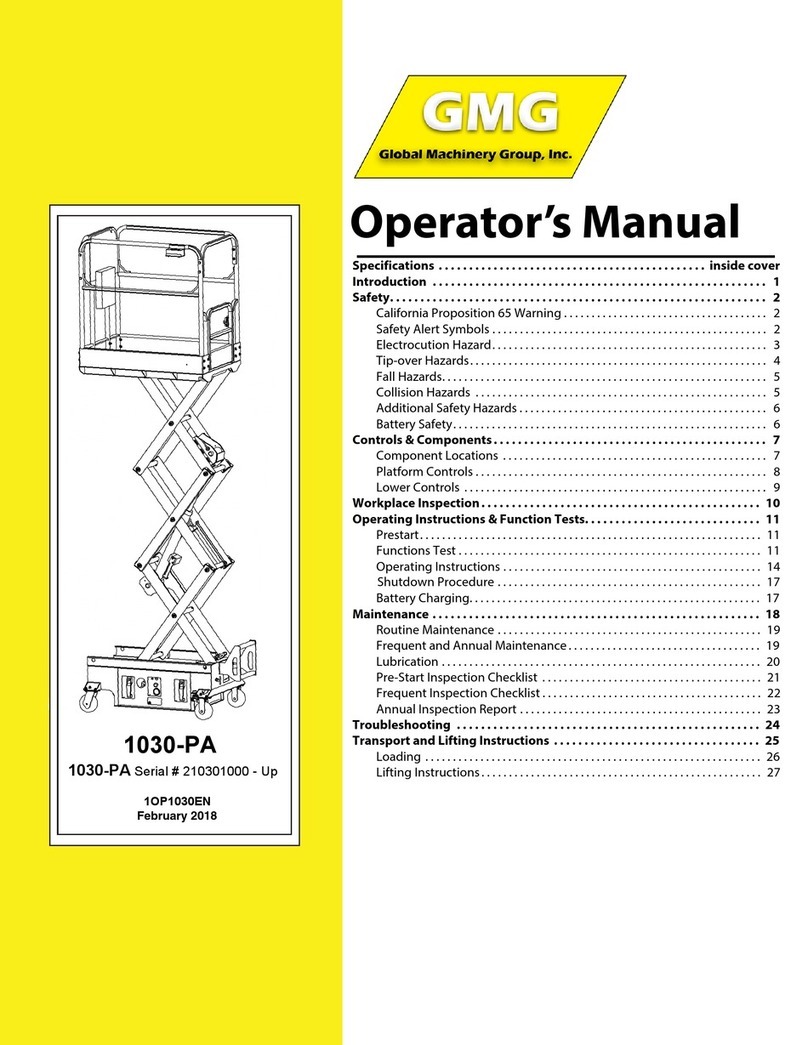

OPERATOR’S MANUAL with Maintenance Information

Safety Rules

3

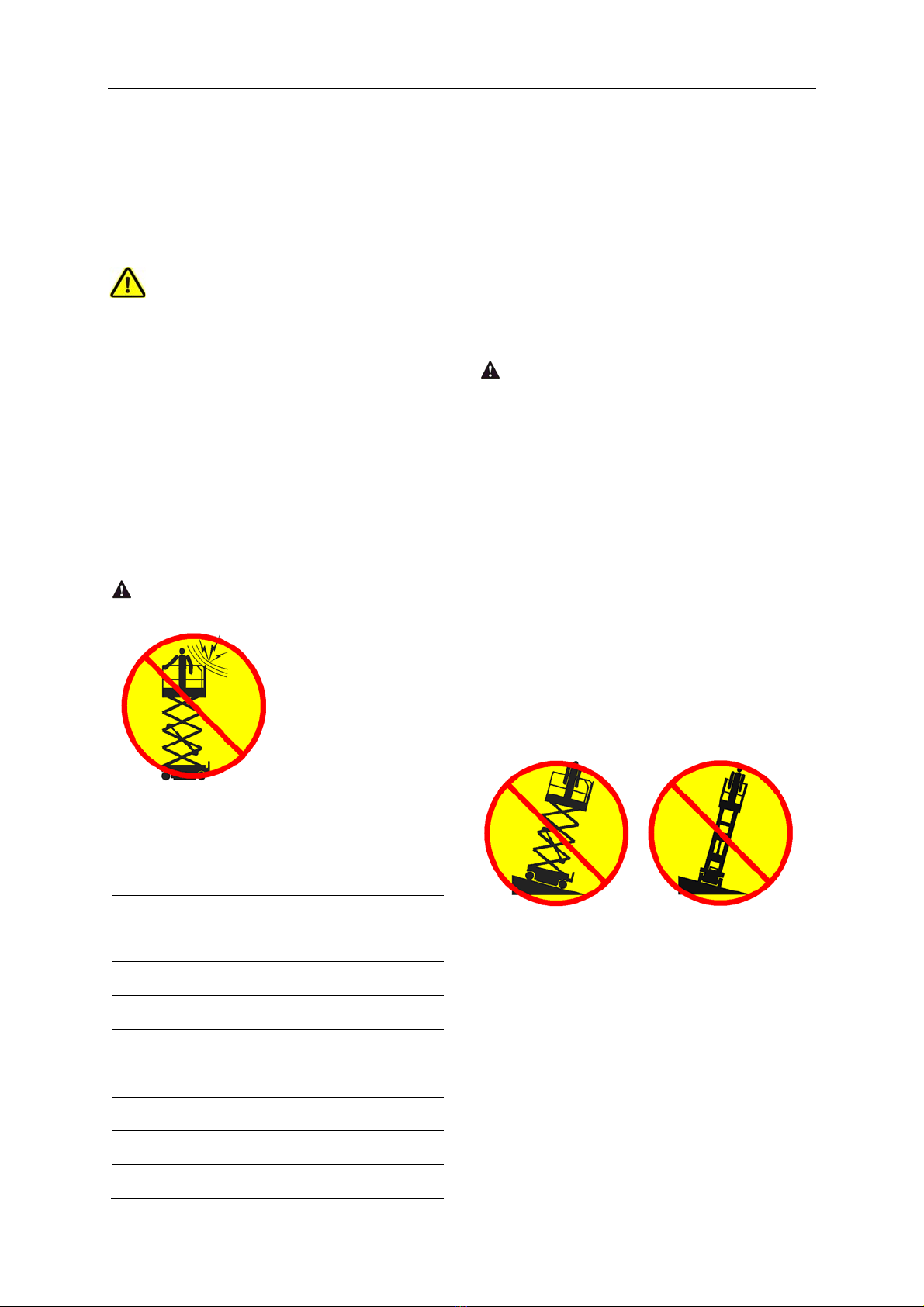

Do not place or attach fixed or overhanging

loads to any part of this machine.

Do not push the machine or other objects with

the platform.

Do not operate the machine with the chassis

trays open.

Do not contact adjacent structures with the

platform.

Do not alter or disable the limit switches.

Do not push off or pull toward any object

outside of the platform.

Maximum allowable manual force 200 N

Do not tie the platform to adjacent structures.

Do not place loads outside the platform

perimeter.

Do not alter or disable machine components

that in any way affect safety and stability.

Do not replace items critical to machine

stability with items of different weight or

specification.

Do not use the machine on a moving or mobile

surface or vehicle.

Do not place ladders or scaffolds in the

platform or against any part of this machine.

Be sure all tires are in good condition.

Do not use battery that weighs less than the

original equipment. The battery is used as

counterweight and are critical to machine

stability. The battery must weigh 25 kg.

Do not modify or alter an aerial work platform

without prior written permission from the

manufacturer. Mounting attachments for

holding tools or other materials onto the

platform, toe-boards or guard rail system can

increase the weight in the platform.

Crushing Hazard

Keep hands and limbs out of scissors.

Use common sense and planning when

operating the machine with the controller from

the ground.

Fall Hazard

The guard rail system provides fall protection.

During operation, occupants in the platform

must wear a full body harness with a lanyard

attached to an authorized lanyard anchorage

point. Attach only one (1) lanyard per lanyard

anchorage point.

Do not sit, stand or climb on the platform guard

rails. Maintain a firm footing on the platform

floor at all times.

Do not climb down from the platform when

raised.

Keep the platform floor clear of debris.

Close the entry gate before operating.

Do not operate the machine unless the guard

rails are properly installed and the entry is

secured for operation.

Do not enter or exit the platform unless the

machine is in the stowed position.