DEMA Nitro Parts list manual

DEMA NITRO/NITRO EXPRESS REPLACEMENT GUIDE

INSTALLATION INSTRUCTIONS

I-993 Pg. 1 of 6

Rev. -- 10/01/09

This instruction sheet will cover the replacement of common components on the Nitro and Nitro Express Ware Wash

systems. If any further questions exist on the replacement of parts for the Nitro or Nitro Express Ware Wash

System please contact DEMA Technical Customer Service at 1-800-325-3362. The replacement instructions will

be broken up by kit number.

WHENEVER SERVICING ELECTRICAL EQUIPMENT BE SURE TO DISCONNECT

MAIN POWER FROM THE NITRO OR NITRO EXPRESS AND FROM THE DISH

MACHINE AS WELL TO AVOID RISK OF ELECTRIC SHOCK.

KIT 81.316.1 – OPEN FRAME POWER SUPPLY REPLACEMENT KIT

KIT INCLUDES: 1 OPEN FRAME POWER SUPPLY (81.281.1) AND 4 #4 SCREWS

(81.20.2) .

To replace the power supply in the unit, disconnect power from the unit and from the dish machine

the unit is attached to. Then, simply unplug the incoming power cable and outgoing power cable

from the old supply. Unscrew the 4 screws securing the power supply in place. Take out the old

power supply noting that the 4 prong connector was toward the bottom of the unit and the 2 prong

connector was toward the top of the unit. Place the new power supply in the unit in the same

orientation. Put the 4 screws in place and reconnect the power cables (see page 2 for wiring

diagram).

KIT 81.316.2 – CONTROL BOARD REPLACEMENT KIT FOR NITRO EXPRESS

TWO PRODUCT UNITS

KIT INCLUDES: CONTROL BOARD NITRO EXPRESS TWO

PRODUCT (81.283.1), 4 #4 SCREWS (81.20.2) AND

PROGRAMMING LABEL FOR FIREWALL (L1186).

To replace the control board, remove all power from the unit and from the

dish machine to which the unit is connected. Then, remove all wiring from

the old board. Make note where the wiring is at and which cables plug in to

which spots (See page 2 for wiring digram). Unscrew the 4 screws securing

the control board. Place the new control board in the unit and secure the

control board with the 4 screws. Use the diagram on the following page to

help reconnect the wires to the proper places.

DEMA NITRO/NITRO EXPRESS REPLACEMENT GUIDE

INSTALLATION INSTRUCTIONS

I-993 Pg. 2 of 6

Rev. -- 10/01/09

WIRING THE REPLACEMENT BOARD

The internal power cables should have labels on

them to denote which is the rinse power cable and

which is the wash power cable. The rinse power

cable gets hooked onto the left connection point

for a two prong connection and the wash power

cable gets hooked onto the right connection point.

The rinse motor and detergent motor or valve

should always get hooked up with the black wire

hooked to the left spade connection and the red

wire hooked to the right spade connection. The

probe cable (if the unit is being run in

concentration mode will get hooked into the probe

cable inlet which is a blue box with screw down

terminals. Once everything is replaced, the unit

will need to be programmed to the specifications

that the last board was running. If the unit is a three product unit, wires from the sanitizer pump will need to be plugged

into the proper spots as well as shown on the diagram.

KIT 81.316.3 – CONTROL BOARD REPLACEMENT KIT FOR NITRO EXPRESS

THREE PRODUCT UNITS

KIT INCLUDES: CONTROL BOARD NITRO EXPRESS THREE

PRODUCT (81.283.2), 4 #4 SCREWS (81.20.2) AND PROGRAMMING

LABEL FOR FIREWALL (L1186).

To replace the control board, remove all power from the unit and from the dish

machine to which the unit is connected. Then, remove all wiring from the old

board. Make note where the wiring is at and which cables plug in to which

spots. Unscrew the 4 screws securing the control board. Place the new control

board in the unit and secure the control board with the 4 screws. Use the

diagram on the top of the page to help reconnect the wires to the proper places.

KIT 81.316.4 – DETERGENT PUMP/MOTOR CONVERSION AND REPLACEMENT

KIT

KIT INCLUDES: DETERGENT MOTOR (81.311.2), DRIVE ADAPTER (81.220.1), DETERGENT PUMP

ASSEMBLY (81.226.2), VALVE BRACKET COVER (81.279.2), #8 HI-LO SCREWS (44.116.2)

If converting from a detergent valve to a detergent pump, the

valve, pump cover, and valve cover inside the unit will need to be

removed. The valve bracket cover is used to cover the hole from

where the valve was connected to the unit.

To replace the detergent motor and pump, disconnect all power

to the unit. Unplug the detergent motor leads from the control

board. Take out the two screws securing the motor to the cover

of the unit. Place the new drive adapter on the motor and tighten

the screws to secure the motor to the cover. To replace the

pump, take the cover off the pump to expose the secure screw.

Take the screw out and take the rest of the pump off the cover.

Place the new pump on the cover and use the secure screw to

keep the pump head in place.

DEMA NITRO/NITRO EXPRESS REPLACEMENT GUIDE

INSTALLATION INSTRUCTIONS

I-993 Pg. 3 of 6

Rev. -- 10/01/09

KIT 81.316.5 – RINSE PUMP/MOTOR REPLACEMENT KIT

KIT INCLUDES: RINSE MOTOR (81.311.1), DRIVE ADAPTER (81.220.1), RINSE PUMP ASSEMBLY

(81.226.1), #8 HILO SCREWS (44.116.2)

To replace the rinse motor and pump, disconnect all

power to the unit. Unplug the rinse motor leads from

the control board. Take out the two screws securing

the motor to the cover of the unit. Place the new drive

adapter on the motor and tighten the screws to secure

the motor to the cover. To replace the pump, take the

cover off the pump to expose the secure screw. Take

the screw out and take the rest of the pump off the

cover. Place the new pump on the cover and use the

secure screw to keep the pump head in place.

KIT 81.316.6 – DETERGENT VALVE CONVERSION AND REPLACEMENT KIT

KIT INCLUDES: DETERGENT VALVE ASSEMBLY (81.300.1), VALVE COVER (81.277.1), PUMP BLANK

COVER (81.278.1), WIRE ASSEMBLY FOR VALVE TO BOARD (81.196.7), #8 HILO SCREWS (44.116.2)

If converting from a detergent pump to a detergent valve, the

detergent motor, pump head and valve bracket cover from the

bottom of the unit will need to be removed. The valve assembly

will fit where the valve bracket cover on the unit was placed.

To replace the detergent valve, disconnect all power to the unit.

Remove the old valve from the unit by disconnecting the wires

and removing the screws from the bottom of the unit. It may be

necessary to remove the valve cover on the inside of the unit to

remove the wires. Place the new wire assembly on the new valve.

Replace the old valve with the new valve. Secure the valve with

the screws provided. Replace the valve cover with the screws to

secure it to the enclosure. Plug the wires into the proper place on

the control board. If converting from a pump to a valve, place the

pump blank cover on the front of the unit and secure with a screw.

KIT O-ADC SANITIZER PUMP REPLACEMENT

KIT

KIT INCLUDES: SANITIZER PUMP (81.290.1), PICK UP TUBE (81.312.1), SCREW AND ANCHOR KIT,

CHECK VALVE, TUBING, AND CABLE TIES.

Separate instruction sheet is included with this unit for proper hanging and operation. See I969.

KIT 81.316.7 – SANITIZER PUMP CONVERSION KIT

KIT INCLUDES: SANITIZER PUMP (81.290.1), PICK UP TUBE (81.312.1) , SCREW AND ANCHOR KIT,

CHECK VALVE, TUBING, CABLE TIES, #4 SCREWS, AND 3 PRODUCT CONTROL BOARD (81.283.2)

This kit is for converting from a 2 product system of detergent and rinse to a 3 product system of detergent, rinse, and

sanitizer. One thing that is required for this is a change of control boards from a 2 product control board to one that will

control 3 products. The picture on the next page shows a 3 product control board with the sanitizer spades and

potentiometer. These are necessary to power the sanitizer pump and control the amount of sanitizer dispensed.

DEMA NITRO/NITRO EXPRESS REPLACEMENT GUIDE

INSTALLATION INSTRUCTIONS

I-993 Pg. 4 of 6

Rev. -- 10/01/09

To convert the system to three products, remove all power from the

unit and from the dish machine. Then remove the wiring from the

control board taking note of where wires connected to the board.

Remove the 4 screws holding the control board to the cover. Take

the old control board out and put the new 3 product control board

in. Secure the board with the four screws provided in the kit. Then

begin rewiring the board as shown on page 2. Once the board is

rewired, the board will need to be programmed. Using the old

board could help in this process to understand the settings.

KIT 81.316.8 – DETERGENT PUMP

ONLY REPLACEMENT KIT

KIT 81.316.9 – RINSE PUMP ONLY

REPLACEMENT KIT

KIT INCLUDES: DETERGENT PUMP

(81.226.2) OR RINSE PUMP (81.226.1) AND

SCREW

To replace the pump head, take off the pump cover to expose the secure screw. Take out the secure screw and

remove the rest of the pump head. Place the new pump head on and tighten the secure screw. The rinse pump head is on

the front left of the unit and the detergent pump head is on the front right of the unit.

KIT 81.316.10 – DETERGENT MOTOR ONLY

REPLACEMENT KIT

KIT 81.316.11 – RINSE MOTOR ONLY

REPLACEMENT KIT

KIT INCLUDES: DETERGENT MOTOR (81.311.2) OR

RINSE MOTOR (81.311.1), DRIVE ADAPTER (81.220.1)

AND SCREWS

DEMA NITRO/NITRO EXPRESS REPLACEMENT GUIDE

INSTALLATION INSTRUCTIONS

I-993 Pg. 5 of 6

Rev. -- 10/01/09

To replace the motor, disconnect all power to the unit and machine. Unplug the motor from the control board. Take the

screws out that secure the motor to the cover. Place the new drive adapter on the motor and place the new motor in place

in the cover. Use the screws provided to secure the motor to the cover and plug the motor wires into the proper

terminals. For assistance with this, see the wiring diagram on page 2.

KIT 81.316.12 – NITRO CONTROL BOARD REPLACEMENT KIT

KIT INCLUDES: NITRO CONTROL BOARD (81.282.1),

AND #4 SCREWS

To replace the control board, remove all power from the unit and

from the dish machine to which the unit is connected. Then,

remove all wiring from the old board. Make note where the wiring

is at and which cables plug in to which spots. Unscrew the 4

screws securing the control board. Place the new control board in

the unit and secure the control board with the 4 screws. Use the

diagram on the following page to help reconnect the wires to the

proper places.

The internal power cables should have labels

on them to denote which is the rinse power

cable and which is the wash power cable. The

rinse power cable gets hooked onto the left

connection point for a two prong connection

and the wash power cable gets hooked onto

the right connection point. The rinse motor

and detergent motor or valve should always

get hooked up with the black wire hooked to

the left spade connection and the red wire

hooked to the right spade connection. The

probe cable (if the unit is being run in

concentration mode will get hooked into the

probe cable inlet which is a blue box with

screw down terminals. Once everything is

replaced, the unit will need to be programmed

to the specifications that the last board was

running. If the unit is a three product unit, wires from the sanitizer pump will need to be plugged into the proper spots

as well as shown on the diagram.

DEMA NITRO/NITRO EXPRESS REPLACEMENT GUIDE

INSTALLATION INSTRUCTIONS

I-993 Pg. 6 of 6

Rev. -- 10/01/09

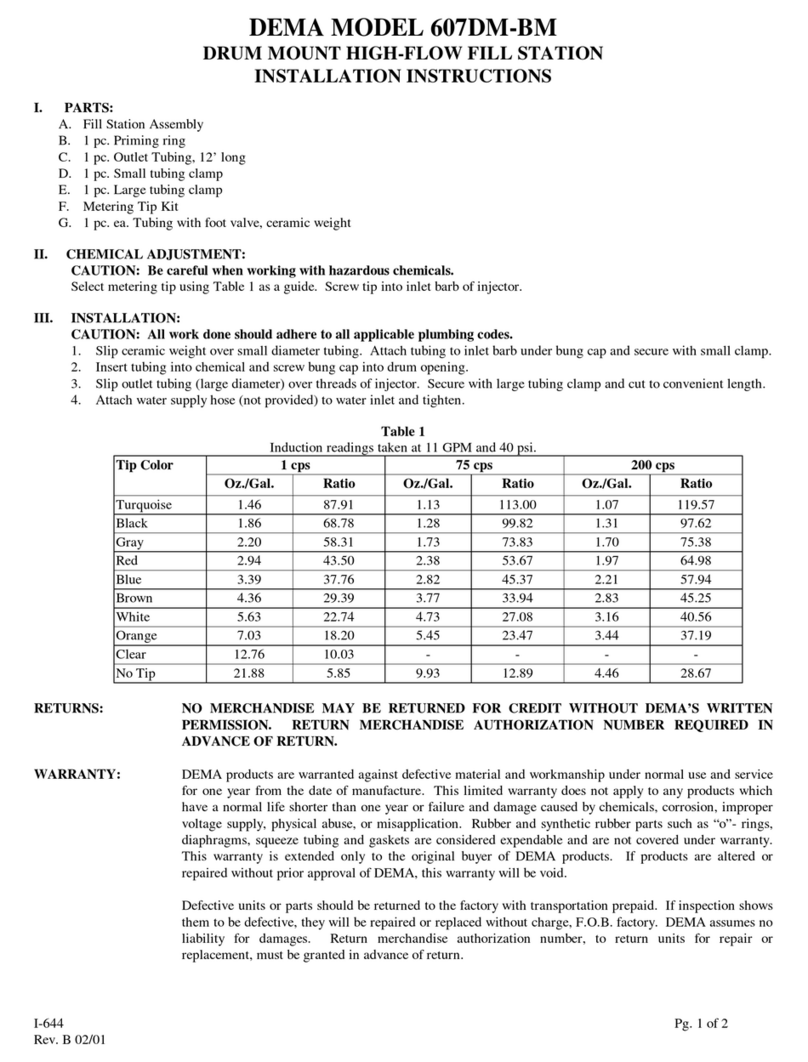

THE FOLLOWING TABLE IS A LIST OF COMMONLY USED PARTS INCLUDING TUBING, SQUEEZE

TUBES, AND VARIOUS KIT PARTS.

PART NO. DESCRIPTION LENGTH

904.8KY CHK VLV ¼” COMP X 1/8” NPT KYNAR --

904.8T CHK VLV ¼” OD –TEFLON BALL --

100.12.SV1 ¼” OD X 1/16” ID VINYL TUBING 16’

100.12.SV2 ¼” OD X 1/16” ID VINYL TUBING 50’

100.12.SV3 ¼” OD X 1/16” ID VINYL TUBING 100’

25.68.10 ¼” LDPE TUBING 10’

25.68.20 ¼” LDPE TUBING 20’

25.68.40 ¼” LDPE TUBING 40’

25.68.60 ¼” LDPE TUBING 60’

25.68.80 ¼” LDPE TUBING 80’

25.75 ¼” LDPE TUBING 100’

25.68.120 ¼” LDPE TUBING 120’

81.312.1 TUBE STIFFENER (PICK-UP TUBE) 12”

81.312.2 TUBE STIFFENER (PICK-UP TUBE) 10”

80.55 LIQUID FEED INJECTION ELBOW --

C.12B CONDUCTIVITY CELL --

58.5 OVERFLOW ELBOW KIT (DRY DET.) --

81.183.5 CABLE STRAIN RELIEF --

25.21.4 SQUEEZE TUBE REPLACEMENT (1 EPDM) --

25.21.5 SQUEEZE TUBE REPLACEMENT (5 EPDM) --

RETURNS: NO MERCHANDISE MAY BE RETURNED FOR CREDIT WITHOUT DEMA’S WRITTEN

PERMISSION. RETURN MERCHANDISEAUTHORIZATIONNUMBERREQUIREDINADVANCE

OF RETURN.

WARRANTY: DEMA products are warranted against defective material and workmanship under normal use and service forone

year from the date of manufacture. This limited warranty does not apply to any products which have a normal life

shorter than one year or failure and damage caused by chemicals, corrosion, improper voltage supply, physical

abuse, or misapplication. Rubber and synthetic rubber parts such as “o”- rings, diaphragms, squeeze tubing and

gaskets are considered expendable and are not covered under warranty. This warranty is extended only to the

original buyer of DEMA products. If products are altered or repaired without prior approval of DEMA, this

warranty will be void.

Defective units or parts should be returned to the factory with transportation prepaid. If inspection shows them to

be defective, they will be repaired or replaced without charge, F.O.B. factory.

units for repair or replacement, must be granted in advance of return.

Other manuals for Nitro

3

This manual suits for next models

1

Table of contents

Other DEMA Dispenser manuals

DEMA

DEMA 651GAP-1 User manual

DEMA

DEMA Titan EP Installation guide

DEMA

DEMA Extreme 4 User manual

DEMA

DEMA Nitro Installation guide

DEMA

DEMA Nitro Plus User manual

DEMA

DEMA 301B User manual

DEMA

DEMA 607DM-BM User manual

DEMA

DEMA PF651GAP User manual

DEMA

DEMA TITAN II Assembly instructions

DEMA

DEMA Nitro User manual

DEMA

DEMA 652AG User manual

DEMA

DEMA 665 Series User manual

DEMA

DEMA Olympian O-PDV User manual

DEMA

DEMA 302-2 User manual

DEMA

DEMA 302-1 User manual

DEMA

DEMA Laundry Master 830 User manual

DEMA

DEMA TITAN II User manual

DEMA

DEMA Nitro User manual

DEMA

DEMA Master Nitro Express User manual

DEMA

DEMA 5800V.BV User manual