DEMA Extreme 4 User manual

I-1091

Rev. L-4

3

Overvi

e

The Extr

e

the great

A

sin

g

Multi-

Integ

r

Warnin

g

accordin

g

Wisconsi

n

of a pres

s

Instruc

t

Category

Package

C

Operation

a

Overall Di

m

Installatio

n

Operation

Metering

T

Troublesh

o

Parts List

Warranty I

n

3

223

e

w

e

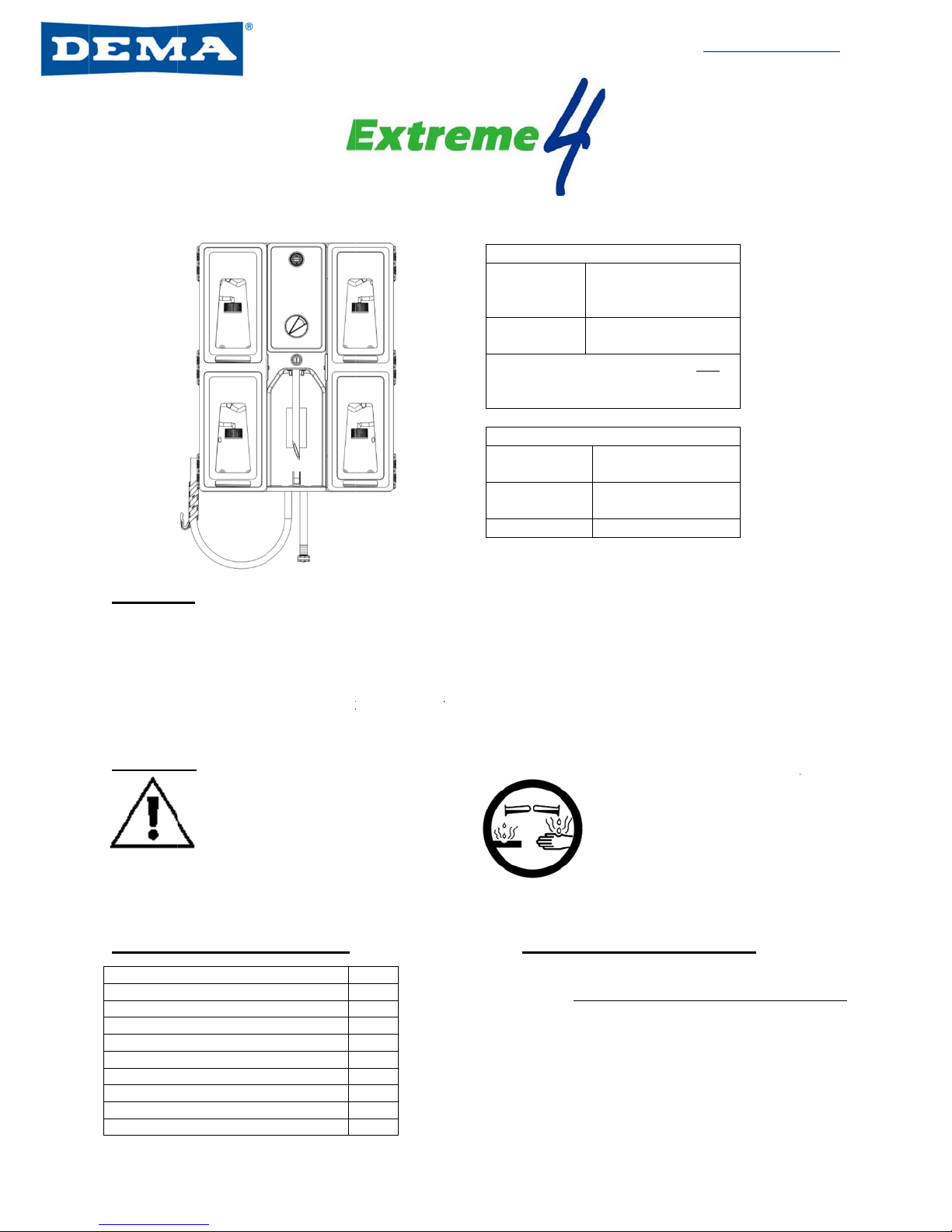

me 4 makes

design featu

r

g

le dial for 8

d

point locking

r

ated ASSE

a

g

s

All inst

a

local pl

u

approv

e

devices

to be in

s

g

to local plu

m

n

and any ot

h

s

ure indicatin

g

t

ion Sheet

C

ontents / Req

u

a

l Requiremen

t

m

ensions

/ Preparation

T

ip Charts

o

oting

n

formation

users more

e

r

es include:

d

ifferent diluti

system for E

x

a

pproved bac

k

llations must

u

mbing code

s

e

d backflow p

. A pressure

s

talled with e

x

m

bing codes i

n

h

er state that

r

g

tee

Contents

u

ired Tools

t

s

e

fficient, fillin

g

on points

x

treme secu

r

k

flow preven

t

conform to

s

and use

revention

indicating te

e

x

isting faucet

n

the state of

r

equires the

u

Page

1

1

2

W

2-3

4

*

a

r

5

6

7

8

665 Se

r

g

bottles and

b

r

ity

t

ion

L

B

O

fi

l

e

is

s

u

se

O

Water Press

u

W

ater Temper

a

*

* Recommen

d

a

nd 70 psi. (5.

5

r

ecommended

Mete

r

k

665

s

disp

e

4 S

a

Bul

k

Ha

m

Drill

w

& 9/

3

P

e

r

ies Dispens

e

buckets with

arge sight wi

n

B

randing pan

e

O

ne-handed

b

ll

A

L

W

C

O

perationa

Water Sup

p

Mi

n

u

re 20 psi

a

ture

d

ed water pres

s

5

2 bar). If pre

s

that a water p

r

Box Co

n

r

ing tip

k

it har

d

s

eries

e

nser In

s

a

feLink cap a

k

tubing, 4 c

e

and foot

v

Suggeste

d

m

mer

w

/ 3/16”

3

2” bits

T

e

ncil

e

r

w

ease and qui

n

dow to iden

t

e

ls to meet th

b

ottle and opt

W

AYS WEA

R

C

LOTHING

A

WHEN WO

CHEMICA

L

l Require

m

p

ly Requirem

e

n

imum

(1.38 bar)

-

s

ure is betwee

s

sure exceeds

r

essure regula

t

n

tains

Mounting

d

ware, templ

a

& key set

s

truction she

e

a

ssemblies O

R

e

ramic weight

v

alves

d

Tools

Phillips

screwdriver

T

ape measur

e

Level

w

ww.demaen

g

1-800-325

Page

8

/

i

ckness. So

m

t

ify product a

n

e ‘look n’ fee

l

ional remote

R

PROTECTI

V

A

ND EYEWE

A

RKING WIT

H

L

PRODUCT

S

m

ents

e

nts Maximum

125 psi (8.62

b

150ºF (65.5

º

n 20 psi (1.38

b

70 psi, it is

t

or is used.

a

te

e

t

R

s

e

g

.com

-3362

1 of 8

/

29/17

m

e of

n

d level

l

’ need

bucket

VE

A

R

H

S

b

ar)**

º

C)

bar)

I-1091

Rev. L-4

3

Overall

Installa

t

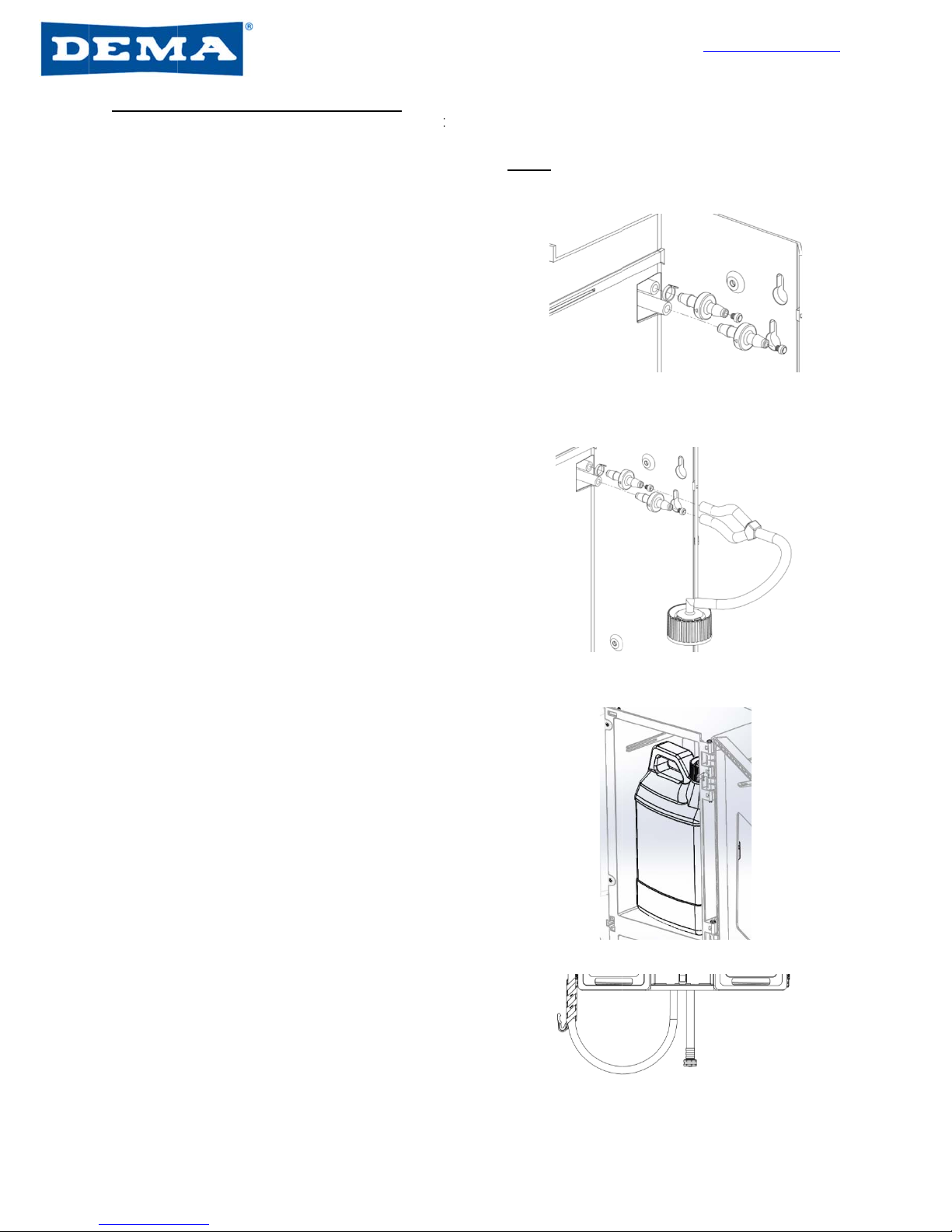

1. Identi

again

[For

a

2. Instal

top t

w

into t

h

3. Tight

e

4. Instal

tab in

[Opti

o

attac

h

chem

3

223

Dimensio

n

t

ion & Pre

p

fy desired lo

c

st wall and

m

a

ccuracy, us

e

l all four sup

p

w

o screws an

d

h

e anchors.

e

n screws ag

l Drip Tray b

y

back of drip

o

nal: Drill 3/1

6

h

¼” ID hose

ical from drip

n

s

p

aration

c

ation of disp

e

m

ark hole loc

a

e

level with te

m

p

lied anchors

d

hang dispe

n

a

inst dispen

s

y

sliding into

p

tray holder.

6

” hole into d

r

(not supplied

tray (Figure

e

nser. Rem

o

a

tions using t

h

m

plate to en

s

into marked

h

n

ser from the

s

er to assure

a

p

lace against

r

ip tray barb

a

) for draining

1)

o

ve cardboar

d

h

e template a

s

ure the disp

e

h

ole location

s

m. Install bot

t

a

secure fit.

a

nd

d

mounting t

e

a

s a guide.

e

nser is level

s

from step 1

.

tom two scre

w

w

e

mplate from

p

on the wall]

. Using supp

w

s through d

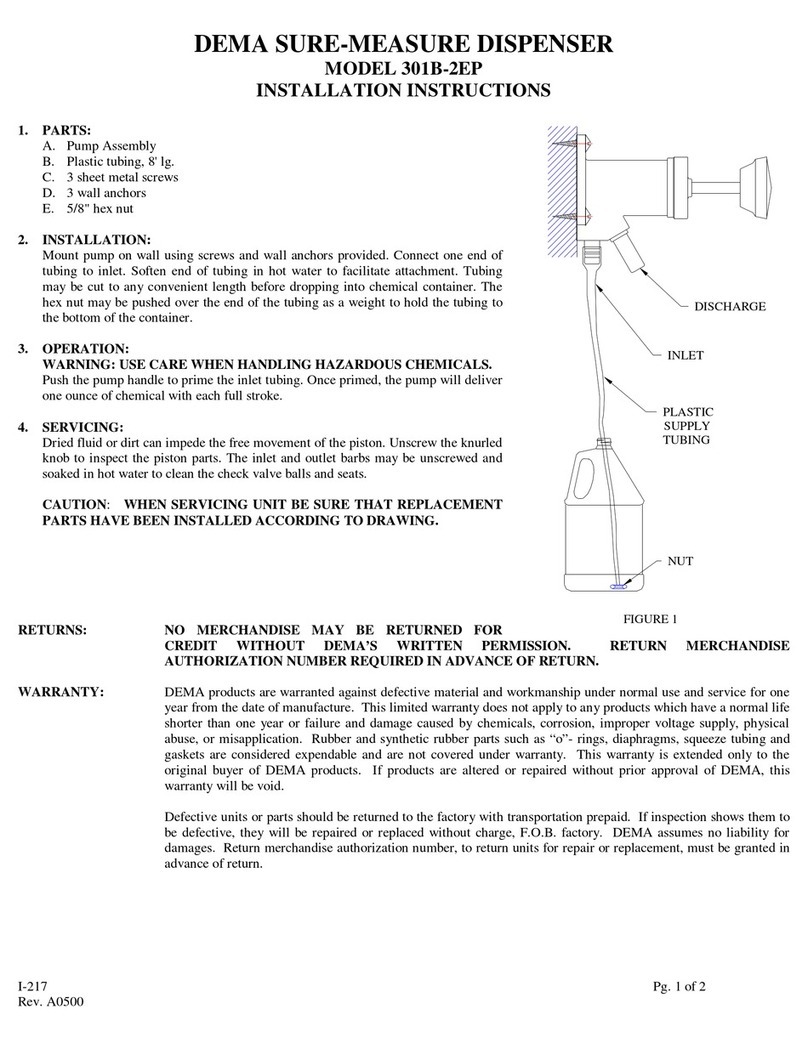

Figure 1

w

ww.demaen

g

1-800-325

Page

8

/

p

ackaging, p

l

p

lied screws, i

ispenser hol

e

g

.com

-3362

2 of 8

/

29/17

l

ace

nstall

e

s

I-1091

Rev. L-4

3

Installa

t

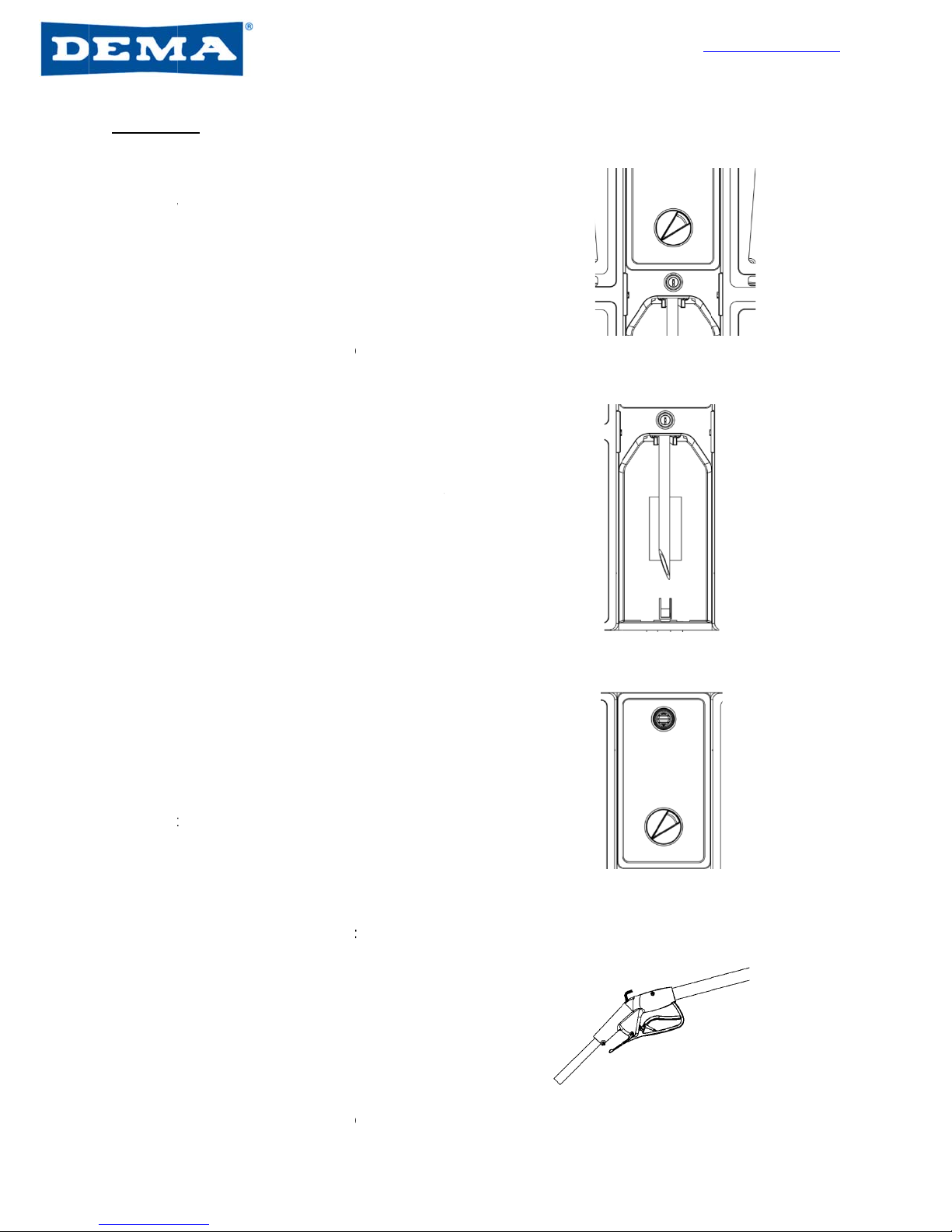

Step

s

valve

5. To in

s

chec

k

desir

e

rate

o

(Figu

r

6. Scre

w

threa

d

Note:

prod

u

7. For S

over

t

For

O

need

e

weig

h

Secu

r

valve

Note:

allow

8. Positi

comp

Safe

L

cera

m

9. Clos

e

10. Conn

sour

c

a pos

buck

e

3

223

t

ion & Pre

p

s

5 through

7

s located in

e

s

tall metering

k

valve in ea

c

e

d metering t

i

o

n the tip cha

r

r

e 2)

w

metering ti

p

d

ed check va

A blank tip c

u

ct from disp

e

afeLink cap

a

t

he exposed

c

O

pen contain

e

e

d and cut to

h

t and foot va

r

e top of tubi

n

barb

Softening th

e

the tube to fi

t

on chemical

c

artment in d

e

L

ink cap or in

s

m

ic weight int

o

e

and lock th

e

e

ct the suppl

i

c

e and activat

ition on the d

e

t or bottle fill

p

aration C

7

explain how

e

ach compart

m

tips, locate t

h

h compartm

e

p based on

c

r

t for bottle a

n

p

clockwise in

lve barb

a

n be used t

o

e

nsing at bottl

a

nd tubing: s

e

c

heck valve

b

e

r: Measure b

length. Inst

a

lve at base o

f

n

g over the e

x

e

tube with h

o

t

over the ba

r

c

ontainer int

o

e

sired positio

n

s

tall tubing w

o

open conta

i

e

cabinet doo

r

i

ed water ho

s

e

the dispen

s

ial and using

activation p

o

ont’d

to install me

t

m

ent. Chec

k

for

h

e correct

e

nt. Identify

c

olor and dilu

t

n

d bucket filli

n

to exposed

o

prevent a

e or bucket f

i

e

cure the tubi

b

arb (Figure

3

ulk tubing

a

ll ceramic

f

tubing.

x

posed chec

k

o

t water will

r

b with ease

o

each

n

and conne

c

foot valve a

n

i

ner (Figure

4

r

s

s

e to your wa

t

s

er by selecti

n

either the

o

int (Figure 5)

t

ering tips.

M

k

valves to bu

bottle fill do

n

t

ion

n

g

ll

ng

3

)

k

t

n

d

4

)

t

er

n

g

M

etering tips

w

u

cket fill have

n

ot.

w

w

ill be installe

a plastic rin

g

Figure 2

Figure 3

Figure 4

Figure 5

w

ww.demaen

g

1-800-325

Page

8

/

d at the two

c

g

, and check

v

g

.com

-3362

3 of 8

/

29/17

c

heck

v

alves

I-1091

Rev. L-4

3

Operati

1. Turn

t

chem

arro

w

2. Disp

e

bottle

trigg

e

3. For ri

n

the w

not d

r

1. Slide

raise

the b

o

2. To st

o

disen

3. Be c

a

as to

1. To st

a

butto

n

2. For c

o

3. To di

s

coun

t

1. To st

a

trigg

e

2. For c

o

rotat

e

trigg

e

3. To di

s

and t

h

3

223

on

t

he chemical

ical position,

w

e

nse chemica

fill lever or b

e

r)

n

se water, p

o

a

ter symbol-

r

ink

the bottle tu

b

the bottle to

e

o

ttle fill asse

m

o

p filling, low

e

g

age

a

reful when r

e

not splash re

Dispens

a

rt the flow o

f

n

on unit abo

v

o

ntinuous flo

w

s

engage, rel

e

t

erclockwise

D

i

a

rt the flow o

f

e

r on handle

o

o

ntinuous flo

w

e

the red leve

r

e

r

s

engage, sim

h

e red lever

w

selector dial

t

indicated by

t

l by either ac

t

ucket fill butt

o

o

int the dial s

t

This is not p

o

Dispe

n

b

e inside the

s

e

ngage the u

-

m

bly

e

r the bottle

a

e

moving the

s

sidual chemi

c

er Activatio

n

f

diluted che

m

v

e selector di

w

, twist butto

n

e

ase button o

r

i

spenser Ac

t

f

diluted che

m

o

f fill gun

w

, while trigg

e

r

downward

a

ply press the

w

ill move out

o

Chemical

S

t

o the desire

d

t

he direction

a

t

ivating the

o

n (or remot

e

t

raight down

a

o

table water,

n

ser Activati

o

s

pray bottle

a

-

shaped leve

r

a

nd the lever

w

s

pray bottle s

o

c

al

n

Points – P

u

m

ical, press

al

n

clockwise

r

twist button

t

ivation Poin

m

ical, press

e

r is pressed

,

a

nd release

trigger agai

n

o

f position

S

elector Dia

d

a

l

e

fill

a

t

do

o

n Points –

B

a

nd

r

of

w

ill

o

u

sh Button

B

ts – Remote

,

n

l

(Figure 6)

B

ottle Fil

l

(F

i

B

ucket Fil

l

(

i

f

Fil

l

(

if equi

p

w

Figure 6

i

gure 7)

Figure 7

f

equipped

)

(

Figure 8

p

ped

)

(Figure

Figure 9

w

ww.demaen

g

1-800-325

Page

8

/

(

Figure 8)

9)

g

.com

-3362

4 of 8

/

29/17

I-1091

Rev. L-4

3

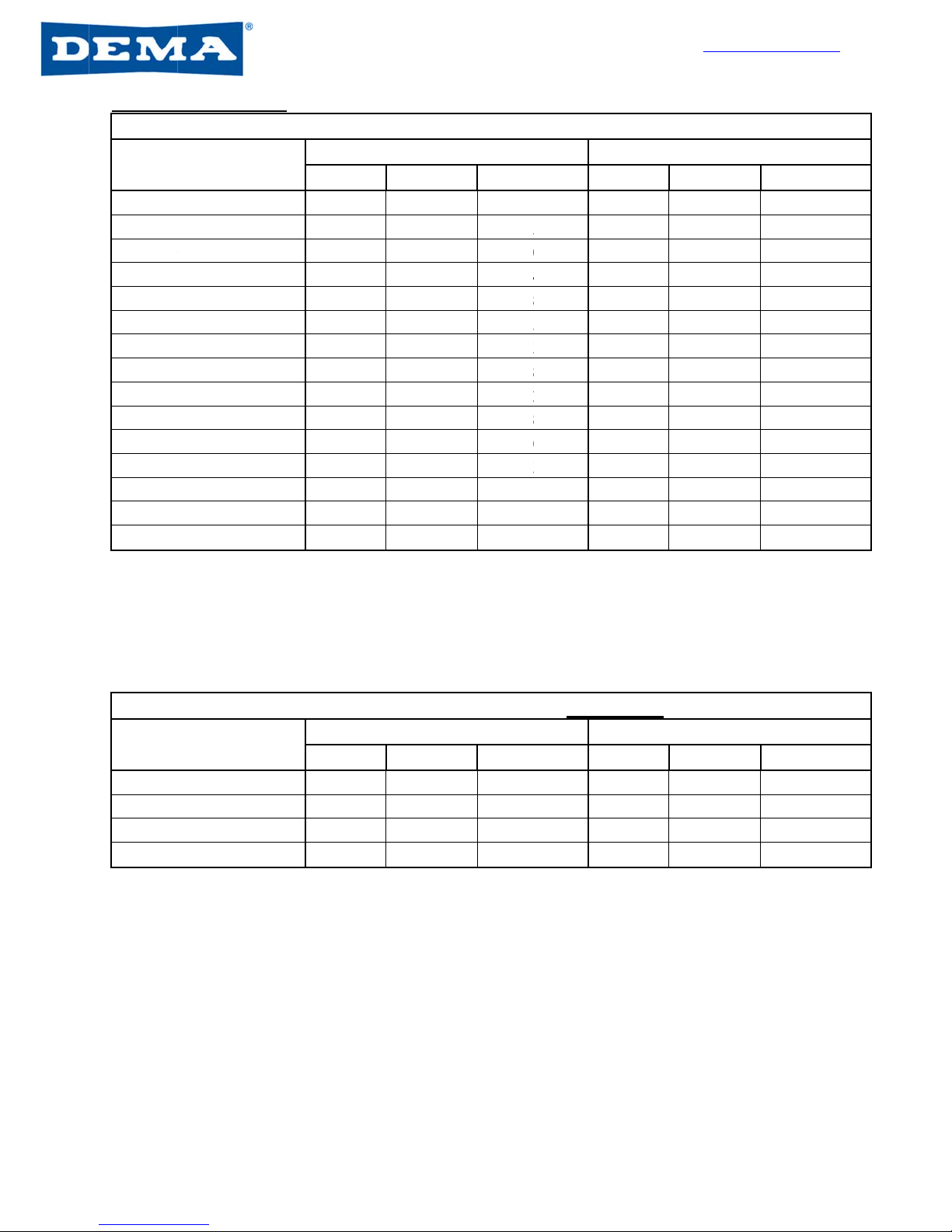

Meterin

Mete

r

Tan

Orange

Turquoi

s

Royal B

Charco

a

Pink

Light Bl

Brown

Red

White

Green

Blue

Yellow

Gray

No Tip

IN

Mete

r

Copper

Pumpki

n

Burgun

d

Lime

IN

3

223

g Tip Cha

r

r

ing Tip Col

o

s

e

lue

a

l Gray

ue

I

N

DUCTION R

A

r

ing Tip Col

o

n

d

y

I

N

DUCTION R

A

r

ts

Tab

o

r

1

G

Oz.

/g

1.2

5

1.7

0

2.1

5

2.3

7

2.6

7

3.0

0

3.9

0

4.5

5

5.8

0

7.0

0

7.9

0

9.8

0

14.

8

31.

6

35.

0

N

DUCTION

R

A

TES VARY

P

Table

o

r

1

G

Oz.

/g

0.5

6

0.7

3

0.9

0

1.2

8

N

DUCTION

R

A

TES VARY

P

le 1: Extrem

G

PM Flow R

a

g

al ml/

L

5

9.8

0

0

13.3

3

5

16.6

7

7

18.5

2

7

20.8

3

0

23.2

6

0

30.3

0

5

35.7

1

0

45.4

5

0

55.5

6

0

62.5

0

0

76.9

2

8

0 111.1

6

0 250.

0

0

0 277.

7

R

ATES BASE

D

P

RODUCT

T

2: Ultra Lea

n

G

PM Flow R

a

g

al ml/

L

6

4.3

8

3

5.7

0

0

7.0

3

8

10.0

0

R

ATES BASE

D

P

RODUCT

T

e 4 Meterin

g

a

te Proporti

o

L

Rati

o

0

1

0

3

7

5

7

6

0

2

5

4

3

4

8

6

4

3

0

3

3

1

2

8

5

2

2

6

1

8

0

1

6

2

1

3

1

9

0

0

4

7

8 3

.

D

ON WATE

R

T

O PRODUC

T

n

Metering

T

a

te Proporti

o

L

Rati

o

8

2

3

0

1

7

3

1

4

0

1

0

D

ON WATE

R

T

O PRODUC

T

g

Tips (Provi

d

o

ner

4

o

: 1 O

z

0

2 0

5 0

0 0

4 0

8 0

3 0

3 1

8 1

2 1

8 1

6 2

3 2

9

3

4

1

1

.

6 1

6

R

THIN PRO

T

. FIELD TE

S

T

ips (Not Pr

o

o

ner

4

o

: 1 O

z

3

0 0

7

5 0

4

3 0

0

0 0

R

THIN PRO

T

. FIELD TE

S

w

d

ed)

4

GPM Flow

z

./gal

m

.30 2

.

.40 3

.

.50 3

.

.56 4

.

.64 5

.

.75 5

.

.00 7

.

.12 8

.

.50 11

.75 1

3

.00 1

5

.50 1

9

.75 3

9

1

.50 9

0

6

.25 12

5

DUCTS (1 c

p

S

TS ARE R

E

o

vided)

4

GPM Flow

z

./gal

m

.16 1

.

.20 1

.

.26 2

.

.34 2

.

DUCTS (1 c

p

S

TS ARE R

E

w

ww.demaen

g

1-800-325

Page

8

/

Rate Propor

t

m

l/L R

a

.

34

.

13

.

91

.

39

.

00

.

88

.

81

.

77

.76

3

.70

5

.63

9

.61

9

.41

0

.91

5

.00

p

s)

E

COMMEND

E

Rate Propor

t

m

l/L R

a

.

25

.

56

.

03

.

66

p

s)

E

COMMEND

E

g

.com

-3362

5 of 8

/

29/17

t

ioner

a

tio : 1

427

320

256

228

200

170

128

114

85

73

64

51

34

11

8

E

D.

t

ioner

a

tio : 1

806

625

490

376

E

D.

S

y

m

p

Leak

i

p

rop

o

Leak

i

off)

Leak

i

S

y

m

p

Disp

e

any l

o

Disp

e

from

Che

m

p

rim

e

Disp

e

che

m

work

S

y

m

p

Prod

u

I-1091

Rev. L-4

3

Trouble

s

p

tom

i

ng at wa

t

er v

a

o

rtioner (dispe

n

i

ng at water v

a

i

ng at Action

G

Trouble

s

p

tom

e

nser won’t di

s

o

cations

e

nser is dispen

wrong positio

n

m

ical inlet tubi

n

e

d with chemi

c

e

nser does not

m

ical from cert

a

s at others

Trouble

s

p

tom

u

ct dilution is

t

3

223

s

hootin

g

:

W

a

lve to

n

ser is on)

a

lve (dispenser

G

ap (if equipp

e

s

hootin

g

: C

s

pense chemic

a

sing chemical

n

n

g does not st

a

c

al after use

dispense

a

in locations,

b

s

hootin

g

: P

r

t

oo weak or st

r

W

ater valve

o

Proble

m

Connec

is Connec

Water

p

e

d) Bucket

p

roport

i

Backfl

o

hemical not

Proble

m

a

l at Screen

w

clogge

d

Water

p

Minera

l

Selecto

r

Trans

m

a

y Check

v

b

ut Chemi

c

Loss o

f

drawin

g

Selecto

r

r

oduct dilut

i

Proble

m

r

ong Water

f

o

r backflow

p

m

tions are not t

i

tion to water

v

p

ressure is abo

v

fill tube is rai

s

i

oner

o

w preventer i

s

drawing pr

o

m

w

asher on wat

d

p

ressure is ins

u

l

deposits are

b

r

valve is not t

u

ission or selec

t

v

alves are wor

n

c

al bottle isn’t

d

f

vacuum is pr

e

g

r

valve is not t

u

i

on is incorr

e

m

f

low to dispen

s

p

reventer is

i

ght, tubing is

n

v

alve is loose

v

e acceptable

r

s

ed higher tha

n

s

faulty

o

perly

er supply hos

e

u

fficien

t

b

uilt up in pro

p

u

rning

t

or valve not e

n

n

and have fai

l

d

rawing prod

u

e

venting chemi

u

rning

e

ct

er is fluctuati

n

leaking

R

n

ot secure

S

t

i

T

r

ange I

n

n

E

o

D

p

R

R

e

is

R

r

e

V

2

a

p

ortione

r

S

m

V

v

R

ngaging

V

v

l

e

d

R

u

c

t

R

i

cal from

C

n

h

I

f

fo

I

f

v

V

v

R

R

n

g I

d

c

i

f

w

R

emed

y

S

ecure tubing

f

i

ghten clamps

T

ighten fitting

s

n

stall pressure

E

nsure dispens

e

o

f 36” off floo

r

D

o not raise b

u

p

roportione

r

R

eplace Actio

n

R

emed

y

R

emove scree

n

eplace

V

erify water p

r

2

0psi, remove

s

a

nd replace

S

oak proportio

n

m

ineral deposi

t

V

erify transmi

s

v

erify transmis

R

eplace trans

m

V

erify transmi

s

v

alves

R

eplace check

v

R

eplace bottle

i

C

heck for vac

u

n

one, check bo

t

h

ave vacuum t

h

f no vacuum,

r

f

or vacuum at

p

f you have va

c

v

alve, If none,

r

V

erify transmi

s

v

alves

R

eplace select

o

R

emed

y

deal water

p

re

s

c

hemical diluti

o

f

over 70psi, i

n

w

ww.demaen

g

1-800-325

Page

8

/

f

irmly against

c

s

at water valv

e

regulato

r

e

r is installed

a

r

u

cket fill tube

h

n

Gap backflo

w

n

washer, clea

n

r

essure is mini

m

s

creen washer,

n

er in delimer

t

s

s

sion aligns to

sion operates

a

m

ission

s

sion alignme

n

v

alves

i

n question wi

t

u

um at cap or f

o

t

h selector val

v

h

en replace ch

e

r

emove select

o

p

roportioner i

n

c

uum then repl

a

r

eplace propo

r

s

sion alignme

n

o

r valve(s)

s

sure range ac

c

o

n is 30psi to

7

n

stall pressure

g

.com

-3362

6 of 8

/

29/17

c

omponents,

e

a

t minimum

h

igher than

w

prevente

r

n

out and

m

um of

clean out

to clean off

selecto

r

s,

a

s intende

d

n

t to selector

t

h new one

o

ot valve, if

v

es, if you

e

ck valves

o

r and check

n

let

ace selector

r

tione

r

n

t to selector

c

urate

7

0psi max.,

regula

r

I-1091

Rev. L-4

3

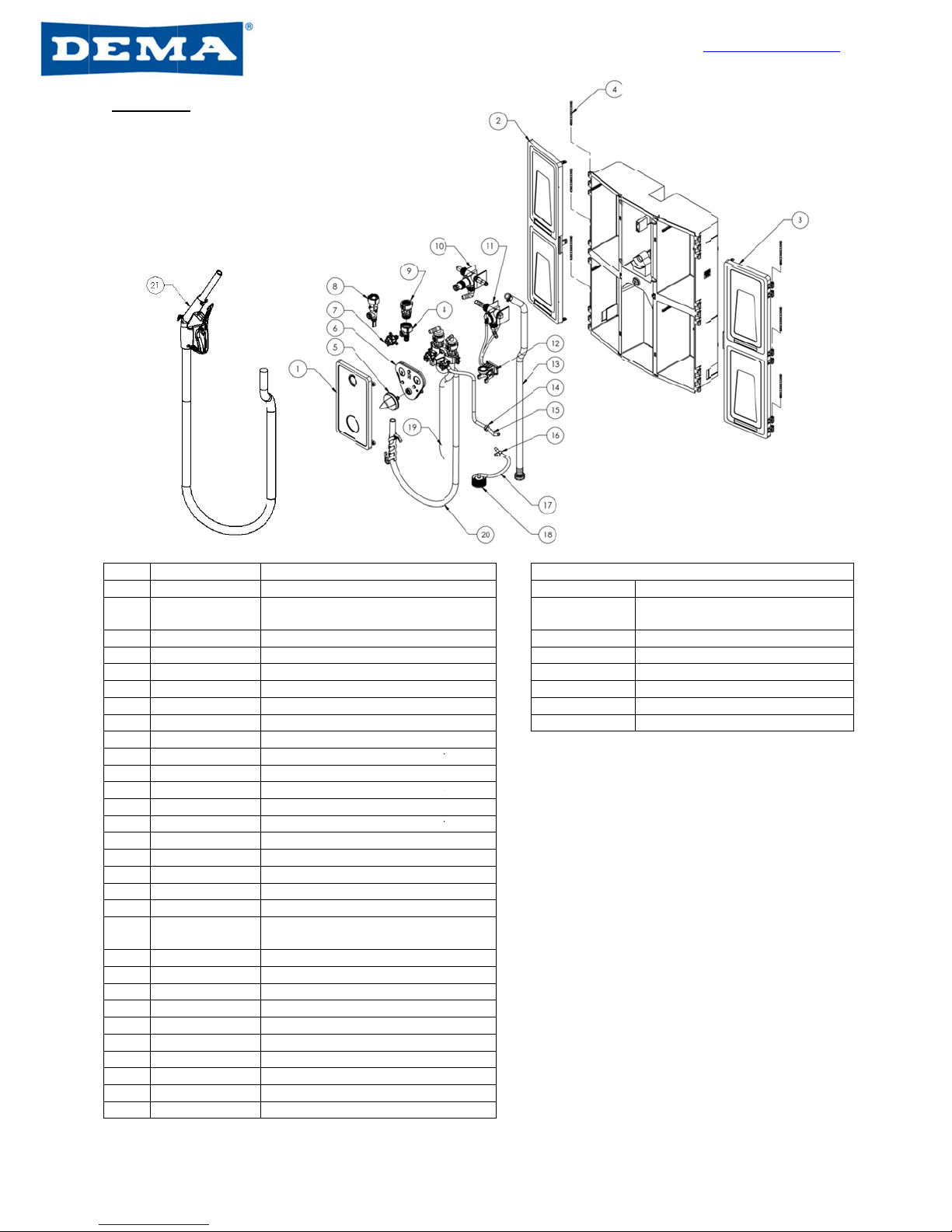

Parts li

s

No.

1

1

2

3

4

5

6

7

8

8 6

8 1

6

8

8

8 6

1

9

10

10

11

12

13 4

4

14

15

1

16

17

1

18 C

3

19

19

20 8

20

8

21

4

3

223

s

t

Part No.

14-3-3

14-3-2

14-2-3

14-2-4

10-47

66-339-1

63-53-15

63-53-12

61-99-4

1-32-AGP

6

3CHA-NB

61-45-4

61-22-4

1

-126AG-4

16-30

14-5-2

14-6-2

14-6-1

98-58-1

4

-3-6FCOS

11-72-1

1

00-12-18

66-500-2

1

00-12-19

3

8CR4W.00

66-242-1

66-242-2

9-30-GAP

8

5-15-29-6

4

0-736-3

D

e

Cover plate (

B

Cover plate (

R

operated)

Door – Left si

d

Door – Right

s

Hinge Pin

Knob

Transmission

Selector Asse

1 GPM Action

1 GPM Air G

a

2.5 GPM Acti

o

2.5 GPM Air

G

4 GPM Action

4 GPM Air G

a

Action Gap A

s

Push Button

V

Remote Gun

V

Bottle Fill Val

v

Lever Assem

b

6’ Black Hose

Strainer

Check Valve

(

7/32” Tubing,

Wye Adapter

7/32” Tubing,

SafeLink Cap

Bottle Fill Tub

e

Bottle Fill Tub

e

Bucket Fill Tu

b

Bucket Fill Tu

b

Remote Gun

A

e

scription

B

utton operate

d

R

emote gun

d

e

s

ide

Assembly

mbly

Gap Proporti

o

p Proportione

r

o

n Gap Propor

t

G

ap Proportion

e

Gap Proporti

o

p Proportione

r

s

sembly

V

alve Assembl

y

V

alve Assembl

v

e Assembly

b

ly

Assembly wit

h

Threaded)

2”

¼”

5”

Assembly

e

– Action Ga

p

e

– Air Gap

b

e – Action G

a

b

e – Air Gap

A

ssembly

d

)

o

ner

r

t

ioner

e

r

o

ner

r

y

y

h

p

a

p

Part No.

66-21K

100-15K-EX

4

10-57-2

100-16V-15

61-107-2

98-40-4

w

Parts Not

S

D

Keyset

4

Metering T

Drip Tray

Tubing &

F

Ceramic

W

Screw & A

n

w

ww.demaen

g

1-800-325

Page

8

/

S

hown

D

escription

ip Kit

F

oot Valve Ass

e

W

eight

n

chor Kit

g

.com

-3362

7 of 8

/

29/17

e

mbly

I-1091

Rev. L-4

3

Warran

t

Merchan

d

N

y

o

Product

W

D

a

n

a

n

c

h

a

s

c

o

If

D

s

h

D

g

r

a

b

3

223

t

y

d

ise Return

s

N

o merchandi

s

o

ur dealer fo

r

W

arranty

D

EM

A

’s prod

u

n

d service fo

r

n

y products t

h

h

emicals, co

r

s

“O”-rings, d

o

vered unde

r

products are

D

efective unit

s

h

ows them t

o

D

EM

A

assum

e

r

anted in ad

b

ove).

s

s

e will be ret

u

r

warranty iss

u

cts are warr

a

r

one year fr

o

h

at have a n

o

r

rosion, physi

c

iaphragms,

P

r

warranty. T

h

altered or re

s

or parts sh

o

o

be defecti

v

e

s no liabilit

y

vance of re

t

u

rned for cre

d

ues.

a

nted against

o

m the date o

f

o

rmal life sho

r

c

al abuse, or

P

VC tubing, a

h

is warranty i

paired witho

u

o

uld be return

e

v

e, they will

y

for damag

e

t

urned units

d

it without D

E

defective m

a

f

manufactur

e

r

ter than one

misapplicati

o

nd gaskets a

r

s extended

o

u

t prior appro

v

e

d to the fac

t

be repaired

o

e

s. Return

m

for repair o

r

E

MA’s written

a

terial and w

o

e

. This limite

d

year or failu

r

o

n. Rubber

a

re considere

d

o

nly to the ori

g

v

al of DEM

A

,

t

ory with tran

s

or replaced

w

m

erchandise

r

replaceme

n

w

permission.

o

rkmanship u

n

d warranty d

o

r

e and dama

g

a

nd synthetic

d

expendabl

e

g

inal buyer o

f

this warrant

y

s

portation pr

e

w

ithout char

g

authorizatio

n

n

t (See “Mer

c

w

ww.demaen

g

1-800-325

Page

8

/

Please cont

a

n

der normal

u

o

es not appl

y

g

e caused by

rubber parts

s

e

and are not

f

DEMA prod

u

y

is void.

e

paid. If insp

e

g

e, F.O.B. f

a

n

number m

u

c

handise Re

g

.com

-3362

8 of 8

/

29/17

a

ct

u

se

y

to

s

uch

u

cts.

e

ction

a

ctory.

u

st be

turns”

Table of contents

Other DEMA Dispenser manuals

DEMA

DEMA Master Nitro Express User manual

DEMA

DEMA Super Sink Series Assembly instructions

DEMA

DEMA TITAN II User manual

DEMA

DEMA Trapper User manual

DEMA

DEMA One User manual

DEMA

DEMA Olympian O-PDV User manual

DEMA

DEMA 693T FOAM STATION II User manual

DEMA

DEMA PF651GAP User manual

DEMA

DEMA Laundry Master 830 User manual

DEMA

DEMA 301B-C User manual

Popular Dispenser manuals by other brands

Kingnode

Kingnode E-404 Series operating manual

Silver King

Silver King Majestic SK12MAJ Technical manual and replacement parts list

START International

START International LD3500 quick start guide

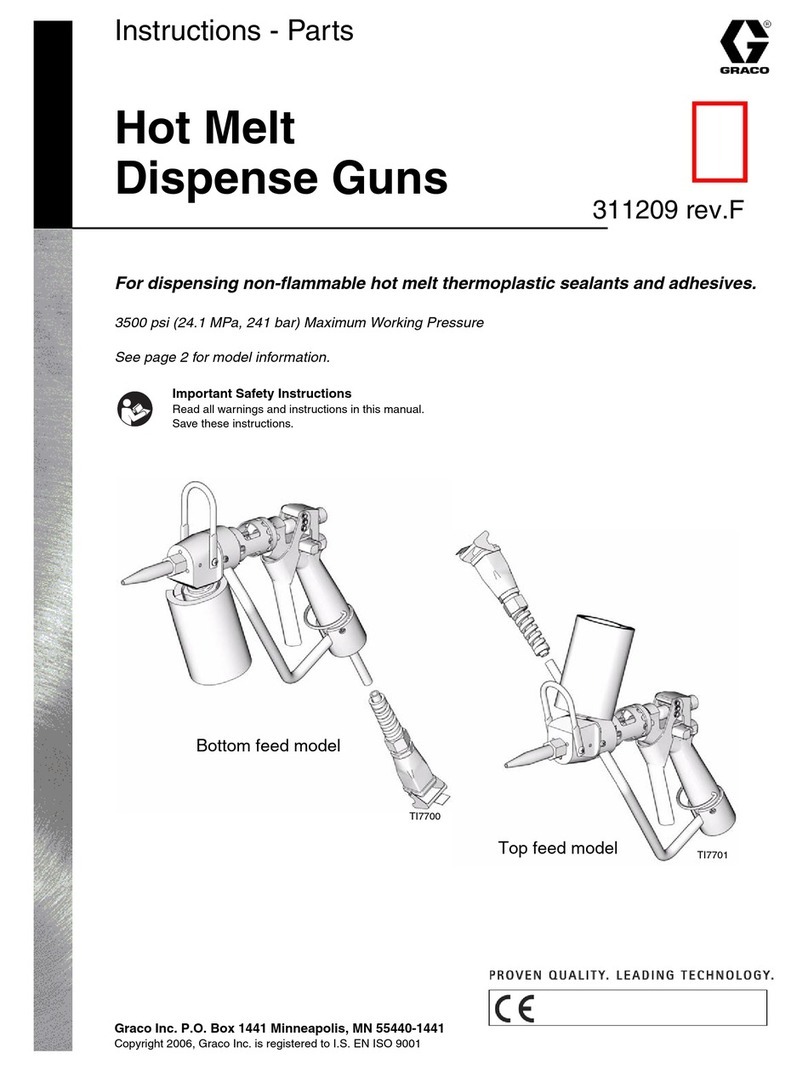

Graco

Graco TI7700 Instructions-parts list

Kohler

Kohler K-9619 Installation and care guide

Loctite

Loctite PULSE EQ RC50 operating manual