5

EN

IP2163EN

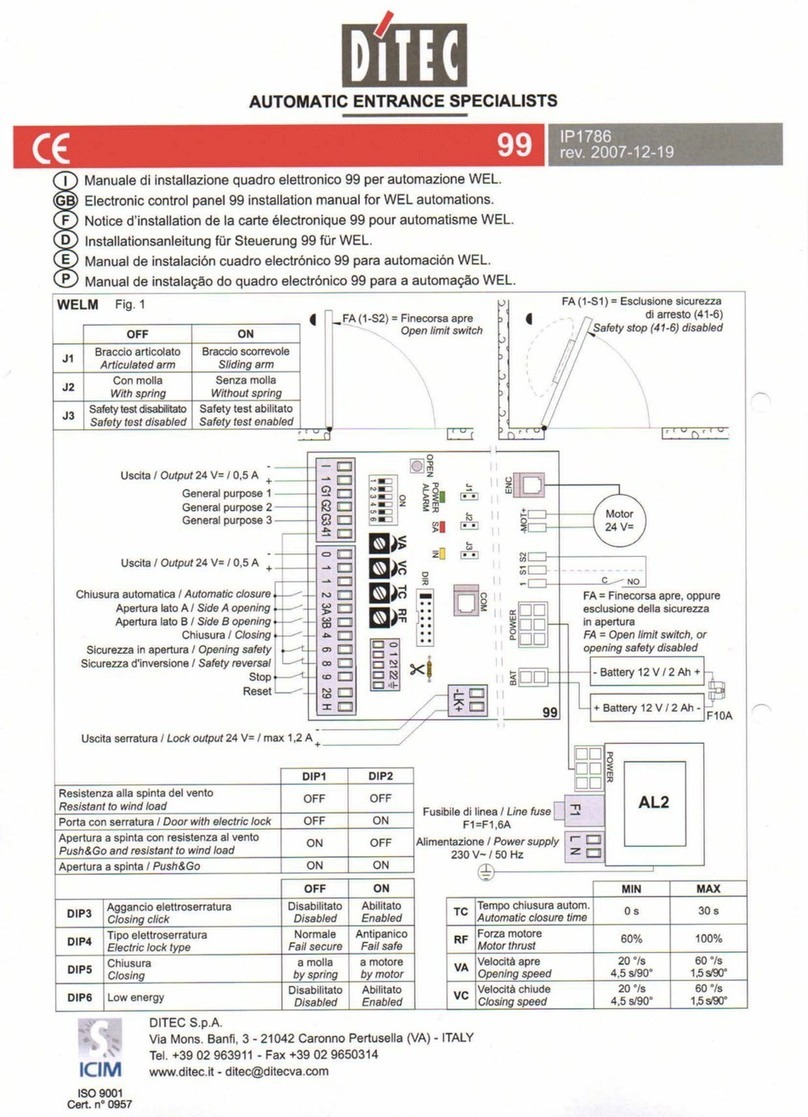

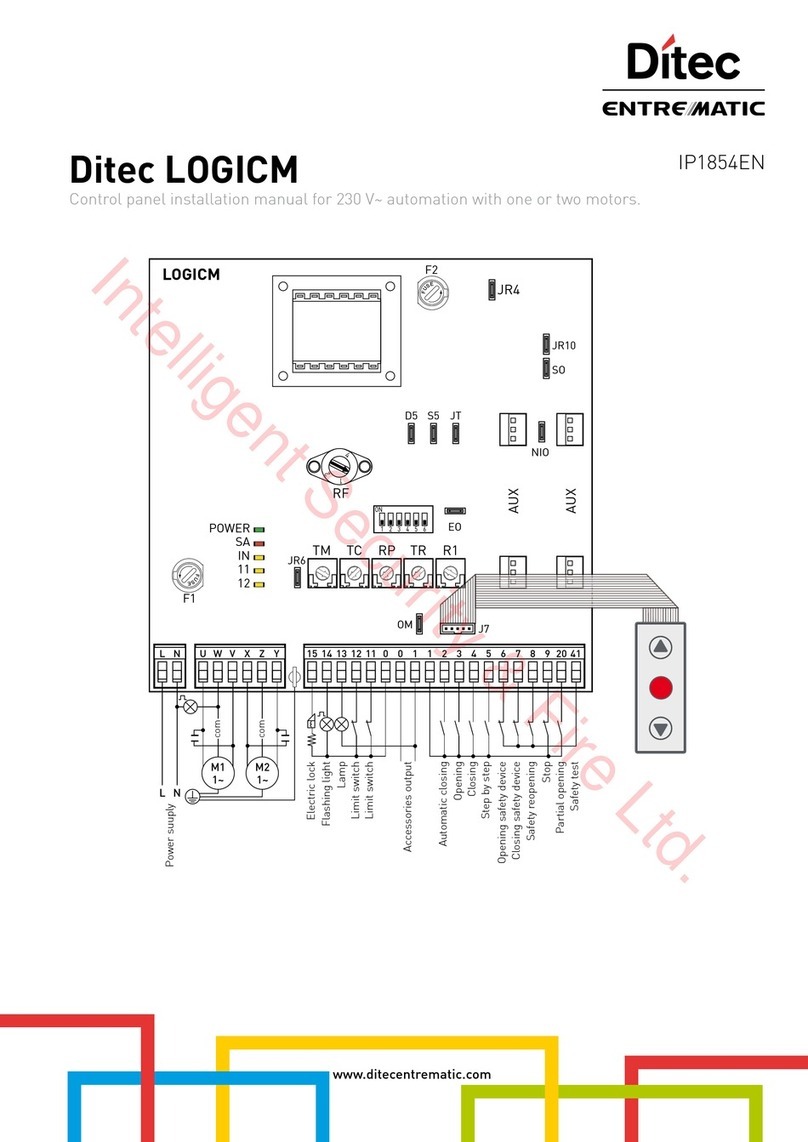

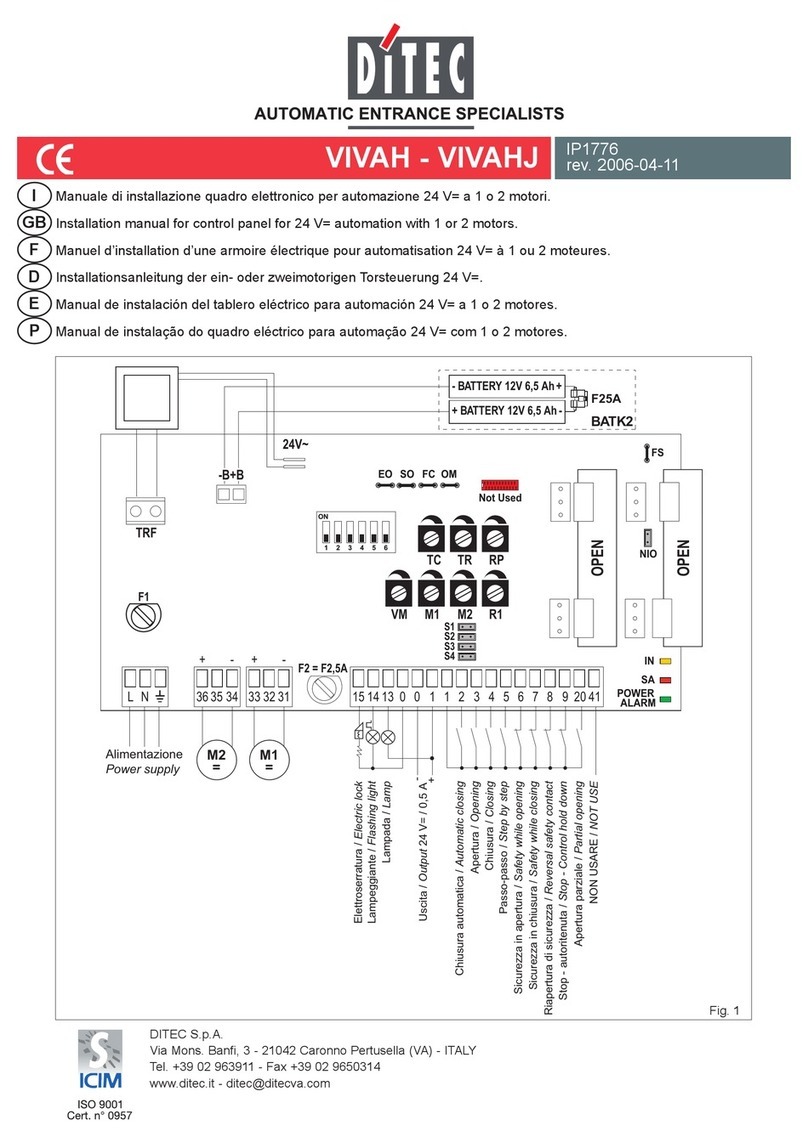

4. Commands

Command Function Description

1 2 NO AUTOMATIC

CLOSING

Permanent closing of the contact enables automatic

closing if →

1 3 NO OPENING Closing of the contact activates an opening operation.

1 4 NO CLOSING Closing of the contact activates a closing operation.

1 5 NO STEP-BY-STEP When selecting → → , closing the con-

tact starts a sequential opening or closing operation:

opening-stop-closing-opening.

WARNING: if automatic closing is enabled, the duration

of the stop can be selected by selecting → .

The sequence “opening-stop-closing-opening” can

be changed to “opening-stop-closing-stop-opening”

→ .

OPENING When selecting → → , closing the contact

activates an opening operation.

1 6 NC SAFETY STOP The opening of the safety contact stops and prevents

any movement.

NOTE: to set different safety contact functions, see the

→ parameter settings.

1 8 NC CLOSING

SAFETY DEVICE

Opening the safety contact triggers a reversal of the

movement (reopening) during the closing operation.

When selecting → → , with the automa-

tion idle, opening of the contact prevents any opera-

tion.

When selecting → → , with the automation

idle, opening of the contact only prevents closing.

1 9 NC STOP Opening of the safety contact causes the movement to

stop and automatic closing is disabled. In this state,

the opening (1-3/1-20) and closing (1-4) controls func-

tion only if held in the pressed position and the auto-

mation stops when the controls are released.

1 9 NC EMERGENCY

STOP

Connect the opening and closing controls to terminal

9 instead of terminal 1 (9-3, 9-4, 9-20)

Opening of the safety contact (for example, connected

to an emergency command) causes the movement to

stop and additional commands are disabled.

1 9 NO COMMAND

WITH OPERATOR

PRESENT

Opening of contact 1-9 enables the operator present

function.

- opening with operator present 1-3;

- closing with operator present 1-4;

- partial opening with operator present 1-20.

NOTE: any safety devices, automatic closing and plug-

in cards inserted in the AUX housing are disabled.

1 20 NO PARTIAL

OPENING

Closing of the contact activates a partial opening op-

eration.

Once the automation stops, the partial opening control

performs the opposite operation to the one performed

before the stop.

WARNING: make a jumper for all NC contacts if not in use. The terminals with the

same number are equal.