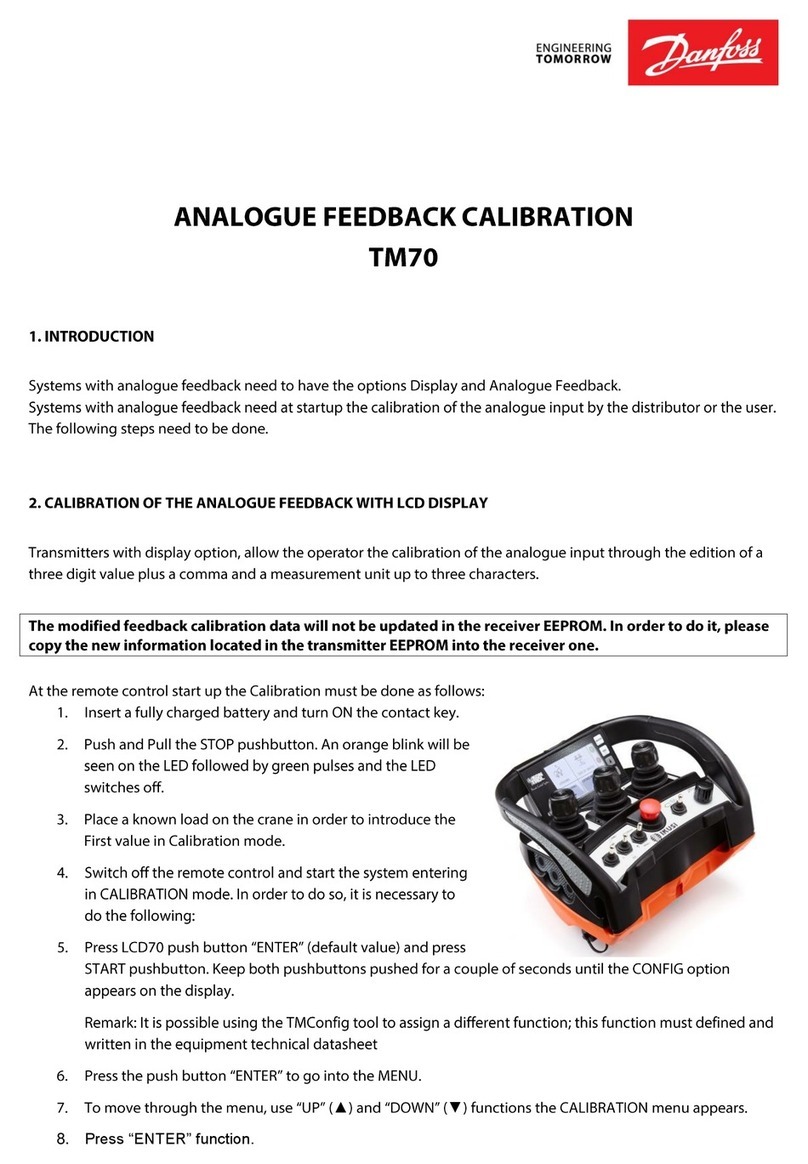

Danfoss TM70 Use and care manual

Danfoss

Danfoss T70 2 User manual

Danfoss

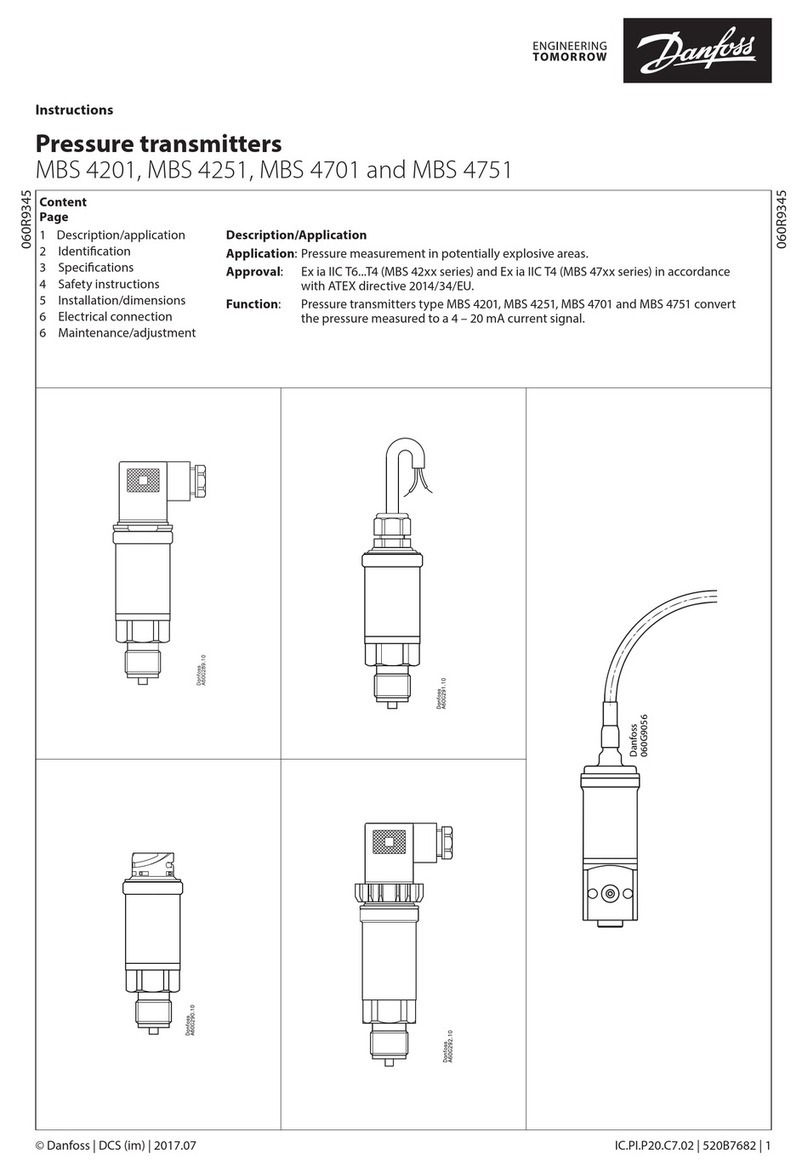

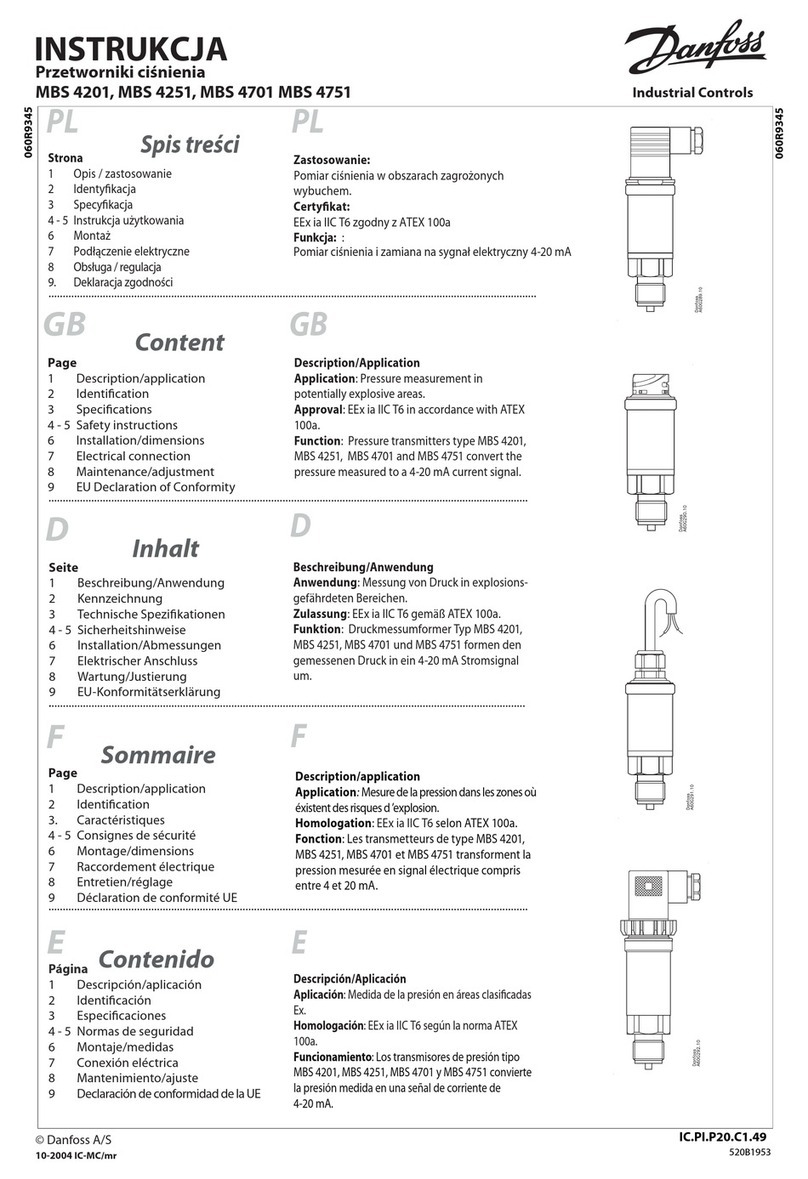

Danfoss MBS 4201 User manual

Danfoss

Danfoss T70 2 User manual

Danfoss

Danfoss T70 1 HALL User manual

Danfoss

Danfoss IK3 User manual

Danfoss

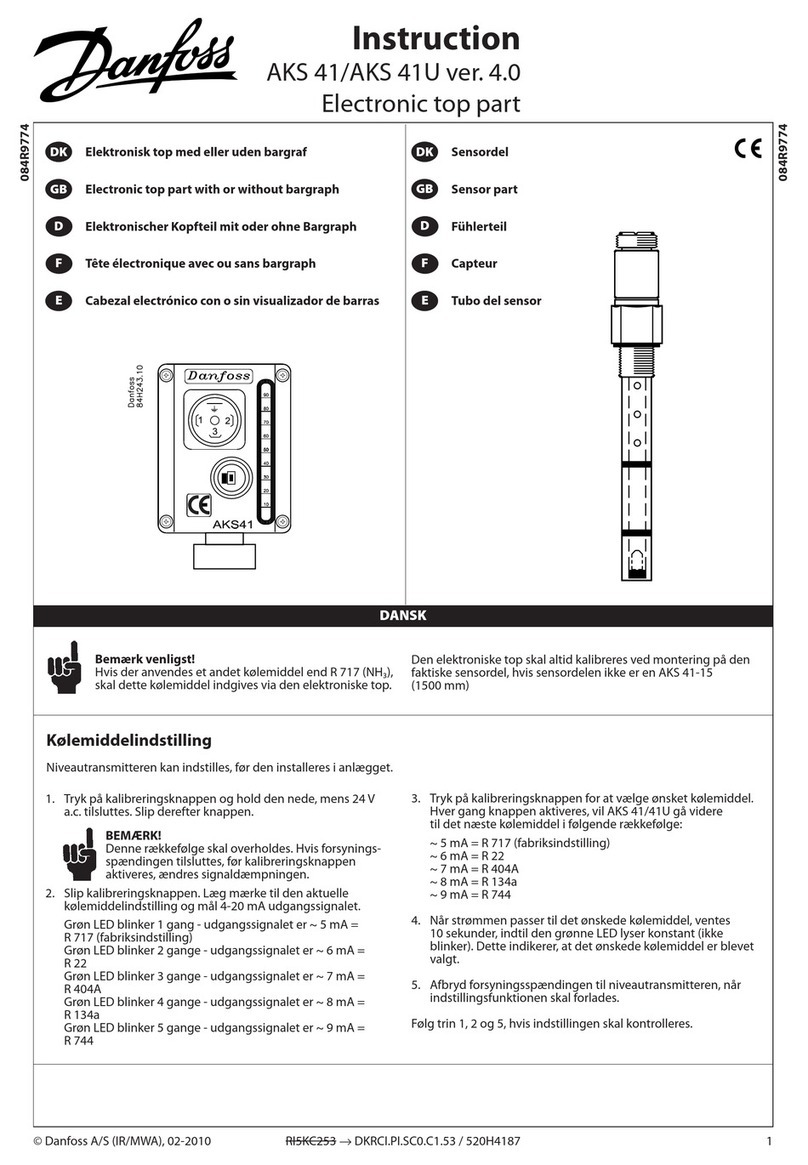

Danfoss AKS 41 Manual

Danfoss

Danfoss IK4 User manual

Danfoss

Danfoss AKS 41 User manual

Danfoss

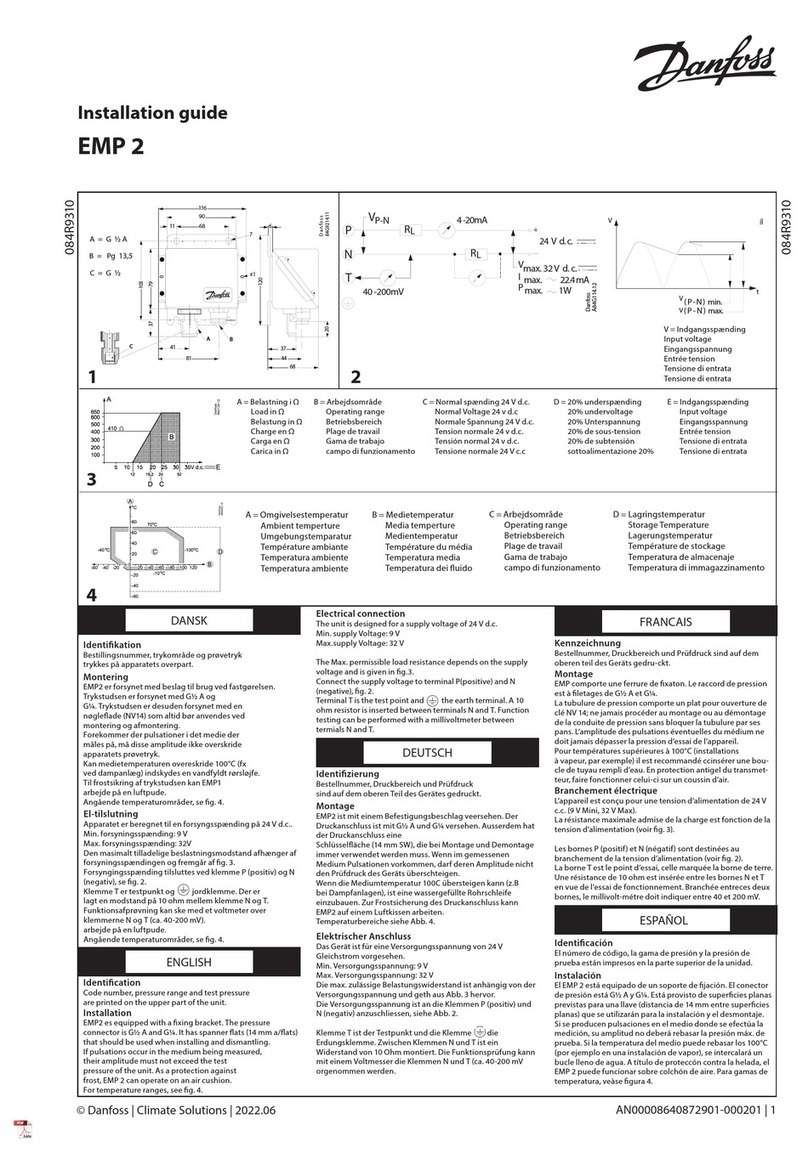

Danfoss EMP 2 User manual

Danfoss

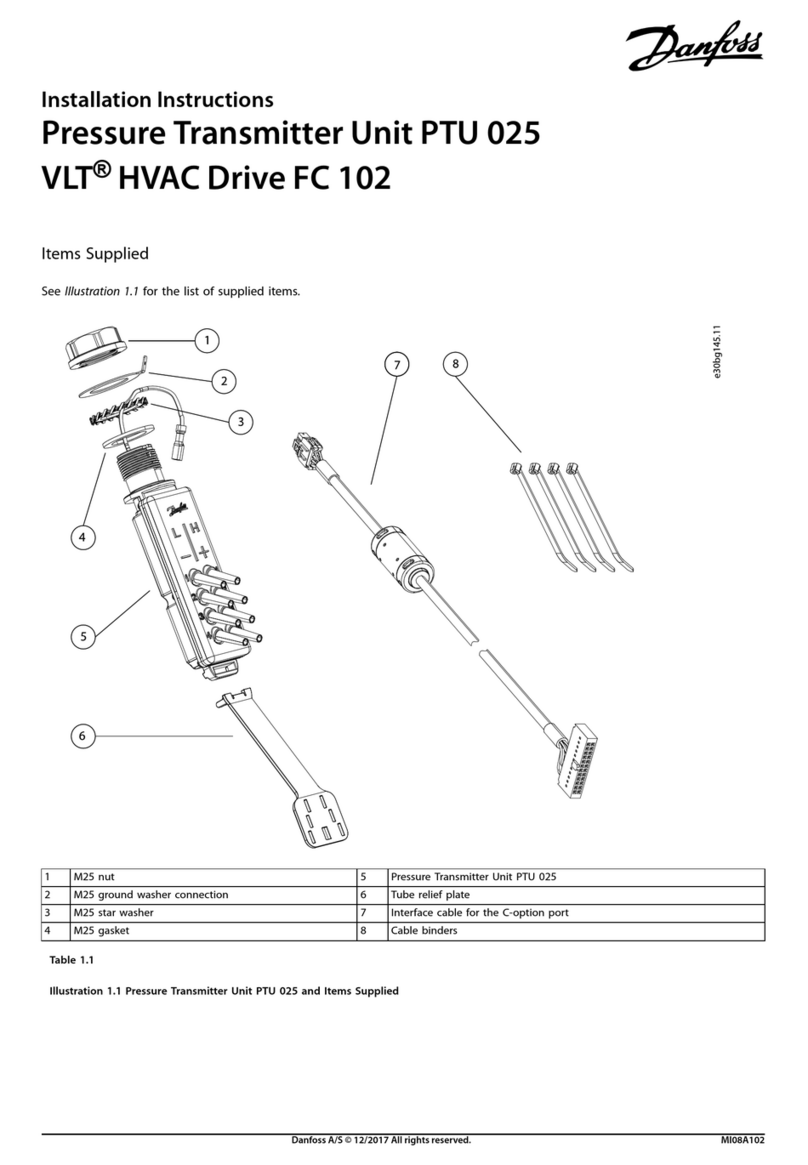

Danfoss PTU 025 User manual

Danfoss

Danfoss MBS 4201 User manual

Popular Transmitter manuals by other brands

Dejero

Dejero EnGo 3x manual

Rosemount

Rosemount 4600 Reference manual

Speaka Professional

Speaka Professional 2342740 operating instructions

trubomat

trubomat GAB 1000 instruction manual

Teledyne Analytical Instruments

Teledyne Analytical Instruments LXT-380 instructions

Rondish

Rondish UT-11 quick start guide