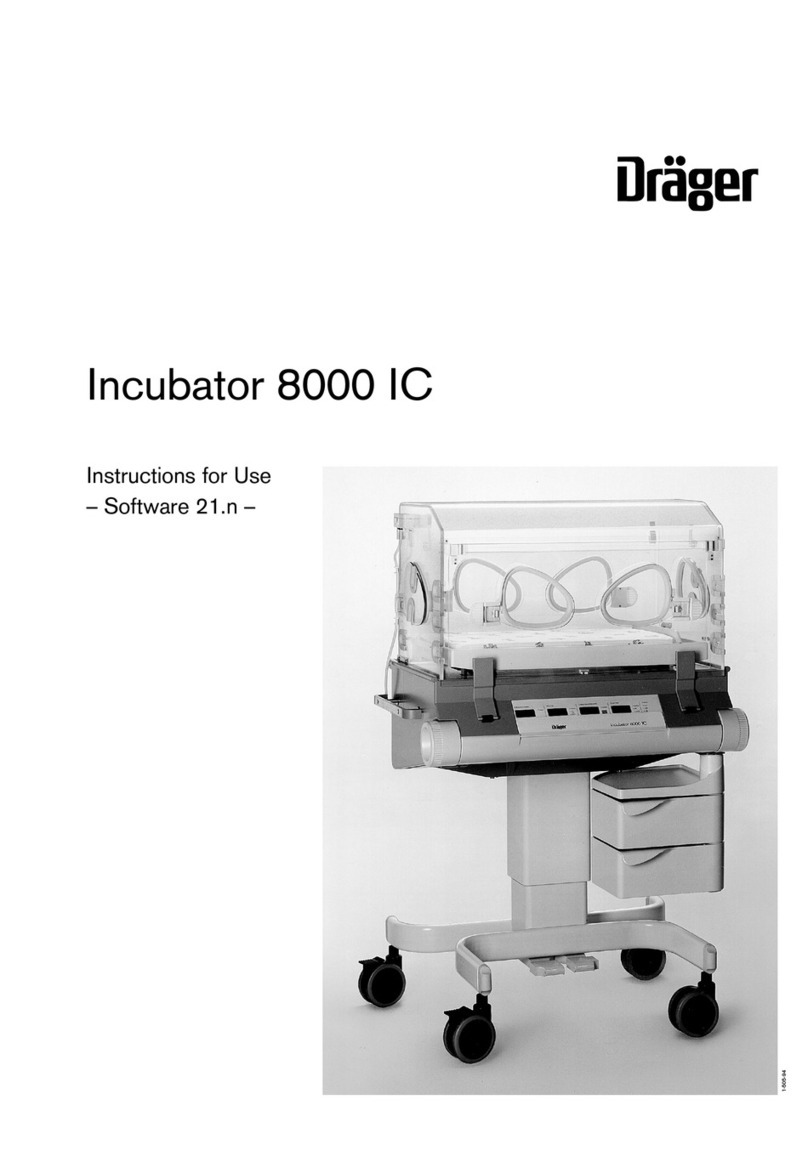

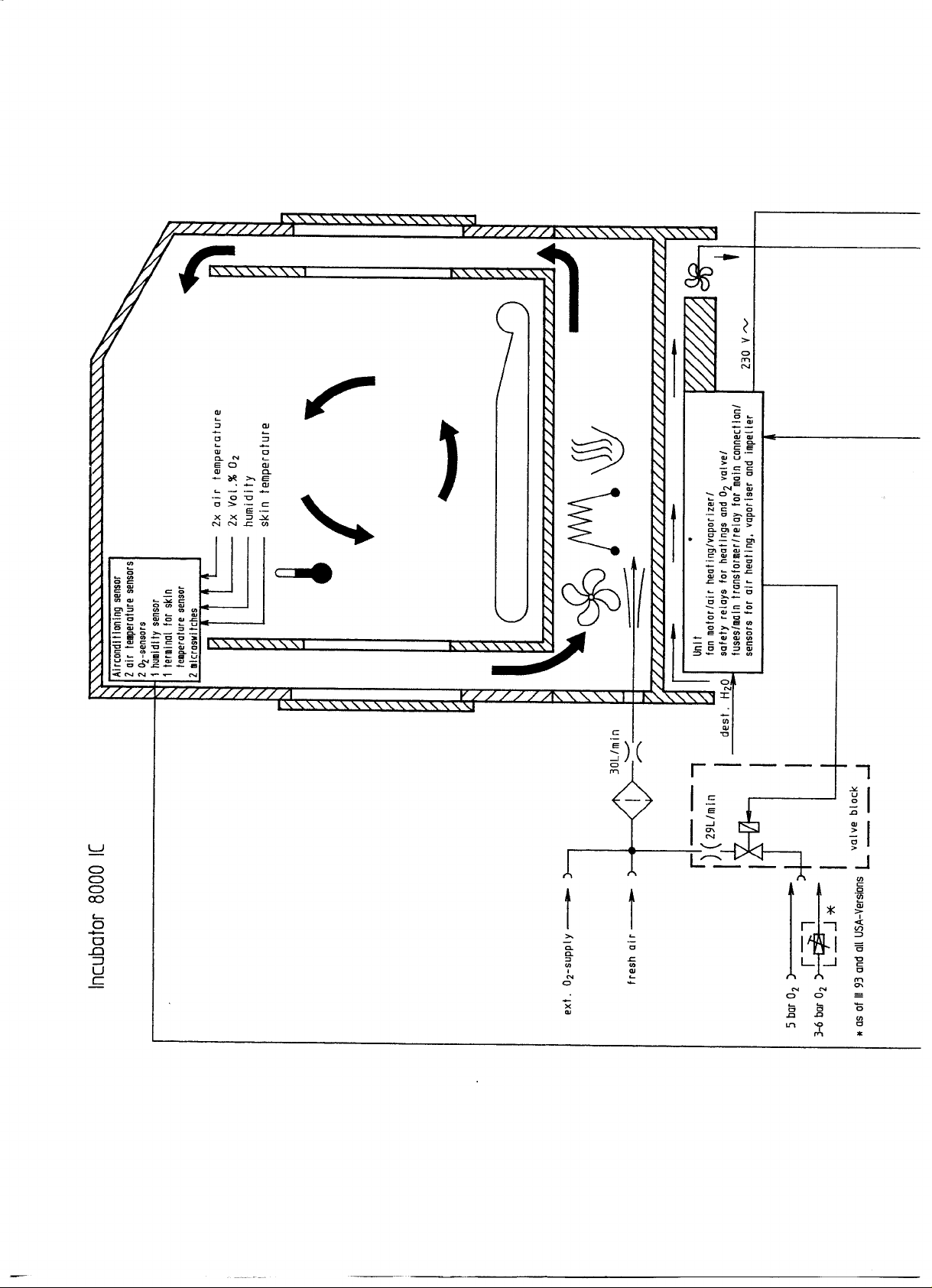

6141.22X Incubator 8000 IC/SC/NC Function Description 09.99 Page 4 of 49

At the Incubator 8000 SC / NC an air temperature sensor located near the baby's head is

attached at the rear of the canopy, the connection point for the skin temperature sensor is

located at the back of the Incubator next to the mains input on units without Thermomonitoring.

The optional oxygen control module on Incubator 8000 IC units permits the required oxygen

concentration within the canopy to be pre-selected and controlled automatically. If the actual

value deviates from the set value, warning signals are given. The control system permits a set

oxygen concentration to be achieved within a very short time (40 % in 1.5 minutes and 60 % in

< 7 minutes). This permits rapid action in emergencies and rapid return to a selected oxygen

concentration after opening the hinged front door or the hand ports.

The humidity control of the Incubator 8000 IC permits a required humidity value to be pre-

selected and maintained. The water required for this is supplied from sterile water bottles.

The humidity supply of the Incubator 8000 SC / NC humidity control can be adjusted in 10

steps.

Evaporation of the water guarantees completely hygienic air humidification.

In accordance with hygienic requirements, all parts of the Incubator which come into contact

with the gas breathed by the baby can be removed from the basic unit.

The electrically-operated height adjustment mechanism permits an optimum working height to

be set for both tall and small nurses. In addition, the Incubator can be lowered so that the

nurse can carry out lengthy procedures whilst sitting down, and there is also adequate

legroom beneath it.

The hand port openings have been designed to provide better access for the arms of the

nursing staff than round openings do, yet have a smaller opening cross-section, thus reducing

heat loss.

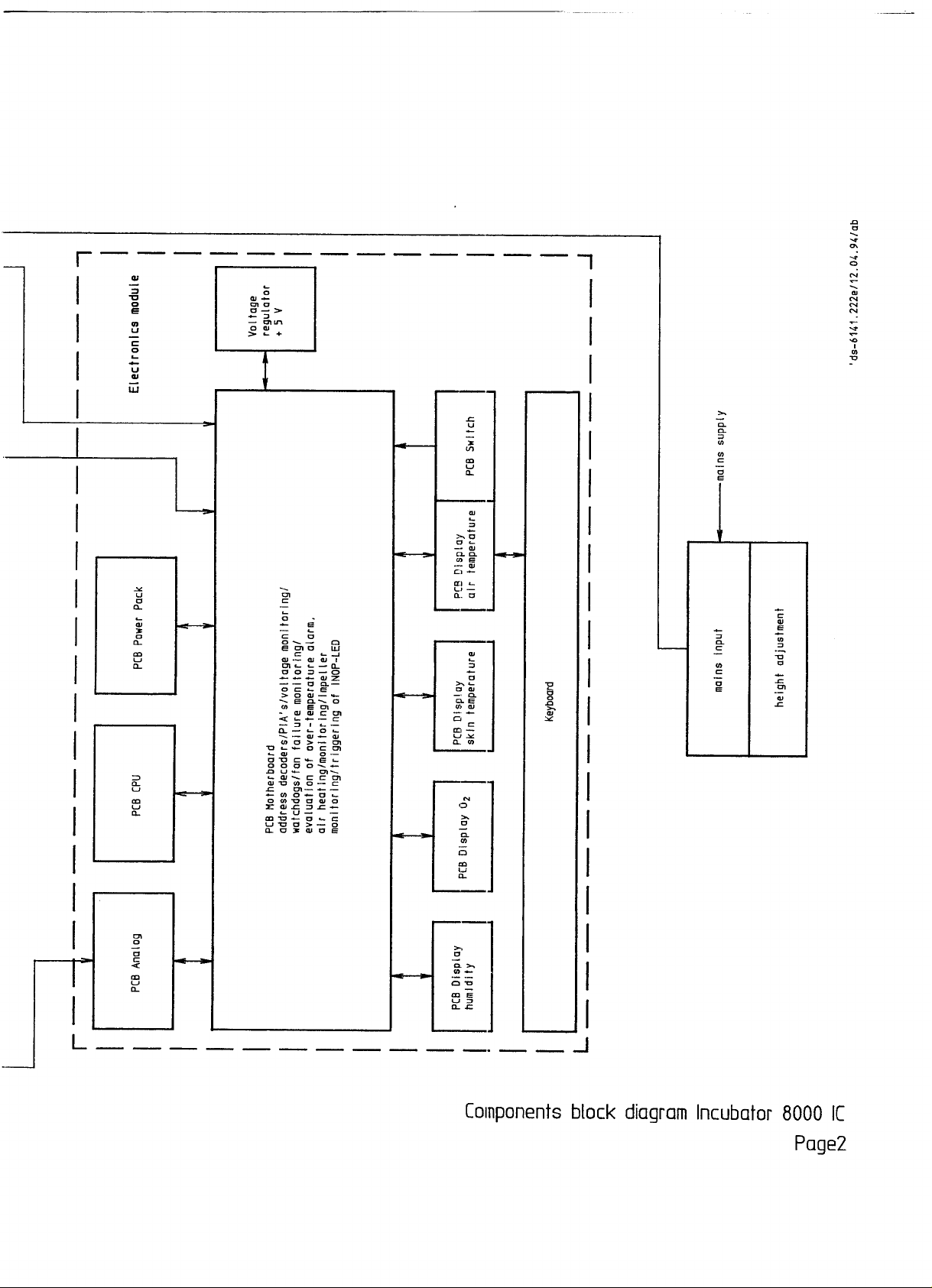

The incubator is controlled by a microprocessor. The Incubator carries out a general self-test

when it is switched on and automatically every 10 minutes thereafter. This test checks the

various assemblies in the incubator which are crucial to safety by operating them briefly. The

operator is automatically requested to recalibrate the oxygen sensors after switching on the 02

control system and, thereafter, after every 24 hours of operation. Measured value deviations or

system failures are indicated visually and audibly. The heating system and valve are

automatically switched off if operating conditions are outside permitted limits.

The control systems for air temperature, skin temperature and humidity are PI- or PID-controls

and give optimum control.

An additional built-in air-cooler produces rapid cooling as soon as the actual value of the air

temperature is a few tenths of a degree above the set value.