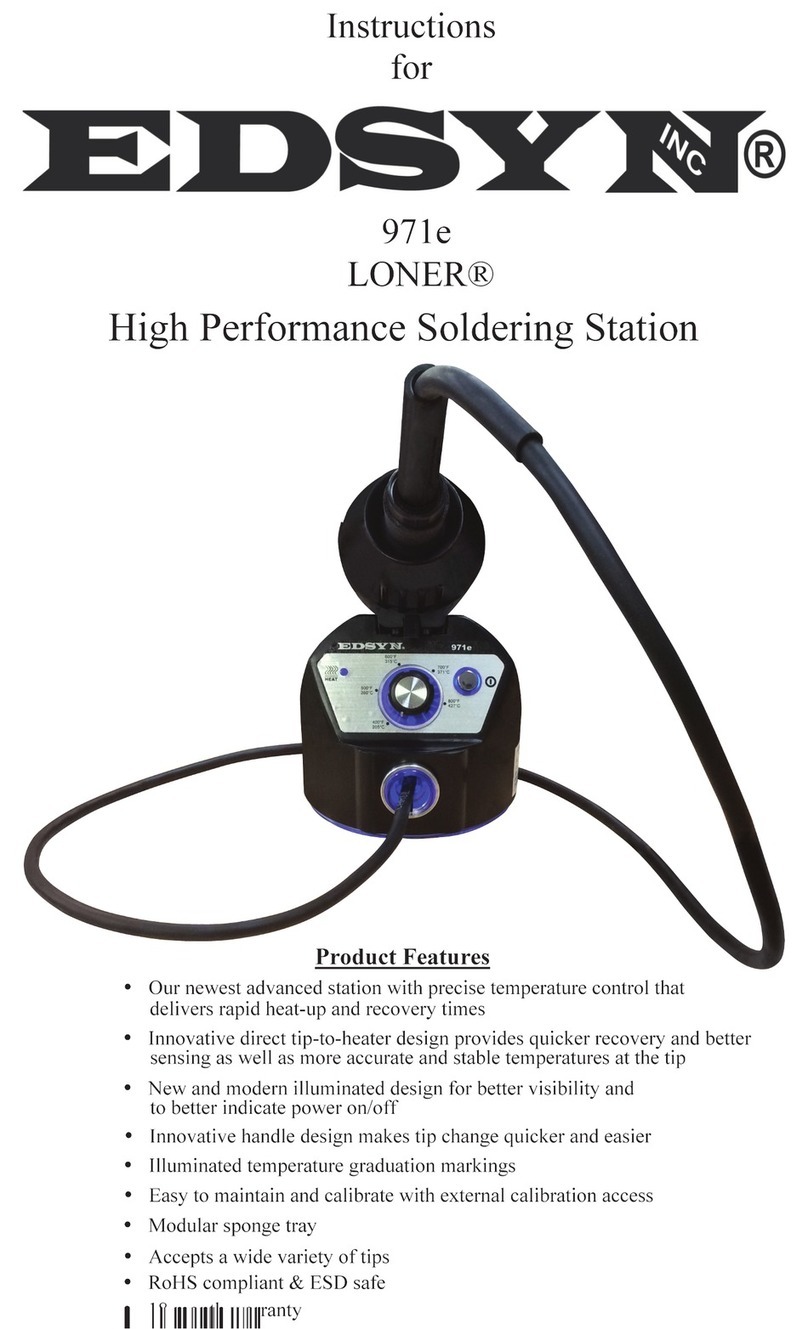

Edsyn ZD905 User manual

Other Edsyn Soldering Gun manuals

Edsyn

Edsyn LONER 971DX User manual

Edsyn

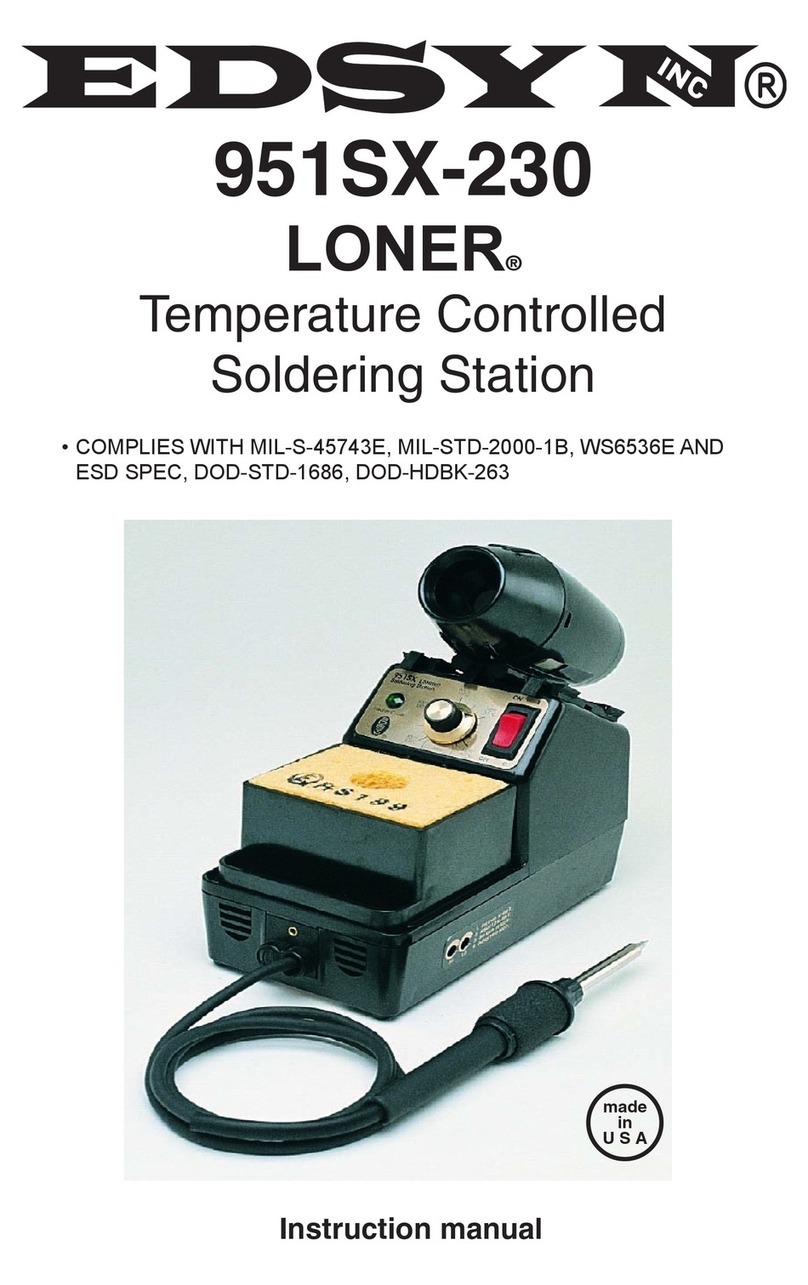

Edsyn LONER 951SX-230 User manual

Edsyn

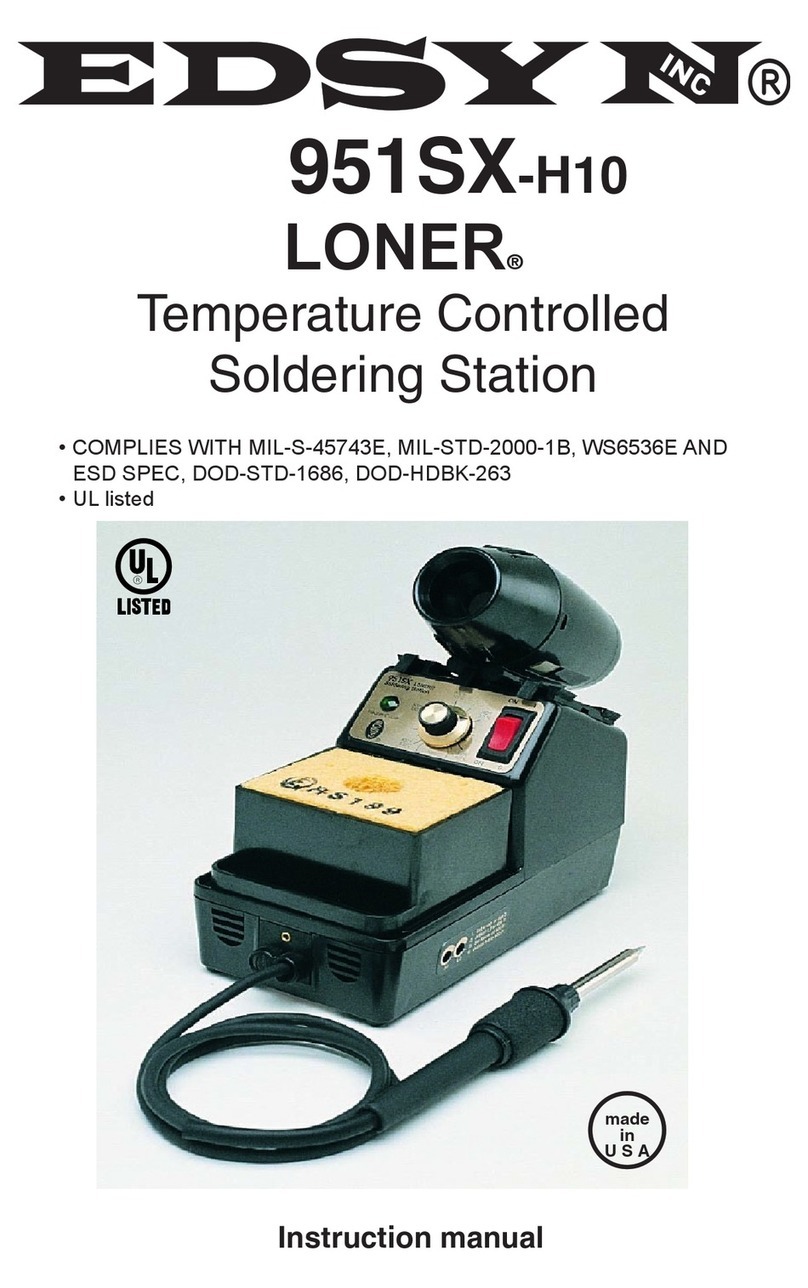

Edsyn LONER 951SX-H10 User manual

Edsyn

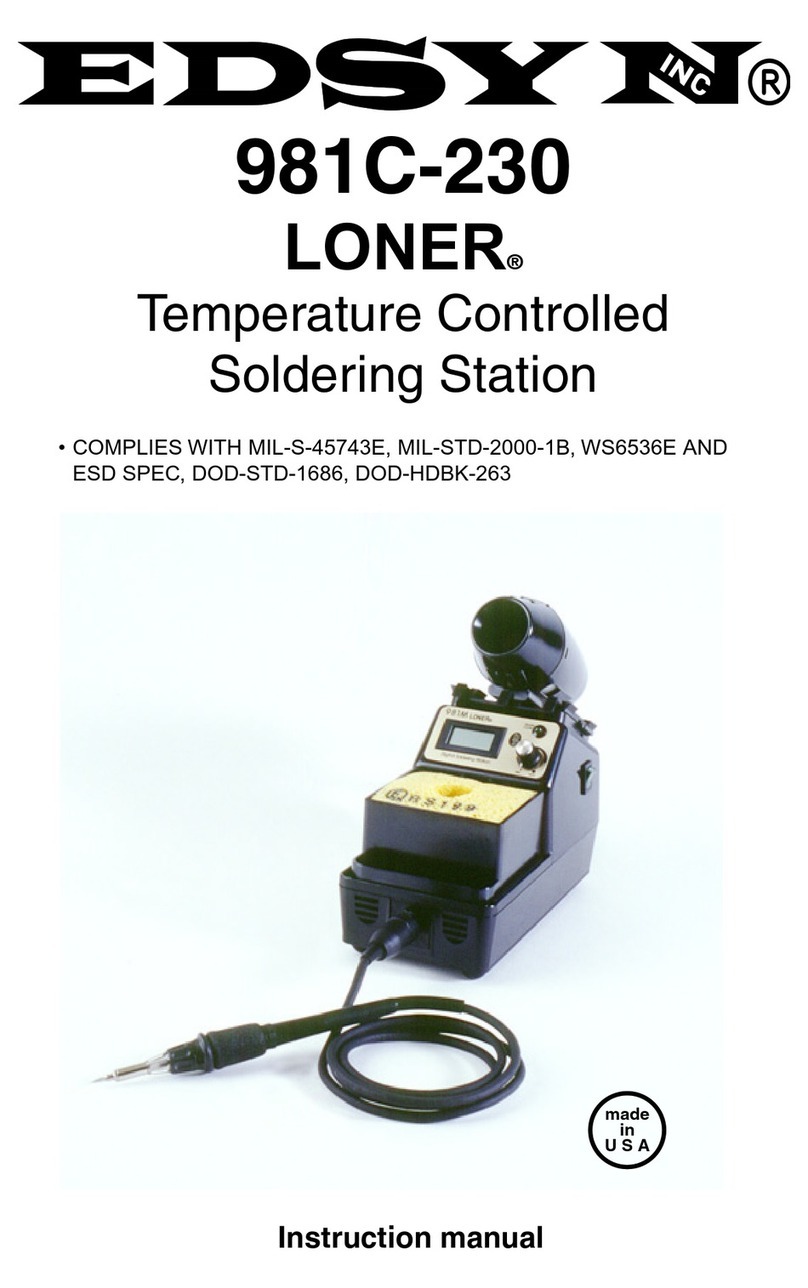

Edsyn 981C-230 User manual

Edsyn

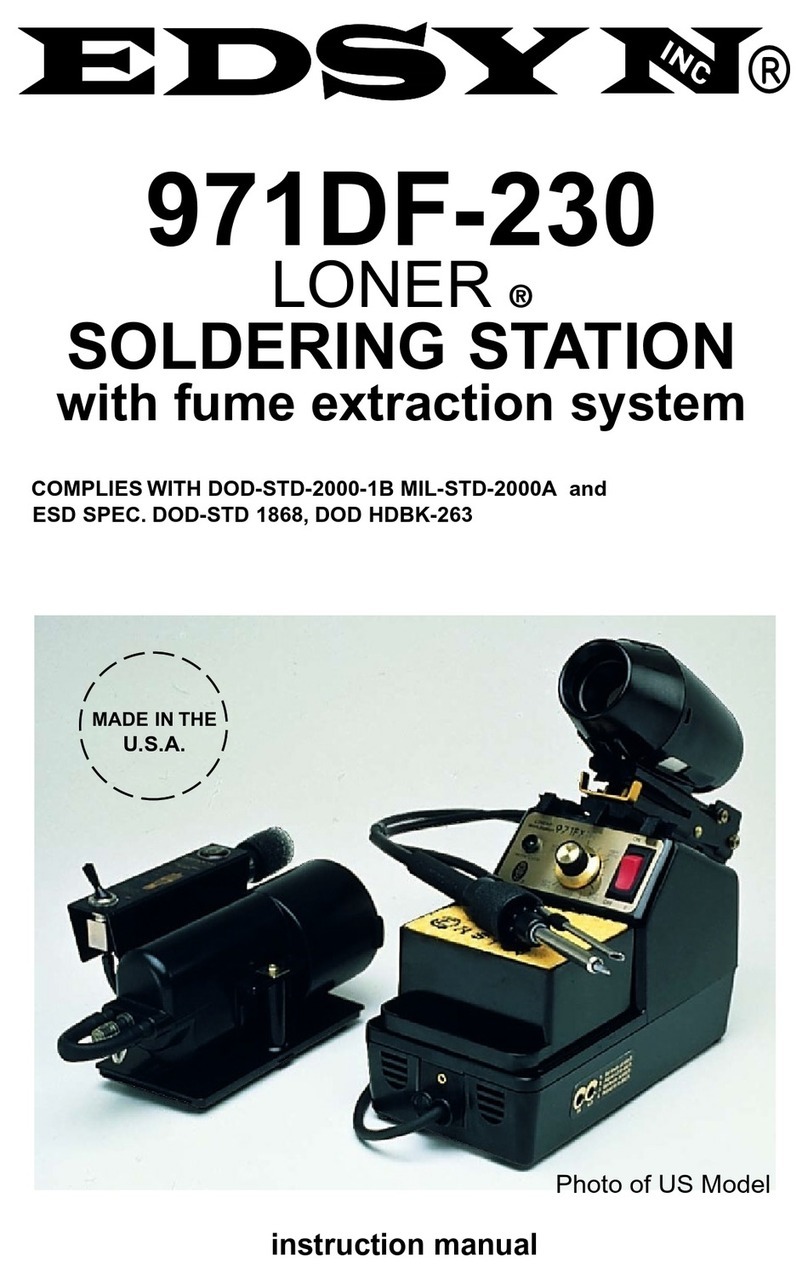

Edsyn LONER 971DF-230 User manual

Edsyn

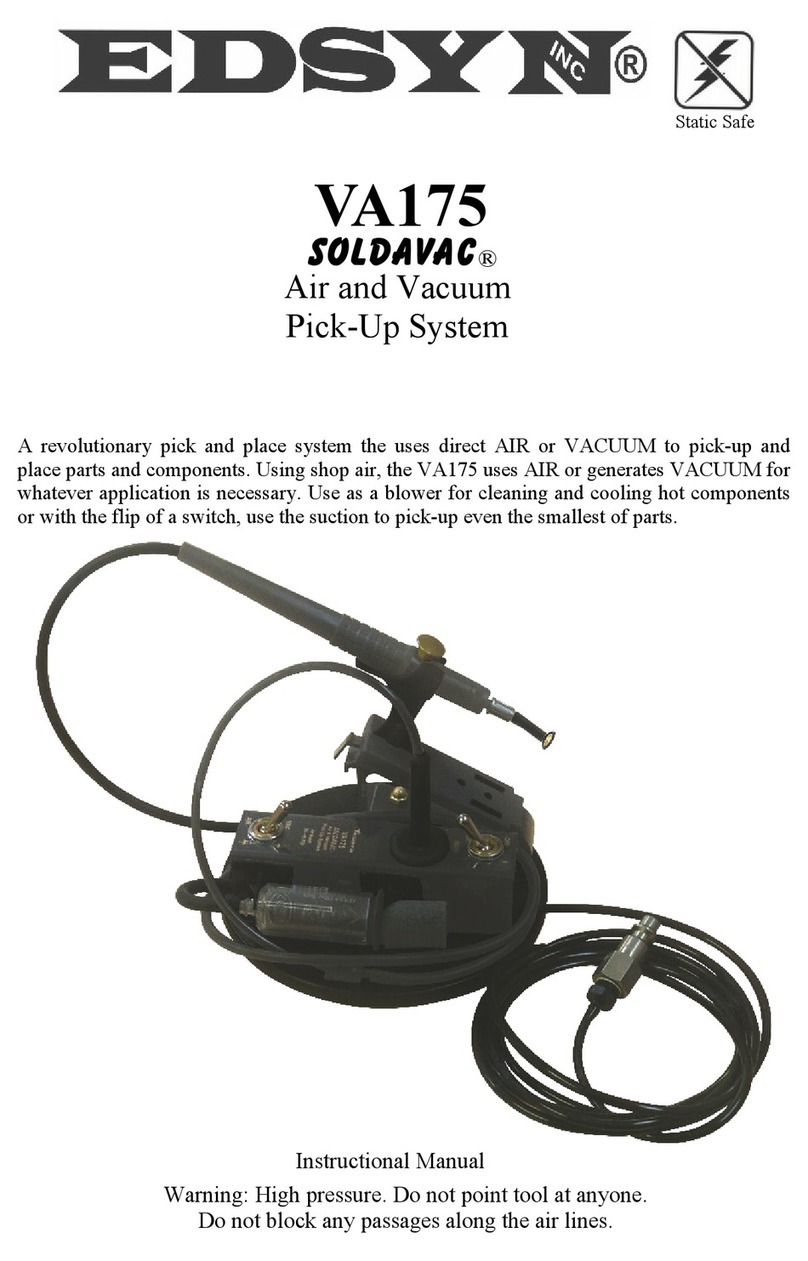

Edsyn SOLDAVAC VA175 Operating and maintenance manual

Edsyn

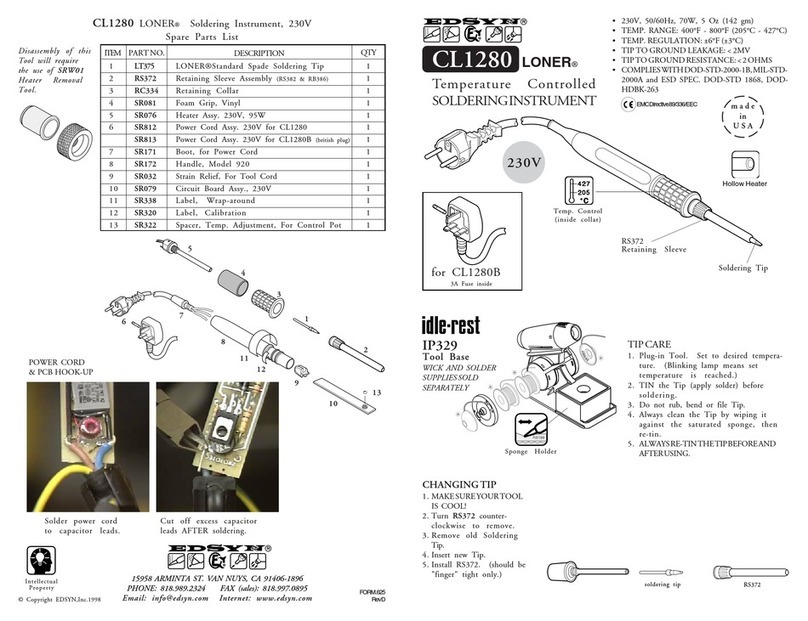

Edsyn CL1280 LONER User manual

Edsyn

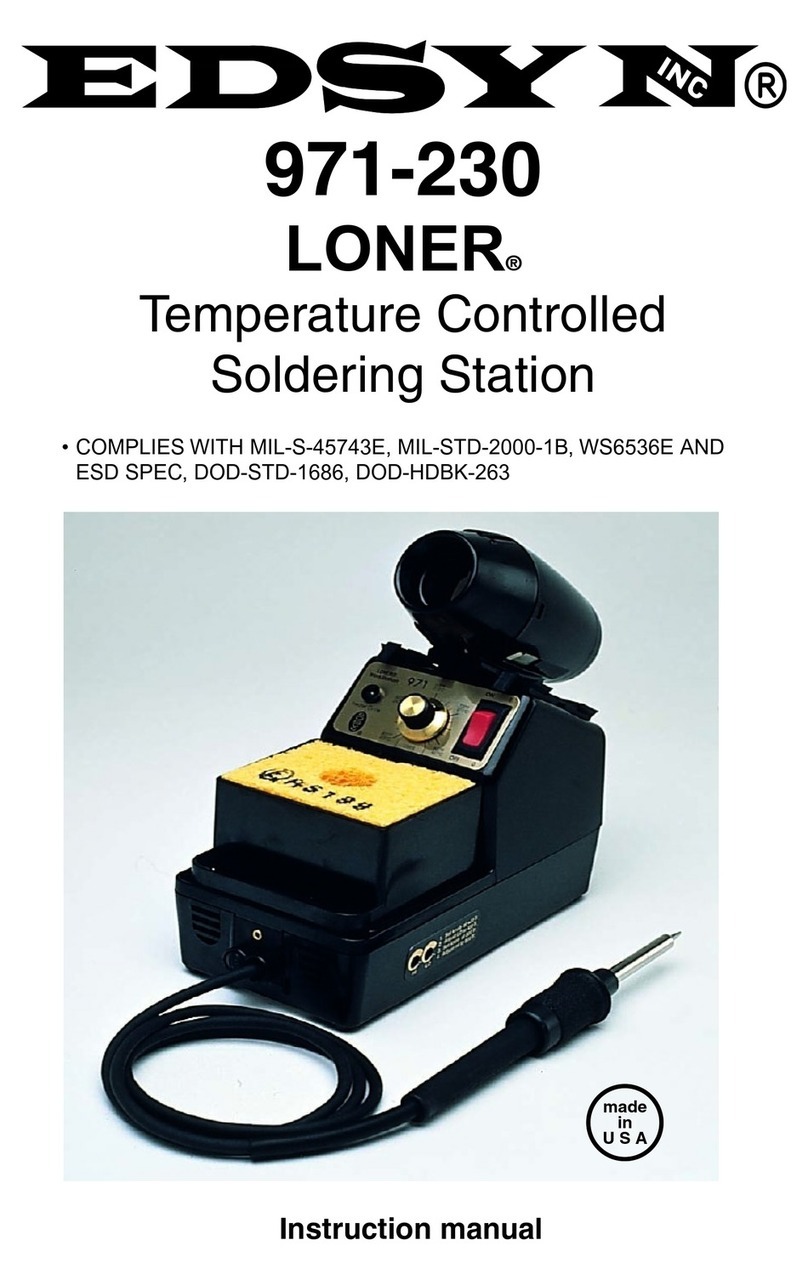

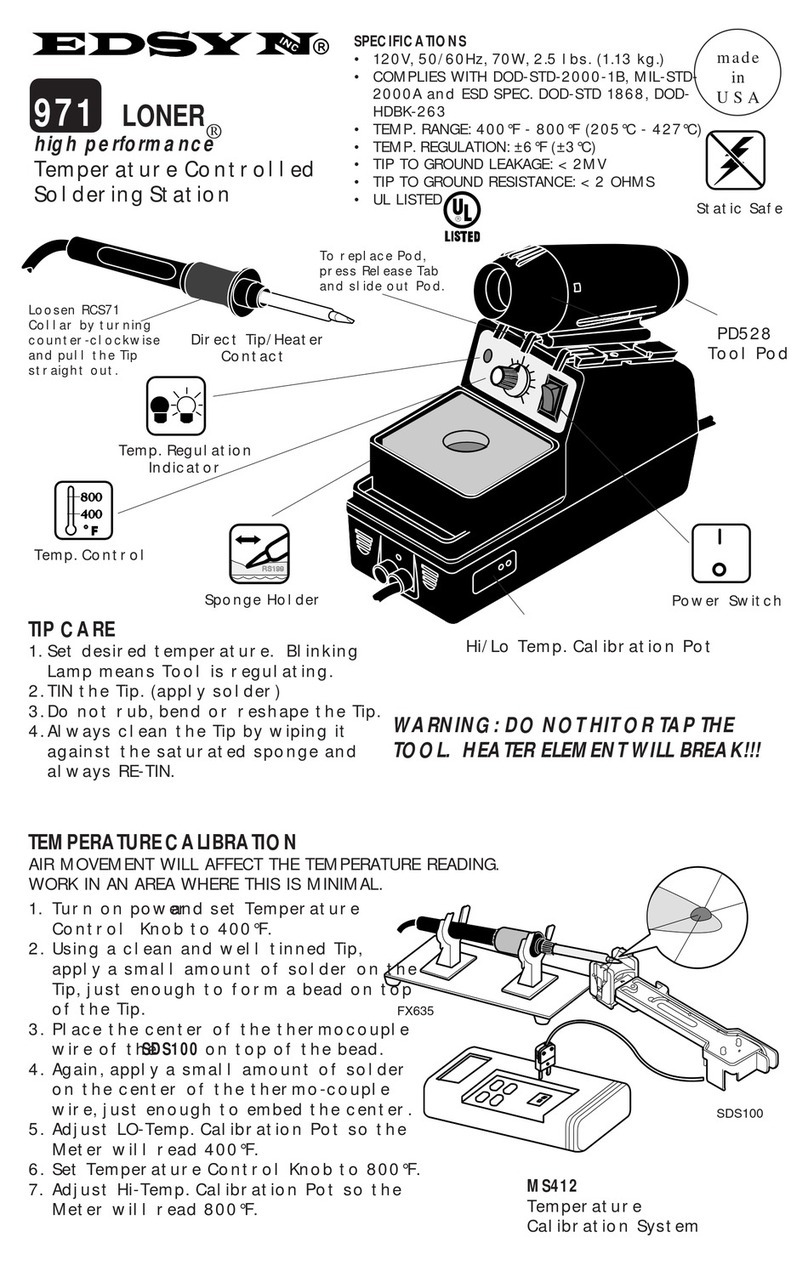

Edsyn 971 LONER User manual

Edsyn

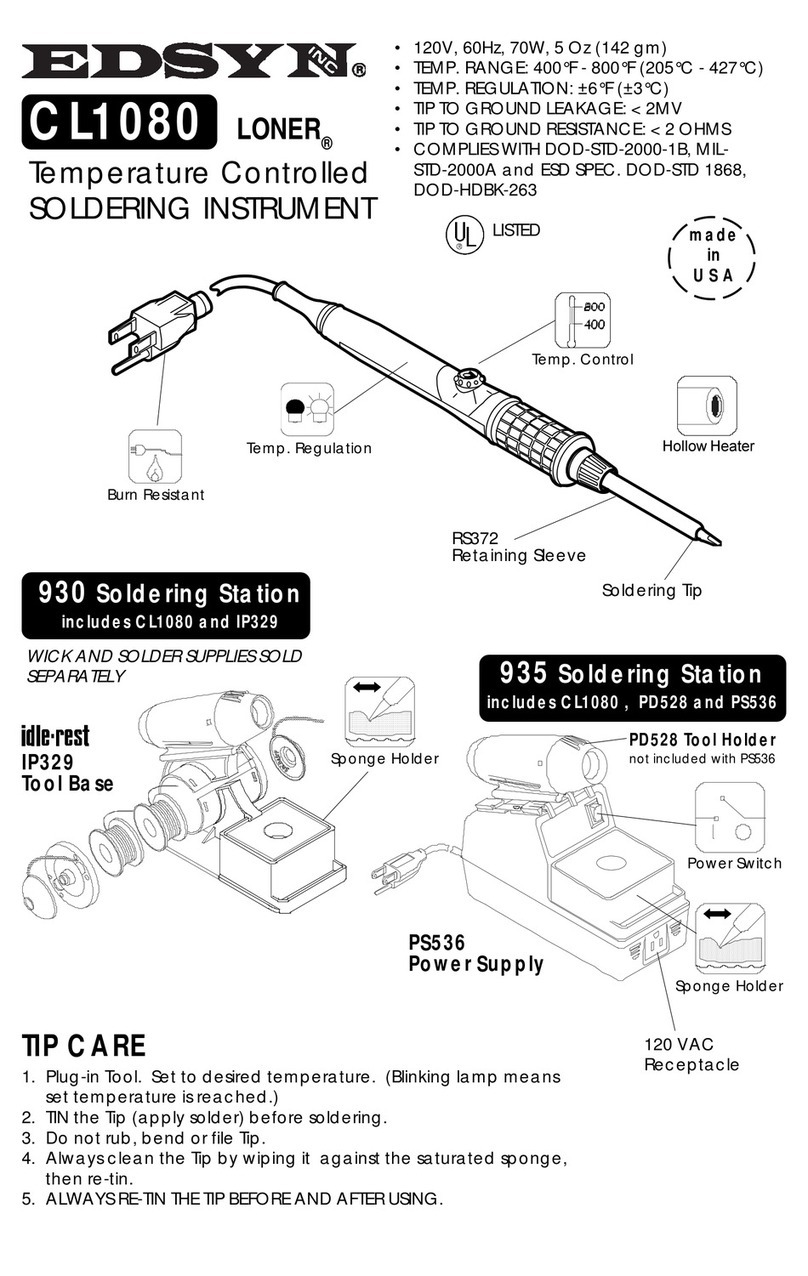

Edsyn CL1080 LONER User manual

Edsyn

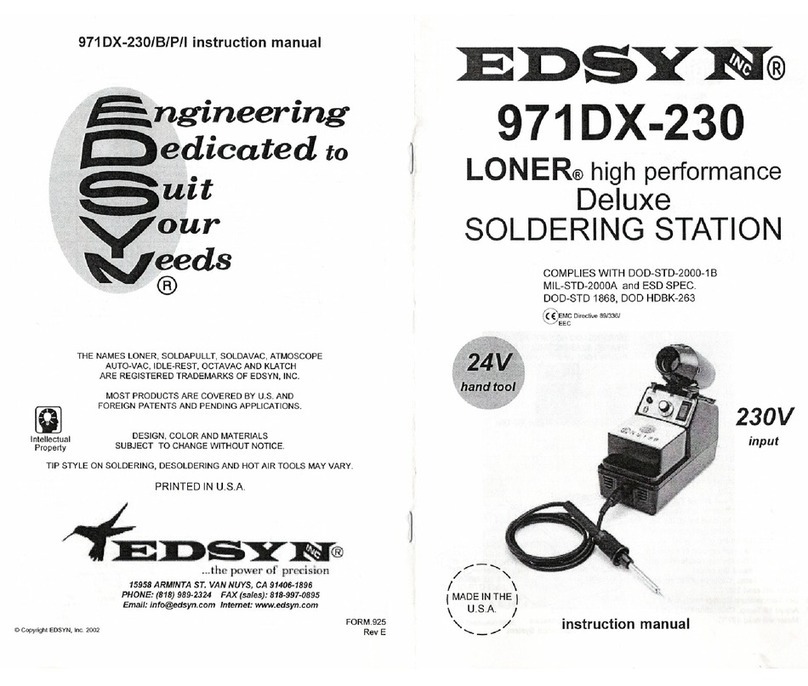

Edsyn 971DX-230 User manual

Popular Soldering Gun manuals by other brands

Velleman

Velleman HRJA151 user manual

Weller

Weller WSM 1 operating instructions

Vishay Precision Group

Vishay Precision Group Micro-Measurements Mark V Operating and maintaining

ersa

ersa i-CON 1V quick guide

Hakko Electronics

Hakko Electronics FX-100 instruction manual

Weller

Weller WAD 101 operating instructions