NOTE: A concentric .0630" diameter (1.60 mm) cylindrical shank (ISO 1797-1. Type 3) bur should be used.

NOTE: Before installing bur, install motor to the motor-to-angle adapter; then install friction grip chuck

angle to motor-to-angle adapter as described in Angle Installation.

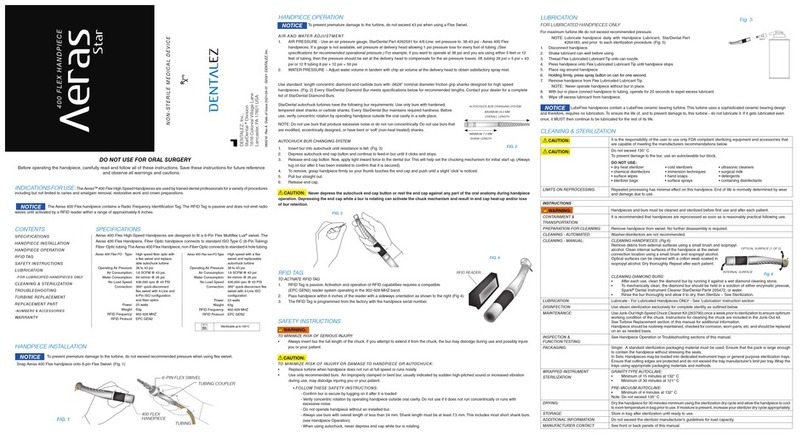

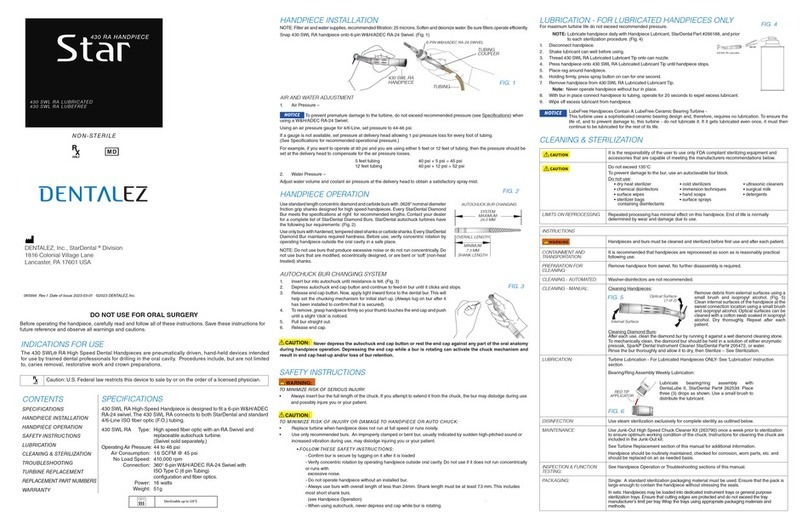

INSTALLATION into the Friction Grip Autochuck Angle (Fig 4)

1. Insert bur into autochuck until resistance is felt.

2. Depress autochuck end cap button and continue to feed-in bur until it clicks and stops.

3. Release end cap button. Now, apply light inward force to the dental bur.This will help set the chucking

mechanism for initial start up.(Always tug on bur after it has been installed to confirm that it is secured.)

DO NOT USE FOR ORAL SURGERY

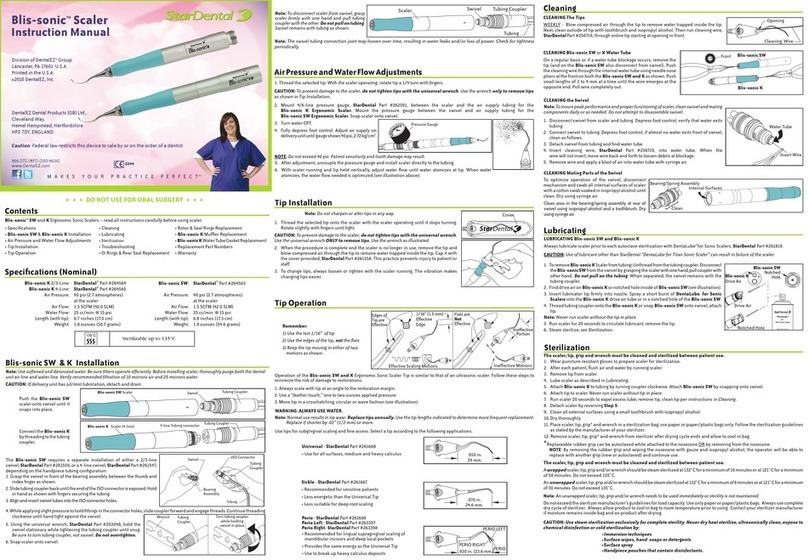

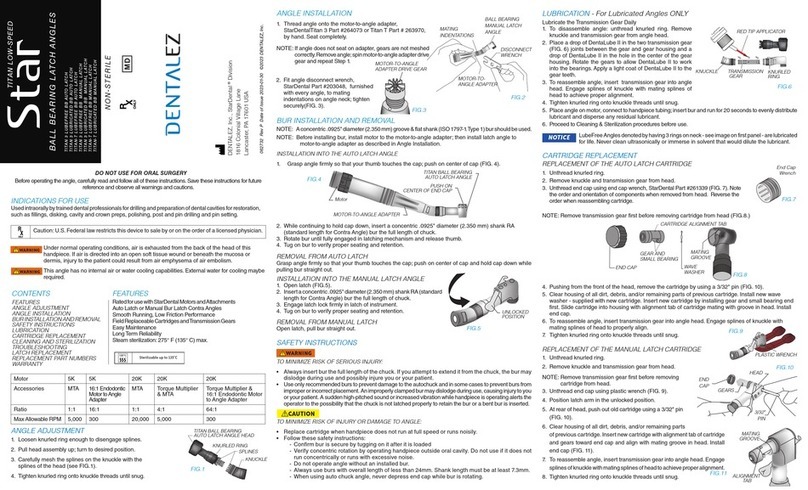

LUBRICATE THE TRANSMISSION GEAR DAILY

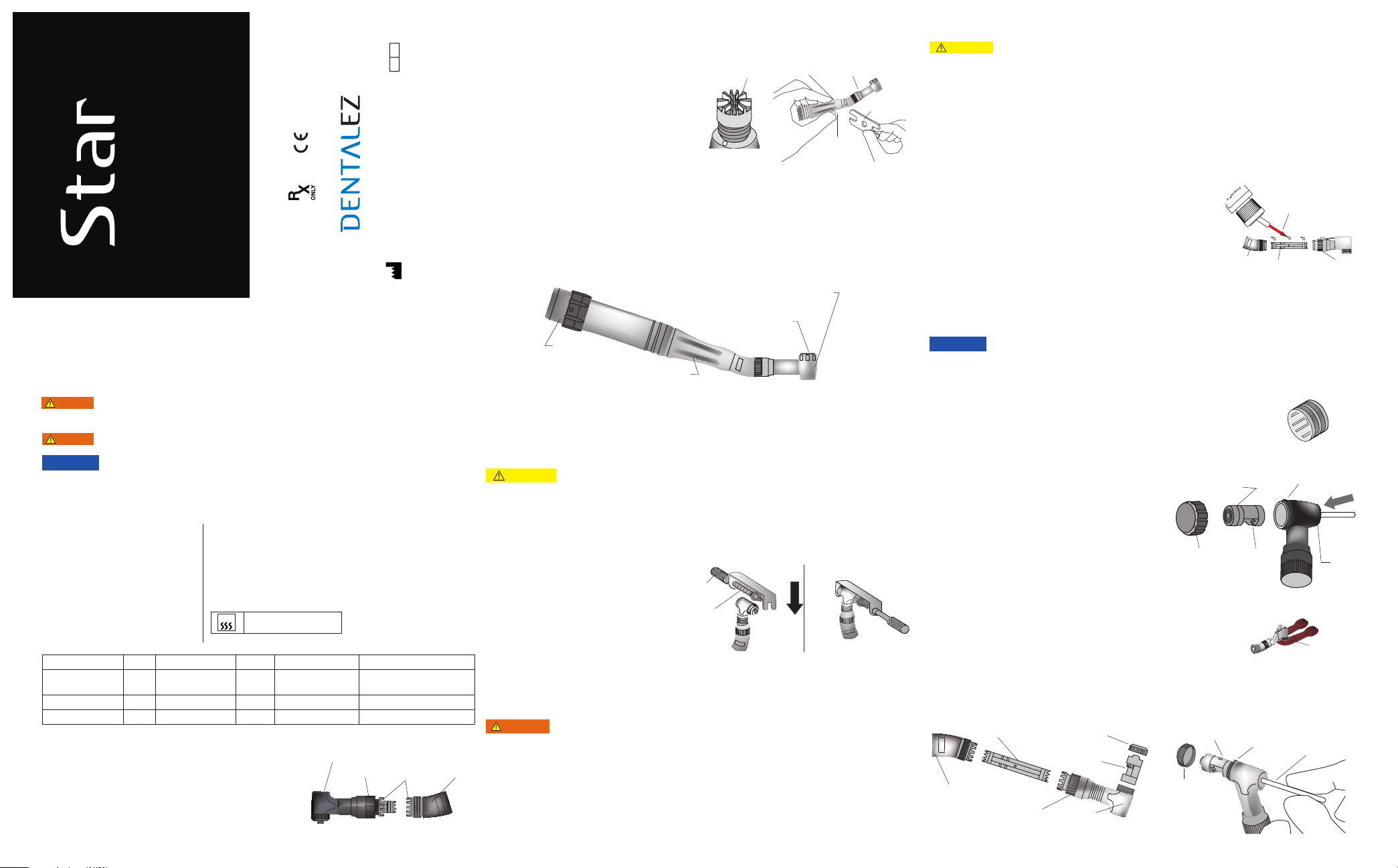

1. To disassemble angle: unthread knurled ring. Remove knuckle and

transmission gear from angle head.

2. Place a drop of DentaLube II in the two transmission gear joints

between the gear and gear housing and a drop of DentaLube II in

the hole in the center of the gear housing. Rotate the gears to allow

DentaLube II to work into the bearings.Apply a light coat of DentaLube

II to the gear teeth. (Fig. 6)

3. To reassemble angle, insert transmission gear into angle head.

Engage splines of knuckle with mating splines of head to achieve

proper alignment.

4. Tighten knurled ring onto knuckle threads until snug.

5. Place angle on motor, connect to handpiece tubing;insert bur and run for 20 seconds to evenly distribute

lubricant and disperse any residual lubricant.

6. Proceed to Cleaning & Sterilization procedures before use.

REMOVAL FROM AUTOCHUCK

Grasp angle firmly so that your thumb touches the end cap and push until a slight click is felt. Pull bur

straight out, then release end cap.

Before operating the angle, carefully read and follow all of these instructions. Save these instructions for future

reference and observe all warnings and cautions.

BUR INSTALLATION AND REMOVAL

LUBRICATION - For Lubricated Angles ONLY

CONTENTS

FEATURES

ANGLE ADJUSTMENT

ANGLE INSTALLATION

BUR INSTALLATION AND REMOVAL

SAFETY INSTRUCTIONS

LUBRICATION

CARTRIDGE REPLACEMENT

CLEANING AND STERILIZATION

TROUBLESHOOTING

REPLACEMENT PART NUMBERS

WARRANTY

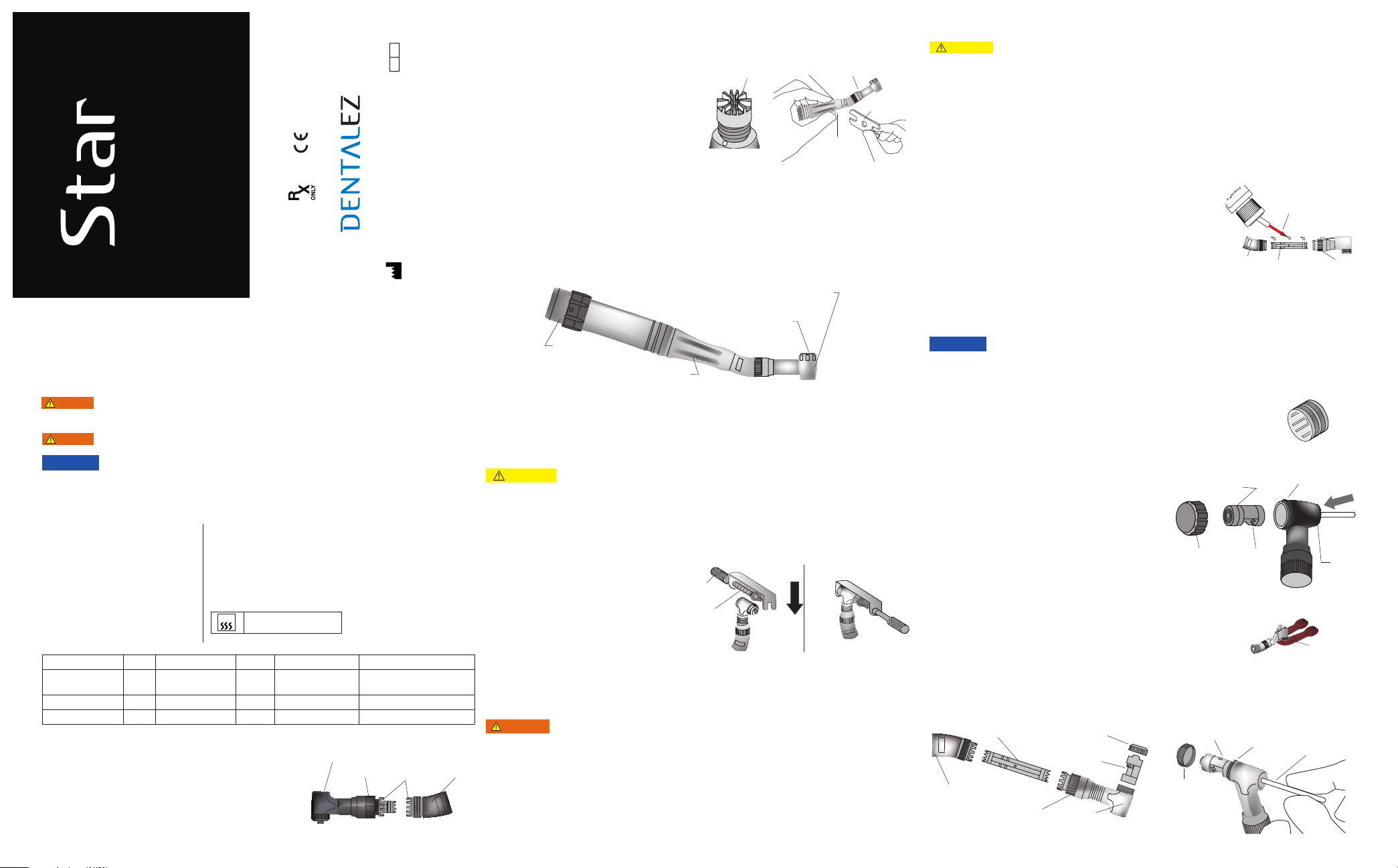

MOTOR

MOTOR-TO-ANGLE ADAPTER

BALL BEARING

FRICTION GRIP AUTOCHUCK ANGLE

PUSH ON

CENTER OF END CAP

NOTICE LubeFree Angles denoted by having 3 rings on neck are lubricated for life. Never clean

ultrasonically or immerse in solvent that would dilute the lubricant.

CAUTION Never depress the autochuck end cap button or rest the end cap against any part

of the oral anatomy during handpiece operation. Depressing the end cap while a bur is rotating can

activate the chuck mechanism and result in end cap heat-up and/or loss of bur retention.

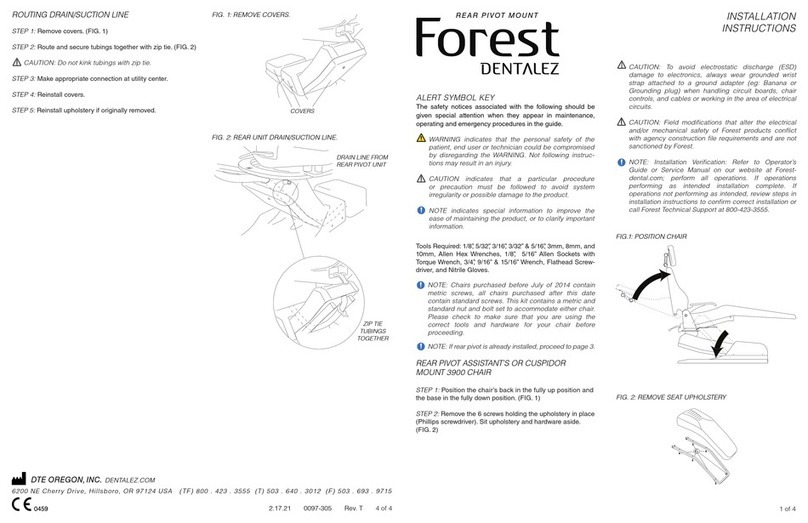

1. Thread angle onto the motor-to-angle adapter,

StarDentalTitan 3 Part #264073 orTitanT Part

# 263970, by hand. Seat completely. (Fig 2)

NOTE: If angle does not seat on adapter, gears

are not meshed correctly. Remove angle;

spin motor-to-angle adapter drive gear and

repeat Step 1.

2. Fit angle disconnect wrench, StarDental

Part #203048, furnished with every angle, to

mating indentations on angle neck; tighten

securely. (Fig.3)

1. Loosen knurled ring enough to disengage splines.(Fig.1)

2. Pull head assembly up; turn to desired position.

3. Carefully mesh the splines on the knuckle with the

splines of the head.

4. Tighten knurled ring onto knuckle threads until snug.

ANGLE ADJUSTMENT ANGLE HEAD

KNURLED RING SPLINES KNUCKLE

StarDental® Instrument Solutions

RED TIP APPLICATOR

KNUCKLE TRANSMISSION

GEAR

KNURLED

RING

INDICATIONS FOR USE

Used intraorally by trained dental professionals for drilling and preparation of dental cavities for restoration,

such as fillings, disking, cavity and crown preps, polishing, post and pin drilling and pin setting.

Under normal operating conditions, air is exhausted from the back of the head of this

handpiece. If air is directed into an open soft tissue wound or beneath the mucosa or

dermis, injury to the patient could result from air emphysema of air embolism.

Thisanglehasnointernalairorwatercoolingcapabilities.Externalwaterforcoolingmayberequired.

WARNING

WARNING

TO MINIMIZE RISK OF SERIOUS INJURY:

• Always insert bur the full length of the chuck. If you attempt to extend it from the chuck, the bur may

dislodge during use and possibly injure you or your patient.

• Use only recommended burs to prevent damage to the autochuck and in some cases to prevent burs from

improper or incorrect placement. An improperly clamped bur may dislodge during use, causing injury to you

or your patient. A sudden high-pitched sound or increased vibration while handpiece is operating alerts the

operator to the possibility that the chuck is not latched properly to retain the bur or a bent bur is inserted.

TO MINIMIZE RISK OF INJURY OR DAMAGE TO ANGLE:

• Replace cartridge when handpiece does not run at full speed or runs noisily.

• Follow these safety instructions:

- Confirm bur is secure by tugging on it after it is loaded

- Verify concentric rotation by operating handpiece outside oral cavity. Do not use if it does not

run concentrically or runs with excessive noise.

- Do not operate angle without an installed bur.

- Always use burs with overall length of less than 24mm. Shank length must be at least 7.3mm.

- When using autochuck angle, never depress end cap while bur is rotating.

CAUTION

WARNING

Rated for use with StarDental Motors and Attachments

Easy Maintenance

Friction Grip Auto Contra Angles

Long Term Reliability

Smooth Running, Low Friction Performance

Steam sterilization: 275° F (135° C) max.

Field Replaceable Cartridges andTransmission Gears

Sterilizable up to 135°C

135°C

FEATURES

Motor 5K 5K 20K 20K 20K

Accessories MTA 16:1 Endodontic Motor

to Angle Adapter

MTA Torque Multiplier

& MTA

Torque Multiplier & 16:1 Endodontic

Motor to Angle Adapter

Ratio 1:1 16:1 1:1 4:1 64:1

Max Allowable RPM 5,000 300 20,000 5,000 300

1. Pull handle back on manual bur tool, StarDental Part #203108, and slide open end of tool onto head

of angle as shown in (Fig 5); release spring loaded handle and seat shaft of tool into the opening in

the rear of angle head.

2. Tounlockchuck,turn manual burtoolhandle

counterclockwise.

3. After inserting a 1.6 mm diameter friction

grip bur fully into chuck, turn handle of tool

clockwise to tighten chuck.

4. Disengage tool and tug on bur to verify

that it is completely engaged and holding

securely.

INSTALLATION INTO THE MANUAL CHUCK

REMOVAL FROM MANUAL CHUCK

Use manual bur tool and turn counterclockwise one full turn, 360° rotation. Pull bur straight out.

HANDLE

MANUAL

BUR TOOL

ANGLE INSTALLATION

MOTOR-TO-ANGLE

ADAPTER DRIVE

GEAR

DISCONNECT

WRENCH

MATING

INDENTATIONS

MOTOR-TO-

ANGLE ADAPTER

BALL BEARING

FG CHUCK ANGLE

NOTICE Any serious incident occurring from the use of this device should be reported to

StarDental immediately. If incident occurred in a EU Member State the Competent

Authority must be notified.

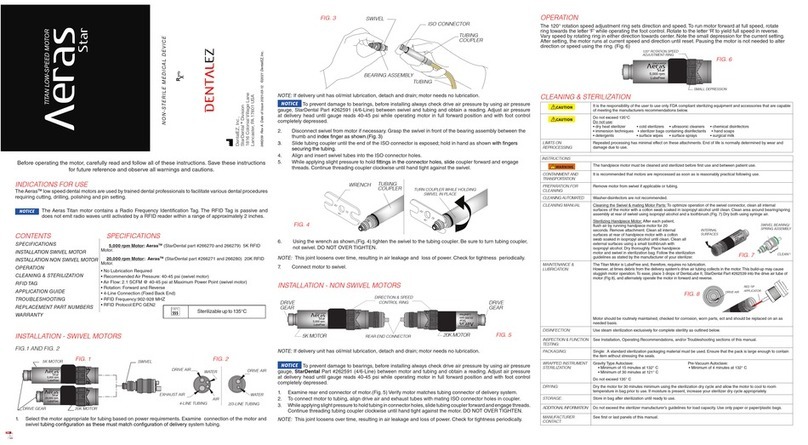

REPLACEMENT OF THE AUTOCHUCK CARTRIDGE

1. Unthread knurled ring.

2. Remove knuckle and transmission gear from head.

3. Unthread end cap using end cap wrench(Fig.7), StarDental Part #261339.

NOTE: Remove transmission gear first before removing cartridge from head.

4. Pushing from the front of the head, remove the cartridge by using a 1/16" pin (Fig.8).

5. Clear housing of all dirt, debris, and/or remaining parts

of previous cartridge. Insert new cartridge by installing

gear and small bearing end first. Slide cartridge into

housing with alignment tab of cartridge mating with

groove in head. Install end cap.

6. To reassemble angle, insert transmission gear into angle

head. Engage splines of knuckle with mating splines of

head to properly align.

7. Tighten knurled ring onto knuckle threads until snug.

CARTRIDGE REPLACEMENT

END CAP

3/32” PIN

ALIGNMENT TAB MATING

GROOVE

TRANSMISSION GEAR

KNURLED RING

KNUCKLE

END CAP

CARTRIDGE

HEAD

REPLACEMENT OF THE MANUAL CHUCK CARTRIDGE

1. Unthread knurled ring.

2. Remove knuckle and transmission gear from head.

NOTE: Remove transmissiongear firstbeforeremovingcartridgefromhead(Fig9).

3. Unthread end cap using plastic wrench (Fig.10).

4. At rear of head, push out old cartridge using a 3/32" pin (Fig.11).

5. Clear housing of all dirt, debris, and/or remaining parts of previous cartridge.

Insert new cartridge with alignment

tab of cartridge and gears toward end

cap and align with mating

groove in head. Install end cap.

6. To reassemble angle, insert transmission gear into angle head. Engage splines of knuckle with mating

splines of head to achieve proper alignment.

7. Tighten knurled ring onto knuckle threads until snug.

PLASTIC

WRENCH

FIG.1

NON-STERILE MEDICAL DEVICE

0344

062734 Rev M Date of Issue 2021-04-30 ©2021 DENTALEZ, Inc.

EC REP

Emergo Europe

Prinsessegracht 20 2514AP

The Hague The Nettherlands

DENTALEZ, Inc.,

StarDental ®Division

1816 Colonial Village Lane

Lancaster, PA 17601 USA

TITAN LOW-SPEED

BALL BEARING FRICTION GRIP

CHUCK ANGLES

TI TAN 3 L U BE FRE E BB F G AU TO C HU CK

TI TAN 3 L U BR ICATE D BB FG AU TOC HUC K

TITAN-T LUBEFREE BB FG AUTOCHUCK

TITAN 3 LUBEFREE BB FG MANUAL CHUCK

FIG.2

FIG.3

FIG.4

FIG.5

SAFETY INSTRUCTIONS

FIG.6

CARTRIDGE

ALIGNMENT TAB

END CAP GEARS

MATING GROOVE

1/16" PIN

HEAD

FIG.7

FIG.8

FIG.11

FIG.10

FIG.9

END CAP

WRENCH