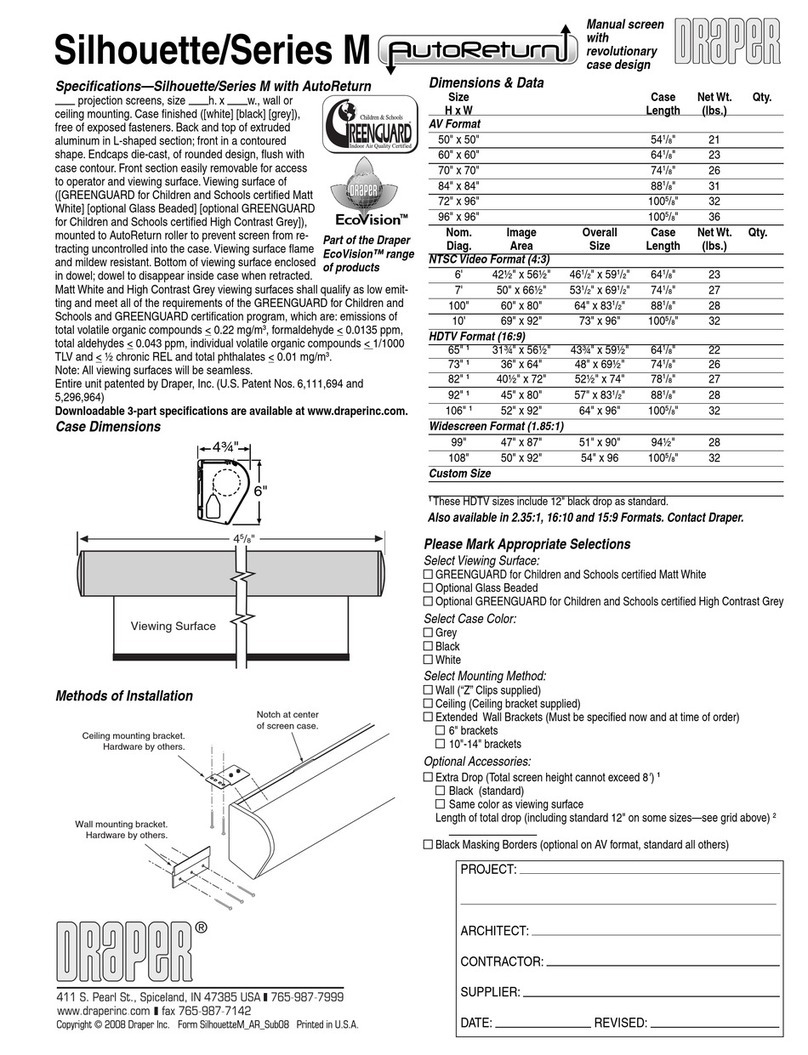

Copyright © 2002 Draper, Inc. Form ArtisanEV_Inst02 Printed in U.S.A.

Installation/Operating Instructions

Artisan/Series E & V Electric Projection Screen by Draper

Caution

➀Read instructions through completely before proceeding.

➁Follow instructions carefully. Installation contrary to instructions

invalidates warranty.

➂Screen should be accessible for complete removal should fabric become

damaged or should other service be required.

➃Screen should be installed level (using a carpenter’s level).

➄Nothing should be fastened to screen dowel or viewing surface.

➅Operating switch(es) packed separately in screen carton. Do not discard

with packing material.

➆Screen operates on 110-120v, 60 Hz. current.

NOTE: Screen has been thoroughly inspected and tested at factory and

found to be operating properly prior to shipment.

Hanging Screen

General:

When locating viewing surface and checking clearance for screen’s operation,

remember surface is centered in case.

Take care to install wall/ceiling electrical box and conduit so they will be fully

concealed by the screen case after installation.

The Artisan’s furniture-quality case should always be handled carefully to

avoid scratching and protect its finish.

Regardless of mounting method, screen should be positively and securely

supported so that vibration or even abusive pulling on the viewing surface will

not cause case to work loose or fall. Installer must insure that fasteners used

are of adequate strength and suitable for the mounting surface chosen.

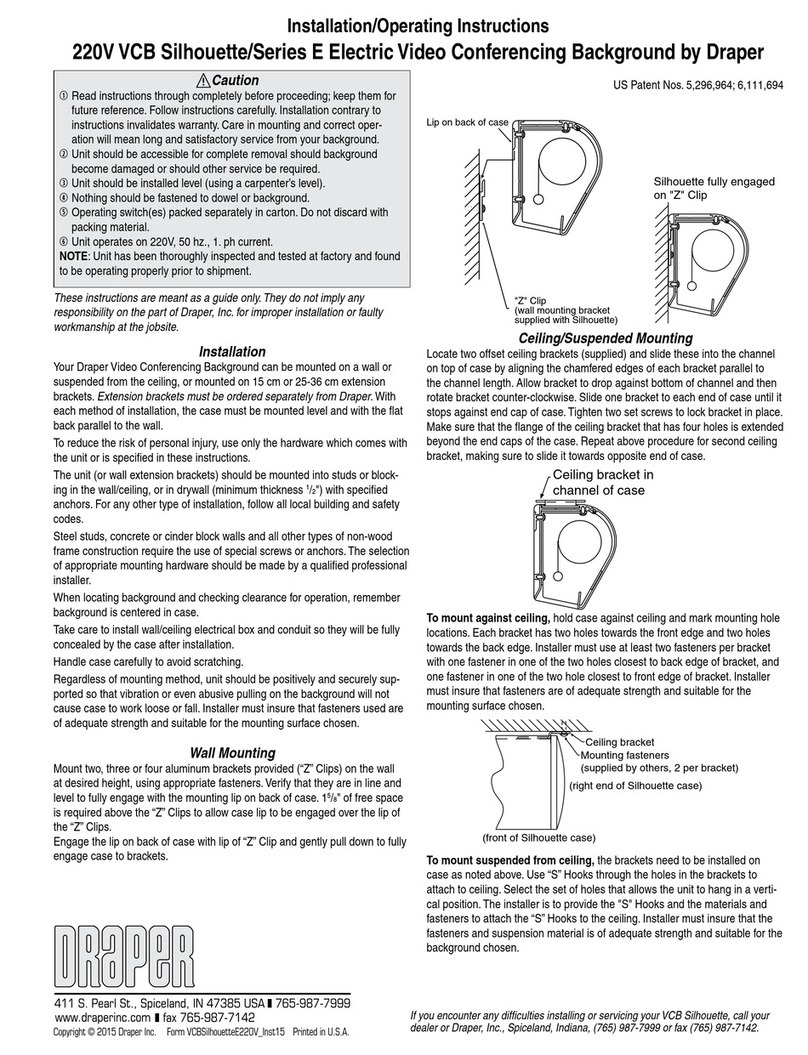

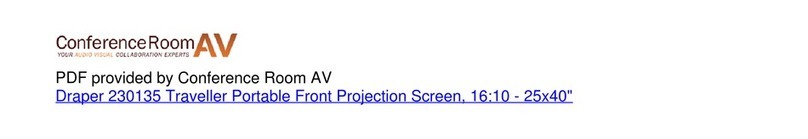

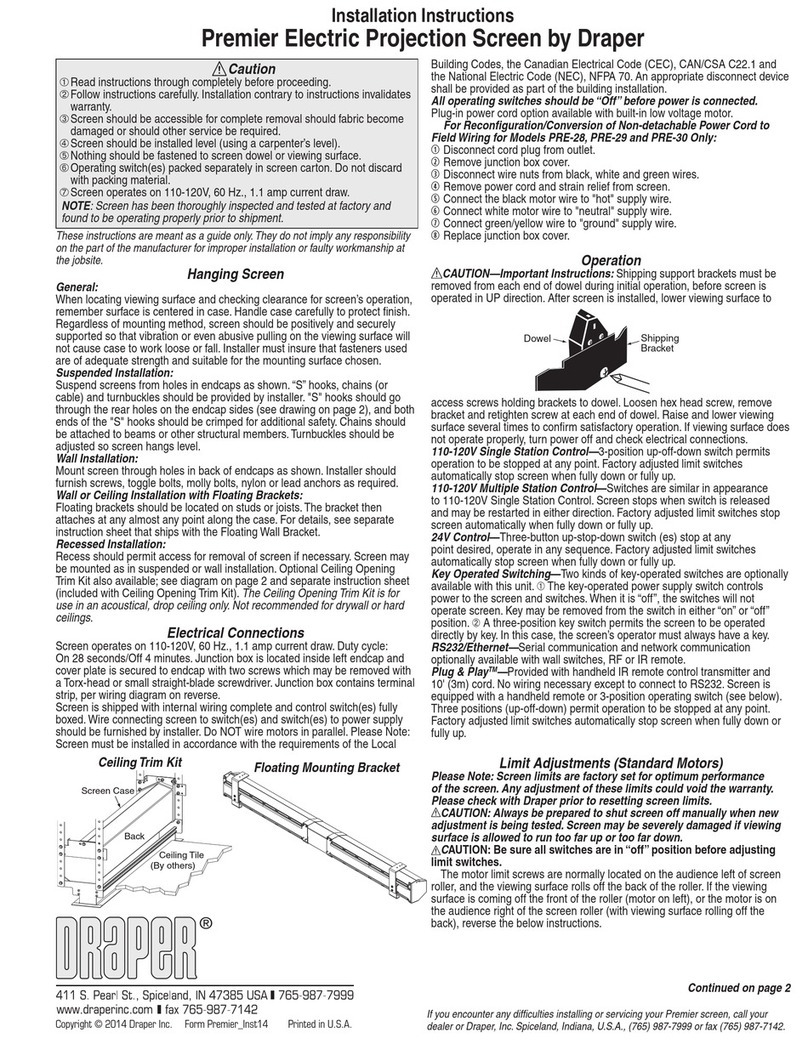

Wall Installation:

Mount 2, 3, or 4 aluminum brackets provided on the wall at desired height,

using toggle bolts provided or other appropriate fasteners. Verify that they are

in line and level to fully engage matching brackets pre-installed on back of

screen case. When screen is set on brackets, pull down gently to ensure that

it is snug and secure.

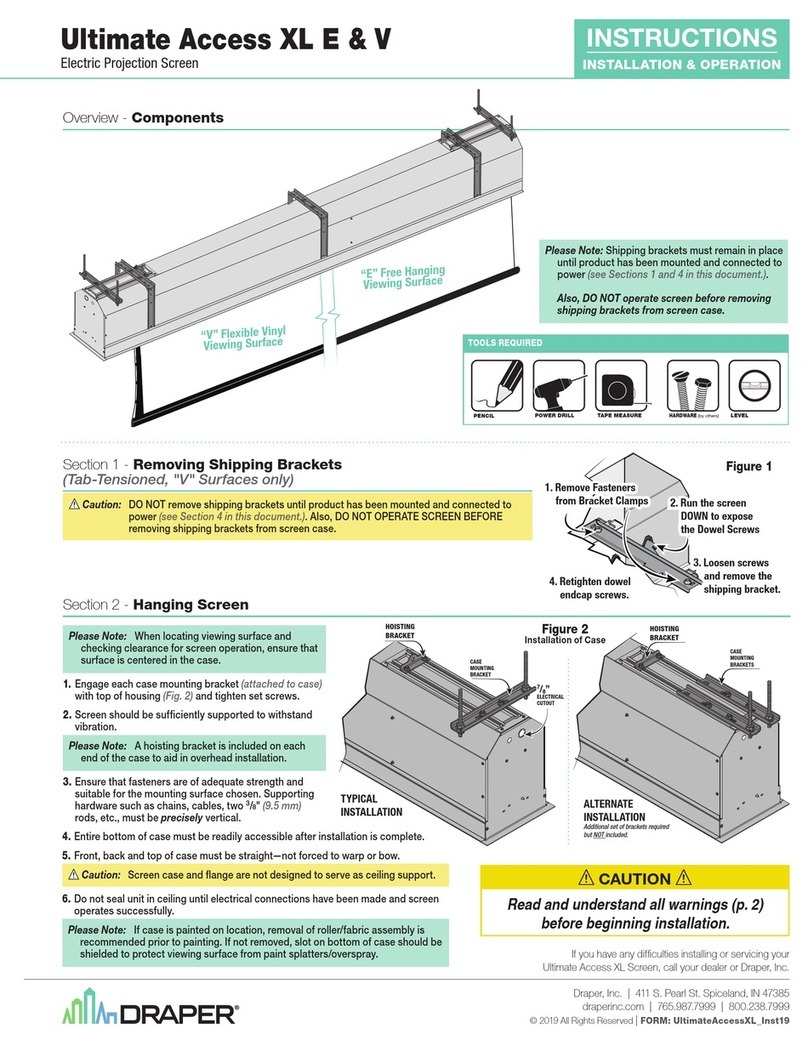

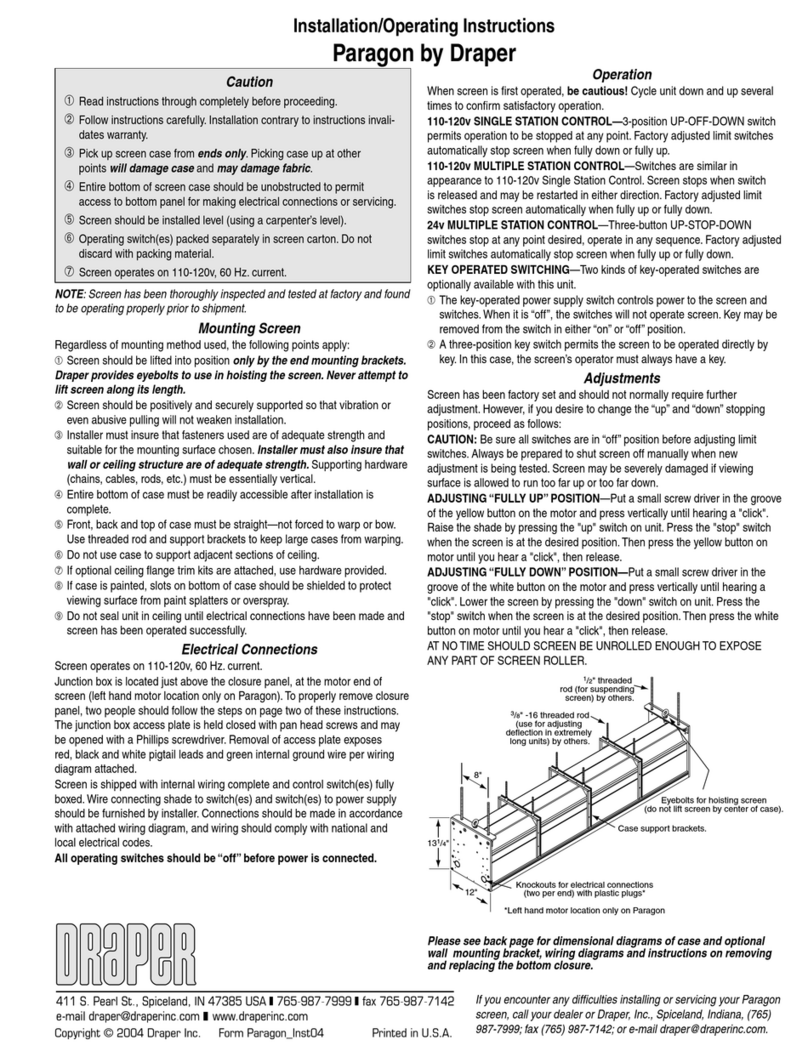

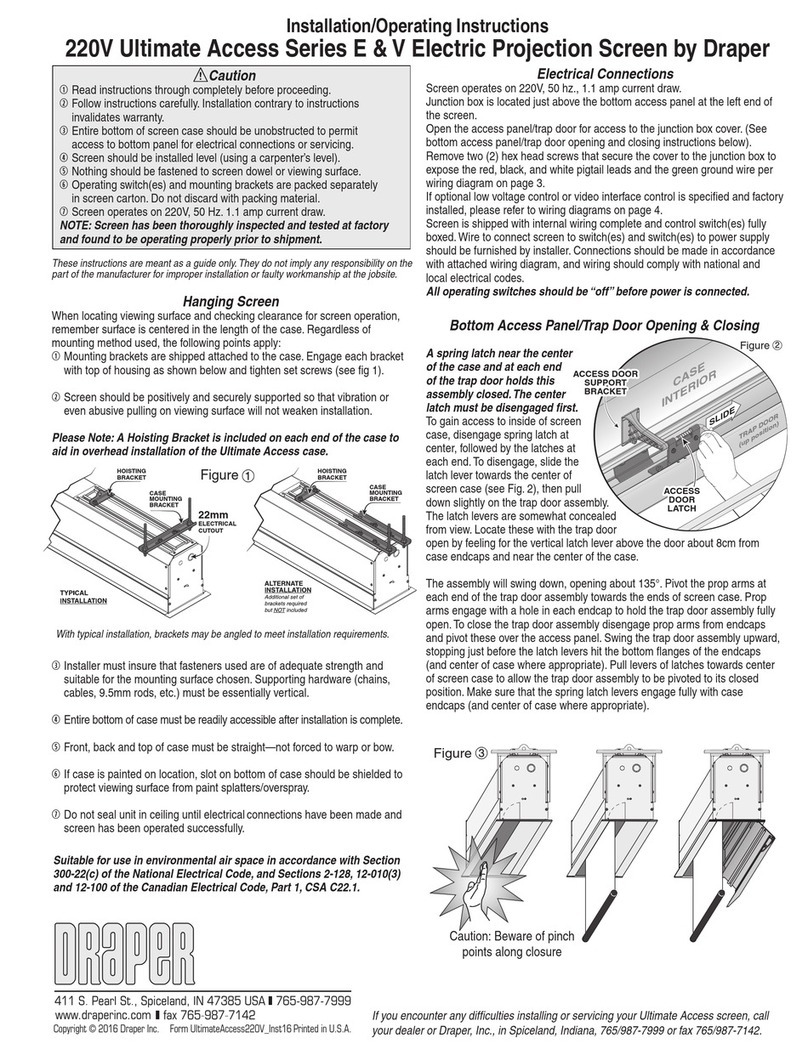

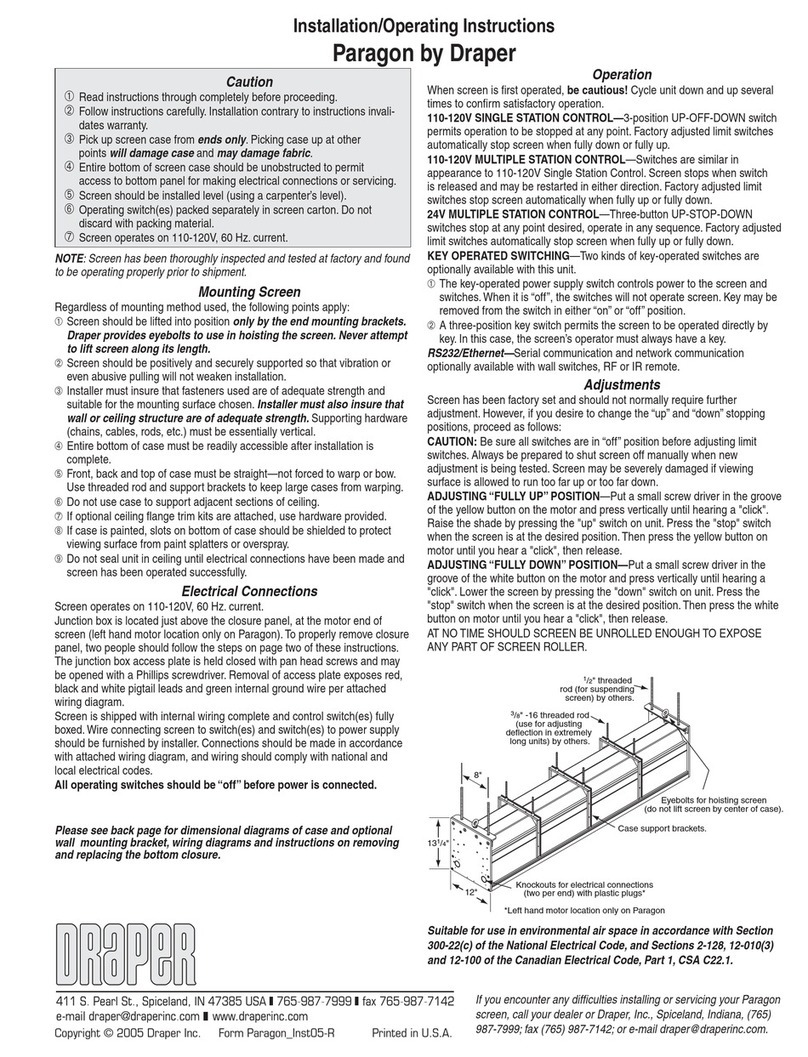

Ceiling Installation:

Install through the two

5

/

16

" diameter mounting holes at each end of the screen

case, using appropriate fasteners.

Electrical Connections

Screen operates on 110-120v, 60 Hz. current.

Junction box is located in the left end of case. It is accessible through bottom

of case when hinged door is opened. Junction box contains red, black and

white pigtail leads and green internal ground wire, per wiring diagram on

reverse.

Wall or ceiling electrical box should be installed so as to be fully concealed by

screen case after installation. Conduit openings are covered by plastic caps

Operation

Before operating screen remove tape securing fabric and dowel to roller. If

viewing surface hangs out of case 8

"

or 9

"

, tape has probably been broken by

rough handling in shipment, allowing surface to “unwrap” one turn about the

roller. Manually wrap fabric back around the roller without turning the roller

itself.

110-120v Single Station Control —

3-position up-off-down switch permits

operation to be stopped at any point. Factory adjusted limit switches

automatically stop screen when fully down or fully up.

110-120v Multiple Station Control

—Switches are similar in appearance to

110-120v Single Station Control. Screen stops when switch is released and

may be restarted in either direction. Factory adjusted limit switches stop

screen automatically when fully up or fully down.

24v Control —

Three-button up-stop-down switches stop at any point

desired, operate in any sequence. Factory adjusted limit switches

automatically stop screen when fully up or fully down.

Key Operated Switching —

Two kinds of key-operated switches are

optionally available with this unit.

➀The key-operated power supply switch controls power to the screen and

switches. When it is “off”, the switches will not operate screen. Key may be

removed from the switch in either “on” or “off” position.

➁A three-position key switch permits the screen to be operated directly by

key. In this case, the screen’s operator must always have a key.

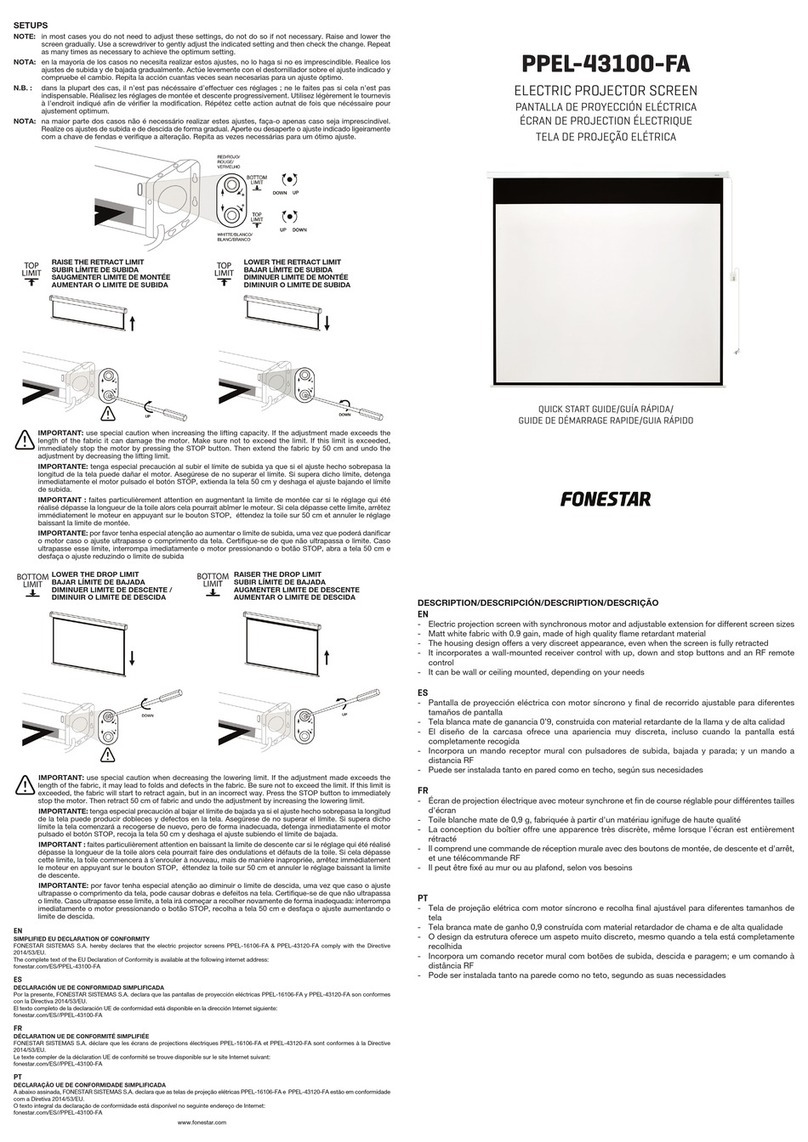

Adjustments

Screen has been factory set and should not normally require further

adjustment. However, if you desire to change the “up” and “down” stopping

positions, proceed as follows:

CAUTION: Be sure all switches are in “off” position before adjusting limit

switches. Always be prepared to shut screen off manually when new

adjustment is being tested. Screen may be severely damaged if viewing

surface is allowed to run too far up or too far down.

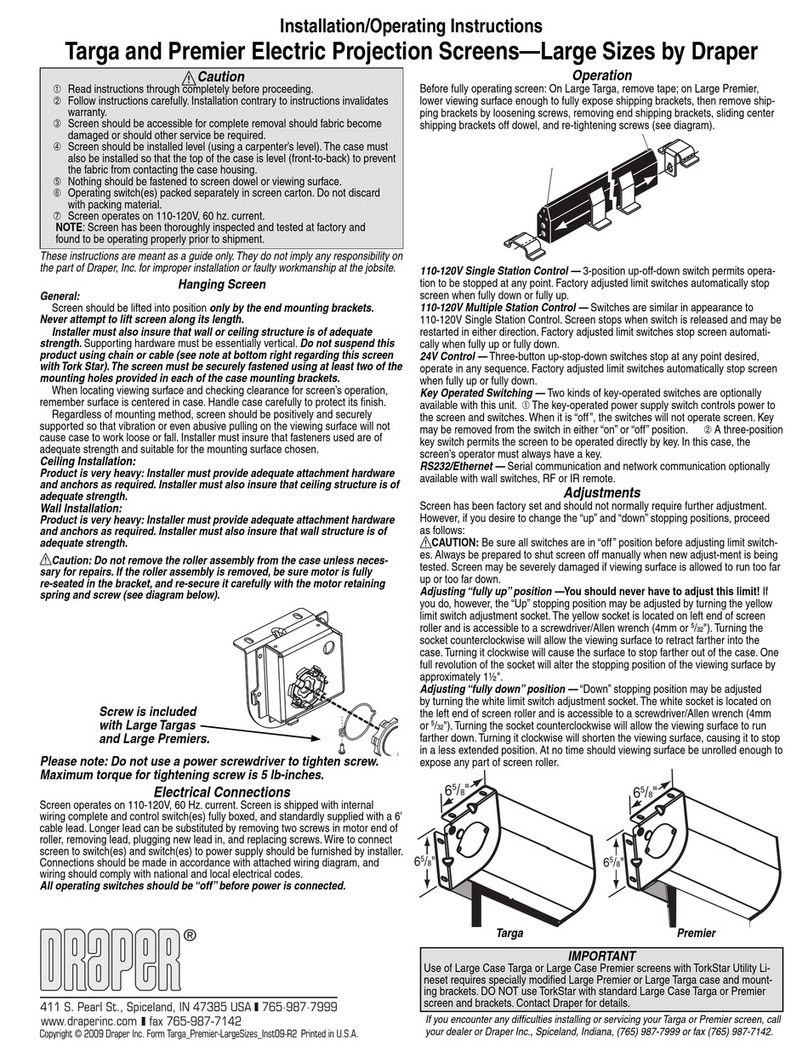

Adjusting “fully up” position —

“Up” stopping position may be adjusted by

turning the yellow limit switch adjustment socket. The yellow socket is located

on left end of screen roller and is accessible to a screwdriver/Allen wrench

(4mm or

5

/

32

"). Turning the socket counterclockwise will allow the viewing

surface to retract farther into the case. Turning it clockwise will cause the

surface to stop farther out of the case. One full revolution of the socket will

alter the stopping position of the viewing surface by approximately 1½".

Adjusting “fully down” position —

“Down” stopping position may be

adjusted by turning the white limit switch adjustment socket. The white socket

is located on the left end of screen roller and is accessible to a screwdriver/

Allen wrench (4mm or

5

/

32

"). Turning the socket counterclockwise will allow the

viewing surface to run farther down. Turning it clockwise will shorten the

viewing surface, causing it to stop in a less extended position. At no time

should viewing surface be unrolled enough to expose any part of screen roller.

If you encounter any difficulties installing or servicing your Artisan

screen, call your dealer or Draper, Inc., Spiceland, Indiana, (765)

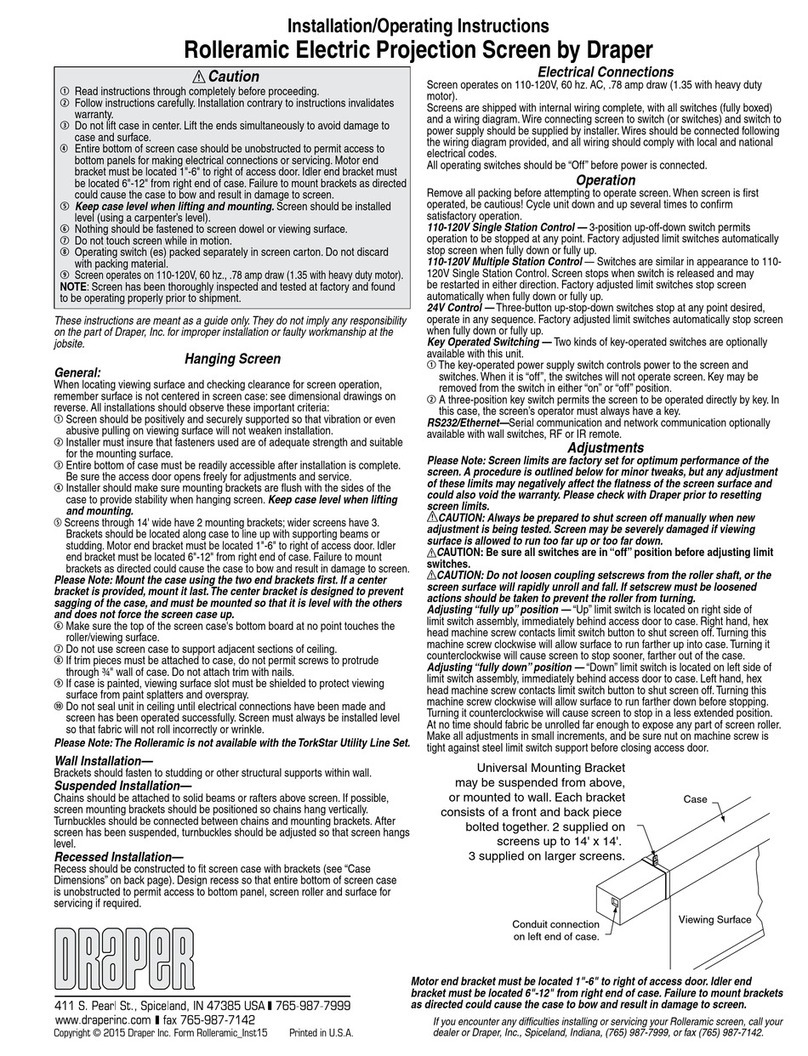

Z-brackets supplied

with screen for

wall mounting.

Hardware by others.

Z-brackets on

rear of case

Screen Case

Knockout for rear

conduit connection

Left end

5/16" holes for

ceiling mounting.

2 each end.

Wall

Knockout for top

conduit connection

(to be removed for installation). Opening for ceiling mounting is located in top,

2

7

/

8

" from the end and 2½" from the back of the case. Opening for wall

mounting is in back, 2

7

/

8

" from the end and 2¾" from the top of the case.

Screen is shipped with internal wiring complete and control switch(es) fully

boxed. Wire connecting screen to switch(es) and switch(es) to power supply

should be furnished by installer. Connections should be made in accordance

with attached wiring diagram, and wiring should comply with National and

local electrical codes.

All operating switches should be “off” before power is connected.

Please Note: Instructions for adjusting Draper’s Tab-Tension System for

Series/V screens are on page 2.