Dover OPW 790 Series User manual

Other Dover Industrial Equipment manuals

Dover

Dover Destaco Robohand RUA Series User manual

Dover

Dover OPW 68EZR User manual

Dover

Dover DESTACO ROBOHAND RA-Toggle Series User manual

Dover

Dover DESTACO ROBOHAND DPP Series User manual

Dover

Dover Hydro TaskMizer 48781 User manual

Dover

Dover Blackmer DMX IV User manual

Dover

Dover Civacon LM1051 Guide

Dover

Dover OPW CIVACON T196SV-CV Instructions for use

Dover

Dover TWG PullMaster PM50 User manual

Dover

Dover MARATHON V-6030 HD User manual

Dover

Dover DESTACO ROBOHAND RPS Series User manual

Dover

Dover OPW SiteSentinel Integra 100 User manual

Dover

Dover DESTACO RFE Series User manual

Dover

Dover WILDEN PSG Equalizer SD Series Instruction Manual

Dover

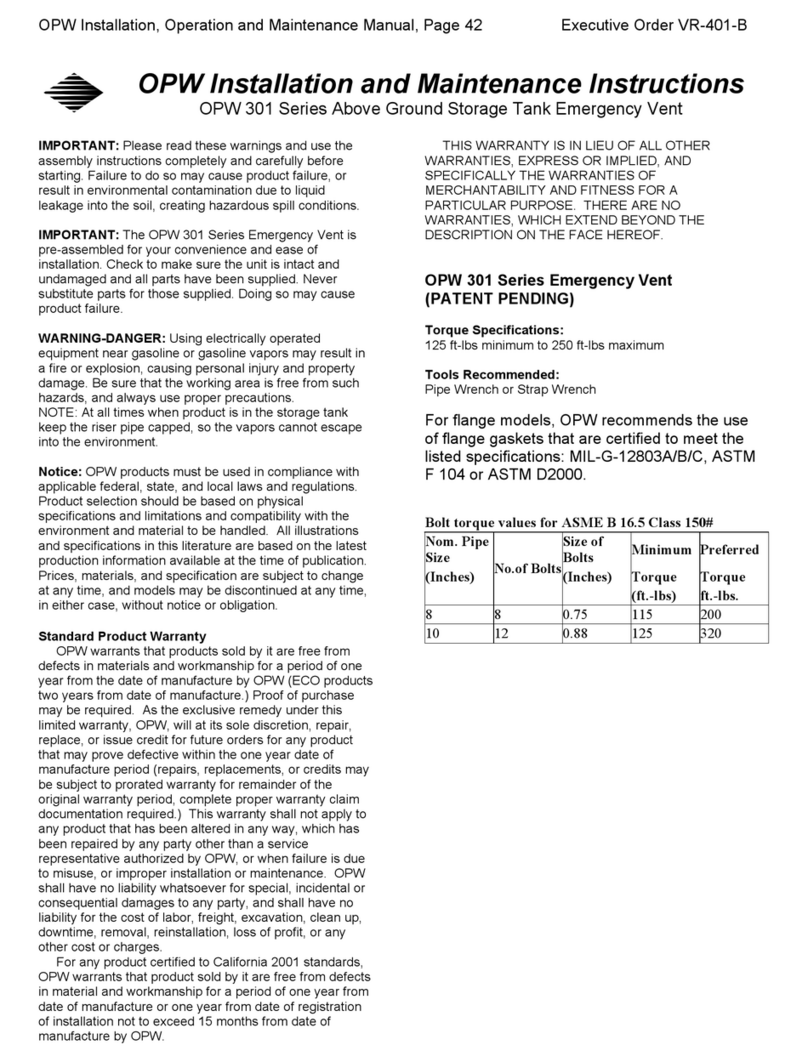

Dover OPW 301 Series User manual

Dover

Dover HEIL LIBERTY TP1L-SM-0520 User manual

Dover

Dover Triton 9610 User manual

Dover

Dover DESTACO TC1 Series User manual

Dover

Dover UIC 5588 Series User manual

Dover

Dover Triton 96 Series User manual