Installation

Dräger Polytron 8200/8310 7

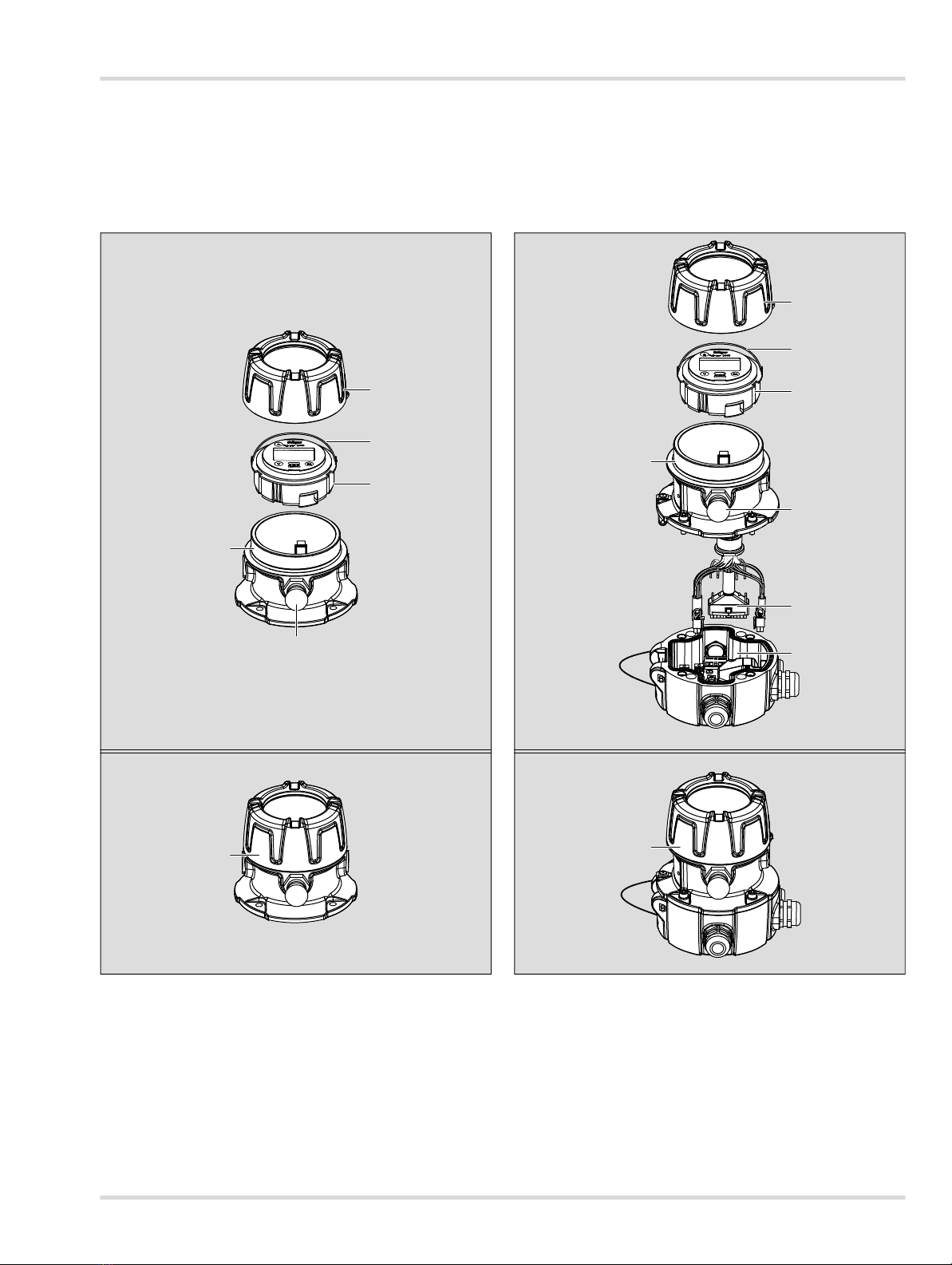

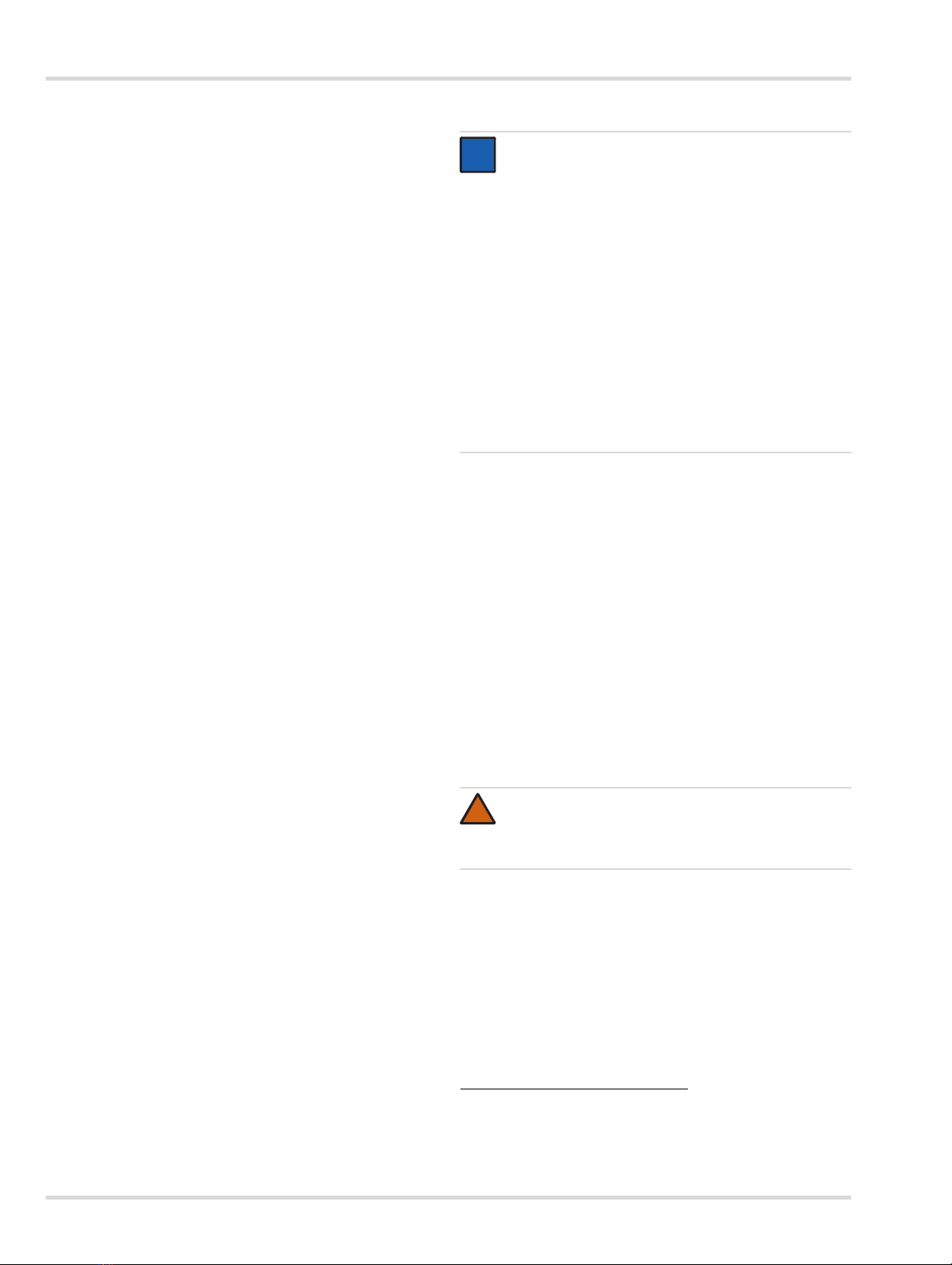

2.3.3 Dräger Polytron 8310 with DrägerSensor IR

Infrared sensor for monitoring flammable gases and vapors

containing hydrocarbons

{Detection range: 0 to 100 % LEL 2)

2.4 Intended operating area and operating

conditions

Hazardous areas classified by zones:

The device is only designed for use in Zone 1 or Zone 2

potentially explosive atmospheres for which a temperature

range as specified on the device must be observed and in which

gases of Explosion Groups IIA, IIB or IIC and Temperature

Classes T4 or T6 (depending on maximum ambient

temperature) or dust of Groups IIIA, IIIB or IIIC may occur.

Hazardous areas classified by divisions:

The device is only designed for use in potentially explosive

atmospheres of Classes I&II, Div. 1 or 2, for which

a temperature range as specified on the device must be

observed and in which gases or dust of Groups A, B, C, D or

E, F, G and Temperature Classes T4 or T6 (depending on

maximum ambient temperature) may occur.

2.5 Approvals

See printed version for approval markings.

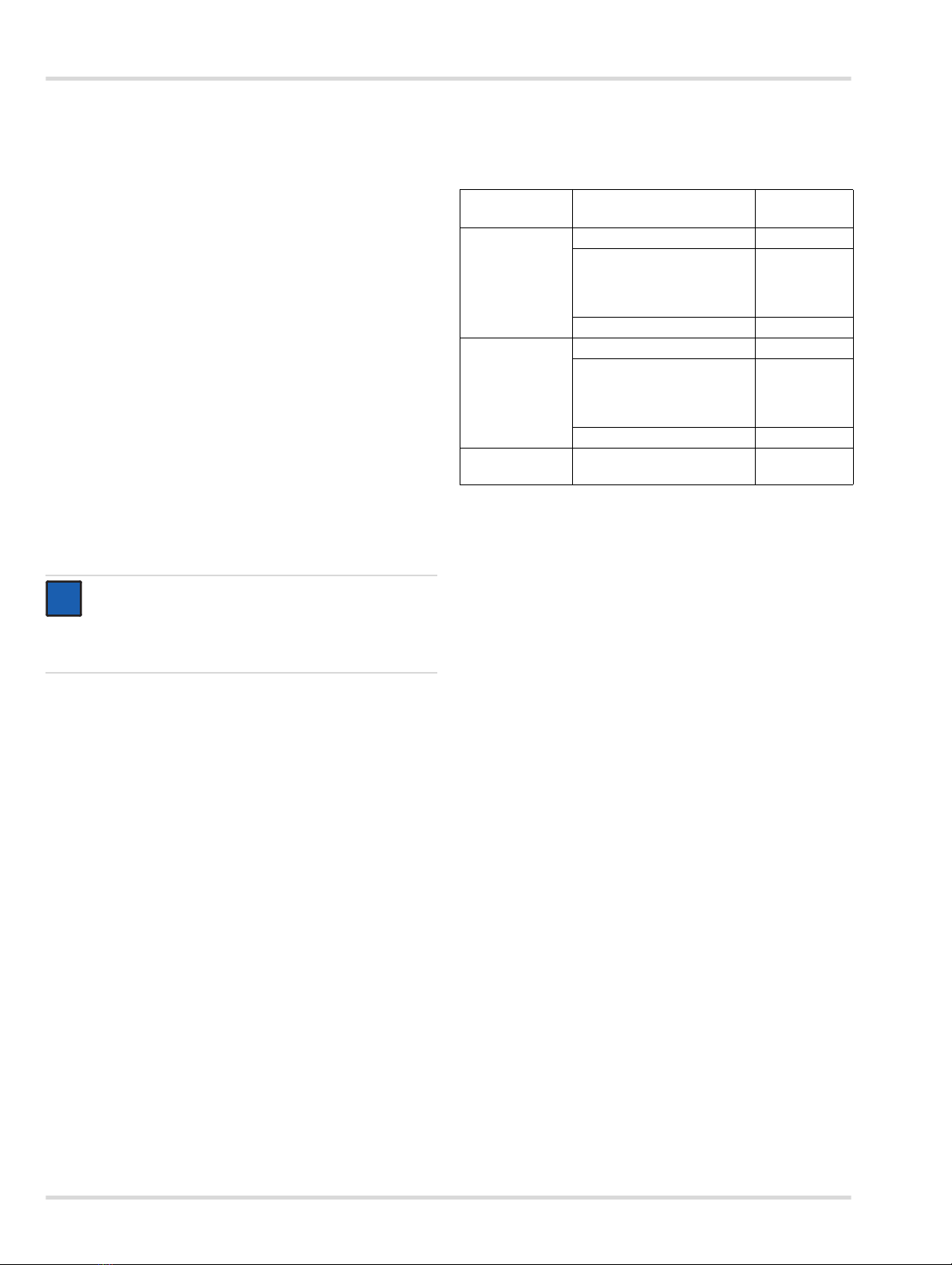

2.6 Device marking

The device marking is supplied with the device as a copy on

a separate document.

Key to the Serial Number: The third letter of the Serial Number

specifies the year of manufacture: A = 2009, B = 2010, C = 2011,

D = 2012, E = 2013, F = 2014, H = 2015, J = 2016, K = 2017 etc.

Example: Serial Number ARBH-0054: The third letter is B,

i.e. the device was manufactured in 2010.

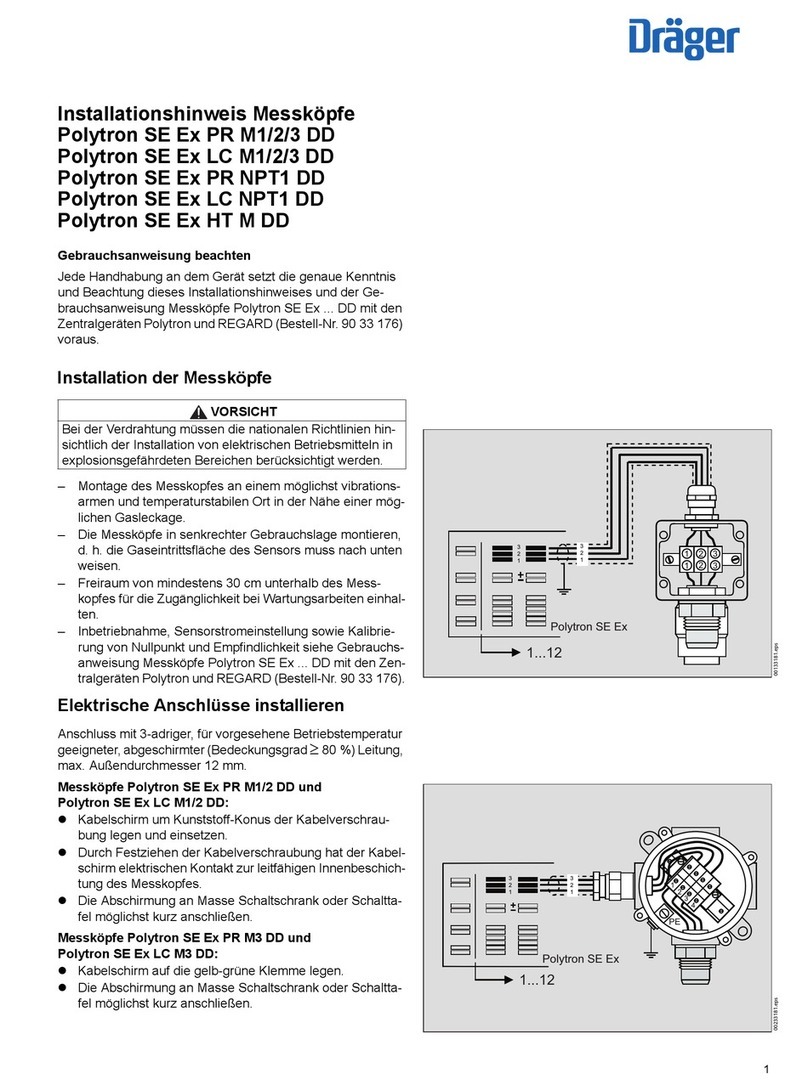

3 Installation

3.1 General information for the installation

The selection of a suitable mounting location is crucial for

the effectiveness and performance of the entire system. Every

detail of the installation must be thoroughly thought out.

The following must be noted in particular:

zthe local and national rules and regulations for the

installation of gas monitoring systems,

zthe applicable regulations for running and connecting

power and signal cables to gas monitoring systems,

zthe full extent of environmental influences to which the

device will be subjected,

zthe physical properties of the gases and vapors to be

measured,

zthe details of the particular application (e.g., potential

leaks, air movements/flows, etc.),

zaccessibility for required maintenance activities,

zthe geometric of the accessories that are used with the

system,

zall other limiting factors and stipulations that may affect the

installation of the system.

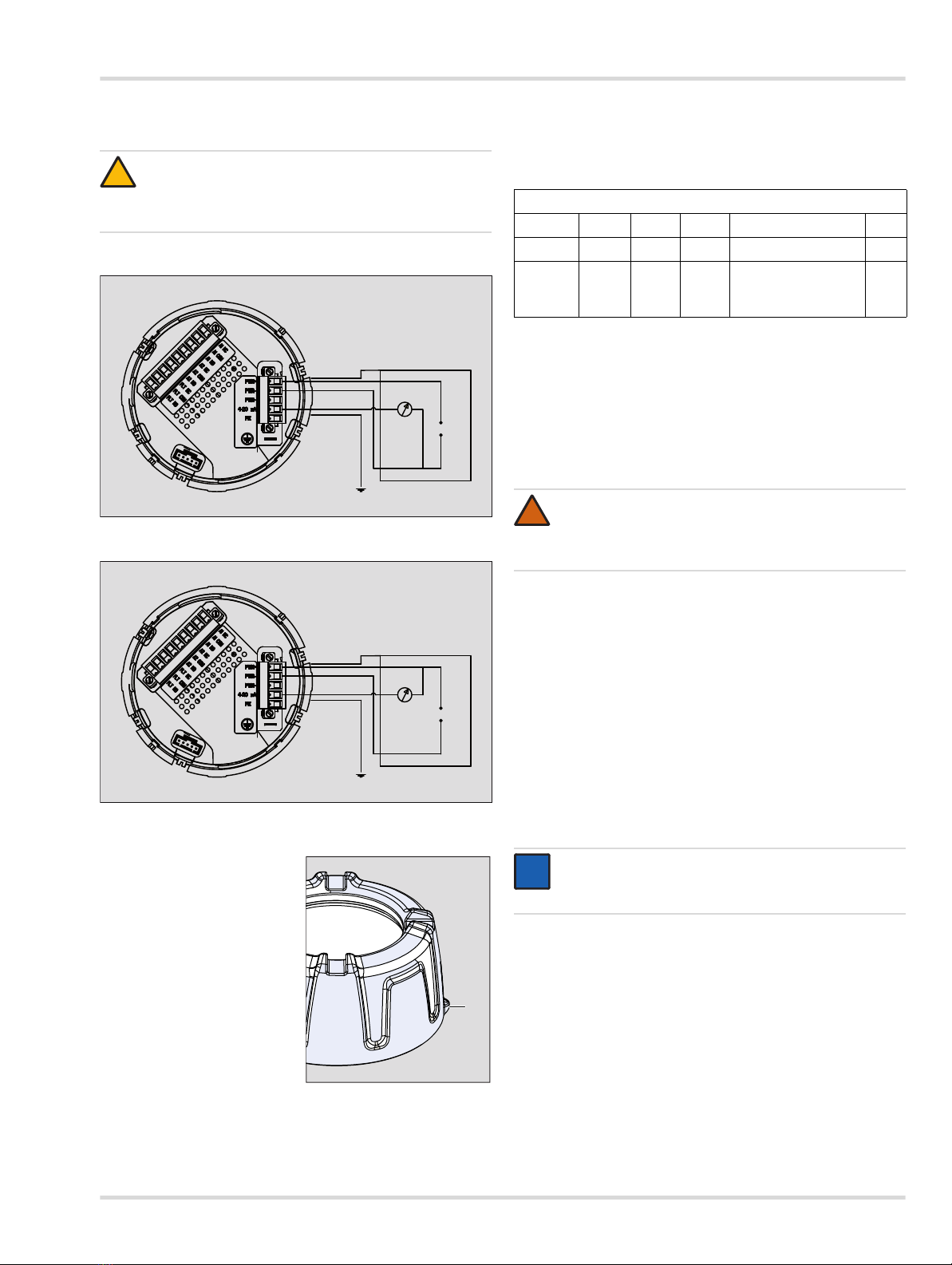

zFor installation without a conduit, an approved cable gland

(e.g. Hawke A501/421/A/¾" NPT or equivalent) must be

used (see chapter 12 on page 28). To increase the RF

interference immunity, it may be necessary to connect the

cable screen to the cable gland and to the control unit.

zThe explosion proof enclosure has three ¾" NPT

connections, which can be used for field wiring, the direct

attachment of a sensor or wiring an external sensor.

Unused openings must be closed off with a plug. For the

correct tightening torques for cable bushings, plugs,

sensors and connectors, see chapter 12 on page 28.

zThe secondary are supposed to be supplied from an

isolating source (does not apply to relay contacts).

zThe optional e-Box has up to four 20 mm connections,

which can be used for field wiring or wiring an external

sensor. The permissible cable diameter is 7 to 12 mm.

zIf the device is installed in locations where ambient

temperatures of over 55 °C prevail, appropriate cables

which are specified for use at temperatures of 25 °C above

the maximum ambient temperature must be used.

zStrip back the insulation on conductors by 5 to 7 mm.

zConnect the cable as shown in Chapter 3.5 on page 9

(shown here also with protective ground) oder Chapter 3.6

on page 10.

zThe connecting wires for the optional relay module must be

selected and fused according to the rated voltages,

currents and environmental conditions.

zWhen stranded conductors are used, an end ferrule must

also be used.

WARNING

Explosive. Not to be used in oxygen enriched

atmospheres. None of the Polytron 8000 transmitters

is certified and approved to be operated in oxygen

enriched atmospheres.

!

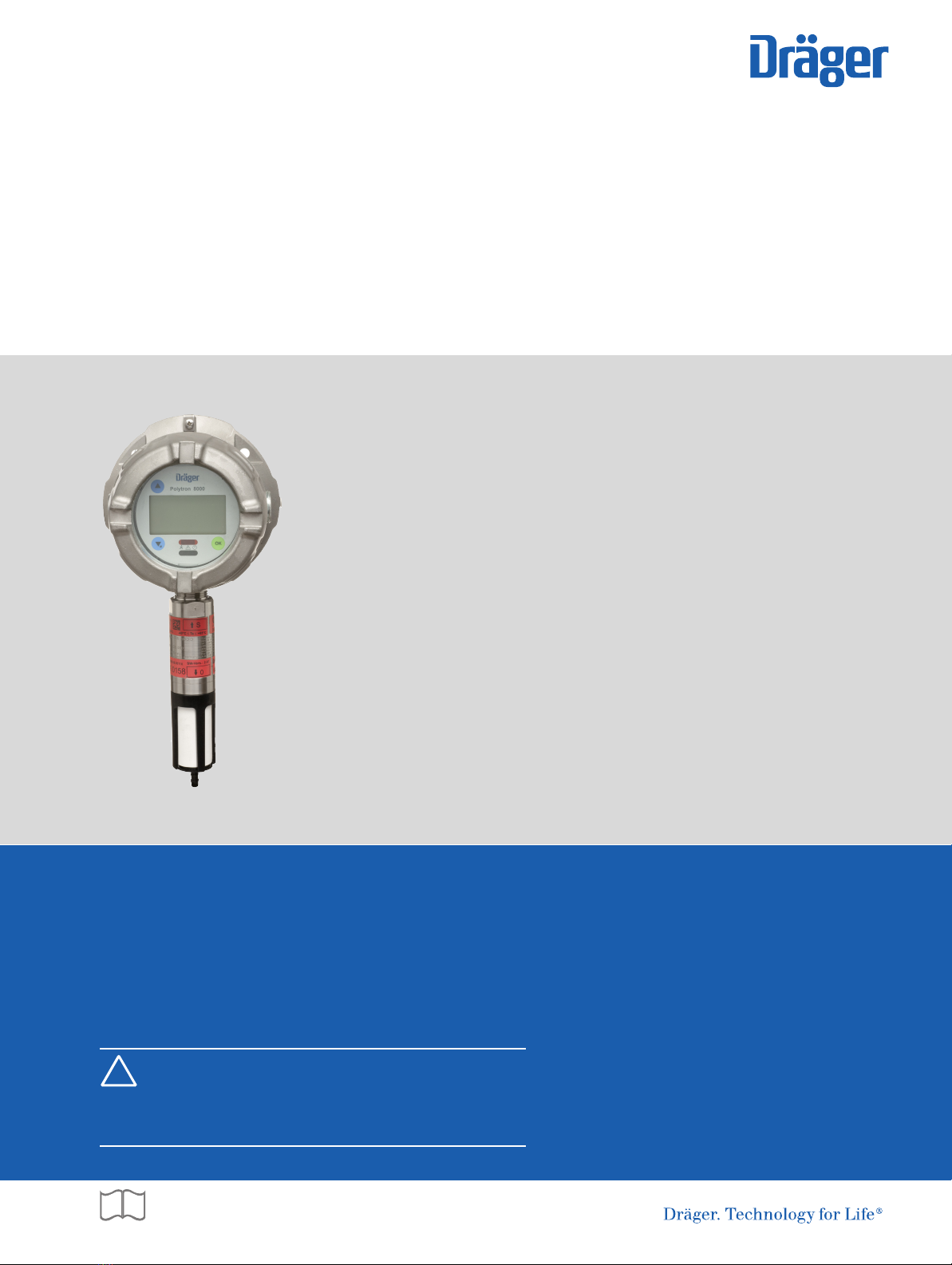

DPolytron 8200

ETR 0400

Dräger Safety 23560 Lübeck, Germany

II 2G

II 2D

WARNING: Do not open when energized

I

S

F

S

I

E

A

D

L

C

9N54

0158

Class I, Div 1, Groups A,B,C,D | Class II, Div 1, Groups E,F,G

Class I, Zone 1, Group IIC | T-Code T6/T4 | Type 4X

Supply: 16...30 VDC, 4...20 mA

CAUTION: Do not open cover. Opening

cover with circuits alive provokes risk of

Ignition of Hazardous Atmospheres.

WARNING: To reduce the risk of Ignition

of Hazardous Atmospheres, the conduit

must be sealed within 18’’ of the enclosure.

WARNING: Read Manual before operating.

Gas Detector for Use in Hazardous Locations as to

Fire, Electrical Shock and Explosion Hazards only

Part No: 4544440

Serial No. XXXX-9999

Ex d IIC T6/T4 Gb

Ex tb IIIC T80/130°C Db

-40°C ≤ Ta ≤ +40/+80°C

PTB 11 ATEX 1005X

IECEx PTB 11.0005X

IP6x | P ≤ 5 W