99.831.12 1.1/02/16

4/16 Deutsch

1x VCD 204-K-TMS+ B with built-in power supply

1x VCD 204-Z-TMS+ A

1x 2,5 m PVC cable

1x 1,2 m patch cable

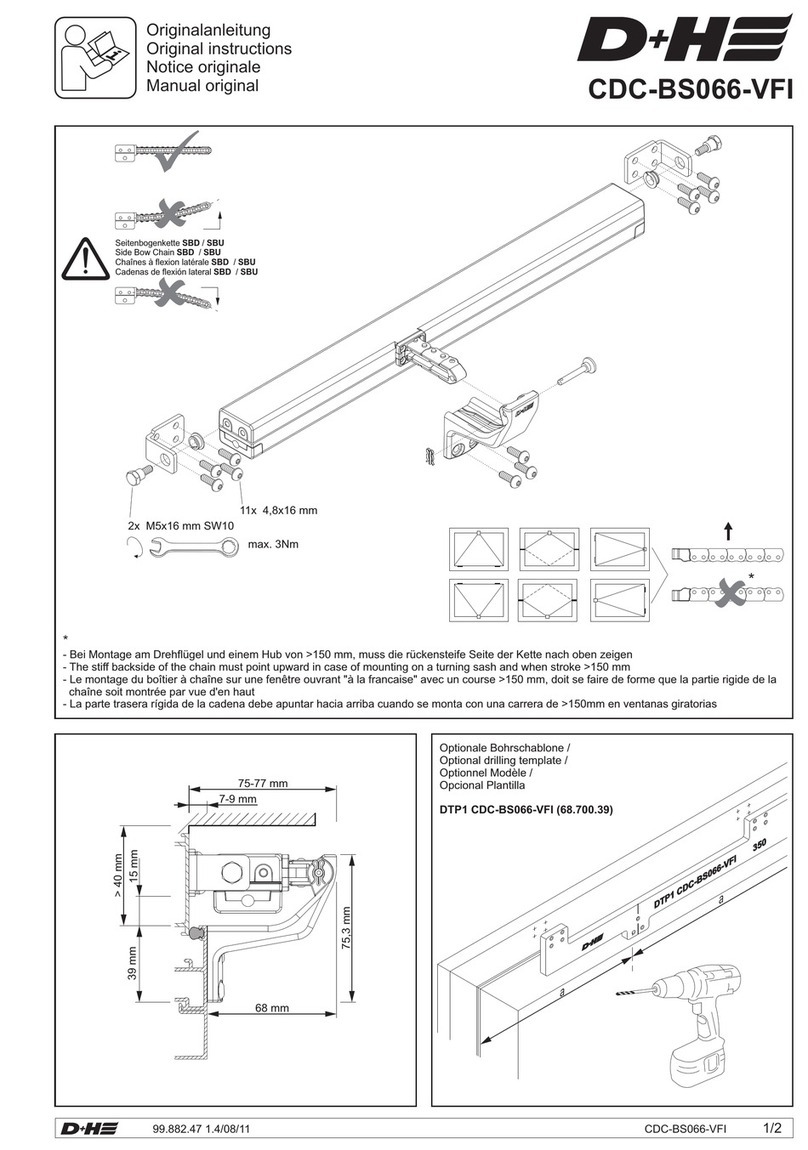

Dependent on the type of window, different bracket

sets are available separately.

Extent of supply

VCD 204-K-TMS+ Set VCD 204-K-TMS+ Set

Safety notes

Operating voltage 230 V AC!

Risk of injury from electric shock!

Do not reverse L+N! Connect PE!

- Connection must be carried out by a certified

electrical technician

- Danger of crushing hands and fingers!

- Keep people away from the operating area of the drive

- Keep children away from the control

- Use only in dry rooms

- Suitable for indoor mounting only.

Use rain detector in locations if there is a risk of rain

- Use unmodified original D+H parts only

- Observe the bracket-set mounting instructions

Observe enclosed red safety note!

Intended use

- Chain drive set for electric opening and closing of

windows and flaps in the facade and roof area

- Useable for daily natural ventilation

- Operating voltage 230 V AC

- Only for inside mounting

- These drives are not compatible with other

VCD 204 drives!

Performance features

- micro processor controlled electronics

- Stroke programming with magnet

- Low running noises

- Connection via plug connector

- Symmetrical chain outlet

- Tandem-safety function (TMS+) for operation of

both drives on one sash

Up to two drives can be used in tandem. This function

connects the cut-offs of the two drives in such a way

that if one drive is cut off due to overload, the other

drive will similarly be cut off.

During the learning phase, the activated stroke is

transferred to the tandem drive via the TMS+ function.

TMS+ function

Hubbegrenzung mit Magnet

Antriebe einfahren.

1Antriebe so lange in AUF-

Richtung fahren lassen bis

gewünschter Hub erreicht wurde.

Sollte ein falscher Hub eingestellt

oder versehentlich die Fahrt

unterbrochen worden sein

oder die Antriebe wieder auf

maximale Hublänge gebracht

werden, muss wieder mit Punkt 1

begonnen werden.

3

An den Antrieben muss in

ZU-Richtung weiter Spannung

anliegen.

Magnet anAntrieb (...-B) halten (ca.

2 sek.), bis nach einem pulsier-

enden Ton ein Dauerton kommt

> Antriebe sind imAnlernmodus.

Der Magnet kann entfernt werden.

Die Spannung muss nicht mehr

am Antrieb anliegen.

ca.100 mm

Anlernmodus

ca. 2 sek.

2

Zur Hubeinstellung müssen beide Antriebe elektrisch verbunden sein.

Es muss aber nur ein Antrieb mit dem Magnet in den Hubanlernmodus versetzt werden.

Antriebe mechanisch spannungsfrei montieren.

Hierdurch wird eine gleichmäßigere Lastverteilung

auf alle Antriebe gewährleistet.

Montagehinweise

VCD 204-K-TMS-B

24 VDC

230 VAC

STOP

Elektrogeräte, Zubehör, Batterien und Verpackungen

sollen einer umweltgerechten Wiederverwertung

zugeführt werden. Werfen Sie Elektrogeräte und

Batterien nicht inden Hausmüll!

Nur für EU-Länder:

Gemäß der Europäischen Richtlinie 2012/19/EU

über Elektro- und Elektronik-Altgeräte und ihrer

Umsetzung in nationales Recht müssen nicht mehr

gebrauchsfähige Elektrogeräte getrennt gesammelt

und einer umweltgerechten Wiederverwertung

zugeführt werden.

Entsorgung

Maintenance and cleaning

Maintenance work is only allowed when the device is in

a de-energized condition! Inspection and maintenance

has to be carried out according to D+H maintenance

notes. Only original D+H spare parts may be used.

Repair is to be carried out exclusively by D+H.

Wipe away debris or contamination with a dry, soft

cloth.

Do not use cleaning agents or solvents.

Guarantee

You will get 2 years guarantee for all D+H products

from date of verified handing over of the system up to

maximal 3 years after date of delivery, when

mounting and starting has been carried out by an

authorized D+H-distributor.

D+H guarantee is expired, with connection of D+H

components with external systems or with mixing of

D+H products with parts of other manufacturers.

WARNING

Read all safety warnings, instructions, illustrations

and specifications provided with this product.

Failure to follow all instructions listed below may

result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future

reference.

Declaration of Conformity

We declare under our sole responsibility that the

product described under “Technical Data” is in

conformity with the following directives:

2014/30/EU, 2014/35/EU

Technical file at:

D+H Mechatronic AG, D-22949 Ammersbek

Dirk Dingfelder Maik Schmees

Member of the Board Authorized signatory, Technical Director

24.02.2016