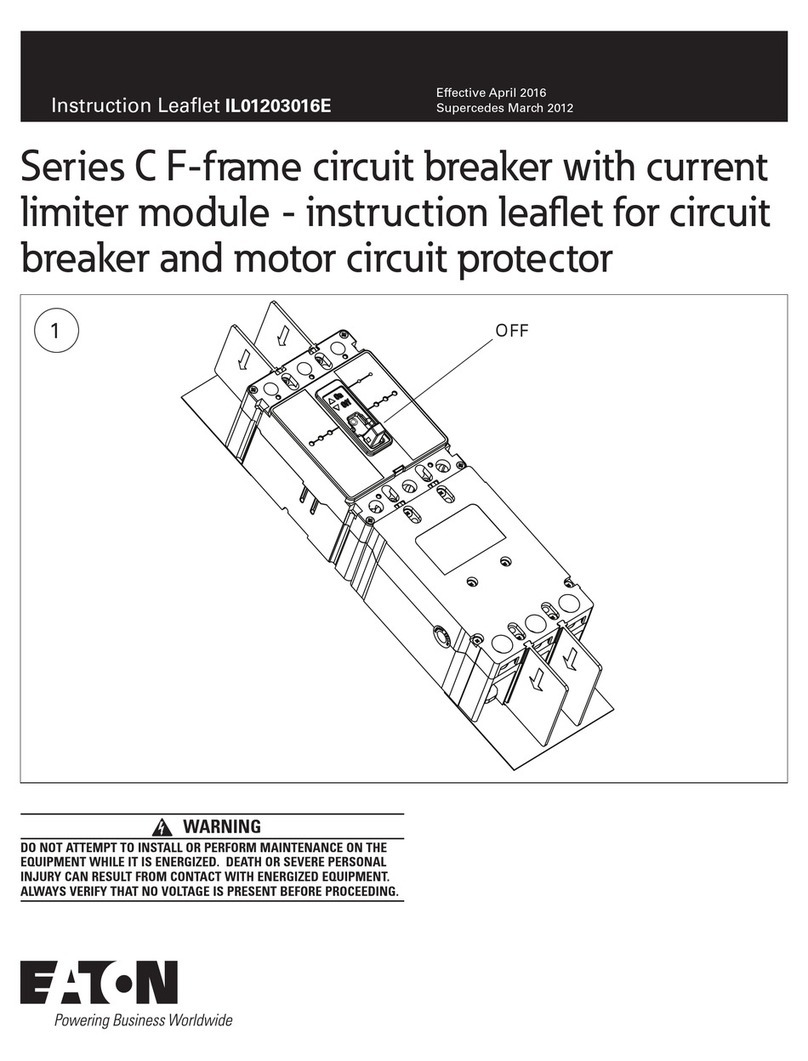

WARNING

INSTALLATION OR MAINTENANCE SHOULD BE ATTEMPTED

ONLY BY QUALIFIED PERSONNEL. THIS SUPPLEMENTAL

INSTRUCTION BOOKLET IS INTENDED TO ACCOMPANY

THE ORIGINAL INSTRUCTION BOOKLET PROVIDED WITH

THE VCP-W CIRCUIT BREAKER AND SHOULD NOT BE

CONSIDERED ALL INCLUSIVE REGARDING INSTALLATION

OR MAINTENANCE PROCEDURES. THIS IS NOT TO BE USED

IN PLACE OF THE VCP-W CIRCUIT BREAKER INSTRUCTION

BOOKLET. IF FURTHER INFORMATION IS REQUIRED, YOU

SHOULD CONSULT EATON.

IMPROPERLY INSTALLING OR MAINTAINING THESE

PRODUCTS CAN RESULT IN DEATH, SERIOUS PERSONAL

INJURY OR PROPERTY DAMAGE.

READ AND UNDERSTAND THE VCP-W INSTRUCTION

BOOKLET BEFORE ATTEMPTING ANY OPERATION OR

MAINTENANCE OF THE CIRCUIT BREAKERS.

THE CIRCUIT BREAKERS FEATURED IN THIS BOOKLET

ARE DESIGNED AND TESTED TO OPERATE WITHIN THEIR

NAMEPLATE RATINGS. OPERATION OUTSIDE OF THESE

RATINGS MAY CAUSE THE EQUIPMENT TO FAIL, RESULTING

IN DEATH, BODILY INJURY AND PROPERTY DAMAGE.

ALL SAFETY CODES, SAFETY STANDARDS AND/OR

REGULATIONS AS THEY MAY BE APPLIED TO THIS TYPE OF

EQUIPMENT MUST BE STRICTLY ADHERED TO.

THESE VACUUM REPLACEMENT CIRCUIT BREAKERS ARE

DESIGNED TO BE INSTALLED PURSUANT TO THE AMERICAN

NATIONAL STANDARDS INSTITUTE (ANSI). SERIOUS

INJURY, INCLUDING DEATH, CAN RESULT FROM FAILURE TO

FOLLOW THE PROCEDURES OUTLINED IN THIS BOOKLET.

ALL POSSIBLE CONTINGENCIES WHICH MIGHT ARISE

DURING INSTALLATION, OPERATION, OR MAINTENANCE,

AND ALL DETAILS AND VARIATIONS OF THIS EQUIPMENT

ARE NOT COVERED BY THESE INSTRUCTIONS. IF FURTHER

INFORMATION IS DESIRED BY THE PURCHASER REGARDING

A PARTICULAR INSTALLATION, OPERATION, OR

MAINTENANCE OF THIS EQUIPMENT, THE LOCAL EATON’S

ELECTRICAL SERVICES & SYSTEMS REPRESENTATIVE

SHOULD BE CONTACTED.

WARNING

TO PROTECT THE PERSONNEL ASSOCIATED WITH

INSTALLATION, OPERATION, AND MAINTENANCE OF THESE

CIRCUIT BREAKERS, THE FOLLOWING PRACTICES MUST BE

FOLLOWED:

•Read the instruction booklet provided with the

VCP-W circuit breaker before attempting any

installation, operation or maintenance of these

circuit breakers.

•Only qualified persons, as defined in the National

Electrical Safety Code, who are familiar with the

installation and maintenance of medium voltage

circuits and equipment, should be permitted to

work on these circuit breakers.

•Always remove the circuit breaker from the

enclosure before performing any maintenance.

Failure to do so could result in electrical shock

leading to death, severe personnel injury or

property damage.

•Do not work on a circuit breaker with the

secondary test coupler engaged. Failure to

disconnect the test coupler could result in an

electrical shock leading to death, personnel

injury or property damage.

•Do not work on a closed circuit breaker or a

circuit breaker with closing springs charged.

The closing spring should be discharged and the

main contacts open before working on the circuit

breaker. Failure to do so could result in cutting or

crushing injuries.

•Do not use a circuit breaker by itself as the

sole means of isolating a high voltage circuit.

Remove the circuit breaker to the Disconnect

position and follow all lockout and tagging rules

of the National Electrical Code and any and all

applicable codes, regulations and work rules.

•Do not leave the circuit breaker in an

intermediate position in the cell. Always have the

circuit breaker either in the Test or Connected

position. Failure to do so could result in a flash

over and possible death, personnel injury or

property damage.

•Always remove the maintenance tool from the

circuit breaker after charging the closing springs.

•Circuit breakers are equipped with safety

interlocks. Do not defeat them. This may result in

death, bodily injury or equipment damage.

Table of Contents

Vacuum Interrupter

Vacuum Interrupter 3

Vacuum Interrupter Assembly 3

Vacuum Interrupter Integrity Test

Vacuum Interrupter Integrity Testing Configuration 4

Insulation Integrity Test

Power Frequency Withstand Voltage Testing Configuration 5

Current Path Resistance Test

Current Path Resistance Testing Procedure 6

Vacuum Bottle Contact Inspection

Contact Erosion Indicator 7

Contact Wipe and Stroke 7

Mechanism Lubrication

150VCP-W Mechanism Lubrication 8

Component Replacement

Replacing The Charging Motor 9

Replacing Spring Release and Shunt Trip Coils 10

Component Installation 11

Installation of Second Shunt Trip 11

Undervoltage Trip Device 12

Component Adjustment 13

Adjustment of the Motor Cutoff Switch 13

Adjustment of the Operations Counter 14

CloSure™ Test 15

CloSure™ Test 13

VCP-W Circuit Breaker Model 16

VCP-W 5/15 63kA 3000A 16

2

EATON |Visual Instruction Booklet Essentials | 150VCP-W 25kA 1200A | January 2017