90 33 655 - ED 4836.300 Dräger Safety AG & Co. KGaA

©Dräger Safety AG & Co. KGaA Revalstraße 1 Tel +49 451 882 0

Edition 04 - June 2019 (Edition 01 - June 2017) 23560 Lübeck, Germany Fax +49 451 882 20 80

Subject to alteration www.draeger.com

Sensor data

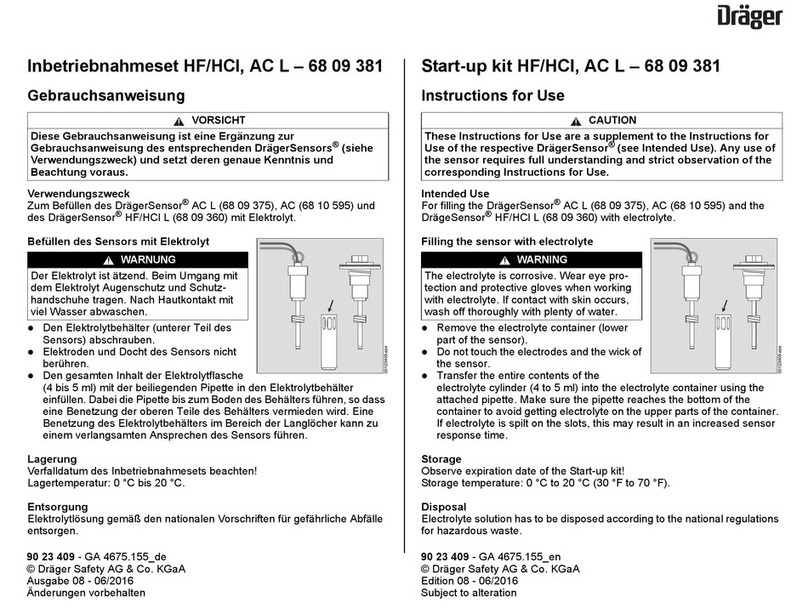

Excerpt: For details, see instructions for use/data sheets for the respective sensor.

The instructions for use, technical manual and data sheets for the utilized sensors can be downloaded from: www.draeger.com/ifu and the PC software CC-Vision from: www.draeger.com/

software

For the conversion of the test gas concentration between %LEL and Vol.% see Information system on hazardous substances (GESTIS) of the German Social Accident Insurance (IFA)

https://www.dguv.de/ifa/gestis/gestis-stoffdatenbank/index-2.jsp or LEL values in accordance with EN 60079-20-1.

Note:

The requirements of the standards regarding error limits are valid for the whole operating range of the device, deviations are:

XXS H2 HC sensor, increased indication at -20 °C; ≤4.5 %LEL between -10 °C and +50 °C

XXS CO-LC sensor, increased indication at >40 °C; at zero-point <=7 ppm, test gas concentration ≤27 %

Dual IR Ex Sensor at measuring range 0-5 vol.% methane (CH4), the deviation from the volume fraction at 1.46 vol.% CH4 caused by added 0.075 vol.% ethane (C2H6) in air, is about + 25 % rel.

In sub-zero temperatures, the response times of the XXS CO-LC and XXS O2 sensor may be increased compared to room temperature. If necessary, check response times (see instructions for use).

DUAL IR Ex / CO2

6811960

CatEx 125 PR

6812950

CatEx 125 PR

Gas

6813080

XXS H2S-LC

6811525

XXS H2-HC

6812025

XXS O2

6810881

XXS CO-LC

6813210

IR Ex

6812180

IR CO2

6812190

X-am 3500/8000 X-am 8000 X-am 3500/8000 X-am 8000 X-am 3500/8000 X-am 3500/8000 X-am 8000 X-am 8000

Measuring principle Catalytic combusti-

on

Catalytic combusti-

on

Electrochemical Electrochemical Electrochemical Electrochemical Infrared Infrared

Indication range 0 to 100 %LEL 0 to 100 %LEL

0 to 100 vol.%

(CH4)

0 to 100 ppm 0 to 100 %LEL 0 to 25 vol.% 0 to 2000 ppm 0 to 100 %LEL

0 to 100 vol.%

(CH4)

0 to 5 vol.%

Measuring range (certified) 0 to 100 %LEL1)

1) CatEx 125 PR: alkanes from methane to n-Octan.

CatEx 125 PR Gas: methane, propane, ethane, ethene, ethine, propene, n-butane, i-butene, hydrogen.

LEL values in accordance with EN 60079-20-1. At air speed of 0 to 6 m/s, the deviation of the reading is 5 to 10 % of the measured value.

0 to 100 %LEL1)

0 to 5 vol.%

0.4 to 100 ppm 0 to 100 %LEL 0 to 25 vol.% 3 to 500 ppm 0 to 100 %LEL2)

0 to 5 vol.% (CH4)

2) IR Ex: methane, propane, n-nonane; LEL values in accordance with EN 60079-20-1.

0.05 to 5 vol.%

Capture range3)

3) This range of measured values is known as capture range where minor measured value fluctuations (e.g. signal noise, concentration fluctuations) does not result in a changing display. Measured values

outside the capture range are displayed using their actual measured values. By using Dräger CC-Vision the set capture range can be read out and activated/deactivated. By default, the capture range

is continuously activated in measuring mode and is disabled in calibration mode.

+2 to -5 % LEL +2 to -5 % LEL ±0.4 ppm ±0.5 %LEL ±0.4 vol.% ±1.4 ppm ±1 %LEL 390 ppm

±100 ppm

Drift per month ±1 %LEL (CH4)

±3 %LEL (C3H8)

±1 %LEL (CH4)

±2 %LEL (C3H8)

1.9 % of

measured value

±4 %LEL ±1 % of

measured value

1.2 % of

measured value

±2 %LEL (CH4)

±1 %LEL (C3H8)

±0.8 % of

measured value

Warm-up time 85 s 85 s 85 s 85 s 120 s 85 s 85 s 85 s

Effect of sensor poisons

HMDS, 10 ppm

hydrocarbons, heavy metals, and

substances containing silicone, sul-

phur or polymerisation

1 %LEL/

8 h

Possible poisoning

1 %LEL/

8 h

Possible poisoning

n/a n/a n/a n/a n/a n/a

Linearity error 2 %LEL (CH4)

5 %LEL (C3H8)

4 %LEL (CH4)

1 %LEL (C3H8)

0.1 % of

measured value

±1.5 %LEL 0.3 vol.% 1.2 % of

measured value

2 %LEL (CH4)

3 %LEL (C3H8)

7.8 % of

measured value

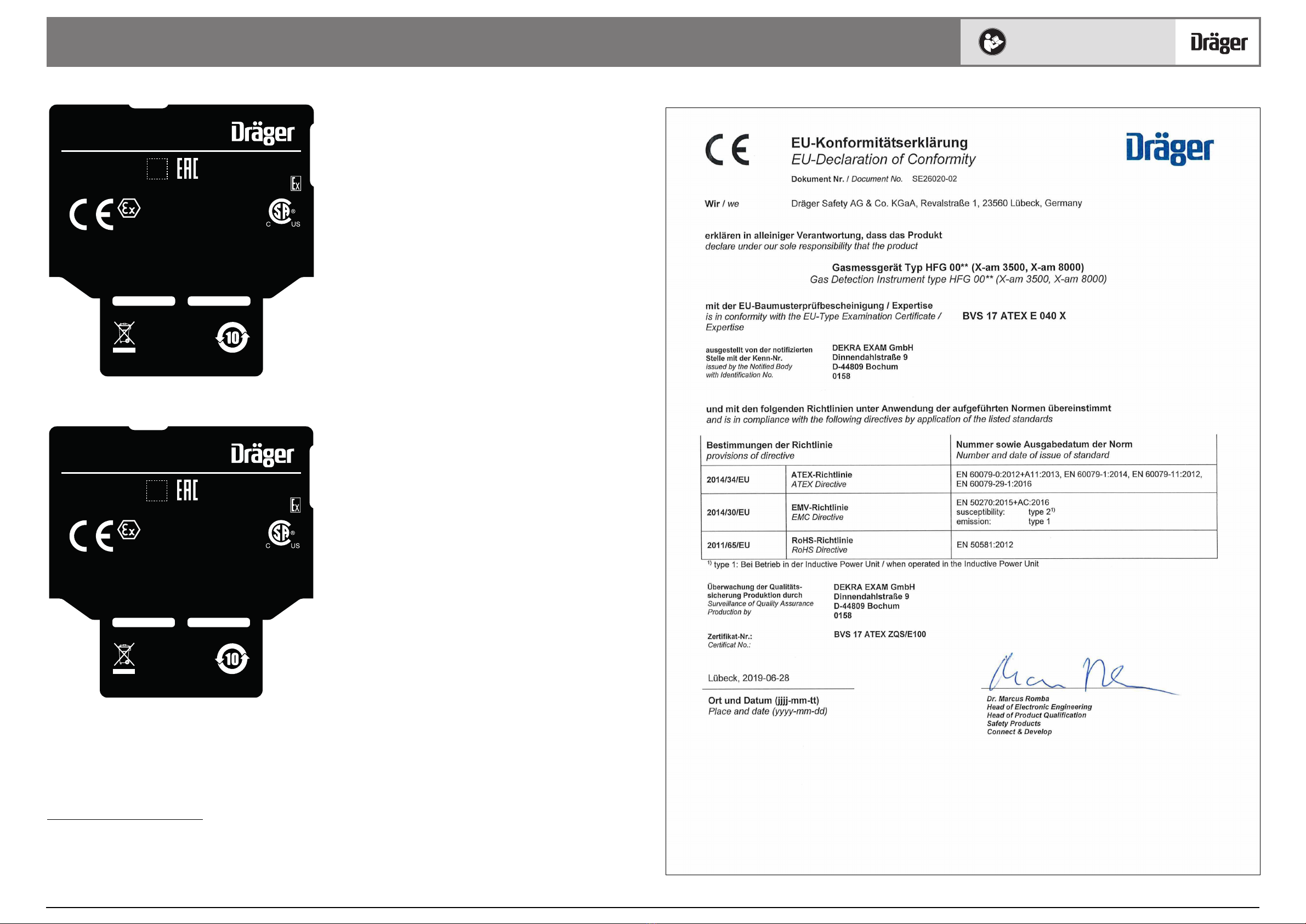

Standards

Measuring function for flammable

gases, oxygen deficiency / enrich-

ment and toxic gases, DEKRA

Testing and Certification GmbH:

BVS 17 ATEX E 040 X 1),

PFG 19 G 001 X

EN 60079-29-1

EN 50271

EN 60079-29-1

EN 50271

EN 45544-1

EN 45544-2

EN 45544-3

EN 50271

EN 60079-29-1

EN 50271

EN 50104

EN 50271

EN 45544-1

EN 45544-2

EN 45544-3

EN 50271

EN 60079-29-1

EN 50271

EN 45544-1

EN 45544-2

EN 45544-3

EN 50271

Cross-sensitivities exist4)

4) The instrument responds to most combustible gases and vapours. The sensitivities differ depending on the type of gas. Dräger recommends a calibration using the target gas to be measured. Regarding

catalytic combustion sensors in the range of alkanes, the sensitivity decreases from methane to nonane. The sensitivity ratios between different gases can change as a result of sensor aging or poiso-

ning.

exist4) Additively affected

by:

SO2, NO2, H2

Negatively affec-

ted by

: Cl2

Additively affected

by: C2H2, NO, CO

Increased hydro-

gen concentra-

tions within the

range of XXS H2

HC may result into

false alarms by ad-

ditive effect on the

XXS H2S and the

XXS CO, as well as

due to the negative

effect on the XXS

O2

Negatively affec-

ted by:

C2H6, C2H4, C2H2,

CO2, H2

No O2measure-

ment in He

Additively affected

by:

C2H2, H2, NO

exist4) n/a

Diffusion

Time of response t0...90 20 s (CH4)

30 s (C3H8)

15 s (CH4)

29 s (C3H8)

20s 15s 9 s 21 s 21 s (CH4)

57 s (C3H8)

48 s

Time of response t0...50 (Ex, Tox)

Time of response t0...20 (O2)

9 s (CH4)

12 s (C3H8)

8 s (CH4)

12 s (C3H8)

14 s 10 s 5 s 13 s 10 s (CH4)

14 s (C3H8)

14 s

Time of recovery t0...10 17 s (CH4)21 s n/a 21 s 30 s (CH4)47 s

Time of recovery t0...50 7 s (CH4)14 s n/a 12 s 10 s (CH4)15 s

Pump

Time of response t0...90 12 s (CH4)

15 s (C3H8)

10 s (CH4)

13 s (C3H8)

20 s 15 s 8 s 16 s 11 s (CH4)

15 s (C3H8)

14 s

Time of response t0...50 (Ex, Tox)

Time of response t0...20 (O2)

9 s (CH4)

11 s (C3H8)

8 s (CH4)

10 s (C3H8)

15 s 11 s 6 s 11 s 9 s (CH4)

10 s (C3H8)

10 s

Time of recovery t0...10 10 s (CH4)20 s n/a 16 s 11 s (CH4)14 s

Time of recovery t0...50 8 s (CH4)14 s n/a 12 s 9 s (CH4)10 s

Calibration adapter

Time of response t0...90 35 s (C8H18)23 s other

certified gases

160 s (C9H20)

Time of response t0...50 100 s (C8H18)12 s other

certified gases

28 s (C9H20)