http://www.delta.com.tw/products/plc.asp

DVP-EH

DVP04PT-H

Platinum Temperature Sensors

Instruction Sheet

1 WARNING

Please carefully read this instruction thoroughly prior to use the DVP04PT-H.

In order to prevent electric shock, do not touch the terminals or conduct any maintenance while

power to the PLC is ON. Do NOT open the PLC. Only qualified personel or Delta staff is allowed

to conduct any internal electrical work on the PLC.

This is an OPEN-TYPE device, and was certified to meet the IEC 61131-2 (UL 508) safety

requirements when installed in an enclosure.

The DVP04PT-H must be kept under the environment away from high temperatures, high

humidity, exceessive vibration, corrosive gases, liquids, airborne dust, and metallic particles.

Do not apply AC power to any of the input/output terminals, or it may damage the DVP04PT-H.

Make sure that the DVP04PT-H is properly grounded , to prevent any electromagnetic noise.

Use wires with resistance when connect the platinum resistance thermister (RTD) to PLC.

Please keep the wires as short as possible when connecting the RTD to PLC, and keep power

wires as far away as possible from I/O wires to prevent noise interference.

2 INTRODUCTION

2.1 Model Explanation and Peripherals

Thank you for choosing DELTA DVP PLC Series. DVP04PT-H allows the connection of four

platinum temperature sensors (PT100 3-WIRE 100 Ω3850 PPM/°C (DIN 43760 JIS

C1604-1989)). The DVP-PLC EH MPU converts the sensors input into a 14 bit digital signal, and

then be manipulated by using TO and FROM instructions in the ladder logic program. There are

49 Controlled Registers (CR, each register has 16 bits) in each module.

Software version DVP04PT-H platinum temperature sensors can be updated via RS-485

communication.

DVP04PT-H displays both Centigrade and Fahrenheit. The input resolution for Centigrade is 0.1

degrees and for Fahrenheit is 0.18 degrees.

Nameplate Explanation

0.1 C or 0.18 F

20.4VDC ~ 28.8VDC

VX.XX 04PT-H0T4250003

PLC model

Input Power Supply Spec.

Analog Input / Outp ut Module Spec.

Barcode

Model Explanation

Model Serial Number

Product Series

Input+Output point

Model type

AD: Analog input module

DA: Analog output module

PT: Platinum temperature sensors(PT-100)

TC: Thermocouple sensors(Type J/K)

S: for SS series MPU

P: for EP series MPU

H: for EH ser ies MPU

Production week

Production place (Taoyuan)

Production year (2004)

Production Model

XA: A/D , D/A Functions

RT: Resistor Thermocouple

HC: High speed count input module

PU: single axis positioning unit

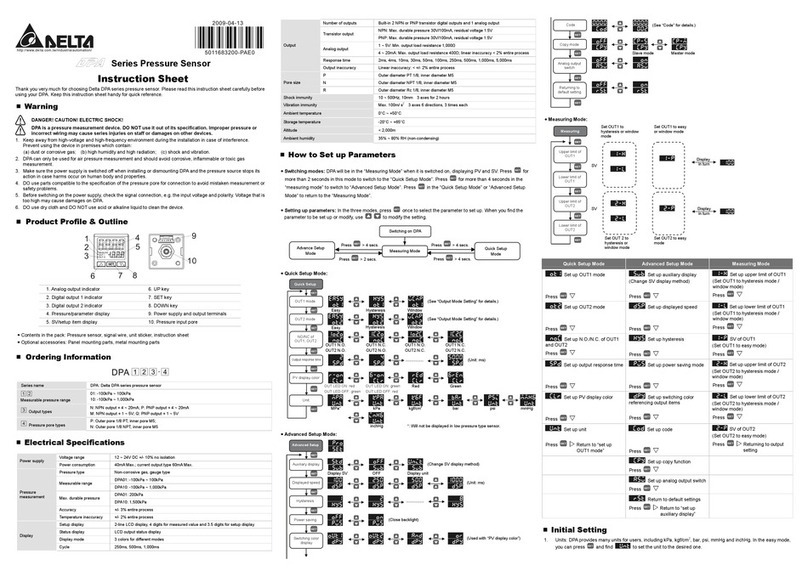

2.2 Product Profile and Outline

1. DIN rail track (35mm) 6. Terminals

2. Mounting hole for wire to connect extension

unit/extension module 7. Mounting hole

3. Model name 8. Terminal layout

4. Indicator for power, error and run status 9. Mounting port to connect extension

unit/extension module

5. DIN rail clip

2.3 External wiring

PT100

PT100

CH1

CH4

1mA

DC/ DC

5V

AG

+15V

-15V

AG

AG

AG

24+

24-

FG

I-

L-

L+

FG

I-

L-

L+

Converter

System

Class 3 Grounding

(100 of less)

terminal of

power module

Shielded*1

*2

*3

1mA

Shielded*1

Grounding

Note 1: Use only the wires that are packed

with the temperature sensor (PT 100)

for analog input and separate from

other power line or any wire that may

cause noise. Please use 3wire for PT

100.

Note 2: Terminal FG is a ground location for

noise suppression.

Note 3: Please connect power supply

module terminal and DVP04PT-H

platinum temperature sensors module

terminal to system earth ground or

connect it to machine cover.

Warning: DO NOT connect wires to the No

Connection (●) terminals.

3 STANDARD SPECIFICATIONS

3.1 Function Specifications

Platinum Temperature Module

(04PT) Centigrade (°C) Fahrenheit (°F)

Power supply voltage 24 VDC (20.4VDC~28.8VDC) (–15%~+20%)

Analog input channel 4 channels per module

Sensors type 3-WIRE PT100Ω3850 PPM/°C(DIN 43760 JIS C1604-1989)

Current excitation 1mA

Temperature input range -200°C~600°C -328°F~1112°F

Digital conversion range K-2000~K6000 K-3280~K11120

Resolution 14 bits (0.1°C) 14 bits (0.18°F)

Overall accuracy ±0.5% of full scale of 25°C(77°F), ±1% of full scale during 0~55°C

(32~131°F)

Response time 200 ms ×channels

Isolation Method Isolation between digital and analog circuitry. But no isolation

between channels.

Digital data format 2’s complement of 16-bit, (13 Significant Bits)

Average function Yes (CR#2~CR#5 may be set and the range is K1~K4096)

Self diagnostic function Upper bound and lower bound detection per channel

Communication mode (RS-485)

Yes, either ASCII or RTU modes, communication rate can be

4800 /9600 /19200 /38400 /57600 /115200. Communication

format of ASCII mode is 7Bit, even bit, 1 stop bit (7 E 1).

Communication format of RTU mode is 8Bit, even bit, 1 stop bit (8

E 1). When connecting to PLC MPU in series, RS-485 can’t be

used. The RS-485 is disabled when the DVP04PT-H is connected

in series to an MPU (use the RS485 on MPU).

Connection to a DVP-PLC MPU

in series

When DVP04PT-H modules are connected to an MPU, the

modules are numbered from 0 – 7. 0 is the closest and 7 is the

furthest to the MPU. 8 modules is the max and they do not occupy

any digital I/O points of the MPU.

3.2 Other Specification

Power Specification

Maximum Power Consumption 2W at 24 VDC (20.4VDC~28.8VDC) (-15 % ~ + 20%)

Environment Condition

Environment Condition Follow the DVP-PLC MPU.

Static Electricity Prevention All places between terminals and ground comply with the spec

4 CR (CONTROLLED REGISTER)

DVP04PT-H platinum temperature sensors Explanation

CR

No.

RS-485

Parameter

address

Latched Register name b15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

#0 H 4064 ○R Model type System used, data length is 8bits (b7~b0). DVP04PT-H model code = H 0402

#1 Reserved

#2 H 4066 ○R/W CH1 average number

#3 H 4067 ○R/W CH2 average number

#4 H 4068 ○R/W CH3 average number

#5 H 4069 ○R/W CH4 average number

The number piece of readings used for the calculation of “average” temperature

on channels CH1~CH4.

Setting range is K1~K4096 and factory setting is K10.

#6 H 406A ╳R CH1 average degrees(°C)

#7 H 406B ╳R CH2 average degrees(°C)

#8 H 406C ╳R CH3 average degrees(°C)

#9 H 406D ╳R CH4 average degrees(°C)

Average degrees for channels CH1~CH4. (unit: 0.1 degrees C)

#10~ #11 Reserved

#12 H 4070 ╳R CH1 average degrees(°F)

#13 H 4071 ╳R CH2 average degrees(°F)

#14 H 4072 ╳R CH3 average degrees(°F)

#15 H 4073 ╳R CH4 average degrees(°F)

Average degrees for channels CH1~CH4. (unit: 0.1 degrees F)

#16~ #17 Reserved

#18 H 4076 ╳R Present temperature of

CH1 (°C)

#19 H 4077 ╳R Present temperature of

CH2 (°C)

#20 H 4078 ╳R Present temperature of

CH3 (°C)

#21 H 4079 ╳R Present temperature of

CH4 (°C)

Present temperature of channels CH1~CH4. (unit: 0.1 degrees C)

#22~ #23 Reserved

#24 H 407C ╳R Present temperature of

CH1 (°F)

#25 H 407D ╳R Present temperature of

CH2 (°F)

#26 H 407E ╳R Present temperature of

CH3 (°F)

#27 H 407F ╳R Present temperature of

CH4 (°F)

Present temperature of channels CH1~CH4. (unit: 0.1degrees F)

#28~ #29 Reserved

#30 H 4082 ╳R Error status Data register stores the error status. Refer to the fault code chart for details.

#31 H 4083 ○R/W Communication address

setting

RS-485 communication address.

Setting range is 01~255 and factory setting is K1

#32 H 4084 ○R/W Communication baud rate

setting

Communication baud rate (4800, 9600, 19200, 38400, 57600 and 115200 bps).

Communication format: ASCII mode is 7Bit, even bit, 1 stop bit (7 E 1).

Communication format of RTU mode is 8Bit, even bit, 1 stop bit (8 E 1).

b0: 4800 bps (bit/sec).

b1: 9600 bps (bit/sec). (factory setting)

b2: 19200 bps (bit/sec).

b3: 38400 bps (bit/sec).

b4: 57600 bps (bit/sec).

b5: 115200 bps (bit/sec).

b6~b13: Reserved.

b14: switch between low bit and high bit of CRC code (RTU mode only)

b15: RTU mode.

b15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

Definition of ERR

LED

CH4 CH3 CH2 CH1

#33 H 4085 ○R/W Reset to factory setting

Example: Setting of CH1

1. b0 Reserved

2. b1 Reserved

3. b2: Set to 1 and PLC will be reset to factory settings.

Definition of ERR LED: b12~b15=1111(factory settings)

1. b12 corresponds to CH1: when b12=1, scale exceeds the range or external

contact has no connection, ERR LED flashes.

2. b13 corresponds to CH2: when b13=1, scale exceeds the range or external

contact has no connection, ERR LED flashes.

3. b14 corresponds to CH3: when b14=1, scale exceeds the range or external

contact has no connection, ERR LED flashes.

4. b15 corresponds to CH4: when b15=1, scale exceeds the range or external

contact has no connection, ERR LED flashes.

#34 H 4086 ○R Software version Display software version in hexadecimal. Example: H 010A = version 1.0A.

#35~#48 System used

○means latched.

╳means not latched.

R means read data by using FROM instruction or RS-485.

W means write data by using TO instruction or RS-485.

Explanation:

1. CR#0: The PLC model type.

2. CR#1, CR#10, CR#11, CR#16, CR#17, CR#22, CR#23, CR#28, CR#29 are reserved.

3. CR#2 ~ CR#5: Used to set the number piece of input readings used for the average temperature

calculation. The available range is K1~K4096 and factory setting is K10.

4. CR#6 to CR#9: The average temperature (°C). Temperature is calculated by averaging multiple

pieces temperature readings. Example: If CR#2 is 10, the temperature in CR#6 will be the

average of the last 10 readings on CH1.

5. CR#12 to CR#15: The average temperature (°C). Temperature is calculated by averaging multiple

pieces temperature readings. Example: If CR#2 is 10, the temperature in CR#12 will be the

average of the last 10 readings on CH1.

6. CR#18 ~ CR#21: display the present temperature (°C) of CH1~CH4 input signal.

Unit: mm