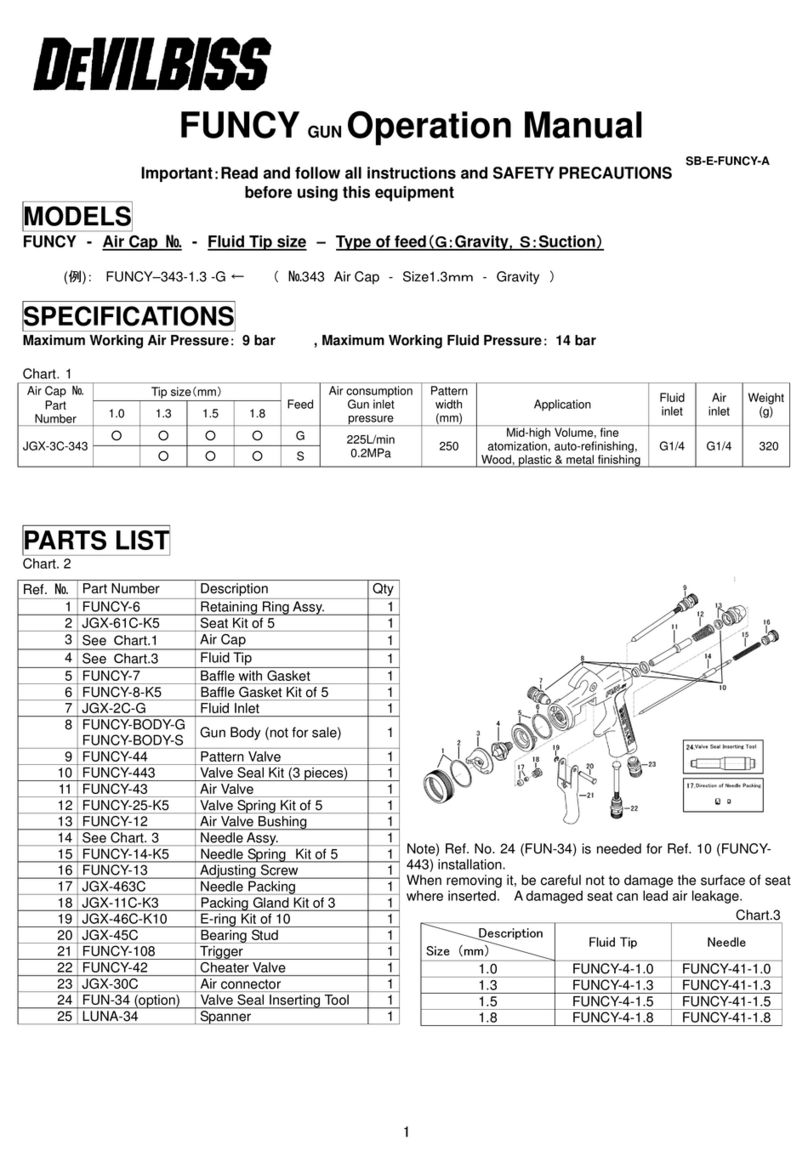

7

REPLACEMENT

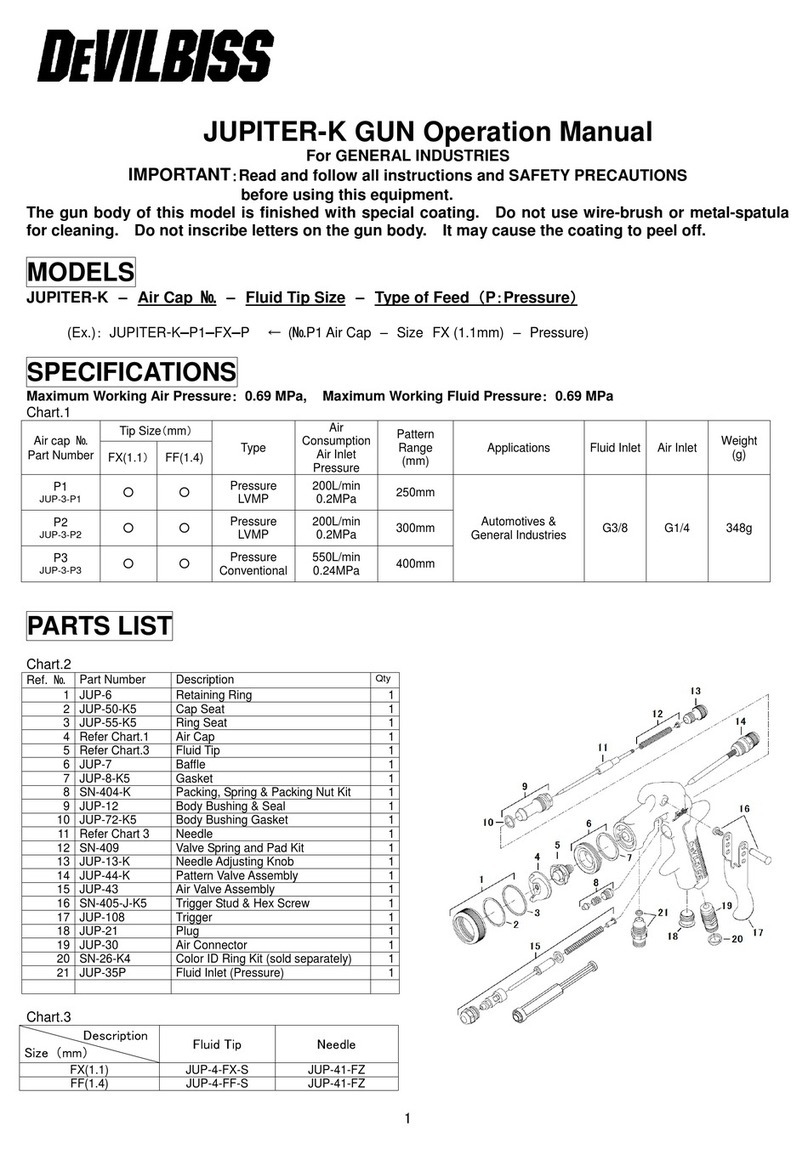

Fluid needle (28) and Tip (3)

CAUTION

To prevent possible damage to the fluid tip (3) or needle (28), always remove the adjustment knob (25) before

loosening or tightening the fluid tip.

CAUTION

To prevent possible damage to the spray gun, do NOT loosen or tighten the fluid tip (3) if the fluid inlet (9) is

removed. The stainless steel insert may turn within the gun body.

1. Relieve all air and fluid pressure in system.

2. Remove retaining ring (1) and air cap (2).

3. Remove fluid tip (3).

4. It is recommended that both the fluid tip (3) and needle (28) be replaced at the same time. The needle packings (11)

should also be replaced when replacing the needle.

5. Remove baffle (5). It should be replaced if it is damaged or filled with foreign material.

6. Remove adjusting knob (25).

7. Remove needle (28) with pliers.

8. Reassemble in reverse order.

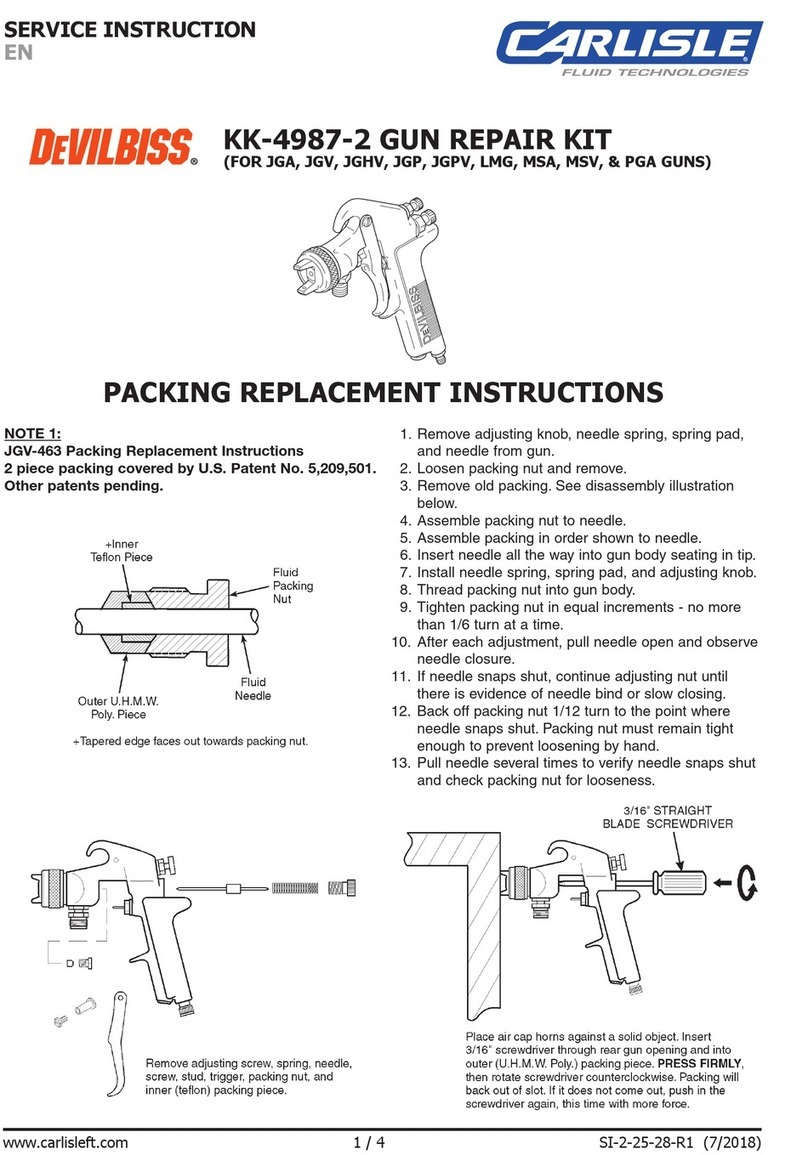

Fluid Needle (28) and Fluid Needle Packings (11)

1. With sprayhead (8) and adjusting knob (25) removed, the fluid needle (28) and packings (11) can be easily removed and

replaced. See step 4 above.

2. Slide onto the new needle (28), in this order, 1 packing (11), spring (12) and 1 packing (11). Be sure to orient packings (11)

as shown. For Model AGX-552, slide brass collar piece and seal (32) over needle.

3. Insert new needle into gun and slide packings and spring over needle.

4. Assemble sprayhead (8) with retaining screws (7).

5. Tighten screws (7) with a 3/16 hexagon key 30-40 in. lbs. until the body is flush with sprayhead assembly.

Piston (19) , O-Rings (17 & 18) and Seal (20)

1. Remove piston housing (29) by removing rear retaining screws (7).

2. Remove fluid needle (28).

3. Remove springs (30, 31 & 27) and piston (19). Care must be taken when removing piston (19). Use a locking long nose

pliers to extract piston by clamping on inner ring on back of piston.

4. Remove air packing (20), o-rings (17 & 18).

5. Wipe clean bore of cylinder. Replace piston o-rings (17 & 18) and lightly lubricate with clean petroleum jelly. See

Lubrication section which follows.

6. To replace air packing (20) (inside of piston), slide packing (20) over the needle (28) with ead-in chamfer towards the fluid

tip end of needle. Insert needle into the piston (19). Hold piston in your hand so that tip end of needle is protruding

downward (protect needle from damage). Lightly tap blunt end of needle to drive packing down into piston. The needle

will stop inside piston at a shoulder.

7. Fit complete assembly into gun.

8. Lubricate outside of springs (27) and (30) (see Lubrication section), then re-install springs and piston housing (29) and

tighten down and torque mounting screws (7) 30-40 in. lbs.

9. Lubricate adjustment knob threads (25) after cleaning with SSL-10 Gun Lube. Loosen locking nut (26) before screwing

the adjustment knob in.

Plug (6) or Fluid Insert(9)

WARNING

Halogenated Hydrocarbon solvents can chemically react with aluminum. A risk of explosion or severe corrosion will

occur. The following assembly step must be carefully performed.

If replacing AGX-415 inlet fitting, or if it should loosen, follow assembly procedures below.

1. If installing a used fitting, clean paint and thread sealant from fitting threads and gun body using a brass or bronze wire

brush/bottle brush.

2. Screw jam nut all the way onto fitting. Then apply Loctite medium strength #242 (blue) to first few threads of the fitting.

3. Install AGX-415 fitting into spray gun and tighten to a maximum of 12 ft. lbs. torque. (Do not overtighten, damage may

occur.)

4. Tighten jam nut to 16 ft. lbs. torque using a thin 9/16" open end wrench.

5. Use two adjustable wrenches when removing a hose connection from AGX-415 to prevent inlet fitting from loosening.