R

www.danvex.fi

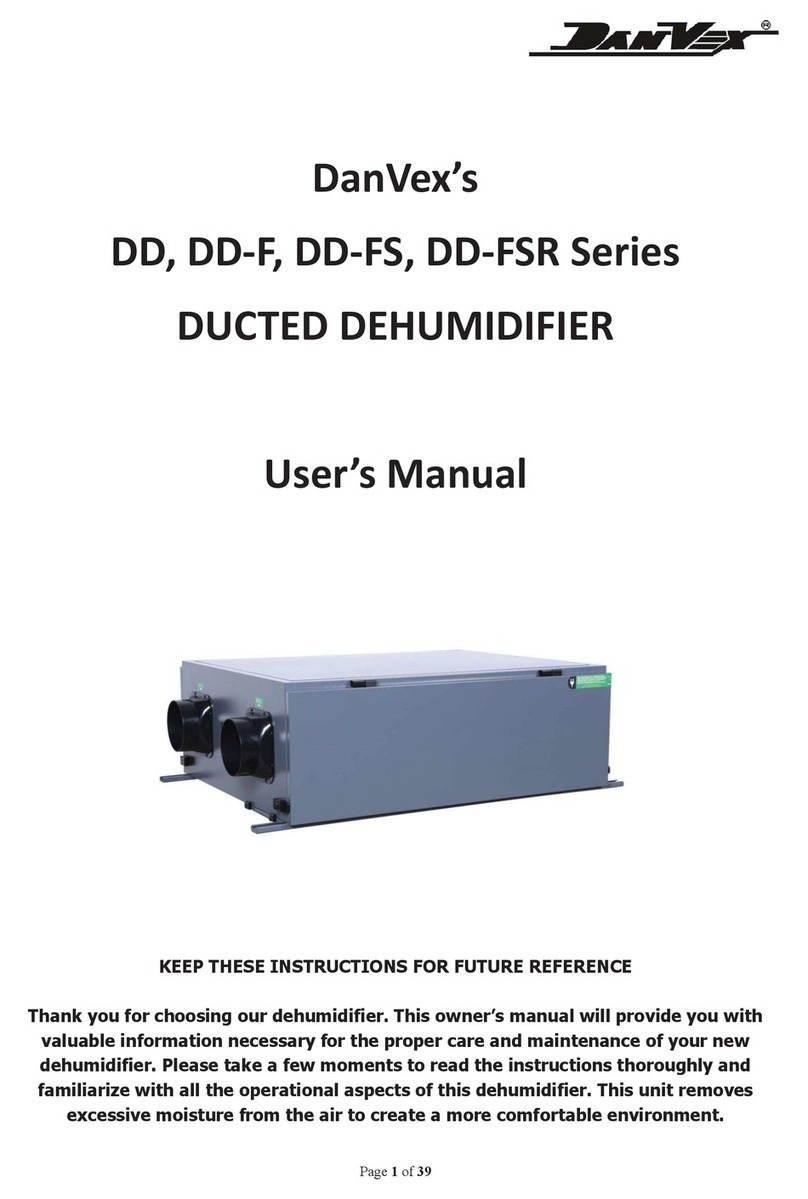

Design

The dehumidifier answers IP 44 protection class according to IEC.

Body

The dehumidifier body is made of stainless zinc-plated steel. It is thermally insulated which

allows the dehumidifier to be used in low-temperature premises and prevents condensate

formation inside the dehumidifier.

The body has a frame structure which allows easy moving of the dehumidifier during

transportation and installation.

The dehumidifier is equipped with detachable panels and doors that assure access for

maintenance and repair.

The rotor drive belt tension mechanism and a sealing system assures the dehumidification

reliable and efficient operation.

Rotor

The dehumidifier is equipped with a drying rotor manufactured in accordance with unique

technologies covered by a patent in force. The rotor represents a matrix consisting of numerous

air channels. It is made of composite material with introduced active SelicaGel and assures a

very large contact area with air flow for moisture adsorption in the small volume of the rotor. This

material is highly efficient for water molecules attraction and retention, it is noncombustible and

explosion-proof, with a long service life. The rotor manufacturing technology assures production

of a product capable of saturated air processing without risk of destruction, it means that the

rotor can be used along with a precooler. Besides, the rotor will not be damaged even if the fan or

the reactivation air heater fail to function.

Filters

The dehumidifier is equipped with two filters. One filter is located at the dehumidified air inlet, the

another one is installed at the reactivation air inlet.

Air flow fans: for dehumidified air flow and for reactivation air flow

The fans are of a radial type, single phase, IP 54 class, ISO F. The fans maintenance can be

performed after the service panels are removed.

Electric panel

Electrical components are located inside the dehumidifier and can be reached through

detachable or opening panels. Switches and indicators are located in the front part of the

dehumidifier.

Reactivation air heater

The reactivation air heater consists of a heating element.

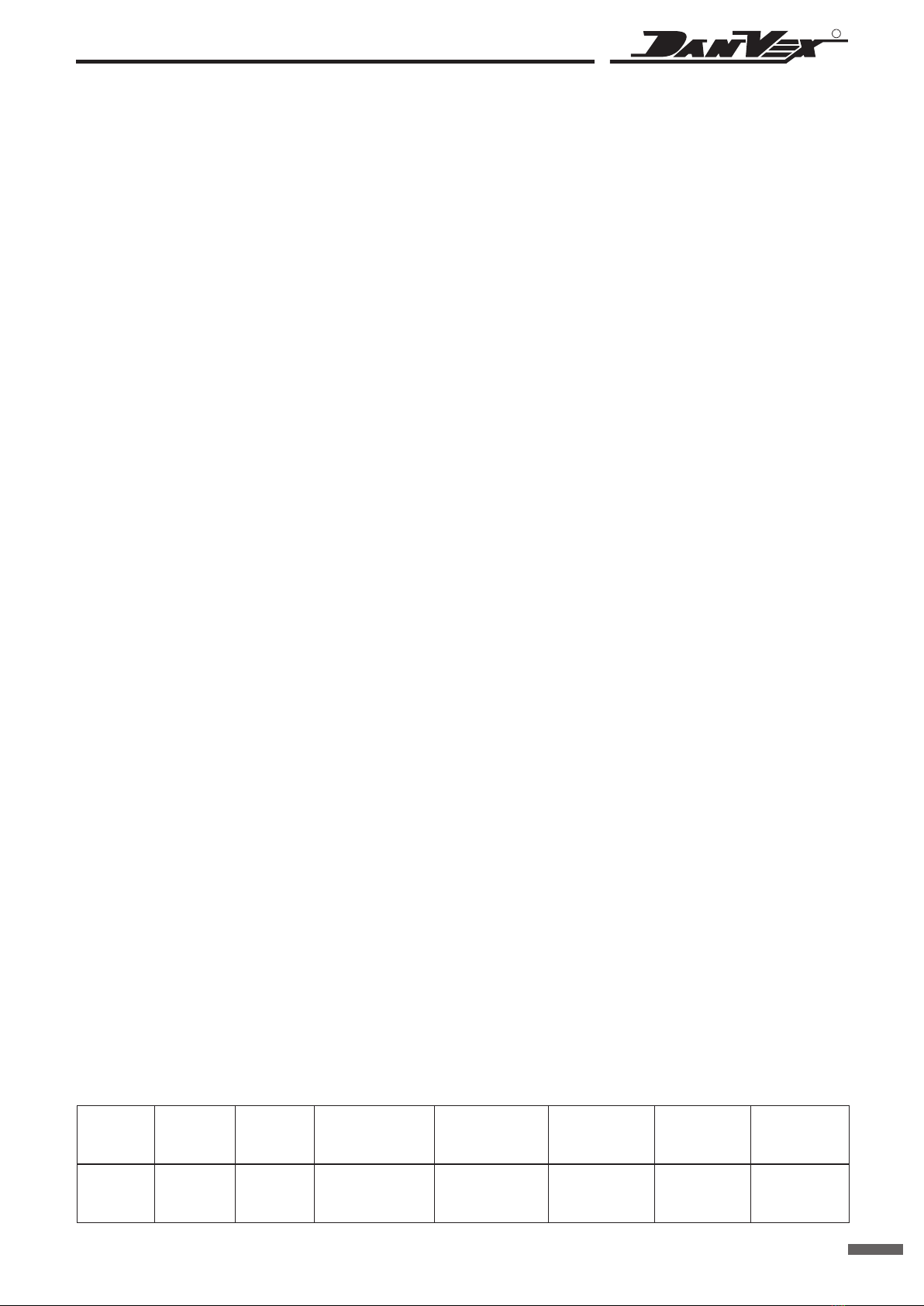

Control panel

DanVex AD- 00 100 dehumidifier is equipped with an automatic control system. All commands

are input using the buttons located on the control panel with a LCD-display.

Dimensions and weight

Insignificant design changes are possible! Table 1

Length Depth Weight

Height Dehumidified

air Dry air Reactivation

air

Moist air

2250mm 1650mm 1800mm ø 630 mm ø 315 mm ø 315 mmø 630 mm 980 kg

5