Edwards CG16K User manual

D35610880

Issue H

Original

Instruction Manual

CG16K Barometrically Compensated

Capsule Dial Gauge

Description Item Number

CG16K Capsule Dial Gauge, 0 to 1040 mbar D35610000

CG16K Capsule Dial Gauge, 0 to 125 mbar D35611000

CG16K Capsule Dial Gauge, 0 to 50 mbar D35612000

CG16K Capsule Dial Gauge, 0 to 25 mbar D35613000

CG16K Capsule Dial Gauge, 0 to 760 Torr D35630000

CG16K Capsule Dial Gauge, 0 to 100 Torr D35631000

CG16K Capsule Dial Gauge, 0 to 40 Torr D35632000

CG16K Capsule Dial Gauge, 0 to 20 Torr D35633000

This page has been intentionally left blank.

© Edwards Limited 2019. All rights reserved. Page i

Contents

D35610880 Issue H

Contents

Section Page

1 Introduction ....................................................................................... 1

1.1 Scope and definitions ................................................................................................... 1

1.2 Description ................................................................................................................ 1

1.3 Construction .............................................................................................................. 1

2 Technical Data .................................................................................... 3

2.1 Mechanical Data ......................................................................................................... 3

2.2 Performance .............................................................................................................. 3

3 Installation ......................................................................................... 5

3.1 Unpack and inspect ...................................................................................................... 5

3.2 Fit the Capsule Dial Gauge ............................................................................................. 5

3.3 Connect to the vacuum system ........................................................................................ 5

3.4 Leak-test the installation ............................................................................................... 5

4 Operation .......................................................................................... 7

5 Maintenance ....................................................................................... 9

5.1 Repairs .................................................................................................................... 9

5.2 Calibration ................................................................................................................ 9

6 Storage and Disposal ........................................................................... 11

6.1 Storage ...................................................................................................................11

6.2 Disposal ...................................................................................................................11

7 Spares and Accessories ........................................................................ 13

7.1 Introduction .............................................................................................................13

7.2 Accessories ...............................................................................................................13

For return of equipment, complete the HS Forms at the end of this manual.

Illustrations

Figure Page

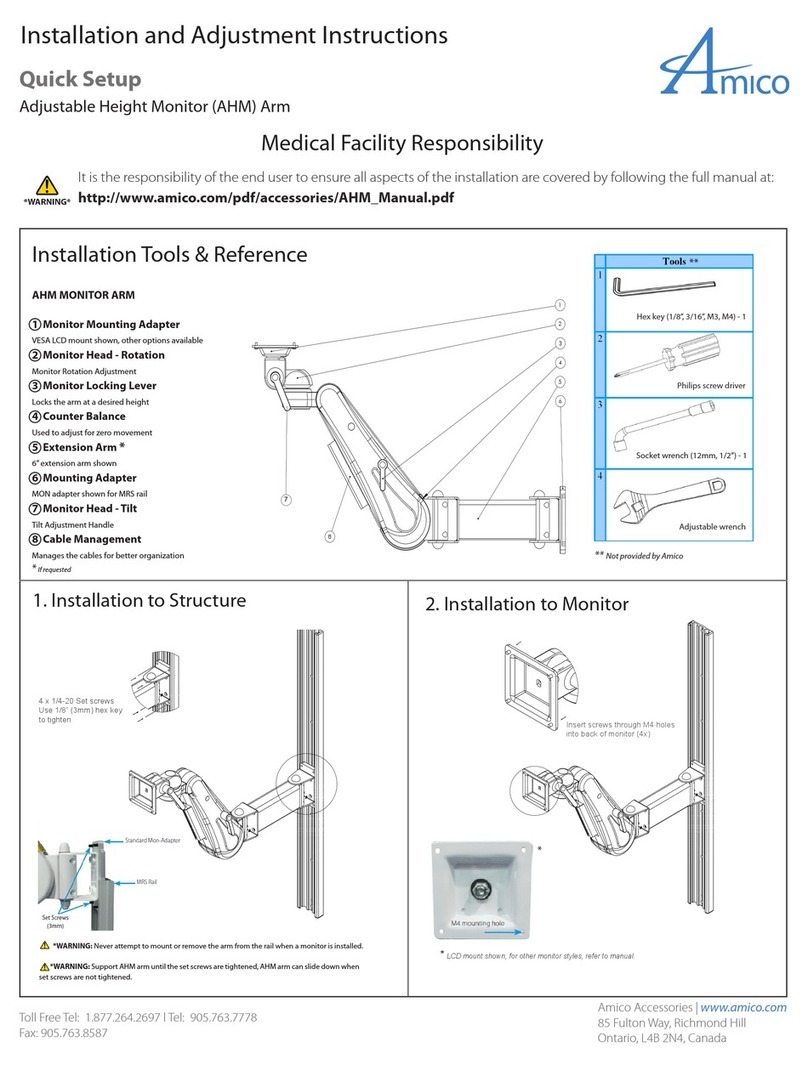

1 Dimensions of panel mounted CG16K (mm) ......................................................................... 3

Associated publications

Publication title Publication number

Vacuum pump and vacuum system safety P40040100

CG092019

D35610880 Issue H

Page ii © Edwards Limited 2019. All rights reserved.

Contents

Trademark credits

Edwards and the Edwards logo are trademarks of Edwards Limited, Innovation Drive, Burgess Hill,

West Sussex, RH15 9TW, UK.

© Edwards Limited 2019. All rights reserved. Page 1

Introduction

D35610880 Issue H

1 Introduction

1.1 Scope and definitions

This manual provides installation, operation and maintenance instructions for the Edwards CG16K Capsule Dial

Gauge. You must use the Capsule Dial Gauge as specified in this manual.

Read this manual before you install and operate the Capsule Dial Gauge. Important safety information is highlighted

as WARNING and CAUTION instructions; you must obey these instructions. The use of WARNINGS and CAUTIONS is

defined below.

CAUTION

Cautions are given where failure to observe the instruction could result in damage to the equipment, associated

equipment and process.

The following IEC warning labels appears on the CG16K:

The units used throughout this manual conform to the SI international system of units of measurement.

1.2 Description

The CG16K Capsule Dial Gauge measures the total absolute pressure of gas in your vacuum system. The composition

of the gas does not affect the measurement; the CG16K Capsule Dial Gauge is therefore useful in applications where

you need to measure the pressure of gases other than air.

The CG16K Capsule Dial Gauge is barometrically compensated, so that pressure measurements are unaffected by the

ambient atmospheric pressure. This is useful when you need to measure low pressures.

1.3 Construction

Internally, the CG16K has a sealed, evacuated capsule with a mechanical linkage which operates the pointer on the

dial. The capsule is enclosed in the case of the gauge.

The case is open to the vacuum system and is sealed from the atmosphere by a sealing ring, which is clamped under

the safety glass by a screwed bezel.

WARNING

Warnings are given where failure to observe the instruction could result in injury or death to

people.

Warning - refer to accompanying documentation.

D35610880 Issue H

Page 2 © Edwards Limited 2019. All rights reserved.

Technical data

2 Technical data

2.1 Mechanical data

2.2 Performance

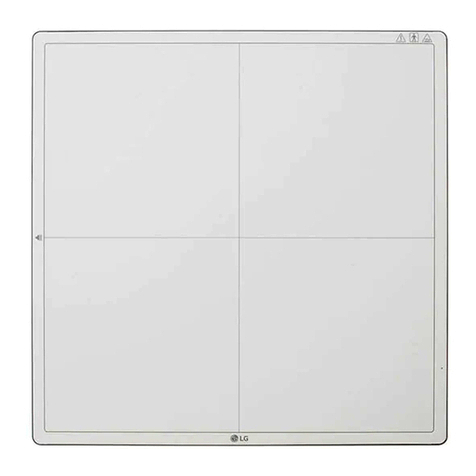

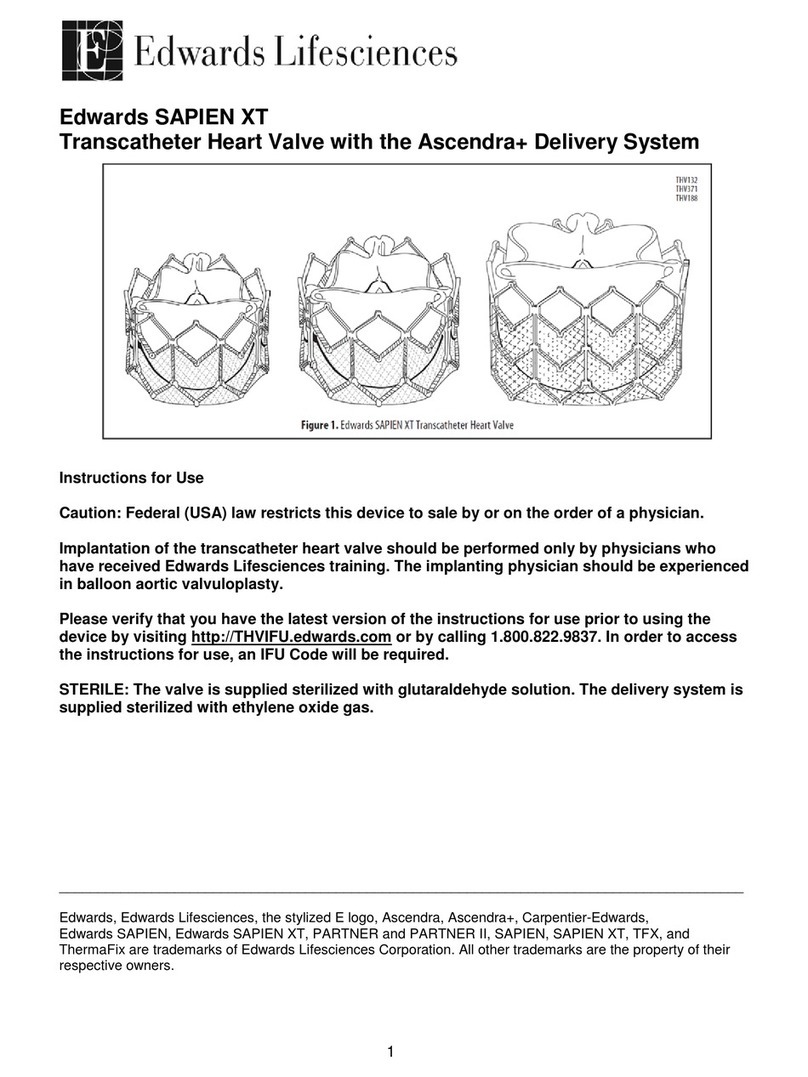

Figure 1 - Dimensions of panel mounted CG16K (mm)

Dimensions See Figure 1

Mass 0.9 kg

Vacuum connection NW16

Internal volume 160 cm3

Materials exposed to vacuum Aluminium, Inconel, glass, Fluoroelastomer, Nical,

copper alloy

Operating temperature range 10 to 50 ºC

Accuracy at 20 ºC ± 2% of full-scale deflection

Leak rate into gauge at a differential pressure

of 1 bar

< 1 x 10-5 ls-1

Maximum internal pressure 1 bar gauge (2 bar absolute)

© Edwards Limited 2019. All rights reserved. Page 3

Installation

D35610880 Issue H

3 Installation

3.1 Unpack and inspect

Remove all packing materials and protective covers and check the CG16K Capsule Dial Gauge.

If the CG16K Capsule Dial Gauge is damaged, notify your supplier and the carrier in writing within three days; state

the Item Number of the gauge together with your order number and your supplier’s invoice number. Retain all

packing materials for inspection. Do not use the gauge.

If the CG16K is not to be used immediately, replace the protective covers. Store the CG16K in suitable conditions as

described in Section 6.1.

3.2 Fit the Capsule Dial Gauge

Fit the CG16K as close as possible to the point in the vacuum system at which you wish to measure the pressure. Do

not use a narrow pipeline or incorporate angled connections, as these may cause errors in the pressure measurement.

You can fit the CG16K so that it is supported by the vacuum connection. If you fit the CG16K in this way, make sure

that the pipeline which connects the CG16K to the vacuum system is as short as possible and that very little vibration

can be transmitted to the gauge.

Alternatively, you can fit the CG16K so that it is panel mounted. If you wish to fit the CG16K on a panel, the panel

must be at least 2 mm thick. Use the procedure below.

1. Cut a 111 to 112 mm diameter hole in the panel where you wish to locate the gauge.

2. Push the rear of the CG16K through the hole and fit the clamp over the bolts as shown in Figure 1.

3. Secure the CG16K in place with the two wing-nuts.

3.3 Connect to the vacuum system

Note: If you need to connect the CG16K to an SC5 connection, you must use the accessories listed in Section 7.2.

The CG16K has an NW16 flange. Use the NW16 fittings to connect the CG16K to the vacuum system.

Alternatively, use the procedure below to connect the CG16K to 6 mm copper pipe:

1. Unscrew and remove the NW16 flange from the body of the CG16K.

2. Fit a 6 mm pipe union (available as an accessory, see Section 7.2) to the body of the CG16K.

3. Braze the brass tail piece of the pipe union to the 6 mm copper pipe in your system.

3.4 Leak test the installation

Leak test the vacuum system after you have installed the CG16K. Hazardous substances which leak from the system

may be dangerous to personnel and there may be a danger of explosion if air leaks into the system.

WARNING

Leak test the vacuum system after installation of the CG16K to prevent leakage of hazardous

substances out of the system and leakage of air into the system.

D35610880 Issue H

Page 4 © Edwards Limited 2019. All rights reserved.

Operation

4 Operation

CAUTION

Dust or solid particles in the vacuum system can enter the gauge mechanism and cause the CG16K to

malfunction.

CAUTION

Do not use the CG16K to measure the pressure of process gases which are corrosive or have a high concentration

of water vapour. If you do, you may get incorrect pressure measurements and you may damage the CG16K.

Once you have installed the CG16K as described in Section 3, the measurement shown on the dial of the CG16K will

indicate the total pressure in your vacuum system.

WARNING

Do not allow the internal pressure to be higher than 1 bar gauge (2 bar absolute). If the pressure

in your system can be higher than 1 bar gauge, you must fit a suitable pressure relief valve.

© Edwards Limited 2019. All rights reserved. Page 5

Maintenance

D35610880 Issue H

5 Maintenance

5.1 Repairs

The CG16K Capsule Dial Gauge contains no parts which can be serviced by the user.

An exchange/replacement service is available, if your gauge is damaged; contact your supplier or your nearest

Edwards company for information.

5.2 Calibration

The CG16K Capsule Dial Gauge must be calibrated regularly to maintain the accuracy (specified in Section 2.2).

A calibration service is available; contact your supplier or your nearest Edwards company for information.

D35610880 Issue H

Page 6 © Edwards Limited 2019. All rights reserved.

Storage and Disposal

6 Storage and Disposal

6.1 Storage

Store the CG16K Capsule Dial Gauge in cool, dry conditions until required for use. When required, prepare and install

the CG16K as described in Section 3.

6.2 Disposal

Dispose of the CG16K Capsule Dial Gauge and any components removed from it safely in accordance with all local

and national safety and environmental requirements.

© Edwards Limited 2019. All rights reserved. Page 7

Spares and Accessories

D35610880 Issue H

7 Spares and Accessories

7.1 Introduction

Edwards products, spares and accessories are available from Edwards companies in Belgium, Brazil, Canada, France,

Germany, Hong Kong, Italy, Japan, Korea, Switzerland, United Kingdom, U.S.A., and a world wide network of

distributors. The majority of these centres employ Service Engineers who have undergone comprehensive Edwards

training courses.

Order spare parts and accessories from your nearest Edwards company or distributor. When you order, please state

for each part required:

Model and Item Number of your equipment

Serial number (if any)

Item Number and description of part

7.2 Accessories

The accessories listed below allow you to connect the CG16K Capsule Dial Gauge directly to an SC5 fitting; you do

not need to make any brazed joints.

The accessory listed below allows you to connect the CG16K Capsule Dial Gauge to 6 mm copper pipe.

7.2.1 Return the equipment or components for service

Before you send your equipment to us for service or for any other reason, you must send us a completed Declaration

of Contamination of Vacuum Equipment and Components – Form HS2. The HS2 form tells us if any substances found

in the equipment are hazardous, which is important for the safety of our employees and all other people involved in

the service of your equipment. The hazard information also lets us select the correct procedures to service your

equipment.

We provide instructions for completing the form in the Declaration of Contamination of Vacuum equipment and

Components – Procedure HS1.

Download the latest documents from www.edwardsvacuum.com/HSForms/, follow the procedure in HS1, fill in the

electronic HS2 form, print it, sign it, and return the signed copy to Edwards.

Note: If we do not receive a completed HS2 form, your equipment cannot be serviced.

Product Item Number

SC5 to NW10 adapter C10511435

NW10/16 Co-seal B27158426

NW10/16 Clamping ring C10512401

Product Item Number

6 mm pipe union D35610201

edwardsvacuum.com

This manual suits for next models

8

Table of contents

Other Edwards Medical Equipment manuals

Edwards

Edwards ES Series User manual

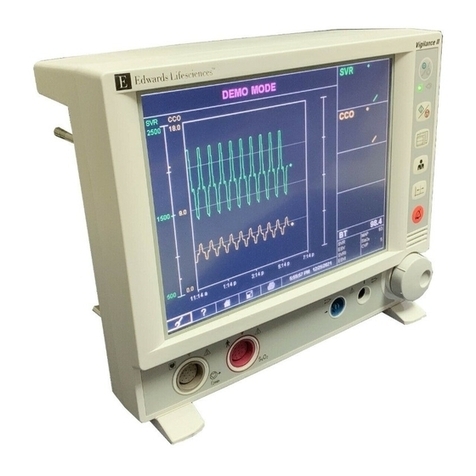

Edwards

Edwards Vigilance II User manual

Edwards

Edwards AUTO 306 User manual

Edwards

Edwards Acumen IQ Cuff User manual

Edwards

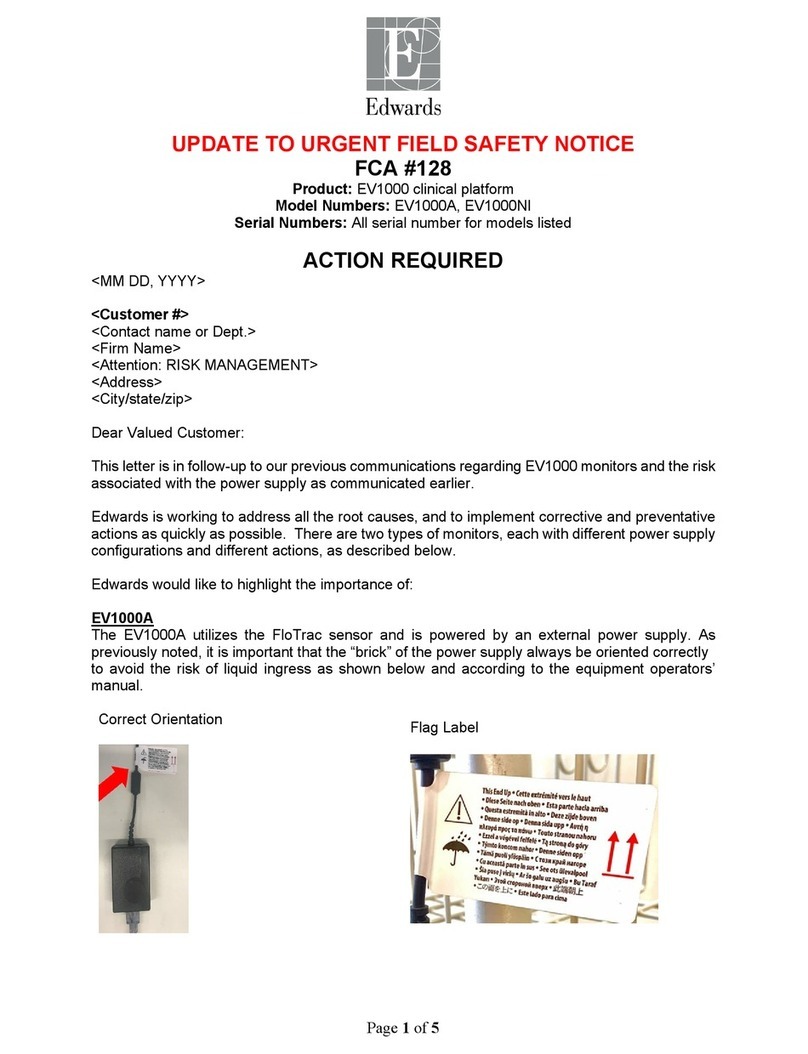

Edwards EV1000 Clinical Platform User manual

Edwards

Edwards EV1000A User manual

Edwards

Edwards SAPIEN XT User manual

Edwards

Edwards VolumeView EV1000 User manual

Edwards

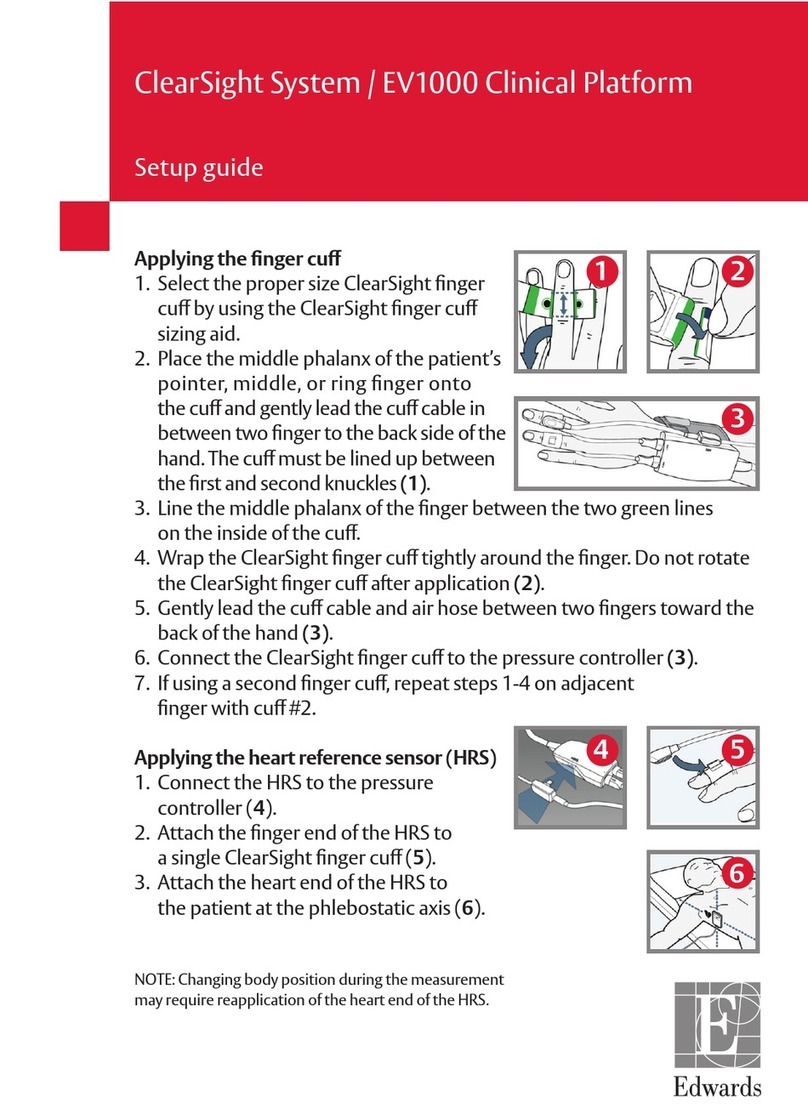

Edwards ClearSight System User manual

Edwards

Edwards EV1000 Clinical Platform User manual