I.B. 8295A61H03

Page vi

Effective 7/97

FIGURES

Figure Title Page

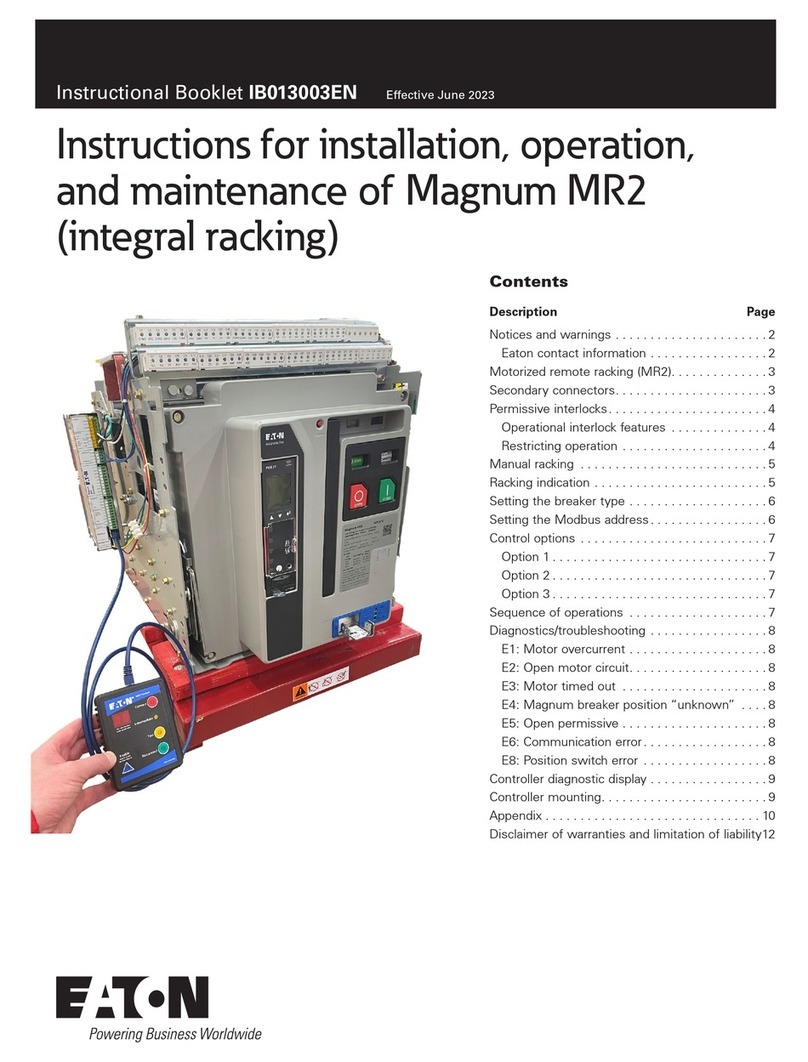

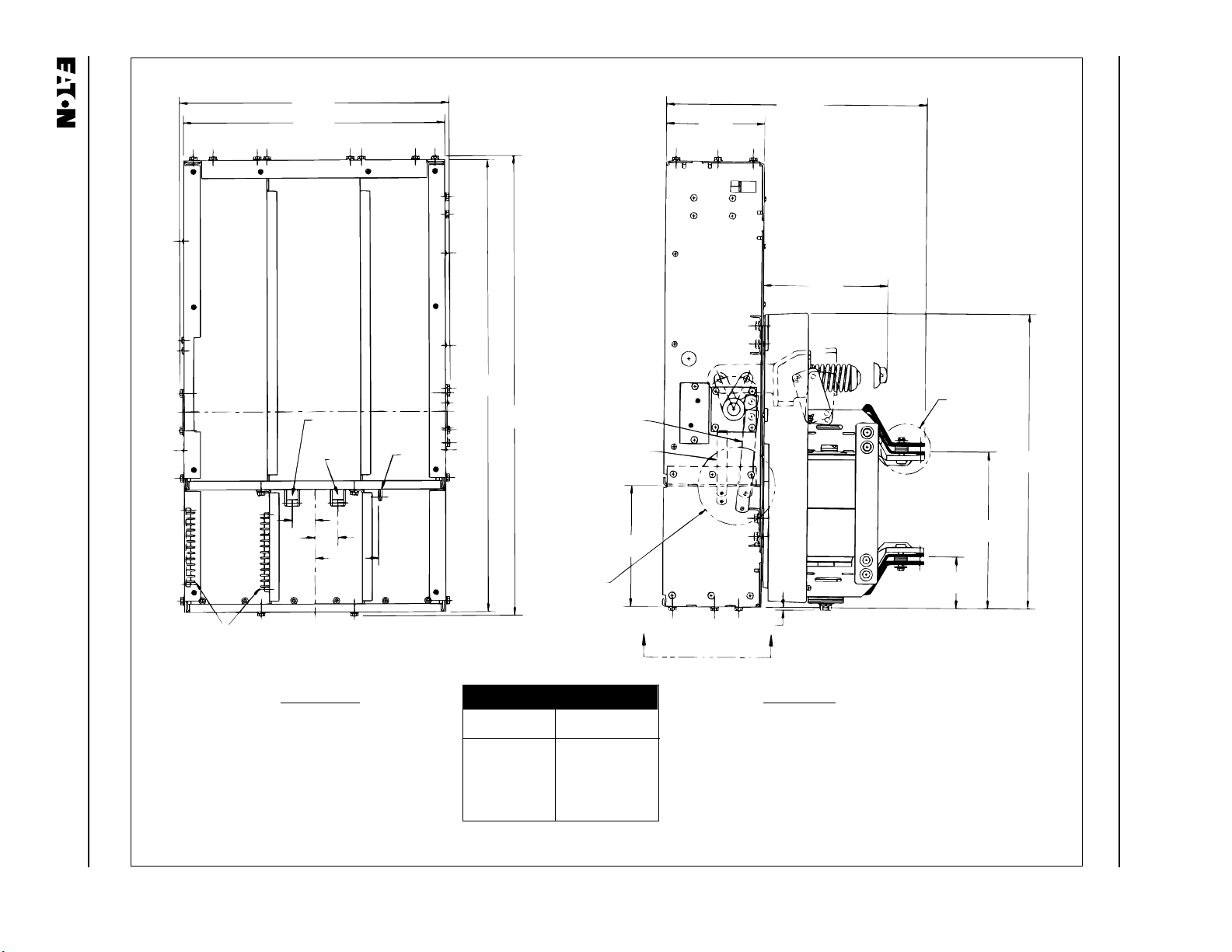

1-1 Type VCP-WR Series 18 Element Outlines and Dimensions (inches)......................................................2

1-2 Type VCP-WR Series 20 Element Outlines and Dimensions (inches)......................................................4

1-3 Type VCP-WR Series 29 Element Outlines and Dimensions (inches)......................................................6

3-1 Front View VCP-WR Series 18................................................................................................................12

3-2 Rear View VCP-WR Series 18 ................................................................................................................13

3-3 Front View VCP-WR Series 20................................................................................................................14

3-4 Rear View VCP-WR Series 20 ................................................................................................................15

3-5 Front View VCP-WR Series 29................................................................................................................16

3-6 Rear View VCP-WR Series 29 ................................................................................................................17

3-7 Typical VCP-WR Escutcheon..................................................................................................................18

5-1 Typical VCP-WR Front Mounted Mechanism..........................................................................................21

5-2 Type VCP-WR Series 20 Interrupter Assemblies....................................................................................22

5-3 Type VCP-WR Series 18 Interrupter Assemblies....................................................................................22

5-4 Type VCP-WR Series 29 Interrupter Assemblies....................................................................................22

5-5 Typical Cutler-Hammer Vacuum Interrupter Shown Attached to

Non-Sliding Current Transfer System......................................................................................................23

5-6 Closing Cam and Trip Linkage ................................................................................................................25

5-7 Charging Schematic ................................................................................................................................26

6-1 Typical VCP-WR Front Cover, Nameplate and Operational Indicators...................................................29

6-2 Typical VCP-WR “DC” and “AC” Control Schematics..............................................................................30

6-3 Series 18 Primary Connection.................................................................................................................31

6-4 Series 18 Showing Bottom Accessed Interlocks and MOC Operator......................................................31

6-5 Series 20 Primary Connection.................................................................................................................32

6-6 Series 20 Showing Bottom Accessed Interlocks and MOC Operator......................................................33

6-7 Series 29 Primary Connection.................................................................................................................34

6-8 Series 29 Showing Bottom Accessed Interlocks and MOC Operator......................................................34

7-1 Lubrication Points....................................................................................................................................35

7-2 Vacuum Interrupter Showing Contact Erosion Indicator with Breaker Open...........................................38

7-3 Vacuum Interrupter Showing Contact Erosion Indicator with Breaker Closed.........................................38

7-4 Typical “T” Contact Wipe Indicator ..........................................................................................................39

7-5 Wipe Indication Procedure.......................................................................................................................40

TABLES

Table Title Page

1.1 Type VCP-WR (Red Line Series) Ratings.................................................................................................1

3.1 VCP-WR Breaker Weights (pounds) .......................................................................................................11

5.1 Breaker Timing ........................................................................................................................................27

7.1 Test Voltage.............................................................................................................................................37

7.2 Typical Resistance Measurements..........................................................................................................39

8.1 Recommended VCP-WR Spare Parts.....................................................................................................45