TEMPERATUREADJUSTMENT

YOUWILL NEED THEMS412 TEMPERATURE CALIBRATION

SYSTEMTO MONITORTEMPERATURE.

1. Loosen RC334 to expose Temp. Control Screw.

2. Using a clean and well-tinned tip do set up according to

illustration so that the thermocouple wire is hanging on

the tip.

3. Apply a small amount of solder on the Tip, just enough to

form a solder bead on top of the Tip. Place the center of

the thermocouple wire of the on top of the solder bead.

4. Again, apply a small amount of solder on the center of

the cross wire, just enough to embed the center.

5. Turn Temp. Control Screw clockwise to increase

temperature or counter-clockwise to decrease

temperature.

6. Tighten RC334.

Temp. Control (A) Calibration Pot (B)

SRF20

original handle

Tools Needed

•SRW01

•SRF20

•MS412

•Pot Adjustment Tool

Pot Adjustment Tool

SRF20

FX635

TI680 Meter

MS412 Temperature

Calibration System

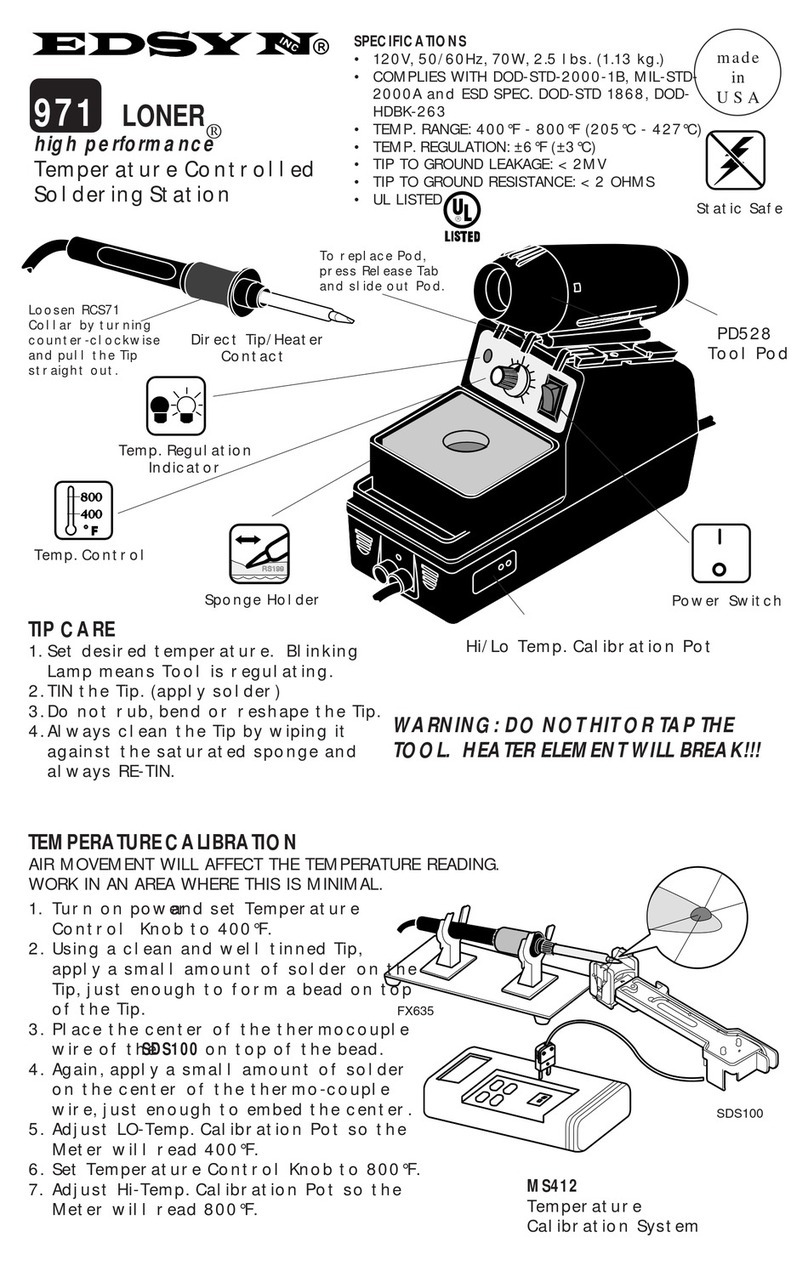

TEMPERATURECALIBRATION

AIRMOVEMENT WILLAFFECT THE TEMPERATUREREADING.

WORK IN AN AREA WHERE THIS IS MINIMUM.

1. Use the SRW01 to pull out heater assembly, PCB & power cord from handle. Leave enough power cord slack

to install SRF20.

2. Place heater assembly, PCB & power cord inside SRF20. Install tip that is clean and well tinned.

3. With the use of the MS412 Temperature Calibration System. Follow set-up shown below.

4. Plug in tool and by using the Pot Adjustment Tool supplied, turn Temp. Control (A) to "solder-melt" tempera-

ture.

5. Apply a small amount of solder on the Tip, just enough to form a solder bead on top of the Tip. Place the

center of the thermocouple wire of the on top of the solder bead.

6. Again, apply a small amount of solder on the center of the cross wire, just enough to embed the center.

7. Turn Temp. Control (A) fully clockwise. Adjust Calibration Pot (B) until reading stabilizes at 800°F.

8. Assemble unit in original handle.

ELECTRICALHAZARD

This should only be done by

qualified personnel.

SDS100

SRW01

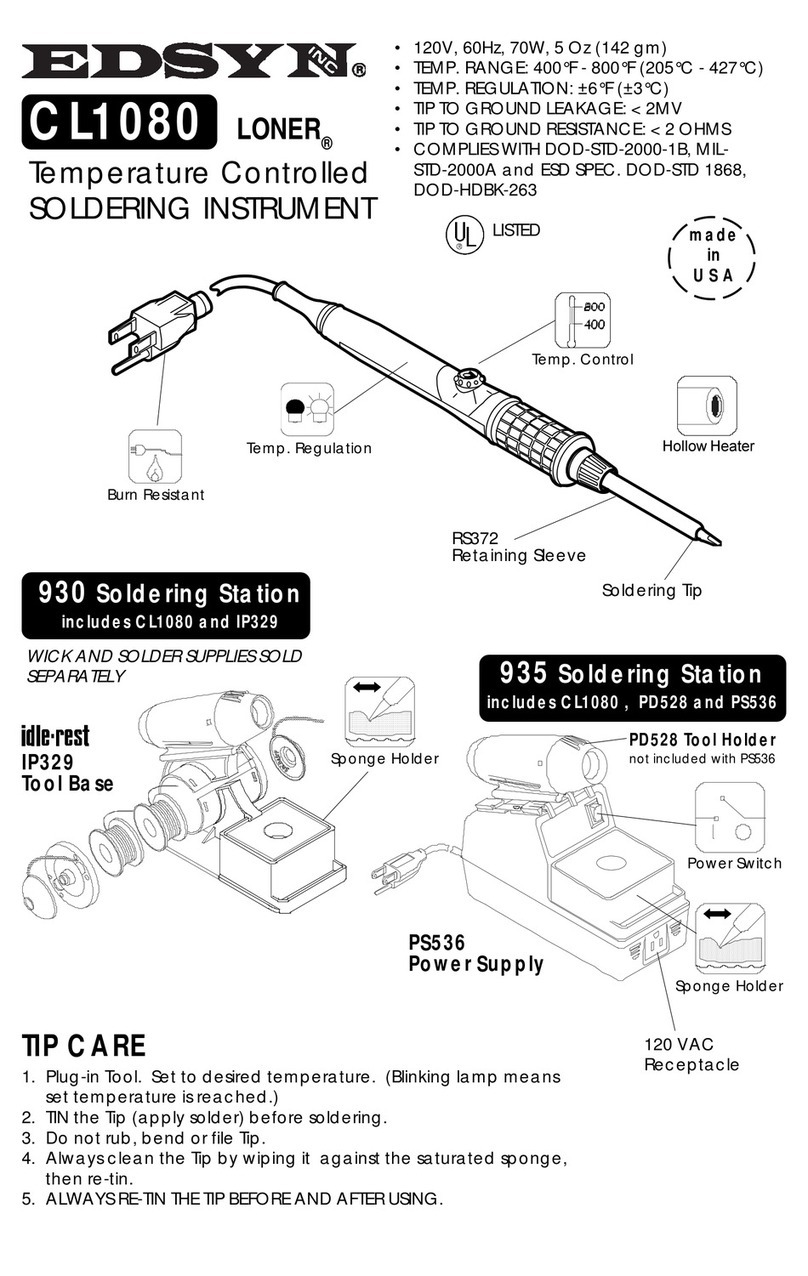

SOLDERINGTIPS

Iron Plated for long life•Nickel and

Chrome Plated for optimum heat transfer

CONTACT EDSYN FOR MORE SELECTIONS ab

Large and heavy tip for

heavy duty soldering.

Fine point tip for SMD

soldering.

.03 (0.8 mm) .48 (12.2 mm)

.06 (1.5 mm) .48 (12.2 mm)

.02 (0.5 mm) 1.13 (28.8 mm)

.07 (2.0 mm) .93 (23.6 mm)

.03 (0.8 mm) .48 (12.2 mm)

.10 (2.5 mm) .74 (18.8 mm)

.06 (1.5 mm) 1.21 (30.7 mm)

.04 (1.0 mm) 1.21 (30.7 mm)

.20 (4.9 mm) .93 (23.6 mm)

.32 (8.3 mm) .97 (21.1 mm)

LT374 Standard Probe

LT375 Standard Spade

LT392 Extra-Long Needle Point

LT394 Extra-Long Spade

LT446 SMD Probe

LT337BC Heavy Duty Terminal Spade

LT223BC Heavy Duty Fine Spade

LT222BC Extra long Needle Point

LT153BH Jumbo Spade

LT155BH Jumbo Angle Spade

SET-UP & REQUIRED ACCESSORIES FOR HEAVY DUTY AND JUMBO TIPS

Apply AN112 or

AN122* Anti-Seize

Compound to

Heater and area of

Tip contact.

*AN122 Anti-Seize Compound comes in

syringe dispenser.

MAINTENANCE

• Replace RS199 Cleaning Sponge

1. Fill water only up to the top of the RS243 Leveling Pad.

2. Depress RS199 to moisten it completely.

• Replace SC581 Solder Collector

1. Hold the Housing firm and turn Cap counter-clockwise

and pull it away from the Housing.

2. Remove used SC581 and replace with a new one.

3. Reassemble Pod with TOP of the Cap in proper position.

LN230

SH230-1

RS243

RS199

CAUTION:

Over-filling can cause thermal shock to the tip or

heating element during tip cleaning.

SC581 SR043

Front Housing

SR042

Thermal Housing

TIP CLEANING To maintain proper Tip to Ground resistance.

1. Remove Tip from Heater Assembly.

2. Using a ST707 Soldering Tool Maintenance Brush, clean Tip and

Heater Barrel at surfaces shown.

If there is no gap, try replacing the RS372 Retaining

Sleeve.

3. Install the tip and tighten RS372 Retaining Sleeve.

Take note of the gap to ensure proper fitting.

gap

clean these areas

"BC"HEAVY DUTY TIP

AC735 TA350 JUMBOTIP RS351

RS271