R

www.danvex.fi 8

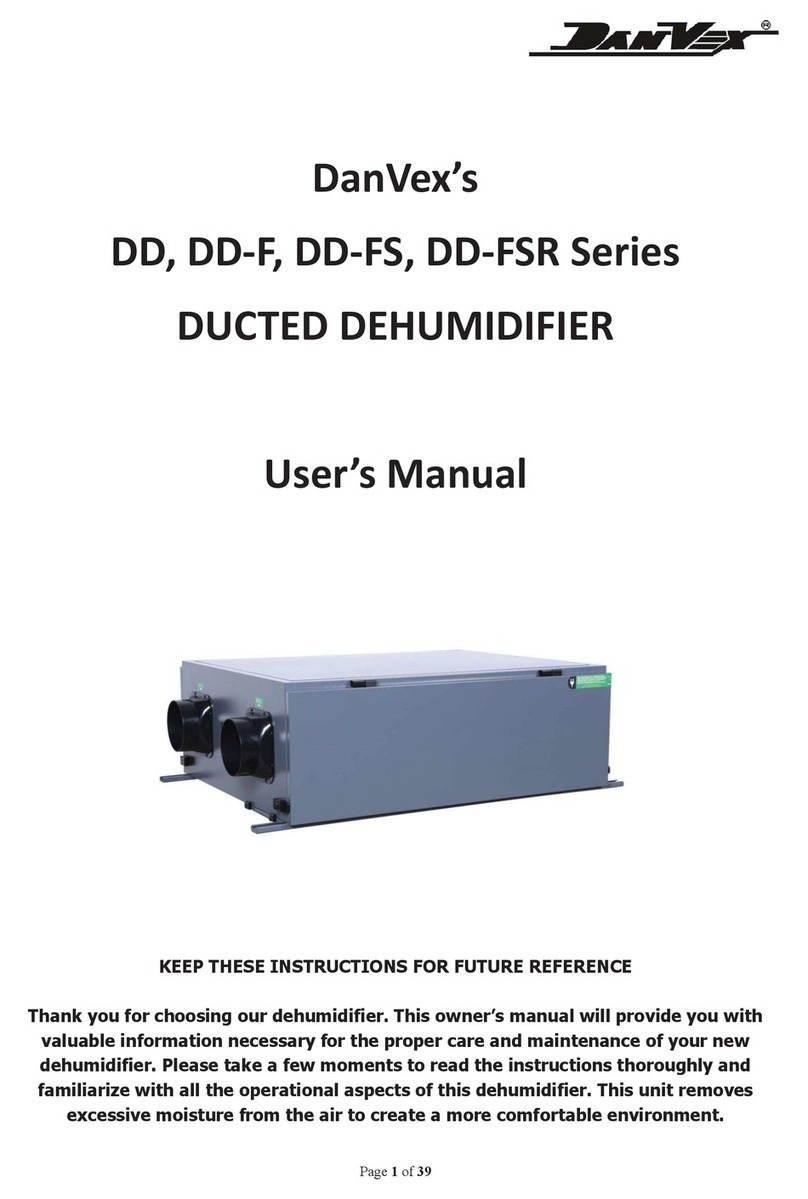

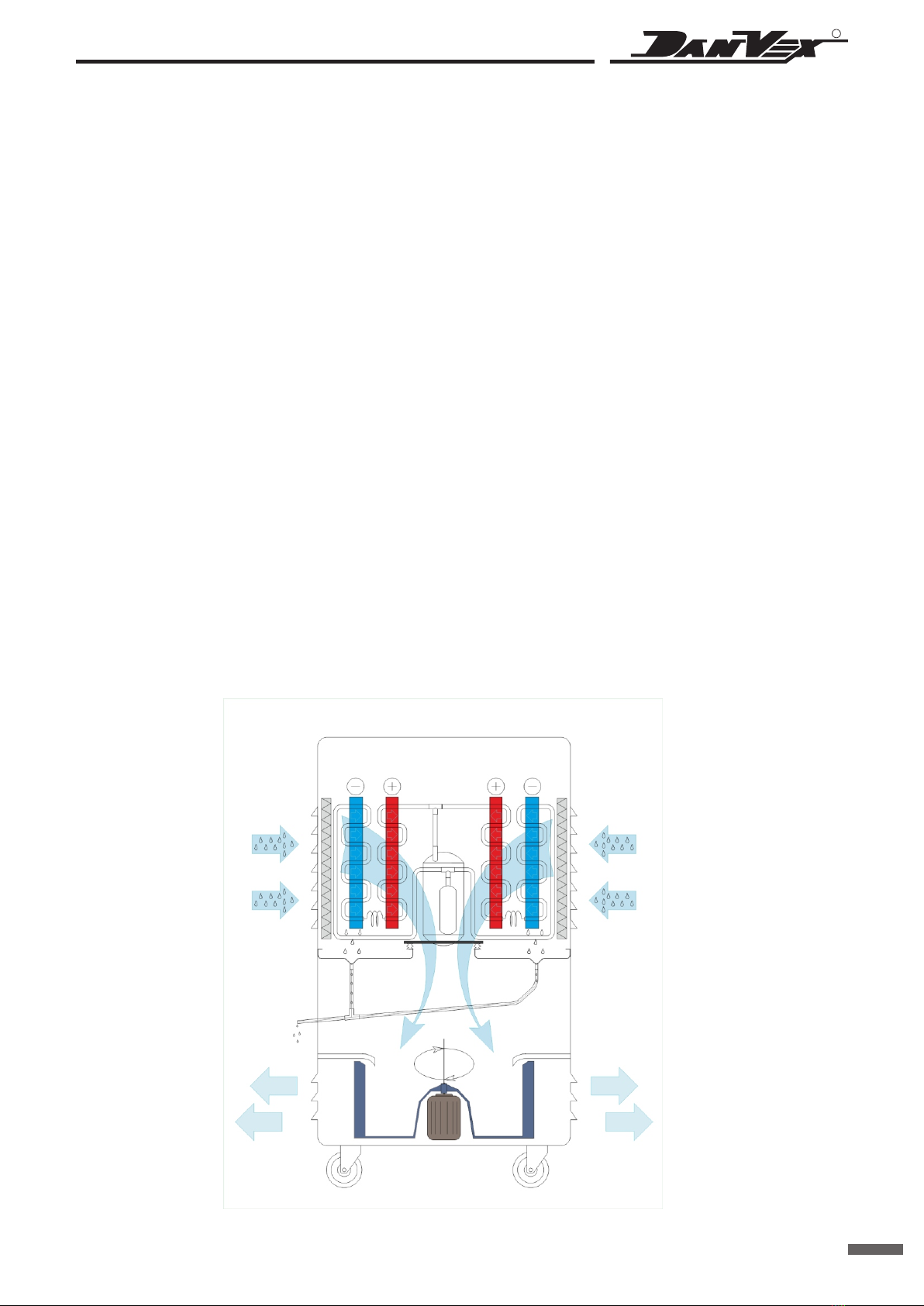

Dried and cooled air is heated in the condenser (radiator) again. Then it is discharged to

outside, the air temperature is about 5 degrees higher than the room temperature.

The dried air is mixed with surrounding air again. The relative humidity gradually drops to the

required RH value due to continuous outside air circulation through the unit.

Depending on the room temperature and relative humidity the condensed water can drip

continuously or only during certain defrosting stages into a condensate tray with further

discharge to outside through integrated drain channels.

For uncontrolled continuous operation of the unit it is required to drain the condensate using

an external water hose.

Installation

For optimum, economical and safe unit operation the following instructions must be followed:

◊ The unit must be installed securely upright to ensure unhindered condensate discharge into

the condensate tray.

◊ If possible the unit must be installed in the centre of the room long wall so that optimal air

circulation is ensured.

◊ It must be ensured that the air is able to be sucked in freely at the front of the unit and to be

discharged through the side parts of the air throttle.

◊ It is prohibited to locate the unit in close proximity to radiators and other heat sources.

◊ The room to be dried or dehumidified must be closed to prevent the air entering from

neighbor rooms and from outside.

◊ Windows and doors must be closed to prevent free air exchange between the room and

ambient atmosphere.

◊ If the unit is used in dust-laden environments it is necessary to take appropriate

maintenance measures specially adapted to the particular operation conditions.

See the chapter «Maintenance and service».

Important information on electrical connections

◊ Electric wiring of the unit should be done in accordance with DIN VDE 0100, Part 704 for

electric current supply sources equipped with automatic circuit-breakers.

◊ If the unit is installed in humid premises such as laundries or cellars it should be equipped

with proper automatic circuit-breakers at the buyer's expense.

Commissioning

Prior to commissioning works or to comply with local requirements it is necessary to check air

intake openings and outlet openings to be sure that they are free from foreign matters. Intake

filters condition should be checked as well.

The following instructions are to be observed:

◊ Extension cables should be of proper cross-section.

◊ It is allowed to use extension cables if they are fully disentangled or stretched!

◊ It is not allowed to pull the unit by the power cord.

◊ Upon actuation the unit operates in fully-automatic mode.

◊ The unit is equipped with a protection device that prevents the compressor from switching

on at restart immediately after the unit switching off, thus preventing the compressor damage.

The compressor switches on after 3 minutes only.

We do not ensure the efficient operation of the unit if the room temperature is below 10

°C and if the relative humidity is below 40 %.