The coaxial cableon the vacuum side of the leadthrough connectsthe leadthrough to the

crystal head. The cableis insulated with PTFEand you do not needto usemore insulation

unlessyou usetemperaturesabove300°c inside thechamber. For normal work, wrap the

coaxialcableloosely round the coiled copper tubes. If you usetemperaturesabove300°C,

wrap the cableand coiled coppertubeswith aluminium foil to protect them. It is important

that you do this if you useelectronbeamand RFsputtering sources.

.

You must position thecrystal headcarefully in RFsputtering systemsto avoid interference.

You must provide sufficient cooling-water to theWater Cooled Crystal Holder, especially

when you areusing radiant heaters.You may usetheWater CooledCrystal Holder without

cooling-water only for short, low temperature depositions. If you usewater which is too

cold, condensation may form on the crystal and the crystal head when the coating system

is vented to atmospheric pressure. Too much condensationmay causethe crystal to stop

oscillating; this condition is temporary and the crystal will function correctly when the

condensationevaporates.

Usea shutter to shield the crystal head during theinitial soakperiod to protect the crystal

from any spitting that may occur. If a small droplet of molten material hits the crystal

surface,the crystal may be damagedand it may stop oscillating.

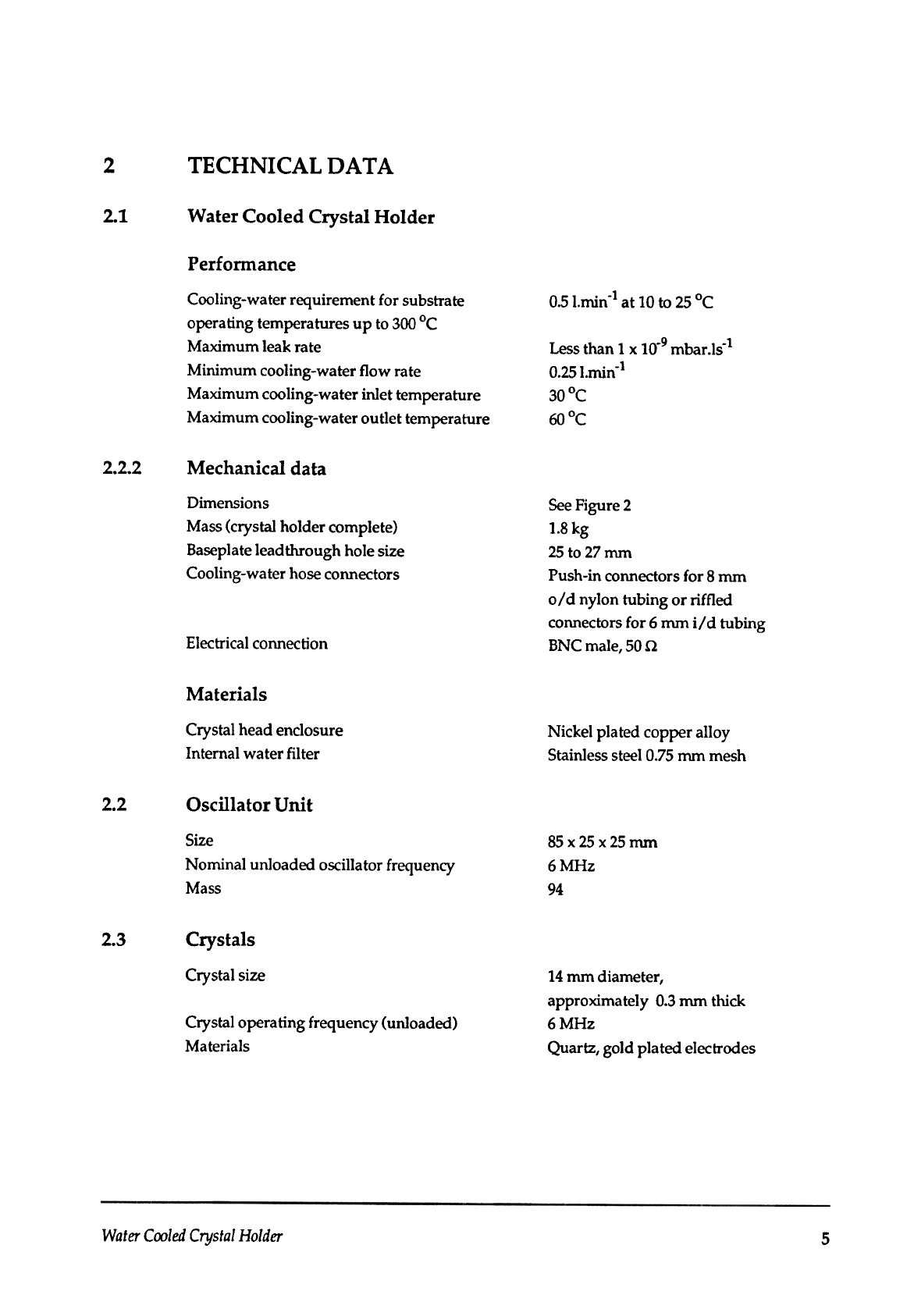

3.4 How to install the Water Cooled Crystal Holder

A typical installation of the WaterCooled Crystal Holder is shown in Figure 2. Figure 4 shows

thewater hoseconnectionsfor anAUTa 306.Figure5showshow tousethequick fit connectors.

Beforeyou start theinstallation procedurebelow, selectthebestbaseplateleadthrough hole for

your application. To prevent vibration of the crystal headwhen it is in use,you may want to

attachthe crystal headtoanearbysupport in your chamber;todo this,you must makeabracket

which canbefixed to the two M3 tapped holesin thebackof thecrystal head(refer to Figure 3).

Oneof thecooling-water connectorson thebottom of theleadthrough hasawater filter inserted

into it (refer to Figure 6, item 13):you must identify this connector and ensure that the water

supply hoseis fitted to this connector.

You must cut the nylon tube (supplied with the Water Cooled Crystal Holder) to the correct

length for your installation: thelength of tubethat you will require will dependon the position

of thebaseplateleadthrough hole you have usedfor the Water Cooled Crystal Holder. For the

AUTO 306,themaximum length of tubethat you will require (if you haveusedthehole furthest

from the side panel with the water hoses)will beabout 1.4m. Cut the tube sothat, when it is

installed, there areno loops or bendsin the tube which could restrict the water flow.

Water Cooled Crystal Holder 9