3720092 (A3-D-P) 2 / 3

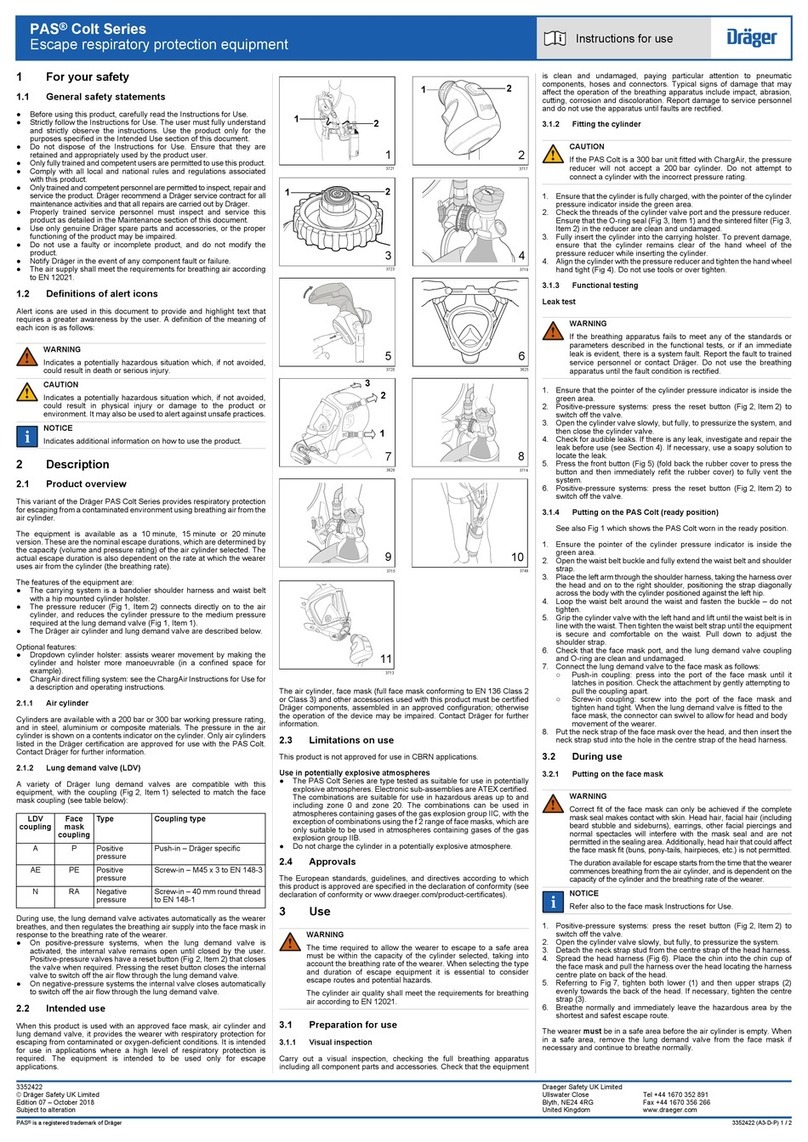

PAS® Colt P18

Combination escape SCBA/airline SAR respiratory protection equipment Instructions for use

ready position until an escape is necessary. Depending on the intended

use, refer to the relevant procedures from the following:

● For combination (escape/airline) use, see Section 3.2.1

● For escape use only, see Section 3.2.2

3.2.1 Combination (escape/airline) use

Putting on the face mask

1. Press the reset button (Fig 1, Item 1) of the lung demand valve to

switch off the positive pressure.

2. Connect the independent air supply to the male coupling (Fig 2,

Item 3). If the independent air supply has a shut-off valve, open the

valve.

WARNING

Correct fit of the face mask can only be achieved if the complete face mask

seal makes contact with skin. Head hair, facial hair (including beard stubble

and sideburns), earrings, other facial piercings and normal spectacles will

interfere with the face mask seal and are not permitted in the sealing area.

Additionally, head hair that could affect the face mask fit (buns, pony-tails,

hairpieces, etc.) is not permitted.

NOTICE

Refer also to the face mask instructions for use.

3. Spread the head harness (Fig 5). Place the chin into the chin cup of

the face mask and pull the harness over the head locating the harness

center plate on back of the head.

4. Referring to Fig 6, tighten both lower (1) and then upper straps (2)

evenly towards back of the head. The wearer’s first inhalation after

achieving a face seal will automatically switch on the air supply into the

face mask.

5. Check that the head has a full range of movement without pulling

against the regulator hose. If any resistance to movement is felt,

readjust the hose routing and then recheck. If resistance is still felt, do

not use the breathing apparatus and contact Dräger.

Function check

1. Isolate the independent air supply (close the valve or disconnect) and

breathe normally to empty the system of air. When empty, the face

mask should hold on to the face to indicate a positive seal.

2. Immediately reapply the independent air supply and breathe normally.

3. Inhale and hold your breath – there should be no audible leak. If a leak

is detected, readjust the head harness and retest.

4. Recommence breathing – exhaled air should flow easily out of the

exhalation valve.

5. Momentarily press the purge button (Fig 1, Item 2) to check for

additional airflow.

When the function check has been satisfactorily completed, breathe

normally and proceed to the working area.

Escape procedure (independent air supply failure)

WARNING

During supplied airline respirator (SAR) use, the PAS® Colt cylinder valve

must remain closed. The escape duration starts from the time of opening

the cylinder valve and disconnecting the airline supply.

Dräger strongly advise that the purge button (Fig 1, Item 2) is not used

during an escape. Using the purge button would use air from the cylinder

and reduce the time available for escape.

NOTICE

If the PAS® Colt is fitted with a low-pressure whistle, during airline use the

whistle sounds to indicate that the independent air supply has fallen below

the required pressure. If the whistle sounds and then stops before the

escape procedure is started, the air supply pressure could have been

restored. The wearer must confirm that the correct pressure (87 to

125 psi) is available, or escape as described below.

If the independent air supply fails, breathe normally and immediately

proceed as follows:

1. Open the cylinder valve (counterclockwise) slowly, but fully, and

continue to breathe normally.

2. Disconnect the independent air supply from the PAS® Colt.

3. Immediately leave the hazardous area by the shortest and safest

escape route.

The wearer must be in a safe area before the air cylinder is empty. When

in a safe area, remove the lung demand valve from the face mask if

necessary and continue to breathe normally.

NOTICE

If the PAS® Colt is fitted with a low-pressure whistle, during an escape the

whistle would sound when the cylinder pressure was in the range 72.5 to

58 psi. This is not an end-of-service-time-indicator (EOSTI).

3.2.2 Escape use only (putting on the face mask and escaping)

WARNING

Correct fit of the face mask can only be achieved if the complete face mask

seal makes contact with skin. Head hair, facial hair (including beard stubble

and sideburns), earrings, other facial piercings and normal spectacles will

interfere with the face mask seal and are not permitted in the sealing area.

Additionally, head hair that could affect the face mask fit (buns, pony-tails,

hairpieces, etc.) is not permitted.

NOTICE

Refer also to the face mask instructions for use.

1. Press the reset button (Fig 1, Item 1) of the lung demand valve to

switch off the positive pressure.

2. Open the cylinder valve (counterclockwise) slowly, but fully, to

pressurize the system.

3. Spread the head harness (Fig 5). Place the chin into the chin cup of

the face mask and pull the harness over the head locating the harness

center plate on back of the head.

4. Referring to Fig 6, tighten both lower (1) and then upper straps (2)

evenly towards back of the head. The wearer’s first inhalation after

achieving a face seal will automatically switch on the air supply into the

face mask.

WARNING

The duration of the cylinder air begins from the time of the first-breath

activation of the lung demand valve.

Dräger strongly advise against using the purge button (Fig 1, Item 2) or

the front button (Fig 1, Item 3) during an escape. Using either button

would use air from the cylinder and reduce the time available for escape.

5. Immediately leave the hazardous area by the shortest and safest

escape route.

The wearer must be in a safe area before the air cylinder is empty. When

in a safe area, remove the lung demand valve from the face mask if

necessary and continue to breathe normally.

3.2.3 Drop-down cylinder holster

To release the drop-down cylinder holster:

a. Hold the cylinder valve with the left hand and, with the right hand,

press and hold the red button to open the locking

mechanism (Fig 7).

b. Lift the cylinder and holster clear of the locking mechanism and

then release the red button (Fig 8).

c. Lower the cylinder until it is supported by the harness

straps (Fig 9). The holster is held by two harness straps, one fixed

and one adjustable.

d. Hold the cylinder valve to move the cylinder and holster as

required.

To reconnect the drop-down cylinder holster, align and press the roller on

the holster into the locking mechanism.

3.3 After use

WARNING

Do not remove the equipment until in safe area, clear of hazard.

CAUTION

Do not drop or throw down equipment as damage could occur.

1. Loosen the face mask straps. As the seal between the face mask and

the face is broken, press the reset button (Fig 1, Item 1) to switch off

the positive pressure. Remove the face mask and fully extend all of the

straps of the head harness.

○ After airline use – isolate and disconnect the independent air

supply from the PAS® Colt. Refit the cap on to the airline

connector.

○ After an escape – close the cylinder valve.

2. Press the purge button (Fig 1, Item 2) to fully vent the system.

3. Remove the lung demand valve from the face mask and stow it in the

holder (Fig 2, Item 1).

4. Unbuckle the waist belt, lift the shoulder strap buckle to loosen the

harness and then remove the equipment.

5. Carry out the after use maintenance tasks in the maintenance table

(see Section 5.1).

4 Troubleshooting

The troubleshooting guide shows fault diagnosis and repair information

applicable to breathing apparatus users. Further troubleshooting and

repair information is available in instructions for use supplied with

associated equipment (e.g. face mask).

Contact service personnel or Dräger when the remedy information

indicates a service task, or if the symptom remains after all remedy actions

have been attempted.

5 Maintenance

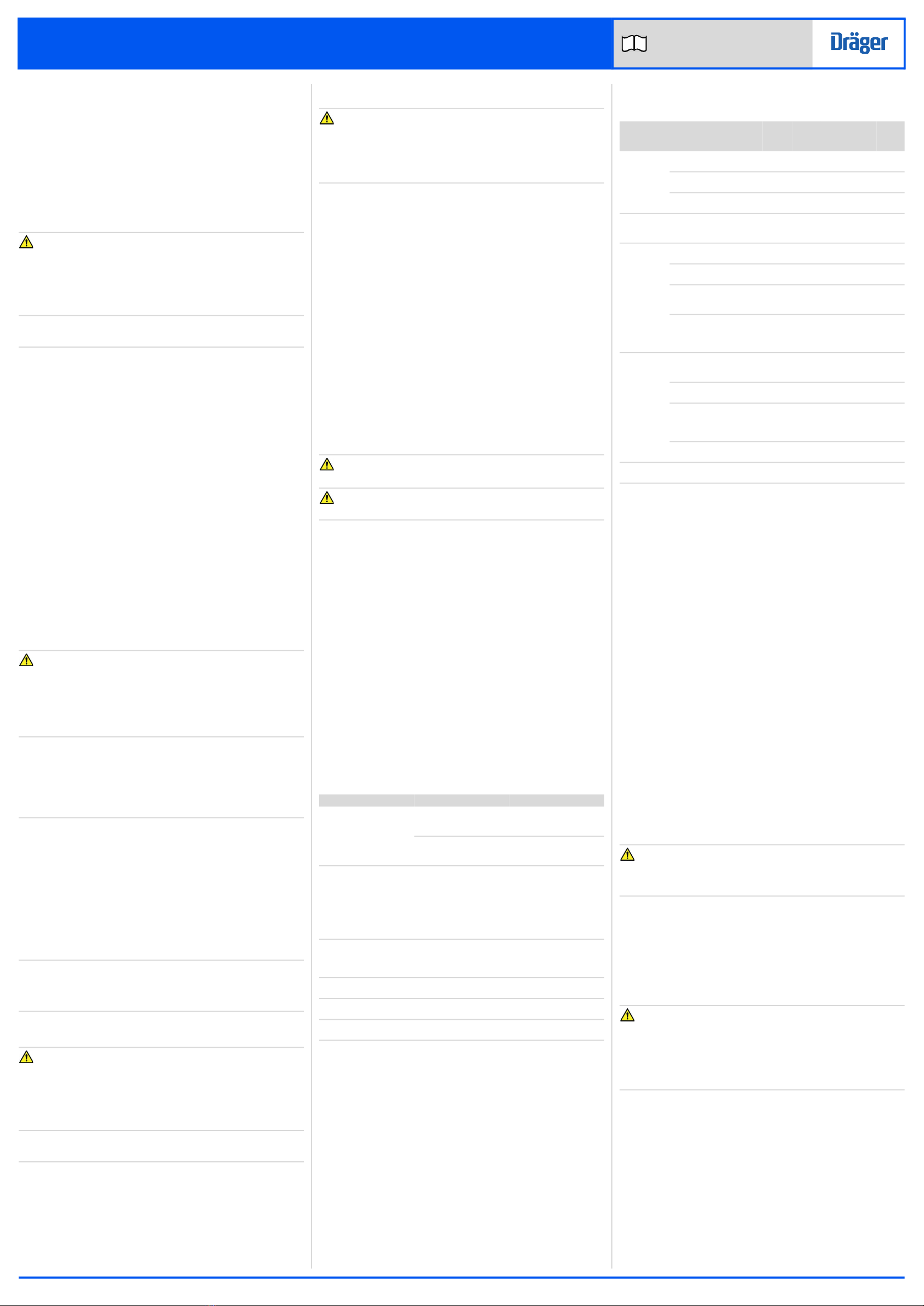

5.1 Maintenance table

Service and test the breathing apparatus, including out-of-use apparatus,

in accordance with the maintenance table. Record all service details and

testing. Refer also to the instructions for use for the lung demand valve,

face mask and other associated equipment.

Additional inspection and testing may be required in the country of use to

ensure compliance with national regulations.

Symptom Fault Remedy

High-pressure air leak or

failed leak test

Loose or dirty connector Disconnect, clean and

reconnect couplings and

retest

Faulty hose or component Substitute user

replaceable accessories

and retest

Air leak from lung demand

valve

Ice particles on sealing

elements

Press the front button

(Fig 1, Item 3) to allow a

rush of air to pass through

the lung demand valve and

then quickly press the

reset button (Fig 1 Item 1)

to switch off the positive

pressure.

Air leak from medium-

pressure hose connection

at the first-stage regulator

(safety relief valve)

Faulty O-ring, retainer,

spring or first-stage

regulator

Service task

High or low medium

pressure

First-stage regulator fault Service task

Poor sounding whistle (if

fitted)

Whistle dirty Clean whistle flute and

retest

Whistle not functioning

correctly (if fitted)

Activation mechanism fault Service task

Daily check – If the PAS® Colt is held in a ready-for-use condition, check

daily that the pointer of the cylinder pressure indicator is inside the green

area. Charge the cylinder if it is in the red area (see Section 5.2.2).

5.2 Maintenance tasks

5.2.1 Removing the cylinder

WARNING

High-pressure air release may cause injury to the user or other personnel

near the breathing apparatus. Close the cylinder valve and fully vent the

system before attempting to disconnect an air cylinder.

1. Close the cylinder valve and press the purge button (Fig 1, Item 2) to

fully vent the system.

2. Remove the anti-vibration strap from the cylinder valve (Fig 4).

3. Disconnect the cylinder valve from the first-stage regulator.

4. Carefully remove the cylinder from the holster. To prevent damage,

ensure that the hand wheel of the first-stage regulator remains clear of

the cylinder.

5.2.2 Air cylinder charging

WARNING

Air quality for compressed-air cylinders must conform to the minimum

grade requirements for Type 1 gaseous air as defined in CGA (Commodity

Specification for Air) G-7.1 Grade D or higher quality.

If the breathing air moisture content exceeds recommended levels, ice

particles can form, reducing or blocking airflow. Water content of the

breathing air in any container must be checked.

● Refer also to the instructions supplied with the cylinder and the

charging unit for recharging the cylinder.

● Only charge compressed-air cylinders which: conform to national

standards, feature the original manufacturer’s test date and test mark,

have not exceeded the test date indicated on the cylinder by the last

testing station, and are not damaged.

● To prevent ingress of moisture into the cylinder, ensure that the

cylinder valve remains closed until connected to the charging unit.

● Recharge to the rated working pressure of the cylinder. Dräger

recommend a charge rate of 300 psi/minute. Rapid charging will

increase the temperature resulting in an incomplete charge. Recheck

at ambient temperature and top up the charge if required.

● To prevent overcharging of the cylinder, Dräger recommend using a

pressure-limiting device on the charging compressor.

Component/

System Task

Before

Use

After

use

Every

month

Every

year

Every

10

years

Complete

apparatus

Visual inspection (see

Note 1 and Section 3.1.1)

Notes

ODräger recommendations

1. Clean the equipment if it is dirty. If it the equipment has been exposed

to contaminants, disinfect any components that come into direct and

prolonged contact with the skin.

O O O

Functional testing

(see Section 3.1.3)

O O

Breathing cycle and static

tests (see Note 2)

2. These maintenance tasks may only be carried out by Dräger or trained

service personnel. Details of the tests are contained in the Technical

Manual which is issued to service personnel that have attended a

relevant Dräger maintenance course.

O

Lung

demand

valve

Check push-in type

connectors for lubricant

(see Note 3)

3. As a guide, lubricant should be felt on the fingers but not seen. If

relubrication is required, lightly apply Molykote®111 (other lubricants

are not tested and may damage the equipment).

O

First-stage

regulator

Medium-pressure check

(see Note 2)

O

Inspect the sintered filter

(see Note 2 and Note 4)

4. Replace the sintered filter if a drop in first-stage regulator performance

is observed during a flow check or if it is visibly damaged.

O

Inspect the high-pressure

connector O-ring (see

Note 2 and Note 5)

5. Replace the high-pressure connector O-ring if it is found to leak during

functional testing or if the O-ring is visibly damaged.

O

Overhaul. Contact Dräger

for the Repair Exchange

(REX) service (see

Note 6)

6. Where the breathing apparatus is subjected to a high level of use (in

training establishments etc.), reduce the overhaul period for the first-

stage regulator. In these circumstances, Dräger recommend that the

overhaul frequency should be less than 5,000 applications of use. An

application of use is defined as a single use of the fully assembled

breathing apparatus, where the user breathes from the air cylinder. It

does not include system pressurization for pre-operational checks.

O

Cylinder Charge cylinder to correct

working pressure (see

Section 5.2.2)

O

Check charged pressure

(stored cylinders only)

O

Check test date of cylinder

(carbon composite

cylinders over 15 years

old must be retired)

O

Recertification According to national regulations in the

country of use

Cylinder

valve

Overhaul At the time of cylinder recertification

Molykote® is a registered trademark of DDP Specialty Electronic Materials US 9, LLC