Trim Frame

Base Frame

Audience

Side

Slot Receives Screw

#8 x 32

Pan Head

Screw

Trim Frame has lip on rear side

Wall Mounting Brackets

Viewing Surface

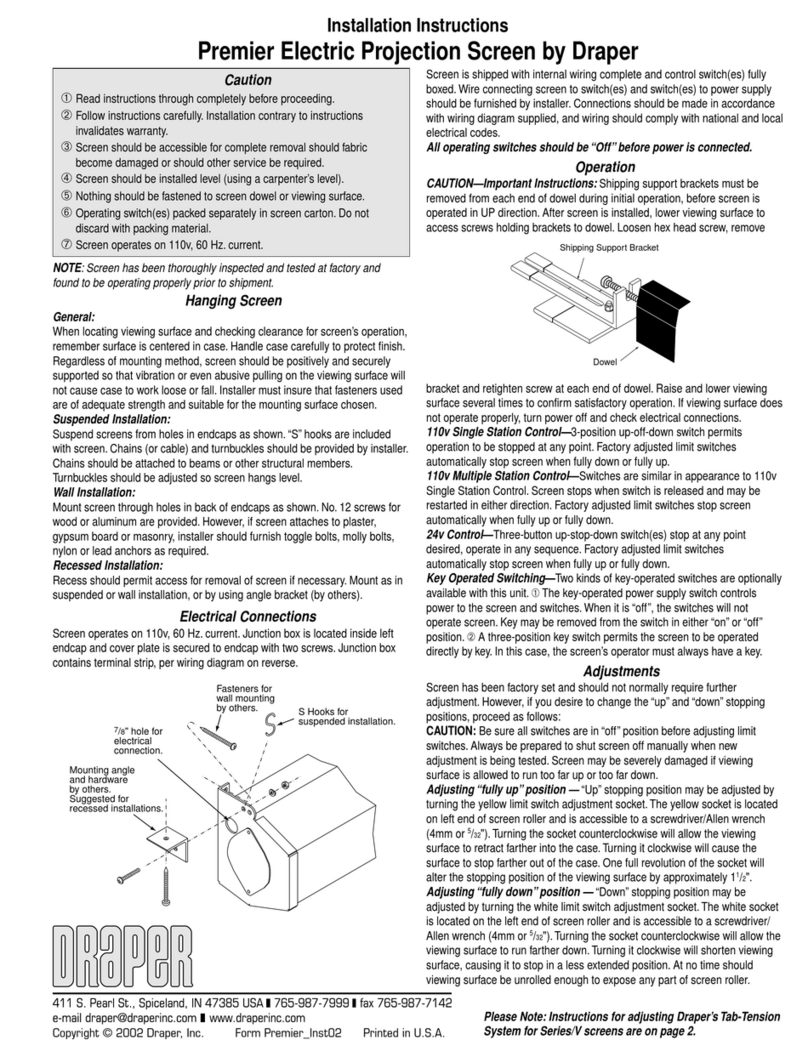

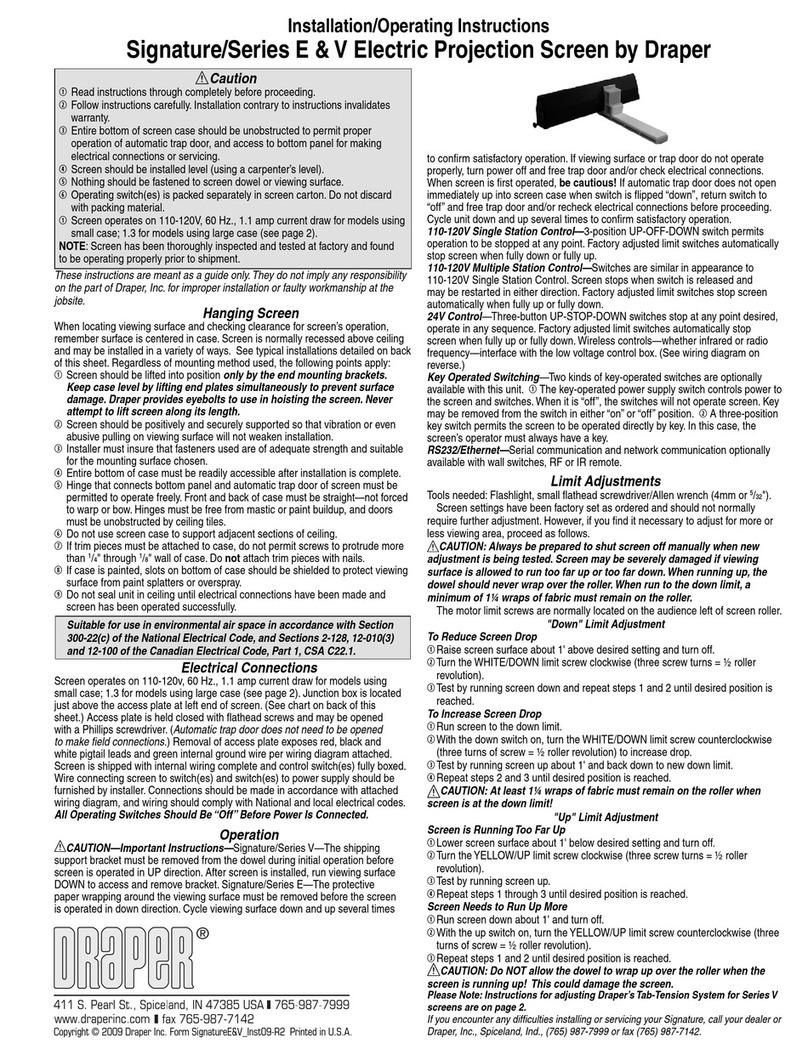

After all four corners of trims are connected, turn entire screen assembly over

so viewing surface is face down. Be sure to protect surface in this position.

The trims must be fastened to the inner frame with #8 x

3

/

8

" screws. Each trim

has predrilled holes in the back flange. Start by screwing the corners together

first. It may be necessary to squeeze the trims together at corners to close any

gaps. Do this before screwing trim to inner frame. Finish attaching trims along

their length with additional screws.

Clarion by Draper Page 2 of 4

The screen frame is assembled and ready for fixed wall mounting or

attachment to tilting angles.

Wall Mounting of Fixed Frames

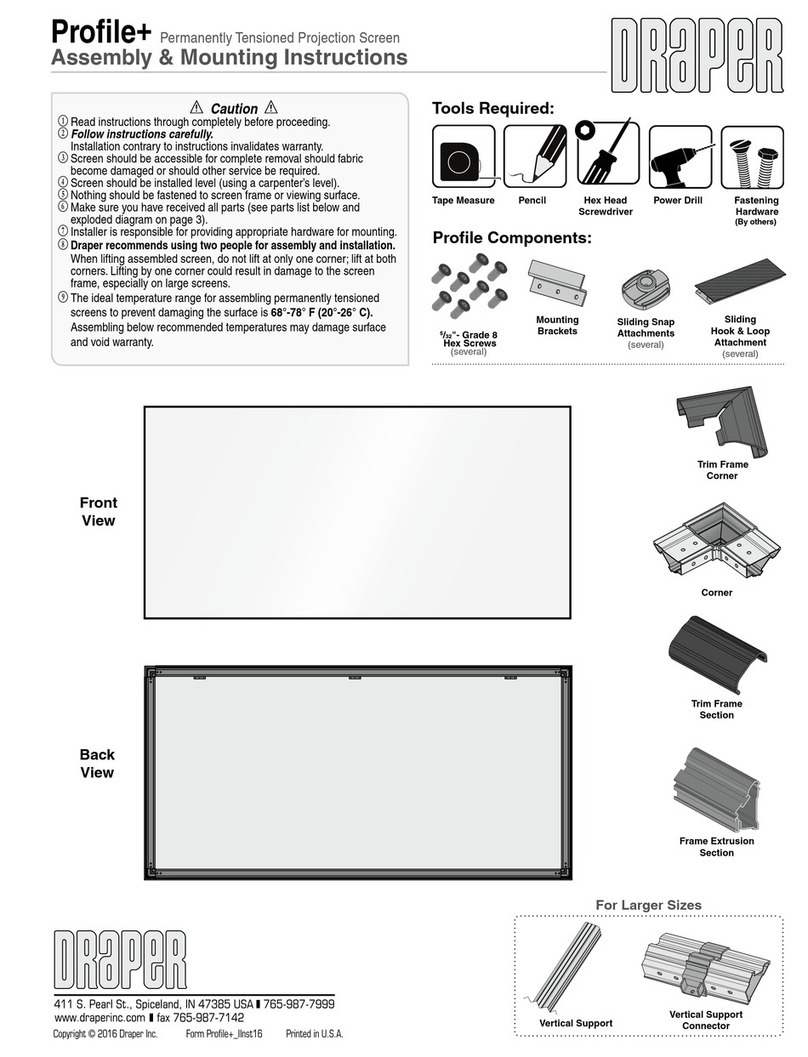

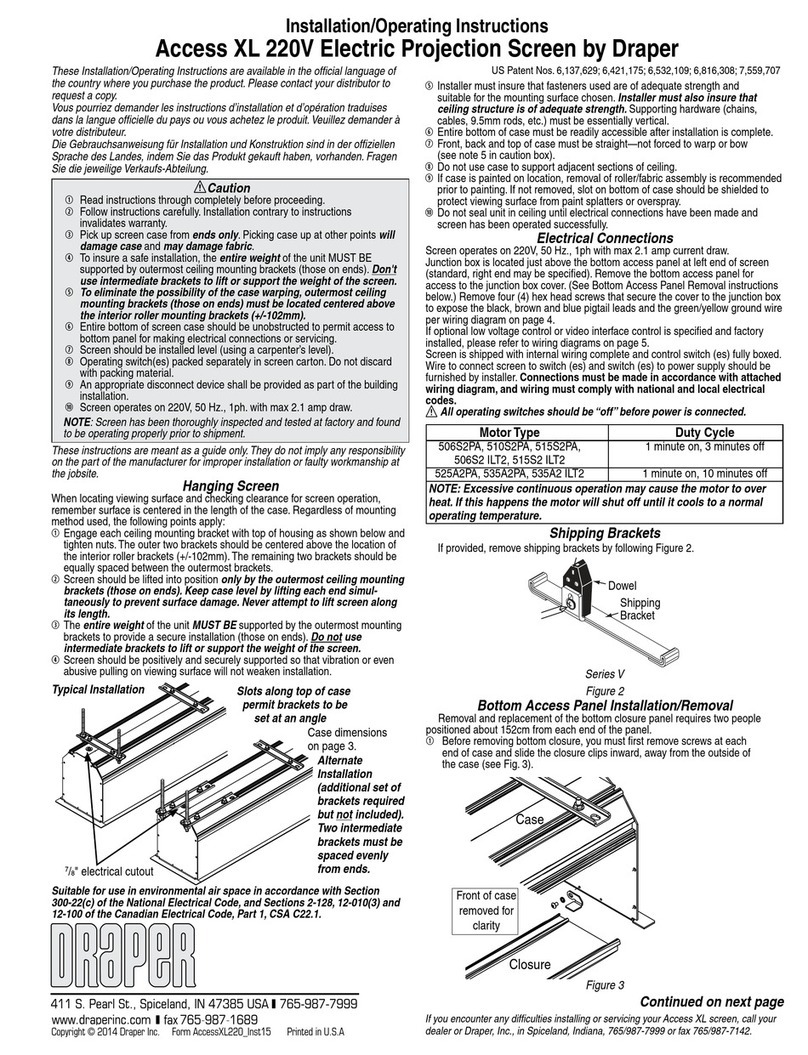

Mount 2, 3, or, 4 aluminum brackets provided on the wall at desired height.

Use carpenters level to ensure these brackets are level. When the screen is

mounted, the top of the frame will be

1

/

8

" above the top of these brackets. ¾"

of free space is required above these brackets. When the screen is set on the

mounting brackets, pull down gently to ensure that the engagement is snug

and secure.

The screen should be positively and securely supported so vibration or

abusive handling will not cause the screen to work loose or fall. The installer

must insure that the fasteners are of adequate strength and suitable for the

mounting surface chosen.

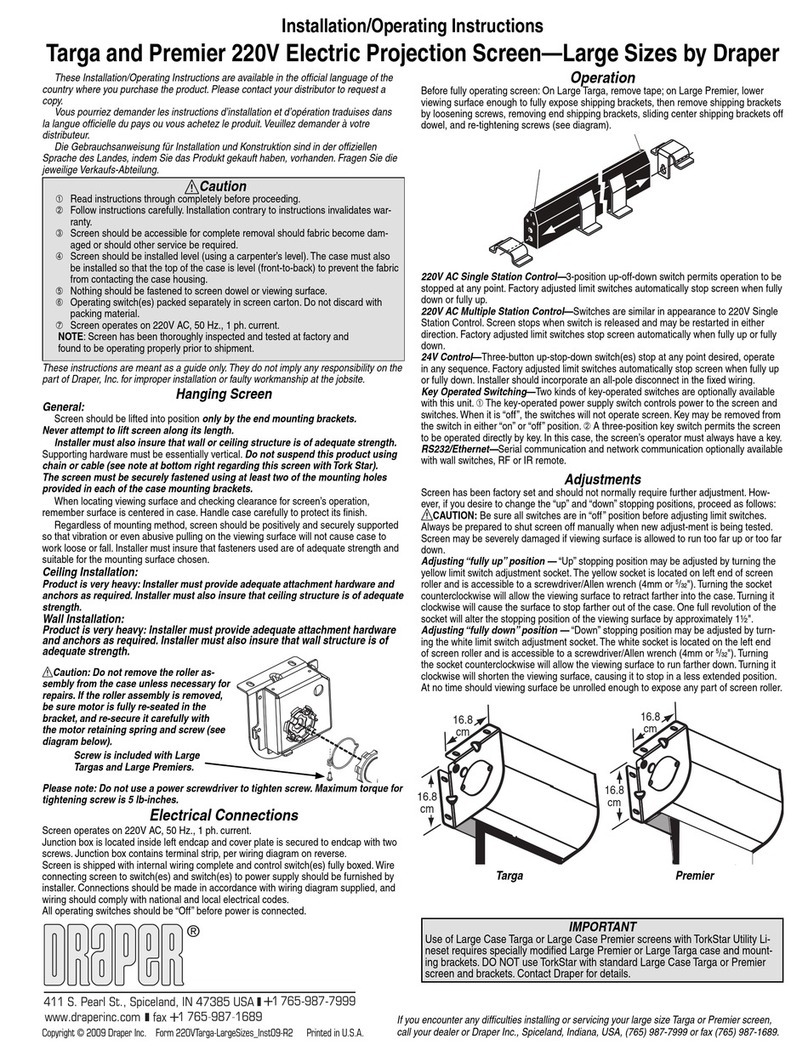

The center line of the gearbox should be mounted so the nylon tape runs

vertically up to the pulley bracket. The horizontal shaft of the crank handle

assembly is inserted into the side of the gearbox. Mount the crank handle

bracket so the horizontal shaft is level and allow

1

/

8

" between the side of the

gearbox and the end of the

1

/

2

" diameter shaft.

Installer must insure that fasteners used are of adequate strength and suitable

for the mounting surface chosen.

Unwind the nylon ribbon from the reel on the gearbox. Pass the end of the

ribbon up and over the pulley on the upper angle.

On the electric model the reel and ribbon are located on the motor shaft on

the lower angle. The ribbon passes over the pulley in the same manner as on

the manual model.

Note: On the electric model you will probably wish to install electrical

box in the wall, so it will be concealed behind the screen frame.

Attach screen frame to the underside of the lower angle with screws and

lockwashers through the hinge plates on the lower backside of screen frame.

Attach the safety chains from the upper angle to the brackets on the upper

backside of screen frame. Attach the end of the nylon ribbon to the center of

the top section of screen frame. (See attached detail drawing.)

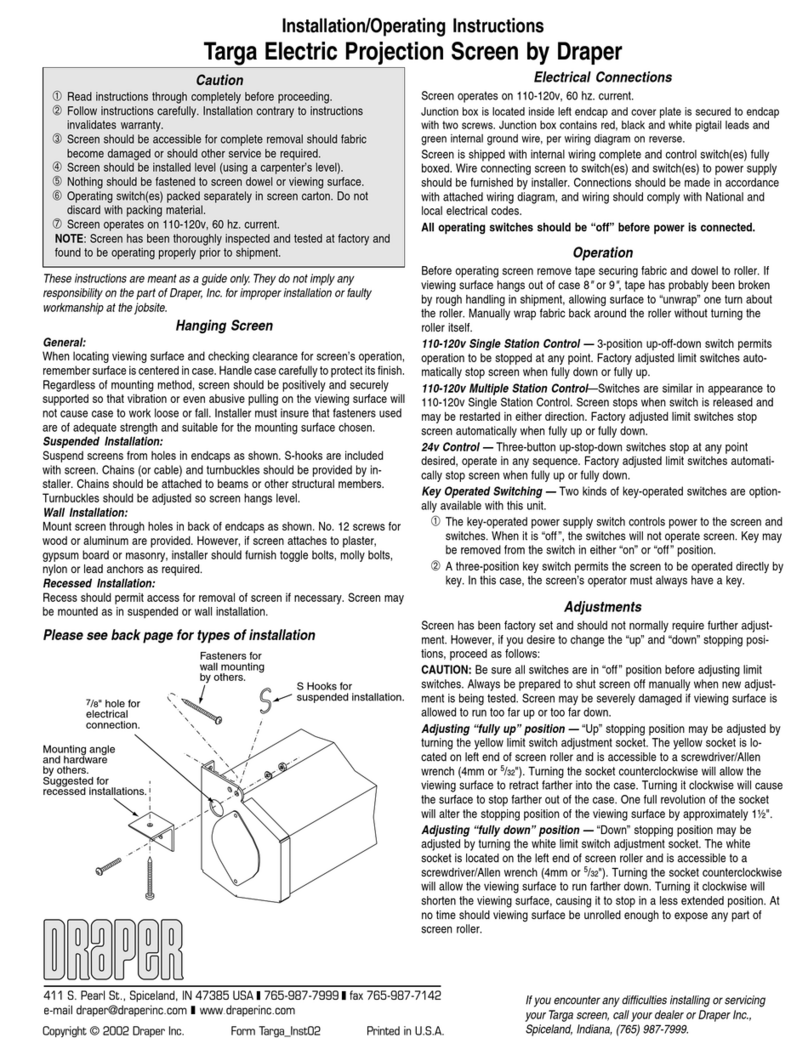

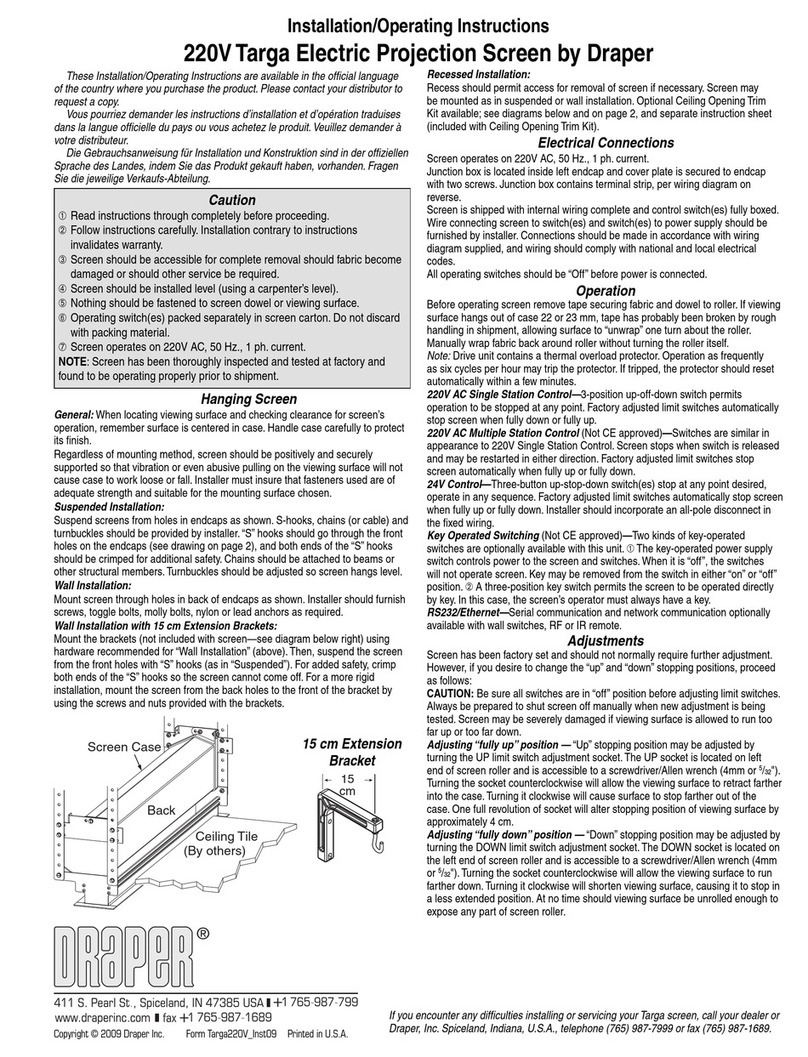

Electrical Connections

Screen operates on 110-120v, 60 hertz current. Wall electrical box should be

installed so as to be concealed by the screen frame after installation. Screen

motor is provided with approximately 6 ft. of cord. Wire connecting screen to

switch(es) and switch(es) to power supply should be furnished by installer.

Connections should be made in accordance with attached wiring diagram and

wiring should comply with local and national electrical codes.

All operating switches should be “off” before power is connected!

Adjustments

Manual models — the maximum tilt is controlled by an internal stop in the

gearbox. Set this as follows before the screen frame is attached to lower

angle. Turn the crank handle in the direction that unwinds the nylon ribbon

from the reel. When the stop is reached, the gearbox will stop - DO NOT

FORCE IT. Leave enough ribbon off the reel to allow the frame to tilt 20°

maximum or less if desired. With screen in maximum tilt position, the nylon

ribbon should be taut and safety chains should be slack. The upper or

minimum tilt limit (0°) is obtained when the screen reaches the vertical

position. The operator should discontinue cranking at this point.

Electric models — the maximum tilt and vertical screen positions are both

controlled by the limit switches in the motor.

Run the motor until it stops automatically in the “up” position (approximately

vertical). Make sure the screen frame is not attached to either of the angles

and the strap(s) on the roller spool can rotate freely before running motor.

The strap(s) may then be unwrapped sufficiently to thread through the pulley

on the upper angle leaving approximately 3 inches exposed past the pulley.

Make sure the strap(s) do not twist along their length.

Mount screen frame per attached instructions and attach safety chains to

brackets on the top backside of the screen frame. The strap(s) can then be

woven through the slotted brackets attached to the frame in the stopped

position (which is nearly vertical).

The exact vertical stopping position can now be fine tuned. Knob #2 on the

motor may be turned counterclockwise in small increments until the desired

vertical position is reached, or by adjusting the strap(s) in slotted brackets.

After the vertical position is set, the maximum tilt position may be adjusted to

desired tilt (20° maximum). Turn knob #1 counterclockwise to increase the tilt

and clockwise to reduce the amount of tilt.

CAUTION: Be sure switches are “off” before making limit switch

adjustments. Always be ready to manually shut off screen when new

adjustments are being made. When properly adjusted, the nylon ribbon

should be taut and safety chains slack at maximum tilt.

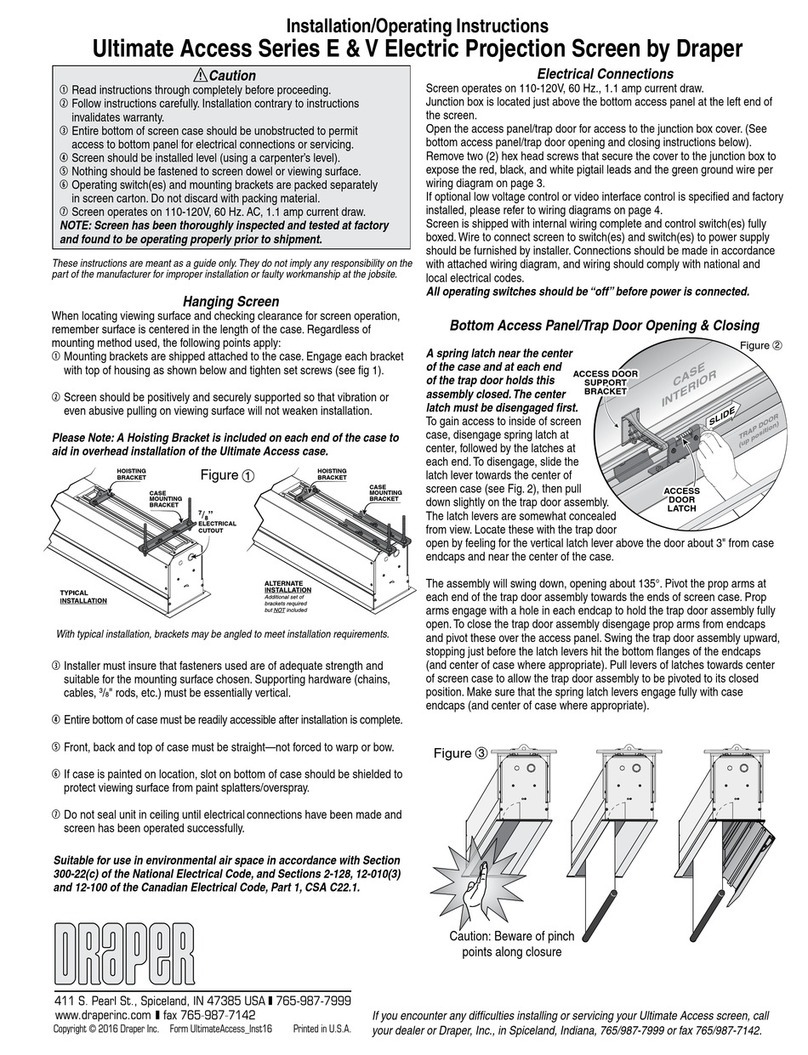

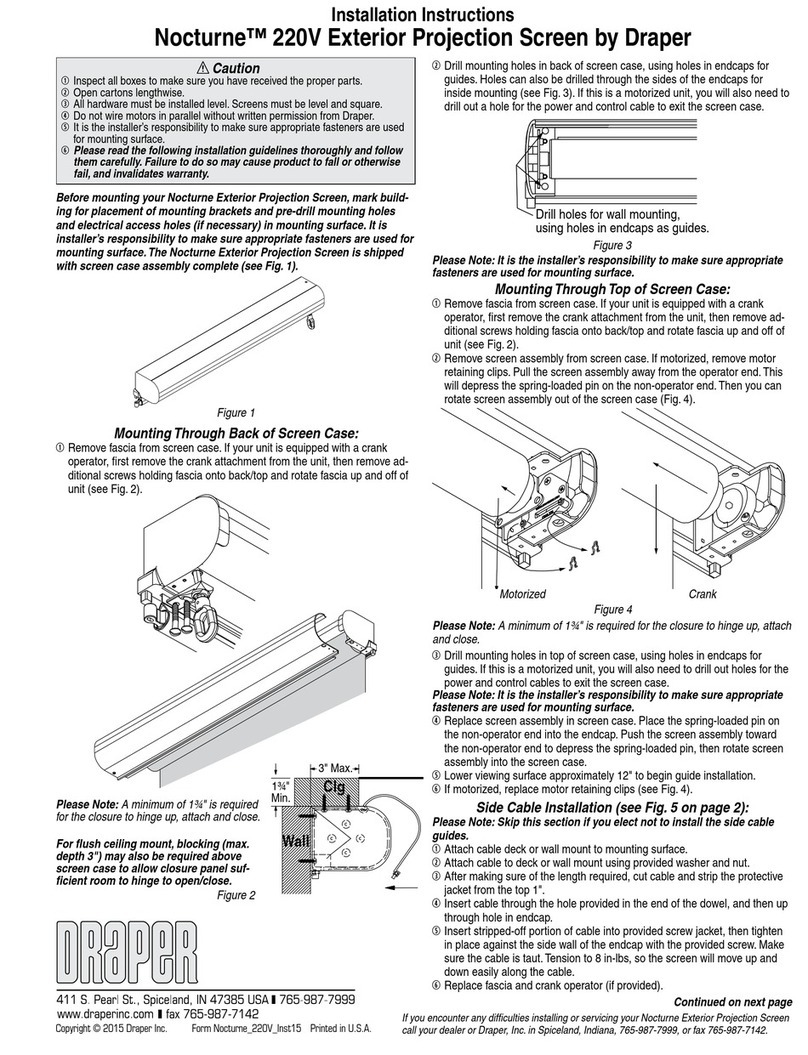

Wall Mounting of Tilting Screens

All tilting screens (manual and electric) require the attachment of the lower

angle and upper angle on the wall at the desired heights. The bottom edge of

the lower angle is 1

3

/

16

" higher than the bottom edge of the screen frame. The

upper angle should be 1

3

/

8

" below the top edge of the screen frame.

Verify that both of these angles are level and that the upper angle is centered

above the lower angle.

The mounting angles should be securely and positively mounted so that

vibration or even abusive pulling will not cause the angles to work loose or fall.

On the manual tilting models there are two additional brackets that need to be

mounted to the wall, the gearbox bracket and the crank handle bracket. (See

attached detail drawing.)