PAS®is a registered trademark of Dräger 3352435 (A3-D-P) Page 1 of 3

3352435

© Dräger Safety UK Limited

Edition 05 – November 2018

Subject to alteration

Draeger Safety UK Limited

Ullswater Close Tel +44 1670 352 891

Blyth, NE24 4RG Fax +44 1670 356 266

United Kingdom www.draeger.com

1 Approvals

The European standards, guidelines, and directives according to which

this product is approved are specified in the declaration of conformity (see

declaration of conformity or www.draeger.com/product-certificates).

2 For Your Safety

This variant of the Dräger PAS®Micro Series of equipment incorporates a

preset and sealed pressure reducer. The associated lung demand Valve

(LDV) has a preset and sealed balanced piston unit assembly. The Dräger

guarantee is void should original sealing caps of these units be tampered

with, removed, or broken. Correct operational condition is only valid if

Dräger service and re-seals the pressure reducer and balanced piston unit.

●Use of this equipment requires wearer training and observance of

these Instructions for Use.

●Use the equipment for the purpose specified in this instruction, or as

confirmed in writing by Dräger.

●Use and maintenance of this equipment requires knowledge and

compliance with National Regulations, Laws and Standards governing

the use of respiratory equipment in the country of use.

●Only trained competent personnel should inspect and service the

equipment at regular intervals and a record kept of such inspections

and service.

●Only trained and competent personnel should carry out the charging of

the compressed air cylinders.

●Dräger recommends a Service Contract be obtained from your Dräger

Branch or Agent.

●Contact Dräger for details of Service Contracts and Service Training

Courses.

●Use only original Dräger Spare Parts for service and maintenance.

●Use only original Dräger Test Equipment for service and maintenance.

●Notify Dräger if there is a component fault or failure.

3 Liability Statement

Terms and Conditions of warranty for the Dräger PAS®Micro Series of

equipment can be obtained from Dräger on request. Responsibility for

reliable function of the equipment transfers to the owner or operator when

serviced or repaired by untrained personnel, (not employed or authorised

by Dräger), or when used in a manner not conforming to its intended use.

4 Description and Intended Use

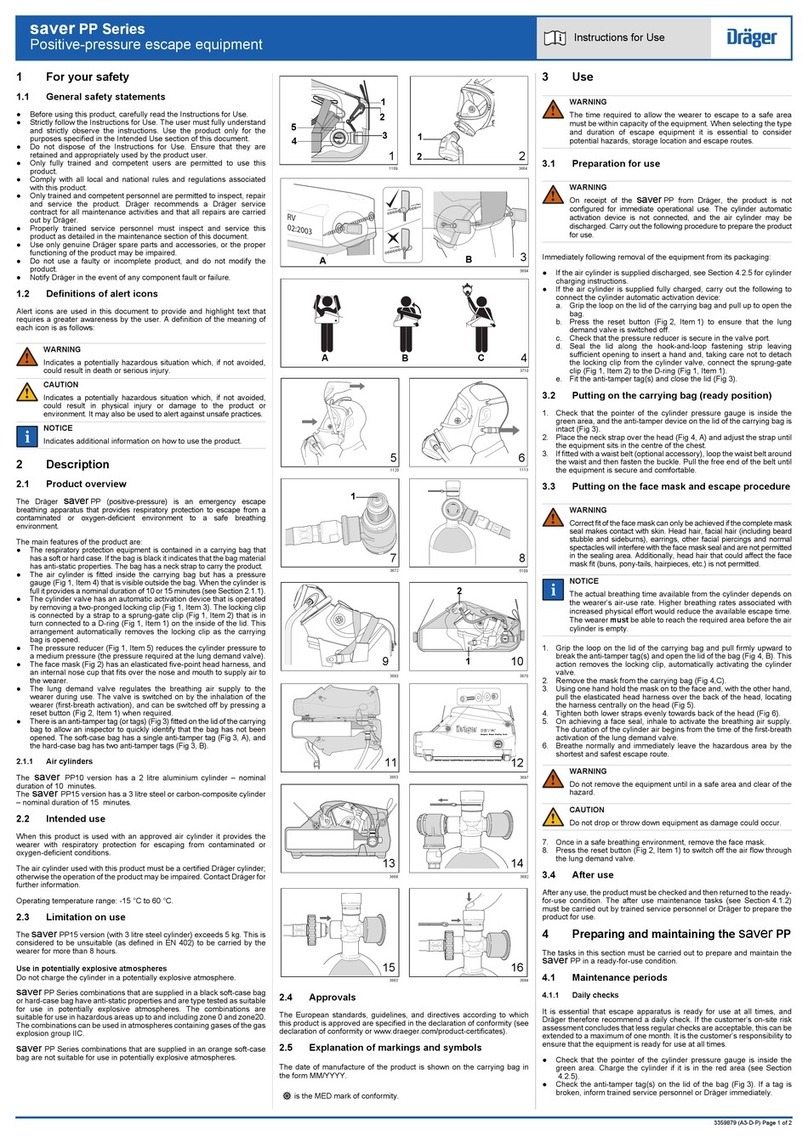

The Dräger PAS®Micro Series of Short Duration/Airline equipment

consists of:

●Back Carrying Harness with Cylinder Strap, Shoulder Straps and

Waist belt.

●Pressure Reducer with HP Gauge, Whistle Warning Unit (WWU) and

integral Lung Demand Valve (LDV).

Alternatively:

●Pressure Reducer with HP Gauge, Whistle Warning Unit (WWU) and

medium pressure hose with Quick Release Coupling (QRC).

●Airline Manifold Connection.

●Valved Cylinder Assembly.

The equipment is available in either 10 minute or 15 minute nominal

duration versions.

This series of equipment is compatible with a range of lung demand valves,

face mask and compressed air cylinders. When used in approved carrying

system, valved cylinder assembly, LDV and face mask combinations, the

equipment provides the wearer with respiratory protection when working in

a contaminated or oxygen deficient gaseous atmosphere.

The effective duration of the equipment is dependant on the capacity

(volume) of the cylinder selected and the breathing rate of the wearer.

Details of the equipment variants, accessories, and any approved

independent air supply source configurations are available from Dräger on

request.

5 Technical Data

5.1 High Pressure Connections

Standard G5/8 as per EN 144-2.

200bar or 300bar

Other connections are available to national standards.

5.2 Whistle Setting

Preset by Dräger to 55bar +/-5bar

(60bar to 50bar)

5.3 LDV to Face mask Connection

Three variants of integral LDV are available:

●Push-In Type A - Positive Pressure (PP).

●Screw-In Type AE - Positive Pressure (PP).

●Screw-In Type N – Normal Demand (ND).

Refer to the Instructions for Use supplied with the face mask.

5.4 Compressed Air Cylinders

Cylinders are available in either steel, or composite materials. Contact

Dräger for details.

Cylinders supplied by Dräger are charged at an ambient temperature of

15o C and to the nominal cylinder pressure.

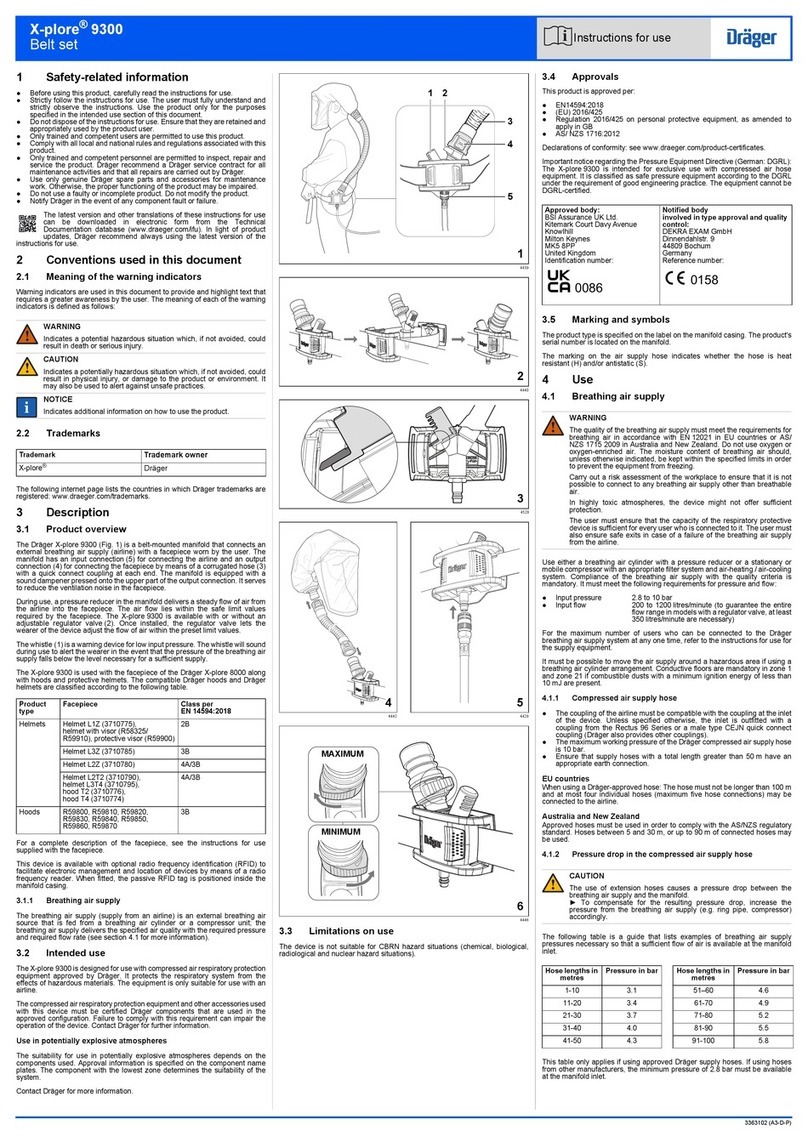

5.5 Airline Manifold Connection

A Male Coupling is incorporated on the airline manifold for the connection

of a hose coupling from an independent air supply.

5.6 Airline Operating Pressures and Flow

The selected low pressure independent air supply must meet the following

parameters.

●One User – 6bar to 10bar - airflow rate of at least 550 Litres/minute.

●Two Users – 7bar to 10bar - airflow rate of at least 550 Litres/minute.

Safety Warning: Air quality for compressed air breathing systems

must conform to the requirements of EN12021. Do Not use oxygen or

oxygen enriched air.

6 Preparation for Use

A trained and competent person must perform the following checks and

preparation procedures before release of the equipment to a potential

wearer for operational use.

6.1 Visual Inspection

Check the integrity of,

●Back Carrying Harness with Cylinder Strap, Shoulder Straps and

Waist belt.

●Pressure Reducer with HP Gauge, Whistle Warning Unit (WWU) and

integral Lung Demand Valve (LDV).

Alternatively:

●Pressure Reducer with HP Gauge, Whistle Warning Unit (WWU) and

medium pressure hose with Quick Release Coupling (QRC).

●Airline Manifold Connection and Hose.

●LDV – refer to the relevant Instructions for Use.

●Face mask – refer to the relevant Instructions for Use.

●Valved Cylinder Assembly.

6.2 Fitting Cylinder

●Place the Carrying Harness on a clean flat surface. Extend the cylinder

strap, shoulder straps and waist belt.

●Refer to Fig. 1. Slide the fully pressurised cylinder through the strap

locating the valve port to the reducer hand wheel.

Caution: To prevent damage, ensure that the hand wheel of the

pressure reducer remains clear of the cylinder.

●Align the cylinder centrally with the Carrying Harness and then screw

the hand wheel of the pressure reducer (clockwise) to the port of the

valve. Do Not tighten.

●Take up the slack on the cylinder strap to tighten around the cylinder

and then pull the strap through the buckle to secure. Insert loose end

of strap into the guide loop. Finally tighten the hand wheel – hand tight.

Do Not use tools.

6.3 Connecting LDV to QRC

This instruction refers to equipment with medium pressure hose with Quick

Release Coupling (QRC).

●Insert the male coupling of the LDV into the female coupling (QRC) of

the equipment medium pressure hose. Check the security of the

connection. Refer also to the Instructions for Use provided with the

LDV.

Important Note: The following test will verify the integrity of the

complete assembly. The pressure leak test described should also be

carried out following the reassembly of any of the component parts

of the pneumatic assembly (spares etc.).

6.4 HP Leak and WWU Test

●Type PP LDV’s - Press the reset button of the LDV to switch ‘Off’

positive pressure.

●Open the cylinder valve slowly, but fully, to pressurise the system then

‘Close’ the valve and observe the gauge.

Test Parameter – Indicated pressure on gauge should not decrease more

than 10bar in 1 minute.

●Proceed to test the whistle warning unit.

●Type PP LDV’s – Cover and seal the outlet of the LDV with the ball of

the hand. Press carefully the centre of the rubber cover then lift the

hand to slowly vent pressure.

Type N – Carefully press the centre of the rubber cover to and slowly

vent pressure.

●Observe the gauge during venting. The whistle should sound at the

preset pressure of 55bar +/- 5bar.

●Type PP LDV’s - Press the reset button of the LDV to switch ‘Off’

positive pressure.

●Should the whistle not sound at the preset pressure, refer to Dräger

Service.

6.5 Leak Test and LP Flow Test - Airline Connection

Refer to Technical Data.

Important Note: If using a works airline to perform the following tests,

then connect the isolation valve (3353449) to the female coupling of

the airline outlet.

●Connect the male coupling (1) Fig. 4 to the female QRC of the

independent air supply.

●Type PP LDV’s - Press the reset button of the LDV to switch ‘Off’

positive pressure.

●‘Open’ the valve of the independent air supply to pressurise the

system.

Test Parameter - Check for no audible leak.

●‘Open’ the cylinder valve of the breathing equipment to pressurise the

system, then disconnect the male coupling (1) Fig. 3 from the female

QRC of the hose from the independent air supply.

Test Parameter - Non-return valve check - Check for no audible leak from

the female QRC.

●‘Close’ the cylinder valve of the breathing equipment, then re-connect

the male coupling (1) Fig. 3 to the female QRC of the independent air

supply.

●Firmly press the centre of the rubber cover of the LDV to activate the

airflow from the LDV. See Safety Warning.

Safety Warning: Do Not direct the airflow onto the face, eyes or skin.

Test Parameters – An unobstructed airflow should vent from the outlet of

the LDV. This test should take a minimum of 3 to 5 seconds.

●‘Close’ the valve of the independent air supply and observe the LP

gauge, or the HP gauge, if fitted.

6.6 Test Parameters

LP Gauge - Indicated pressure should not decrease more than 1bar in

1 minute.

HP Gauge - Indicated pressure should not decrease more than 10bar in

1 minute.

●Disconnect the male coupling (1) Fig. 3 from the female QRC of the

independent air supply. Press carefully the centre of the rubber cover

of the LDV to vent pressure.

●Type PP LDV’s - Press the reset button of the LDV to switch ‘Off’

positive pressure.

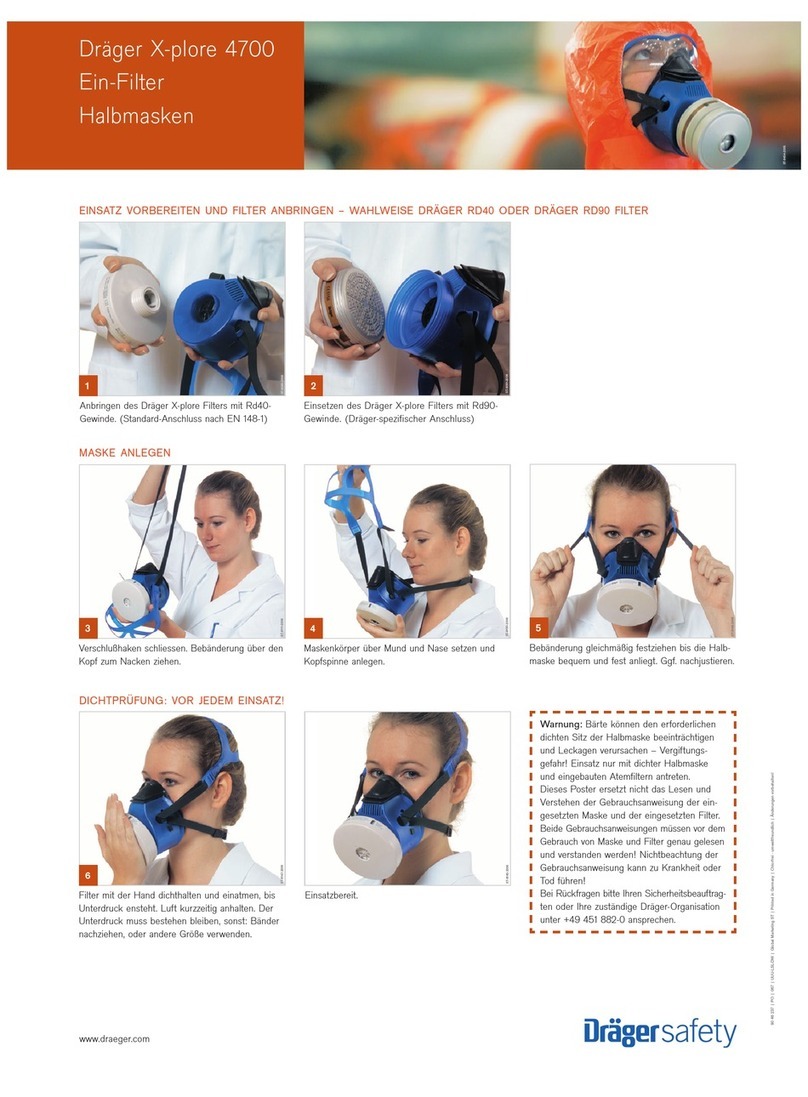

6.7 Fitting LDV to Face mask

●Inspect the face mask as defined in the relevant Instructions for Use.

●Fully extend (open) the straps of the head harness.

Type A

●Check that the face mask port and the connector O ring of the LDV are

clean and undamaged.

●Push the connector of the LDV into the port of the face mask until it

‘clicks’ in position.

●Check that the attachment is secure by pulling the LDV away from the

face mask – there should be no axial movement.

Types AE and N

●Check that the face mask port and sealing ring are clean and

undamaged.

●Screw the hand wheel of the LDV into the port of the face mask, align

the LDV as shown in Fig. 2 then finally tighten.

●Having ‘passed’ the test, and the LDV fitted to the face mask, the

equipment is now available for use.

7 Use

7.1 Putting on equipment

●Extend the shoulder straps. Open the buckle of the waist belt and

extend the straps.

●While supporting the face mask, put on the equipment taking the

weight on the shoulders by pulling evenly on the shoulder adjusting

straps. Put the neck strap of the face mask over the neck then insert

the neck strap stud into the hole in the centre strap of the head

harness. Face mask is now in the ready position.

●Loop the waist belt around the waist and fasten the buckle. Pull the

ends of the waist belt strap until secure and comfortable. Do Not

overtighten. Make any final adjustment necessary to the shoulder

adjusting straps.

Figure 3 shows the correct wearing position.

7.2 Pre Operational Checks

●Type PP LDV’s - Press the reset button of the LDV to switch ‘Off’

positive pressure.

●‘Open’ the cylinder valve.

Note: Refer to Instructions for Use provided with the Face mask.

Safety Warning: Facial hair, beard stubble, side-whiskers, and the

wearing of spectacles will adversely affect and interfere with face

mask seal. Correct fit of face mask only ensured if face mask seal

makes close contact with skin.

●Detach the neck strap stud from the centre strap of the head harness.

●Spread the head harness (Fig. 4), place chin into the face mask then

position the harness over the head, locating the centre plate with the

back of the head.

●Tighten both lower (1), then upper straps (2) evenly towards back of

head. Fig. 5. Tighten the centre strap (3) only if necessary.