Operation Checklist

Operation ChecklistOperation Checklist

Operation Checklist

The following checklist should be followed prior to each use of your Freeze Dryer:

1. Wipe the interior of the collector chamber with a soft cloth or paper towel to

remove any accumulated moisture.

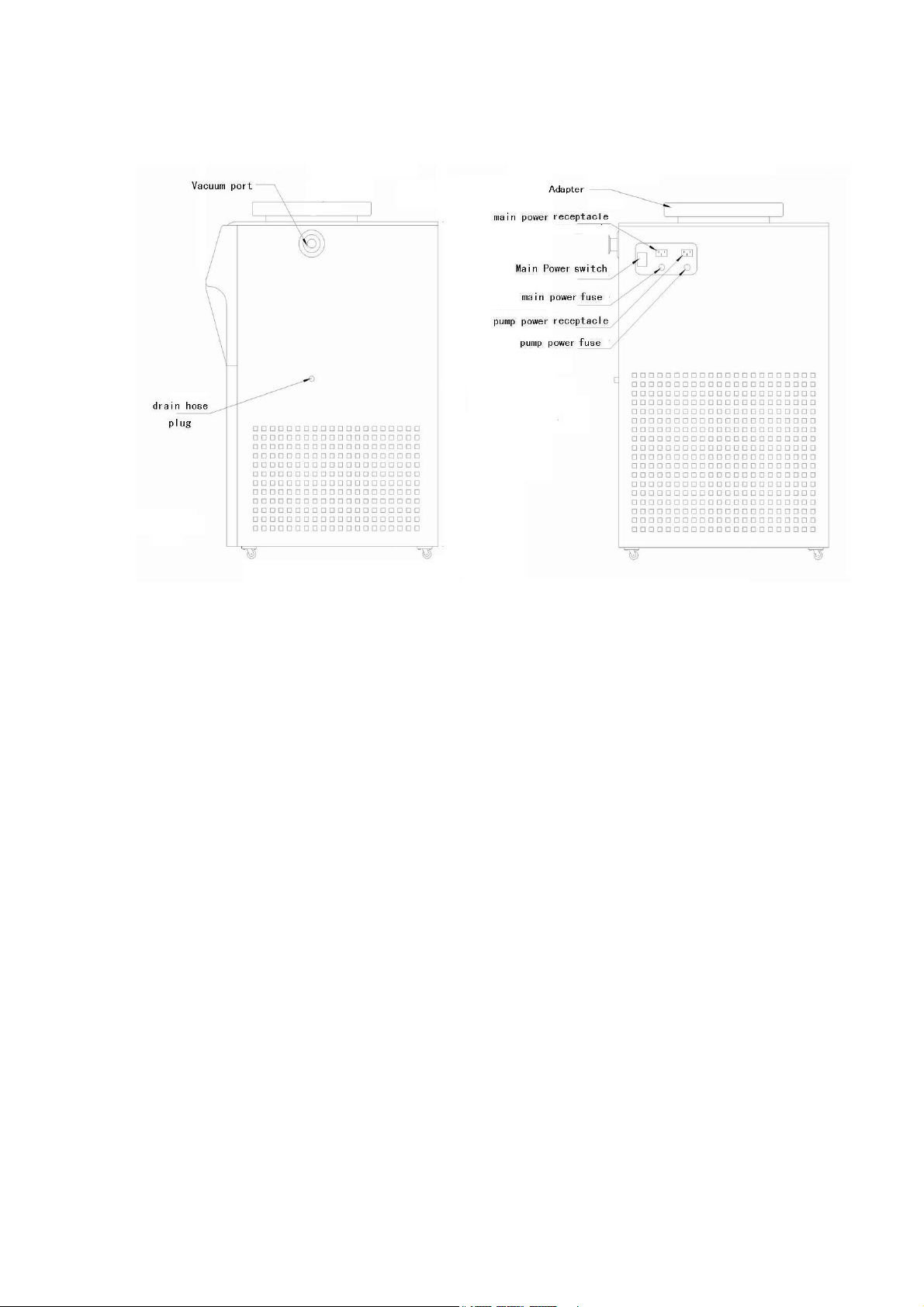

2. Check the collector chamber drain hose to ensure that the hose is free of

moisture and that the drain plug is securely installed. The freeze dryer will not

start if moisture is detected.

3. Using a soft, lint-free cloth or paper towel, wipe the collector chamber lid

gasket to remove any dirt and contaminants that could cause a vacuum leak.

Vacuum grease is not required on the lid gasket to obtain a proper vacuum seal.

4. Remove the accessory drying chamber or manifold from the connection port

and using a soft, lint-free cloth or paper towel, wipe the port gasket and sealing

surfaces of the drying chamber/manifold to remove any dirt and contaminants that

could cause a vacuum leak. Reinstall the drying chamber or manifold on the port.

Vacuum grease is not required on the port gasket to obtain a proper vacuum seal.

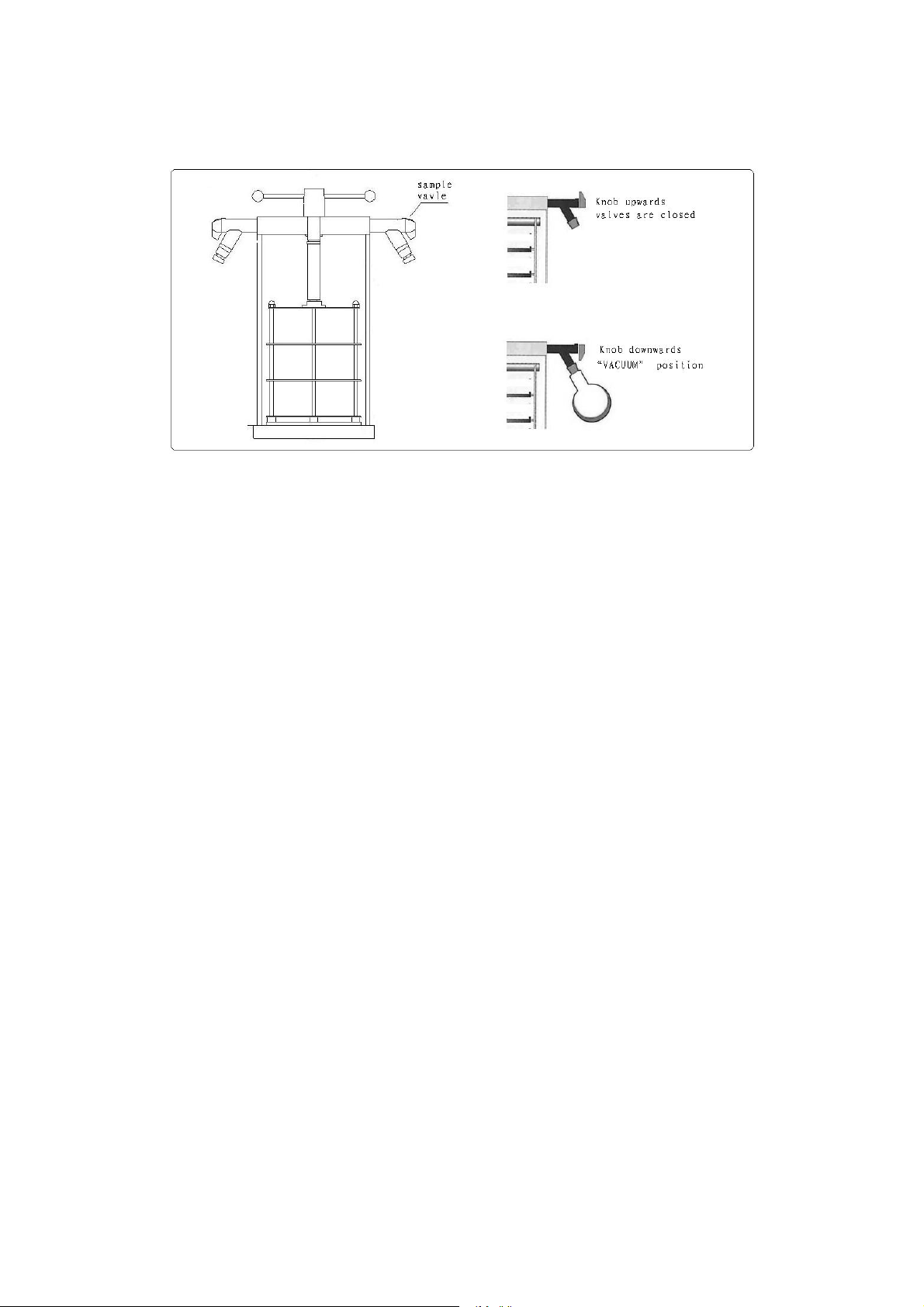

5. Check that each sample valve is closed or in the “upwards” position.

Vacuum Pump Ballast Setting

Vacuum Pump Ballast SettingVacuum Pump Ballast Setting

Vacuum Pump Ballast Setting

Most vacuum pumps are equipped with a gas ballast mechanism. The freeze dry

process requires high vacuum. Therefore, it is recommended that the gas ballast

be closed during the operation of the Freeze Dry System. If the gas ballast is left

open for extended periods of operation, the oil can be pumped out the exhaust,

causing the pump to fail.

Operating the Freeze Dryer

Operating the Freeze DryerOperating the Freeze Dryer

Operating the Freeze Dryer