3356233 (A3-D-P) Page 3 of 4

PSS®7000 Series

Self contained breathing apparatus with Sentinel 7000 Instructions for Use

Carrying harness – Thorough cleaning

Do not immerse pneumatic or electronic components in cleaning

solutions or water.

Remove the harness from the carrying system and clean using one of the following

methods:

a. Clean manually in a bath containing recommended cleaning or disinfecting agents.

b. Machine wash (at 86 °F (30 °C)) using a suitable cleaning agent.

Rinse the harness thoroughly with clean water to remove all cleaning and disinfecting

agents.

Dry all components including internal parts.

Storage (Ready for Use)

Fully extend the shoulder straps, waist belt and head harness straps.

Store apparatus in a cool dry environment, free from dust and dirt (do not expose to

direct sunlight).

WhentheSCBAisstoredwiththecylindertted,theapparatusmustbesupportedby

the cylinder and not the backplate.

Remove the batteries if the equipment is not used for long periods (a small amount of

discharge occurs during storage).

Storage preparation

Extend the shoulder straps, waist belt and the straps of the face mask.

For storage, place the face mask in a protective bag (contact Dräger for supply of a

suitable bag).

Route rubber hoses in such a way that the bend radius is not too acute and the hose

is not stretched, compressed or twisted.

Withthesystemswitchedo,asmallamountofbatterypowerisconsumed.Ifthe

system is not to be used for a long period, remove the batteries.

Storage conditions

Store the equipment between 5 °F and 77 °F (-15 °C and +25 °C). Ensure that the

environment is dry, free from dust and dirt, and does not subject the equipment to wear

or damage due to abrasion. Do not store the equipment in direct sunlight.

Fix the breathing apparatus securely to any raised mounting point to prevent it from

falling.

Special instructions

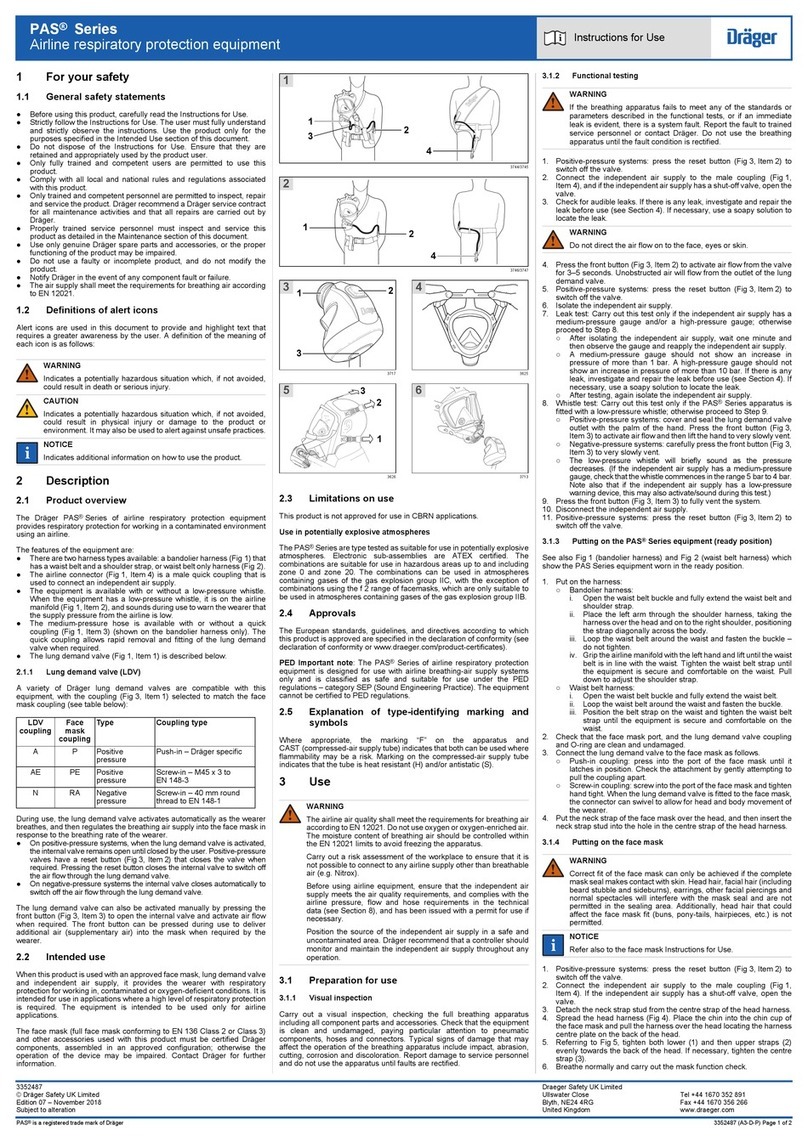

Use of an Independent Air Supply (SAR Airline Connection)

Air quality must conform to the statutory requirements.

Use of an airline connection by a second person (buddy-breather) voids

NIOSH approval.

The time required for the wearer to escape to a safe area must be within the

remaining breathing time of the cylinder, taking into account the remaining

air content in the cylinder and the breathing rate of the wearer.

Independent air supplies must meet the following standards:

Type-1gaseousairasdenedin:CGACommoditySpecicationforAir,G-71(grade

D or higher)

NFPA 1989 Standard on Breathing Air Quality for Fire and Emergency Services

Respiratory Protection

Air supply pressure – 87 psi to 125 psi

Airline hose length – 5 feet to 300 feet (maximum working hose length must not

exceed 12 individual hose lengths)

Airlineowrate–550liters/minute

Approved for use at temperatures above minus 25 degrees Fahrenheit (minus 31.7

degrees Centigrade).

Sentinel 7000 alarms and warning signals will operate as normal.

The user interface display will show cylinder pressure when the cylinder

valve is open.

Turn on the independent air supply.

Connect the independent air supply coupling to the secondary supply hose (refer to

instruction no. 3355853) and breathe normally.

Close the cylinder valve (if the EOST warning signal activates, silence by taking several

short deep breaths or momentarily operating the LDR bypass button (3, Fig 15).

If any air supply problems are encountered, proceed as follows:

Open the cylinder valve to return to breathing from the attached cylinder.

Disconnect the independent air supply coupling.

Leave the hazardous area by the shortest and safest escape route, if necessary.

Cautions and Limitations

D – Air-line respirators can be used only when the respirators are supplied with respirable

air meeting the requirements of CGA G – 7.1, Grade D or higher quality.

E–UseonlythepressurerangesandhoselengthsspeciedintheUser'sInstructions.

I–Containselectricalpartsthatmaycauseanignitioninammableorexplosiveatmospheres.

J – Failure to properly use and maintain this product could result in injury or death.

M–Allapprovedrespiratorsshallbeselected,tted,used,andmaintainedinaccordance

with MSHA, OSHA, and other applicable regulations.

N – Never substitute, modify, add, or omit parts. Use only exact replacement parts in the

congurationasspeciedbythemanufacturer.

O–RefertoUser'sInstructionsand/ormaintenancemanualsforinformationonuseand

maintenance of these respirators.

S–SpecialorcriticalUser'sInstructionsand/orspecicuselimitationsapply.Referto

User'sInstructionsbeforedonning.

CBRN Use

TheDrägerPSS®7000SeriesiscertiedbyNationalInstituteforOccupationalSafetyand

Health (NIOSH), for limited chemical, biological, radiological or nuclear (CBRN) use and by

the Safety Equipment Institute (SEI) to meet the requirements of NFPA 1981. Approvals are

only valid when the apparatus is used with compressed air cylinders approved by NIOSH.

EquipmentcongurationsforCBRNusearedetailedinaCBRNApprovalLabel(referto

instruction no. 3356226).

IfanFPSNFPALDR,Drägerrecommendthataquantitativettest(QNFT)beperformed

onthefacemaskbeforeuseinaCBRNenvironment.Thettestmustbeconducted

strictly in accordance with the requirements outlined in the OSHA Respiratory Protection

Standard 29 CFR, Section 1910.134.

Q – Use in conjunction with personal protective ensembles that provide appropriate levels

of protection against dermal hazards.

R–SomeCBRNagents maynot presentimmediateeectsfromexposure,but can

result in delayed impairment, illness or death.

T – Direct contact with CBRN agents requires proper handling of the SCBA after each

use and between multiple entries during the same use. Decontamination and disposal

procedures must be followed. If contaminated with liquid chemical warfare agents,

dispose of the SCBA after decontamination.

U – The respirator should not be used beyond 6 hours after initial exposure to chemical

warfare agents to avoid possibility of agent permeation.

!

i

i

After Use

Do not remove the SCBA until in a safe area. Do not drop or throw down

the SCBA as damage could occur.

Release and loosen all of the face mask straps.

Lift and remove the face mask.

Fully extend all of the straps of the head harness.

Close the cylinder valve.

Release the waist belt buckle. Lift the shoulder strap ends to release the strap

retainers (Fig 18) and then lift the shoulder strap buckles to loosen the straps.

Press the front button (2, Fig 15) of the LDR to vent system.

Presstheresetbutton(1)toswitchothepositivepressure.

If the LDR has been set to bypass, press and rotate the bypass button (3) to switch

othebypass.

Press and hold the RH and LH buttons of the user interface until the display clears,

then immediately release the buttons. After approximately 180 seconds, all six HUD

LEDswillashtwicetoindicatethattheunithasloggedo.

Carry out a visual inspection of the complete SCBA including any ancillary equipment

used during the operation.

If required, lightly lubricate the LDR O-ring (recommended lubricant is Molykote 111).

PasstheSCBAtotheservicedepartment,withdetailsofanyfaults/damagethat

occurred during use.

Removing the Cylinder

Do not attempt to remove the cylinder with the system pressurised.

Close the cylinder valve and fully vent the system.

Lift the free end of the cylinder strap from the Velcro fastening and lift the strap

against the cam-lock mechanism to release the strap tension. Loosen the strap.

Unscrewthehandwheeloftherst-stageregulatorfromcylindervalve.

Liftandcarefullyslidethecylinderawayfromrst-stageregulatortowardsthetopof

the backplate.

Remove the cylinder from the apparatus.

Inspect and recharge the cylinder (refer to Charging the Cylinder).

Charging the Cylinder

Air quality for compressed air cylinders must conform to the minimum

grade requirements for Type 1 gaseous air as dened in the CGA

Commodity Specication for Air, G-7.1 (Grade D or higher quality)

and where appropriate be in accordance with: NFPA 1989 Standard on

Breathing Air Quality for Emergency Services Respiratory Protection.

Recharge cylinders to the indicated working pressure marked on the

cylinder.

If the moisture content exceeds the recommended levels, ice particles

can form, reducing or blocking the airow.

Cleaning the SCBA

Cleaning agents and disinfectants listed below are not manufactured

by Dräger and have been reviewed only for compatibility when used to

clean or disinfect the subject Dräger product(s). Read and comply with

all instructions for use provided by the manufacturers of such agents

and disinfectants. Dräger expressly disclaims all responsibility for any

damage, personal injury or loss resulting from the use of such agents

or disinfectants.

Do not exceed 86 °F (30 °C) for washing, disinfecting and rinsing

solutions. Do not exceed 140 °F (60 °C) for drying, and remove

components from the drying facility immediately when dry. Drying time

in a heated dryer must not exceed 30 minutes.

Do not immerse pneumatic or electronic components in cleaning

solutions or water.

If water is trapped and then freezes inside the pneumatic system of the

breathing apparatus (such as the lung demand regulator), operation

will be impaired. Prevent any liquid from entering, and thoroughly dry

the breathing apparatus after cleaning to prevent this from occurring.

Refer also to the Instructions for Use for the lung demand regulator, face mask and other

associated equipment.

Manual cleaning of the breathing apparatus (USA)

Cleaning and disinfecting materials:

Cleaning agent – 1008 Green Liquid Hand Dish Wash

Disinfecting agent – 800 Spur-Tex Disinfectant Cleaner-deodorant (concentration: 1.6 %

(2ozpergallon))

Use only clean lint-free cloths

1. Prepare cleaning solution as per manufacturer’s instructions. Clean the breathing

apparatus manually using a cloth moistened with cleaning solution to remove excess

dirt.

2. Prepare disinfecting solution as per manufacturer’s instructions. Apply to all internal

and external surfaces, ensuring that all surfaces remain visibly wet for 15 minutes.

3. Rinse all components thoroughly with clean water to remove all cleaning and disinfecting

agents.

4. Dry all components using a dry cloth, in a heated dryer or in air.

5. Contact service personnel or Dräger if disassembly of pneumatic or electronic

components is required.

Manual cleaning of the breathing apparatus (Canada)

Cleaning and disinfecting materials:

Cleaning agent – mild soap solution

Disinfectingagent–NeutralDisinfectantCleaner(concentration:0.5%(0.5ozper

gallon or 15 ml per 3.785 liters))

Use only clean lint-free cloths

1. Prepare cleaning solution as per manufacturer’s instructions. Clean the breathing apparatus

manually using a cloth moistened with cleaning solution to remove excess dirt.

2. Prepare disinfecting solution as per manufacturer’s instructions. Apply to all internal

and external surfaces, ensuring that all surfaces remain visibly wet for 10 minutes.

3. Rinse all components thoroughly with clean water to remove all cleaning and disinfecting

agents.

4. Dry all components using a dry cloth, in a heated dryer or in air.

5. Contact service personnel or Dräger if disassembly of pneumatic or electronic

components is required.

!

!

!

!

S – Special or Critical Users’ Instructions

Approved for use at temperatures above minus 25 degrees Fahrenheit (minus 31.7

degrees Centigrade).

Whenusedasacombinationsupplied-airrespirator/self-containedbreathingapparatus

(SAR/SCBA),notmorethan20percentoftheairsupplycanbeusedduringentry.

During supplied air use, the cylinder valve must remain closed. If the supplied air fails,

open the cylinder valve and immediately proceed to fresh air.

Suppliedairsourcemustmeetthefollowingcriteria:pressure87–125psi,airowrate

atleast550liters/minute.

Important Note: If it is decided to exit the working area with the airline disconnected

or, in an emergency, if the air supply fails, breathe normally and immediately proceed

as follows:

Open the cylinder valve (counterclockwise) slowly, but fully and breathe normally.

Disconnect the hose of the independent air supply from the male coupling of the airline

hose connection. Breathe normally and immediately leave the hazardous area by the

shortest and safest route.

Safety Warning: The remaining duration begins from the time of opening the

cylinder valve and disconnecting the independent air supply. The time required to

allow the wearer to escape to a safe area must be within the remaining air capacity

(volume) of the cylinder taking into account the breathing rate of the wearer.

RIC UAC Use

Use of the RIC UAC should be by trained and competent personnel only.

TheRICUACllinghoseisarequiredcomponentoftheNFPA1981certication.

OnlyuseallinghosewhichhasbeencertiedtoNFPA1981foruseinimmediately

dangerous to life or health (IDLH) atmospheres.

Do not use the RIC UAC connection for second person (buddy-breather).

Do not use the RIC UAC support pack to transfer air from one compressed air

breathing apparatus to another.

Do not allow oil, grease or other contaminants to contact the RIC UAC connection.

Do not attempt to disassemble or repair the RIC UAC connection.

Caution: The secondary air supply pressure to the RIC UAC must not exceed

maximumratedworkingpressureofthecylinder(s)beinglled.

Caution: If the pressure relief valve of the RIC UAC is activated, the SCBA must be

returned to the nearest Dräger branch or agent.

Caution:Ifaleakisdetectedwhilerellinginacontaminatedoroxygen-decient

gaseousatmosphere,stoprellingandimmediatelyleavethehazardousarea.

Contact Details

Any issues with the equipment, including damage, malfunction, or failure of the

breathing apparatus that may present a hazard to the user should be reported to

Dräger US Customer Service – Phone: 1-800-437-2437.

Contactwiththecerticationorganisationsmaybereachedat:

NIOSH, NPPTL

Phone: 1-412-386-4000

SEI (NFPA)

1307 Dolley Madison Blvd

Suite 3A, McLean

VA 22101

Phone: 1-703-442-5732

Equipment Maintenance Procedures

TasksidentiedinTables2or3asmaintenancetasksaretobecarriedoutbytrained

and competent personnel only (authorised by Dräger). Refer to the maintenance manual

for further information.

Equipment servicing

Service and test the breathing apparatus, including out-of-use apparatus, in accordance

with the Table 2. Record all service details and testing. Refer also to the Instructions for

Use for the lung demand regulator, face mask and other associated equipment.

Additional inspection and testing may be required in the country of use to ensure

compliance with national regulations.