Dräger Polytron 8100 5

Contents

1 For your safety.........................................................7

1.1 General safety statements.........................................7

1.2 Definitions of alert icons.............................................7

2 Description ...............................................................8

2.1 Product overview .......................................................8

2.2 Intended use..............................................................8

2.3 Intended operating area and conditions.....................8

2.4 Design........................................................................8

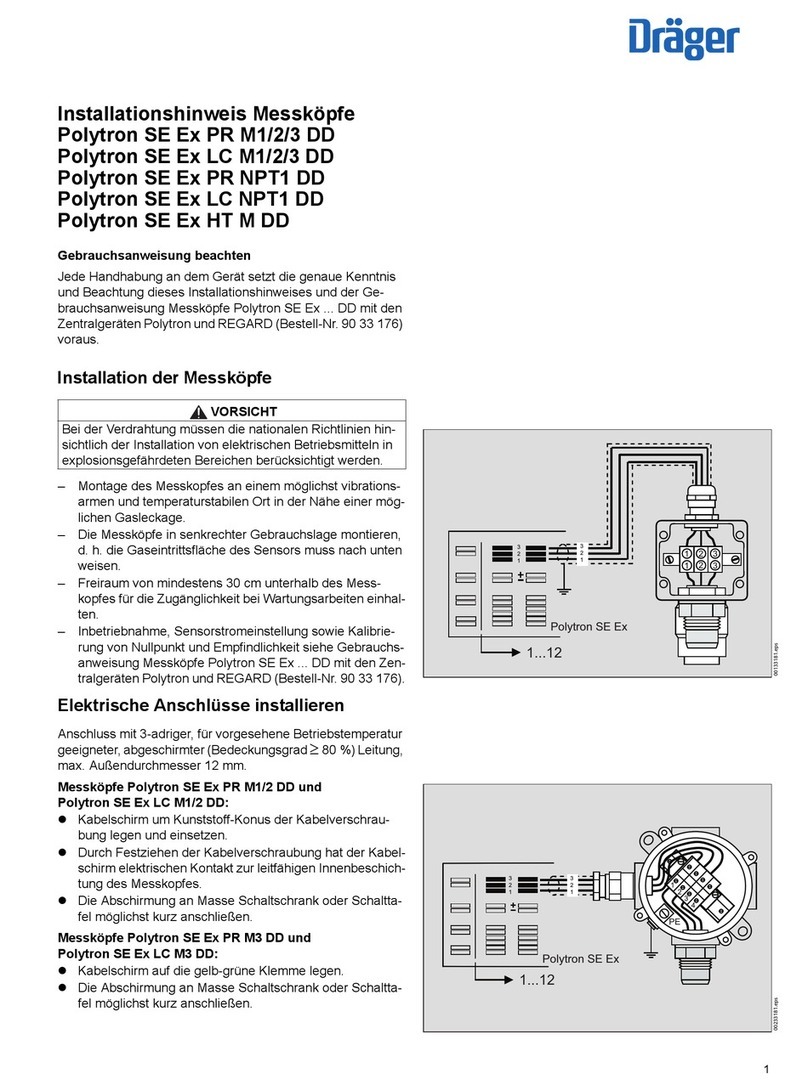

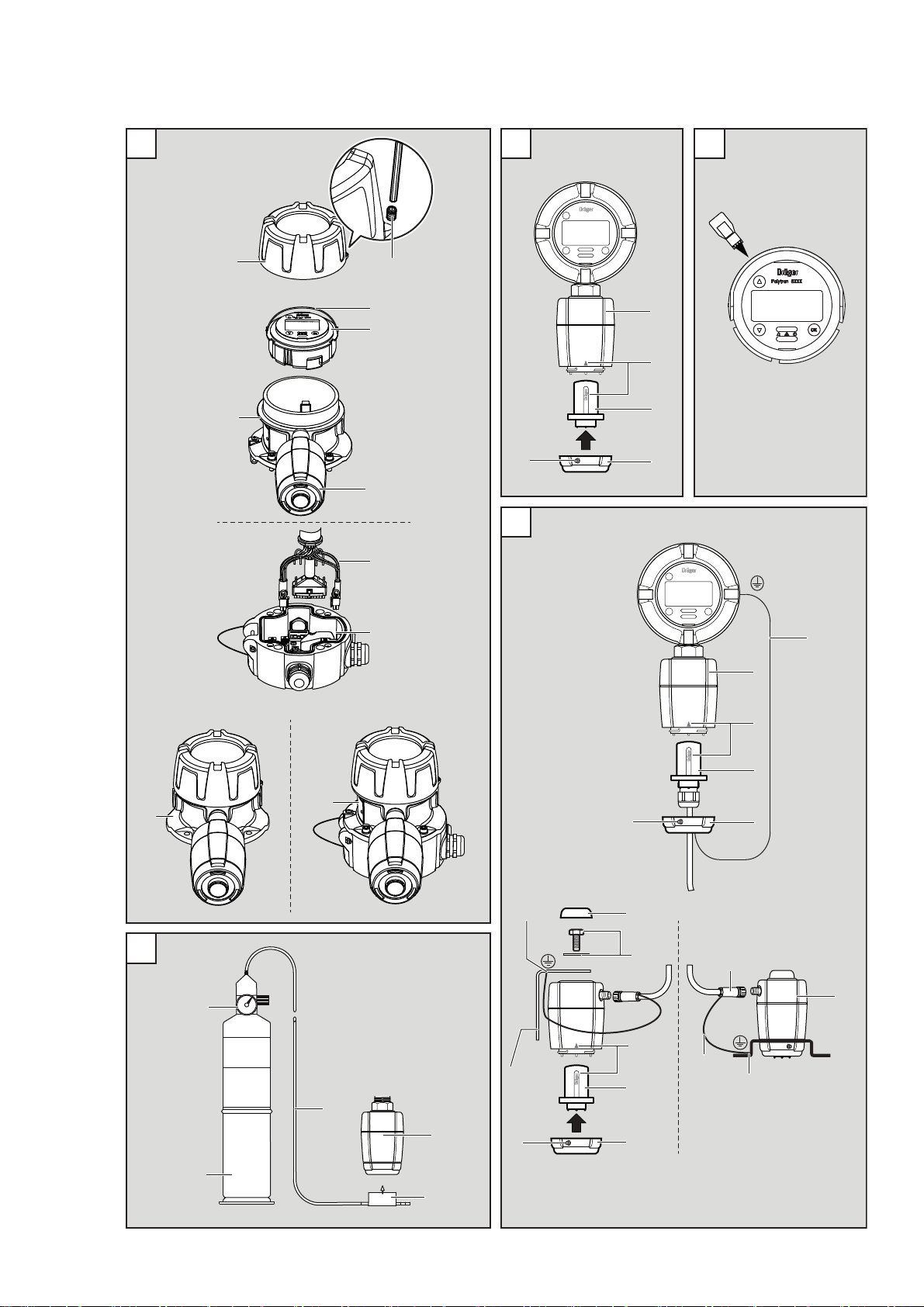

3 Installation................................................................9

3.1 General information for installation ............................9

3.2 Installation restrictions ...............................................9

3.3 Impedance of signal loop.........................................10

3.4 Mechanical installation.............................................10

3.5 Electrical installation without Docking Station..........10

3.5.1 Electrical connection for 4-20 mA/HART interface...10

3.5.2 Electrical connection for fieldbus interface...............10

3.5.3 Relay option.............................................................11

3.6 Electrical installation with Docking Station...............11

3.6.1 Field wiring...............................................................11

3.7 Installing sensor.......................................................12

3.8 Installation of EC sensing head remote...................12

3.8.1 Wall or pipe mounting kit..........................................12

3.8.2 Installing sensor.......................................................12

3.9 Connecting the EC sensing head remote to ...............

Polytron 8100 .......................................................................12

3.10 Connecting the instrument to a controller

from Dräger..............................................................12

3.11 Connecting the instrument to a PC..........................12

3.12 Dräger PolySoft PC software (optional)...................12

3.13 Installing software dongles.......................................13

4 Operation................................................................13

4.1 Normal operation .....................................................13

4.1.1 Analog signals..........................................................13

4.2 The display and LEDs..............................................14

4.2.1 Measuring mode ......................................................14

4.2.2 Special states...........................................................14

4.2.3 The LED symbols.....................................................14

4.2.4 Status indicators in the display ................................14

4.3 Activating the Info mode ..........................................15

4.4 Activating the Quick Menu.......................................15

4.5 Menu navigation.......................................................15

4.5.1 Password .................................................................16

4.5.2 Graphic symbols ......................................................16

4.5.3 Changing parameter values or statuses ..................16

4.5.4 Exiting the menu ......................................................16

5 Menu........................................................................16

5.1 Menu overview.........................................................17

5.2 Information instrument .............................................18

5.2.1 Warning messages ..................................................18

5.2.2 Fault messages........................................................18

5.2.3 Installed modules.....................................................18

5.3 Information sensor ...................................................18

5.3.1 Display last calibration date.....................................18

5.3.2 Display next calibration due date.............................18

5.3.3 Vitality ......................................................................18

5.3.4 Sensor temperature .................................................18

5.4 Information data-logger........................................... 18

5.4.1 Display the data-logger status................................. 18

5.4.2 Display graph .......................................................... 18

5.5 Calibration............................................................... 18

5.5.1 Zero calibration ....................................................... 18

5.5.2 Span calibration ...................................................... 18

5.5.3 Auto calibration ....................................................... 18

5.6 Settings SIL activation............................................. 19

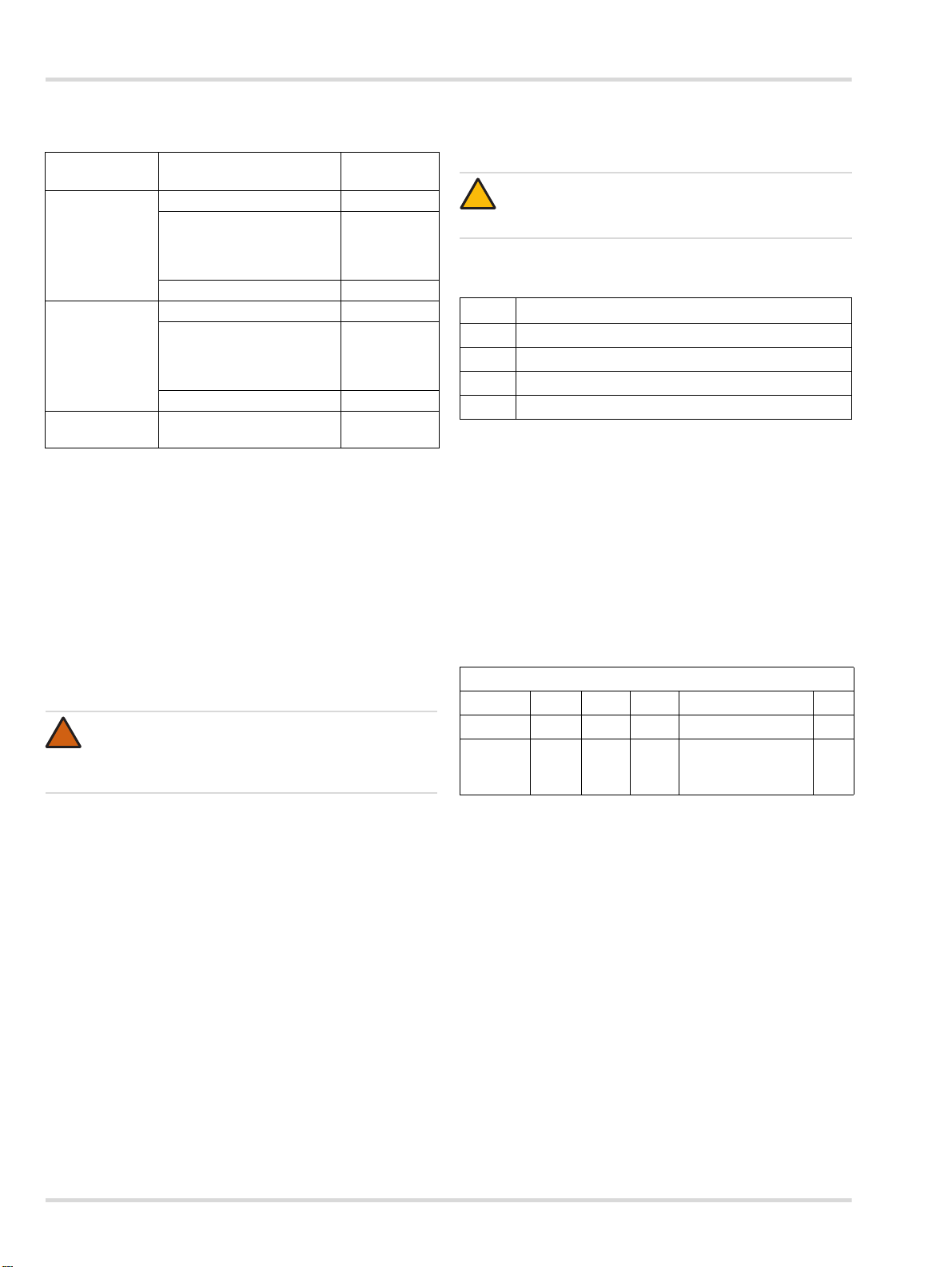

5.7 Combinations of acknowledgments, latching and

the corresponding relay/ LED status....................... 19

5.7.1 Acknowledgments and latching............................... 19

5.7.2 LED status:.............................................................. 19

5.7.3 Combinations with corresponding LED and

relay status:............................................................. 20

5.8 Settings instrument ................................................. 21

5.8.1 Alarm settings ......................................................... 21

5.8.2 Passwords............................................................... 22

5.8.3 Date and time.......................................................... 22

5.8.4 Language................................................................ 22

5.8.5 Function key............................................................ 23

5.8.6 Device initialization.................................................. 23

5.8.7 Bump test................................................................ 23

5.8.8 Software dongle ...................................................... 23

5.8.9 Display settings....................................................... 23

5.9 Settings communication.......................................... 24

5.9.1 HART interface........................................................ 24

5.9.2 Analog interface ...................................................... 24

5.9.3 Modbus ................................................................... 26

5.9.4 Profibus address ..................................................... 26

5.10 Settings sensor ....................................................... 27

5.10.1 Sensor change........................................................ 27

5.10.2 Auto CAL................................................................. 27

5.10.3 Sensor test.............................................................. 27

5.10.4 Sensor lock ............................................................. 27

5.10.5 Sensor type............................................................. 27

5.10.6 Gas settings ............................................................ 28

5.10.7 Reset sensor........................................................... 28

5.10.8 Calibration interval .................................................. 28

5.10.9 Set sensor test ........................................................ 28

5.10.10Fast response ......................................................... 28

5.10.11Display capture ....................................................... 28

5.11 Data-logger ............................................................. 29

5.11.1 Data-logger on or off ............................................... 29

5.11.2 Set data-logger........................................................ 29

5.11.3 Clear data-logger .................................................... 29

6 Maintenance .......................................................... 30

6.1 Maintenance intervals ............................................. 30

6.1.1 During commissioning............................................. 30

6.1.2 Every 6 months....................................................... 30

6.1.3 Change sensor on demand..................................... 30

6.2 Calibration............................................................... 30

6.2.1 Zero Calibration....................................................... 31

6.2.2 Span calibration ...................................................... 31

6.2.3 Auto Calibration....................................................... 32

6.3 Troubleshooting ...................................................... 33

6.3.1 Fault reference........................................................ 33