EnglishEnglish

32

WARNING:

Read all safety warnings,

instructions, illustrations and specications

provided with this product. Failure to follow all

instructions listed below may result in serious injury.

3) WORK AREA SAFETY

2) GENERAL REQUIREMENT

1) PERSONAL SAFETY

WARNING:

Prior to using the equipment, please

record the product identication information found

on the ID label of your fall arrestor in the equipment

record table of this manual.

a ) It is crucial that the Authorized person/user

of this fall protection equipment reads and

understands these instructions. In addition, it is

the employer's responsibility to ensure that all

users are trained in the proper use, inspection,

and maintenance of fall protection equipment.

b ) Proper use of fall arrest systems can save lives

and reduce the potential of serious injuries from

a fall.

c ) The user must be aware that forces experienced

during the arrest of a fall or prolonged

suspension may cause injury.

d ) Consult a physician if there is any question about

the user's ability to use this product.

e ) Pregnant women and minors must not use this

product.

DANGER: Do not skip this instruction manual.

Alterations or misuse of this product, or failure to follow

instructions may result in serious injury or death.

WARNING:

This product is part of a personal

fall arrest or restraint system. The user must

follow the manufacturer’s instructions for each

component of the system. These instructions must

be provided to the user of this equipment. The user

must understand these instructions before using

this equipment. Manufacturer’s instructions must

be followed for proper use and maintenance of

this product. These instructions are intended to

meet the manufacturer’s instructions as required

by OHSA, ANSI Z359.1-2007, ANSI 10.32-2012

Regulations.

a ) All warnings and instructions shall be provided

to Authorized persons/users.

b ) All Authorized persons/users must refer to the

regulations governing occupational safety, as

well as applicable ANSI standards.

c ) Please refer to product labels for information on

specific OSHA regulations, and ANSI standards

met by the product.

d ) Proper precautions should always be taken to

remove any obstructions, debris, material, or

other recognized hazards from the work area

that could cause injuries or interfere with the

operation of the system.

e ) All equipment must be inspected before each use

according to the manufacturer's instructions.

f ) All equipment should be inspected by a

Competent person on at least an annual basis.

g ) To minimize the potential for accidental disen-

gagement, a Competent person must ensure

system compatibility.

h ) Equipment must not be altered in any way.

Repairs must be performed only by the

manufacturer, or persons or entities authorized

in writing by the manufacturer.

i ) Any product exhibiting deformities, unusual

wear, or deterioration must be immediately

removed from service for inspection by Qualified

person.

j ) Any equipment subject to a fall must be removed

from service.

a ) Keep children and bystanders away while

working. Distractions can cause hazardous

conditions.

b ) The authorized person/user shall have a rescue

plan and the means at hand to implement it

when using this equipment.

c ) All synthetic material must be protected from

slag, hot sparks, open flames, or other heat

sources. The use of heat resistant materials is

recommended in these applications.

d ) Environmental hazards should be considered

when selecting fall protection equipment.

Equipment must not be exposed to chemicals

which may produce a harmful effect.

e ) Polyester should be used in certain chemical or

acidic environments. Use in highly corrosive or

caustic environments dictates a more frequent

inspection and servicing program to ensure the

integrity of the device is maintained.

f ) Do not allow equipment to come in contact

with anything that will damage it including, but

not limited to, sharp, abrasive, rough or high-

temperature surfaces, welding, heat sources,

electrical hazards, or moving machinery.

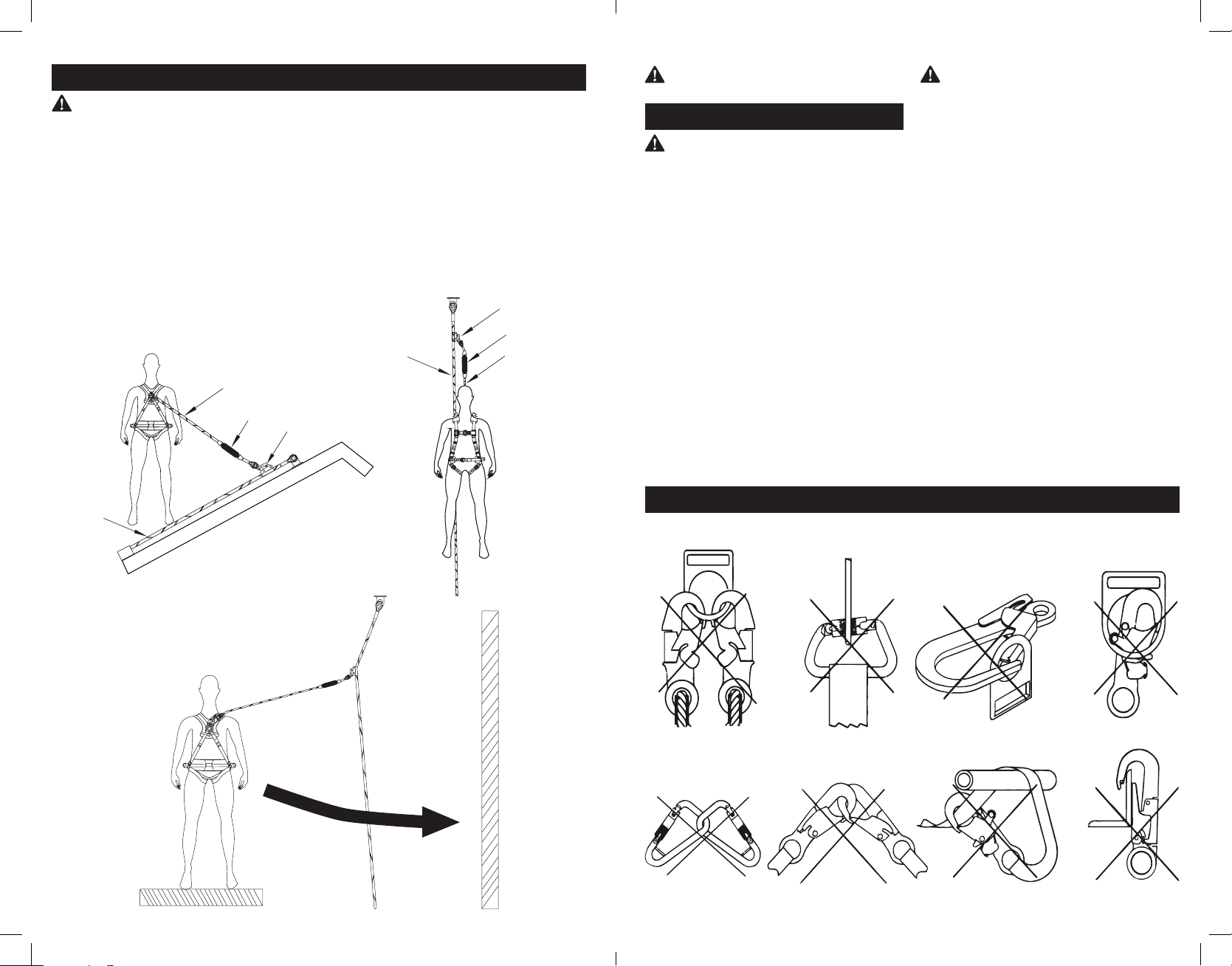

g ) Always check for obstructions below the work

area to make sure potential fall path is clear.

h ) Allow adequate fall clearance below the work

surface.

i ) Never remove product labels, which include

important warnings and information for the

authorized person/user.

WARNING:

DEWALT

rope grabs are designed

for use with

DEWALT

approved components.

Substitution or replacement with non approved

component combinations or subsystems or both

may aect or interfere with the safe function of

each other and endanger the compatibility within

the system. This incompatibility may aect the

reliability and safety of the total system. Always

use

DEWALT

rope grabs with specied

DEWALT

vertical lifelines with a minimum tensile strength of

6000 lbs. (27kN).

WARNING:

Read all safety warnings, instructions,

illustrations and specications provided with this

product. Failure to follow all instructions listed below

may result in serious injury.

DANGER:

For use by ONE person only.

Maximum capacity is 310 lbs.(140.6 kg), including

user weight, tools, clothes, materials.

DO NOT EXCEED THIS WEIGHT.

a ) Do not use if any part of the device appears to be

damaged.

b ) Do not attempt to service the device or alter it in

any way.

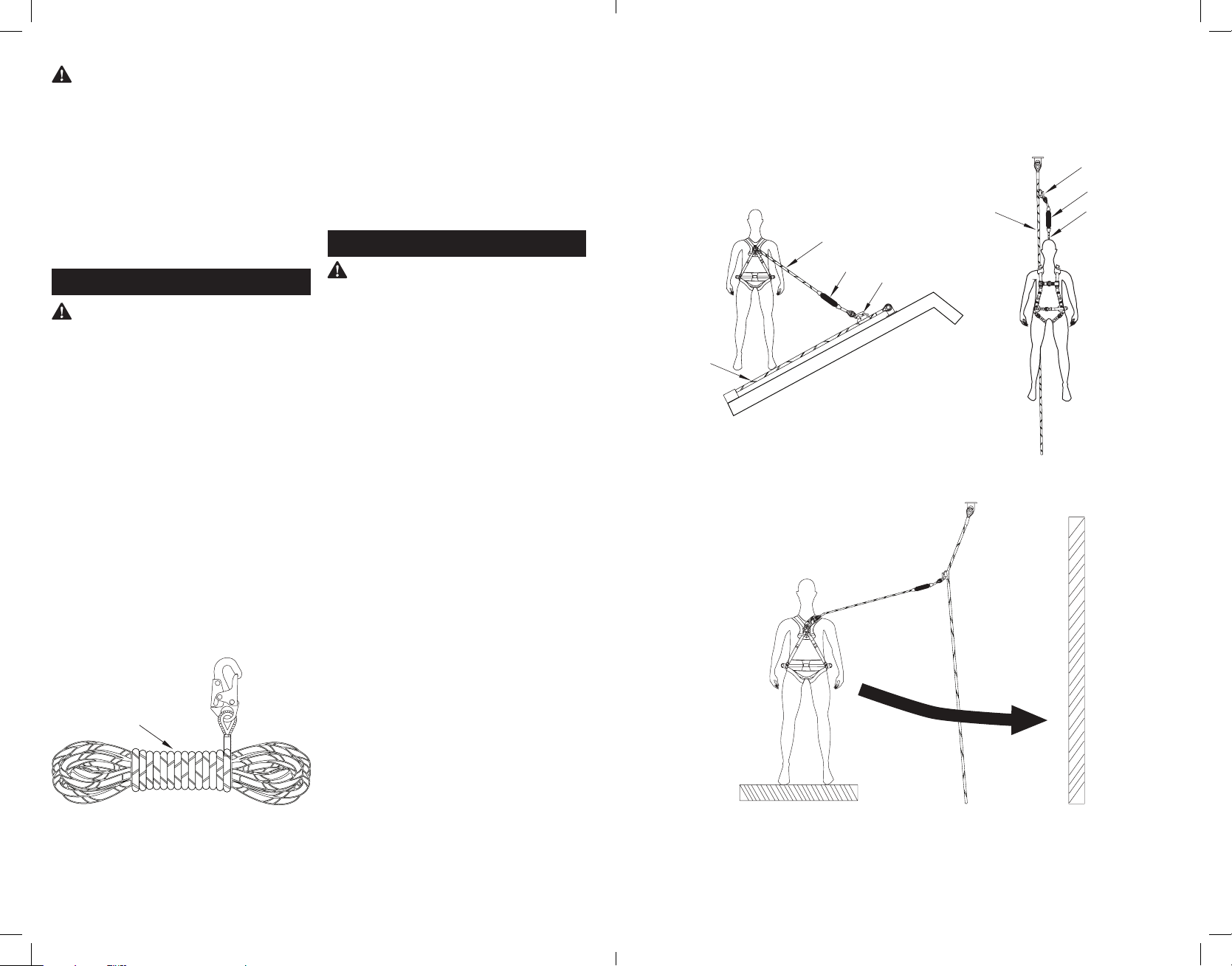

c ) Attach the device to appropriate vertical lifelines

only. The DEWALT rope grabs work best with

DEWALT lifeline.

d ) Use of this product is not suitable when the user

is positioned on an unstable surface, fine grain

material, or particulate solids such as sand or

coal.

e ) Maximum arrest distance: 54" / 1.37 m.

ROPE GRAB

Sna

Hoo

WARNING:

Never use fall protection equipment

for purposes other than those for which it was

designed. Fall protection equipment should never

be used for towing or hoisting.

WARNING:

The product shall be used by trained

personnel or under supervision of qualied

personnel. The steel snap hook end of the life

line should be connected to an approved anchor

(anchor selection must be done with relative

normative reference). The steel snap hook end of

the rope grab assembly shall be attached to the

user’s front mounted attachment point of the full

body harness. DEWALT provides pre-installed

lifelines with rope grab assembly having energy

absorption mechanism. If user needs to assemble

both products, it should be done by authorized

personnel only.

WARNING:

Read all safety warnings, instructions,

illustrations and specications provided with this

product. Failure to follow all instructions listed below

may result in serious injury.

a ) For use by ONE person only. DEWALT vertical

lifelines have a minimum tensile strength of 6000

lbs. / 27kN. ( OSHA requires a minimum tensile

strength of 5000 lbs. 22.2kN).

b) Lifeline must be kept clean.

c) Never allow the lifeline to become slack or to pass

under or entwine around arms, legs, neck, or any

other obstacle.

d) Do not tie knots in lifelines.

e) Elastic elongation of no more than 22% at 8kN

load is allowed.

f) Store in a clean, dry area, free of exposure to

fumes or corrosive elements.

g) Avoid excessive heat, steam, or long periods of

sunlight.

VERTICAL LIFELINES

Polysteel Twisted Rope

The DEWALT vertical lifeline assembly DXFP210050,

comes with 50 ft. 5/8” Polysteel twisted rope, a

permanently attached snap hook and rope grab with

attached energy absorber.

The assembly uses an ANSI rated 3600 LBS snap hook on

one end for attachment to an anchor point.

The Lifeline should always be used along with its robe

grab assembly and an energy absorbing mechanism.