3

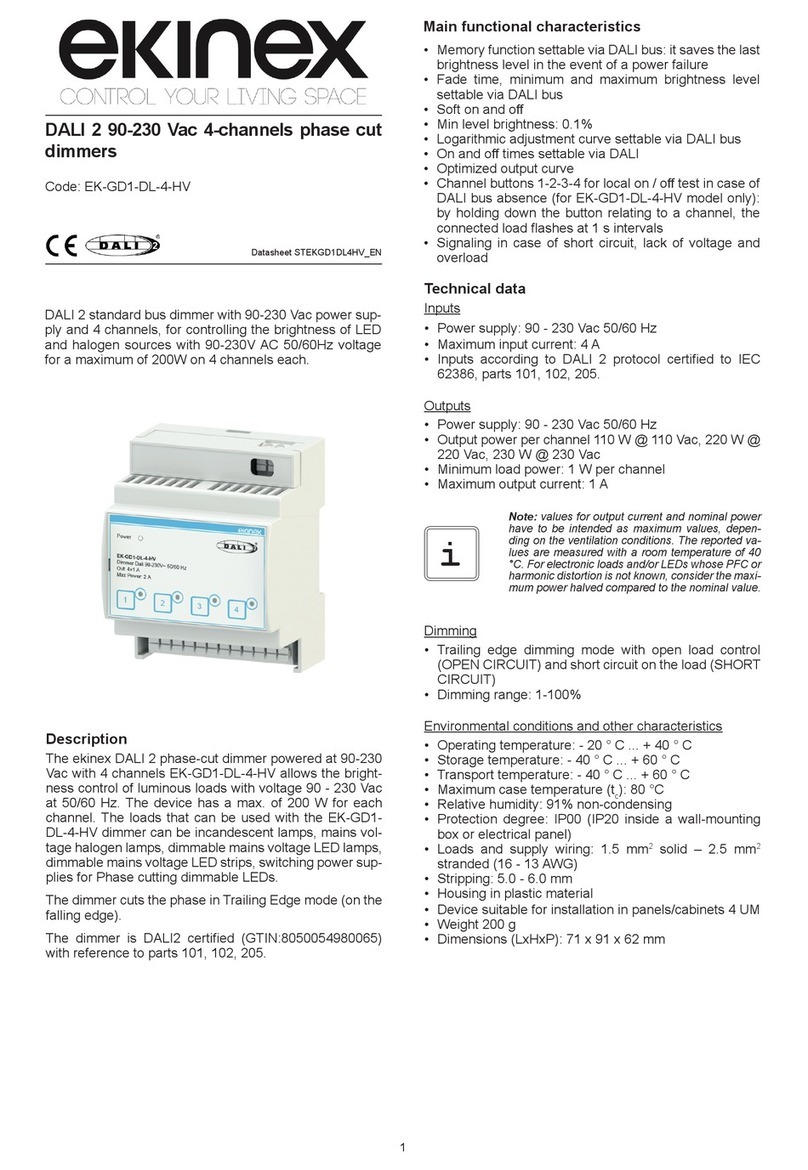

The 12-way dip-switch setting (under the front cover) of-

fers a wide choice of possible congurations.

Note. When mounting the device in boards and ca-

binets it shall be provided the necessary ventilation

so that the temperature can be kept within the ope-

rating range of the device.

i

a b

dc

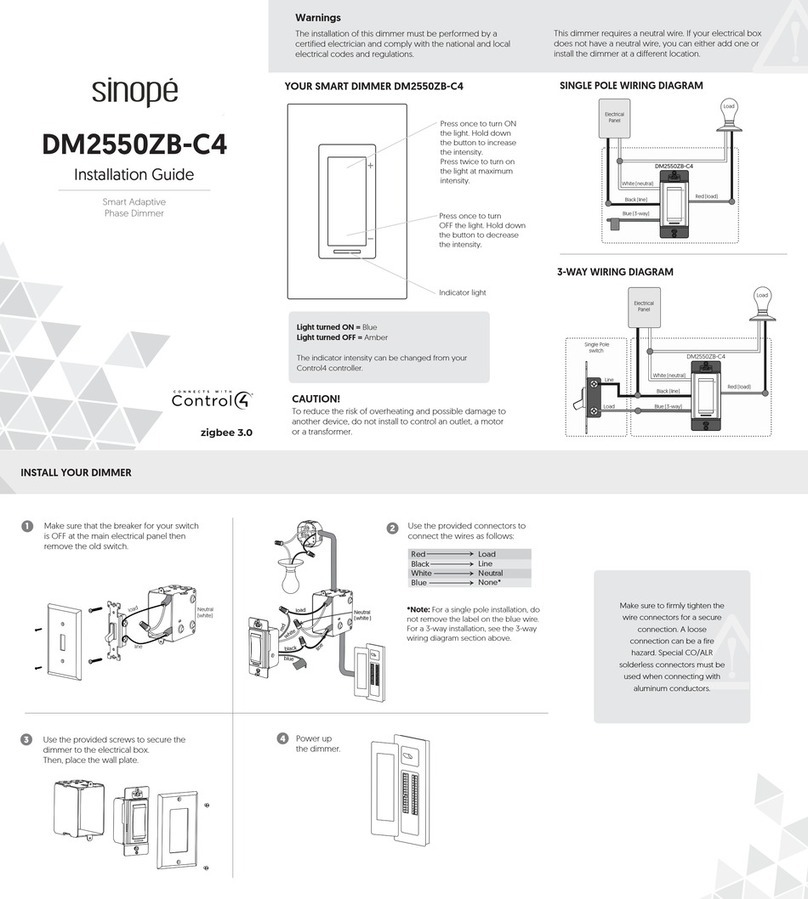

INSTALLATION TECHNICAL NOTES

• Installation and maintenance must be

performed only if the power supply has

been turned o.

• Installation and maintenance must only

be performed by qualied personnel in

compliance with current regulations.

• The product must be installed insi-

de an electrical panel protected against

overvoltages.

• The product must be installed in a verti-

cal position with the front / label facing

the front or in a horizontal position with

the front / label facing upwards. Other

product installation positions are not al-

lowed. The bottom position with the front

panel / label facing down is not allowed.

• Keep separated the circuits at 230V (LV)

and the circuits not SELV from circuits

to low voltage (SELV) and from any con-

nection with this product. It is absolutely

forbidden to connect, for any reason

whatsoever, directly or indirectly, the

230V mains voltage to the bus or to other

parts of the circuit.

!

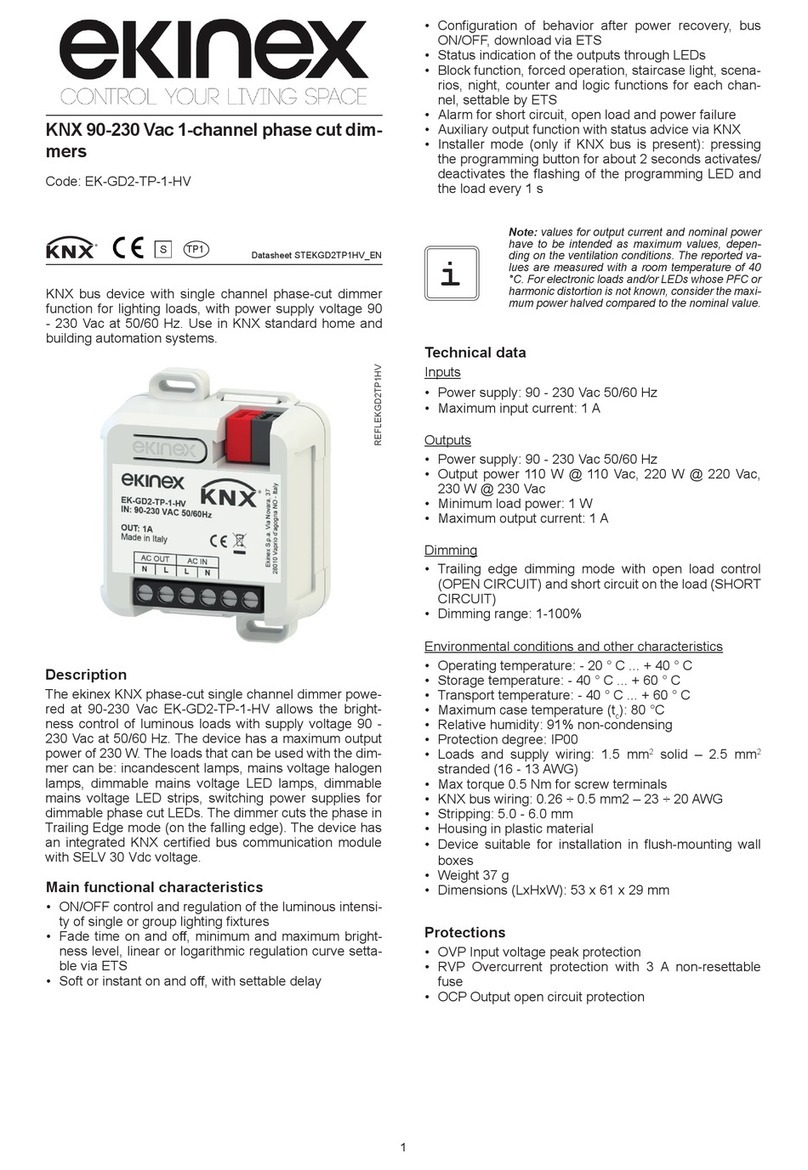

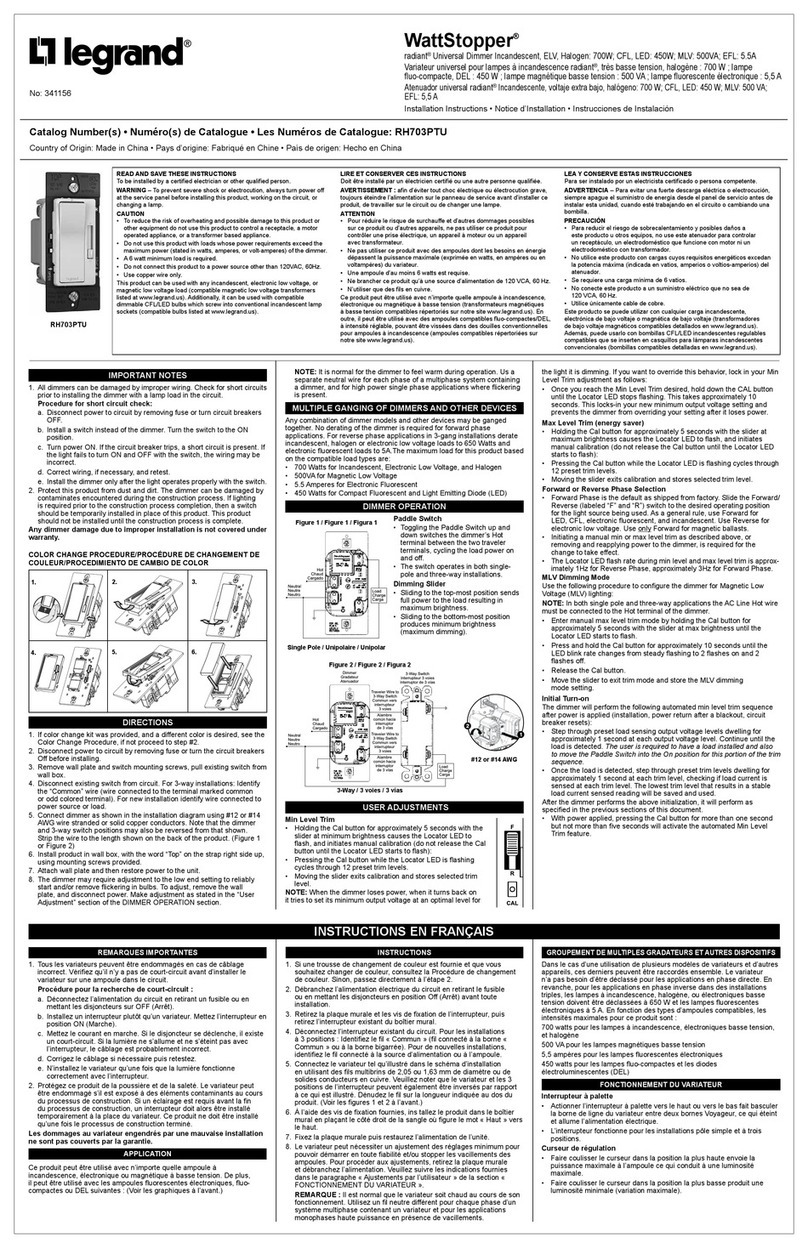

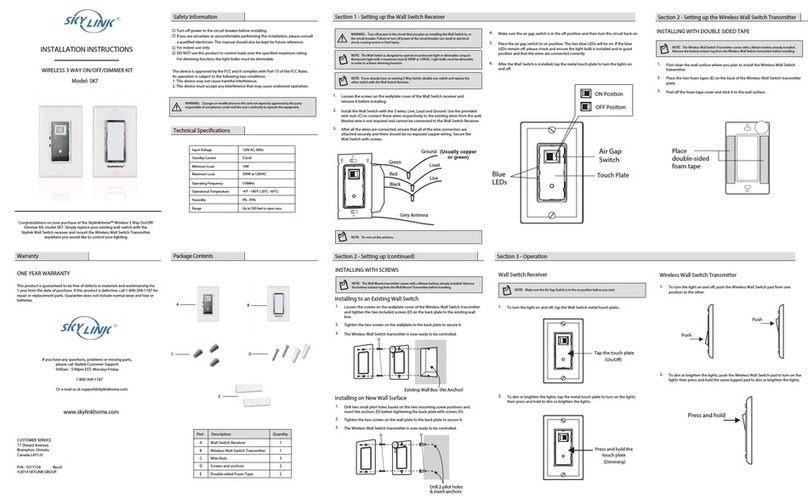

Setup and installation

In order to setup the dip-switches and the rotary selector

switches, it is necessary to open the device front cover,

by means of a screwdriver as detailed in the image below.

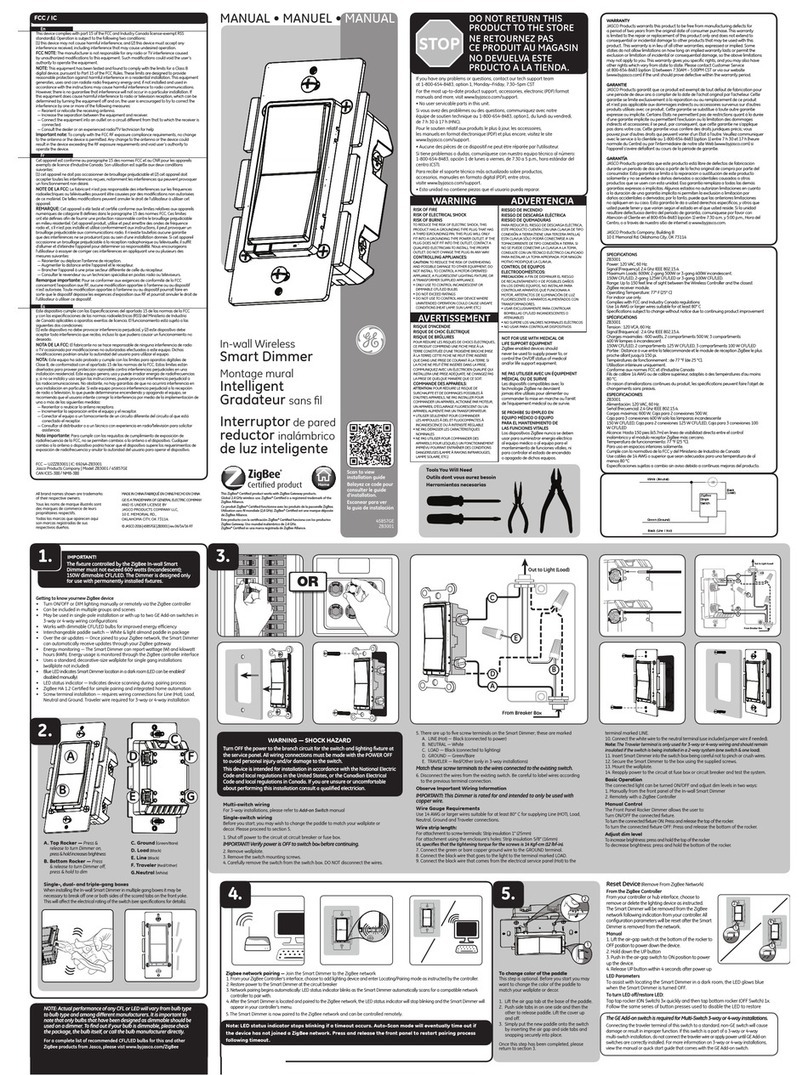

Conguration Settings

Switches 1-2 = Load type

Switch 3 = Parallel outputs

Switches 4-5-6 = Map

Switches 7-8 = Dimming curve

Switches 9-10 = Input type (local

commands)

Switches 11-12 = Dimming fre-

quency (output frame rate)

Note: Factory settings = all OFF

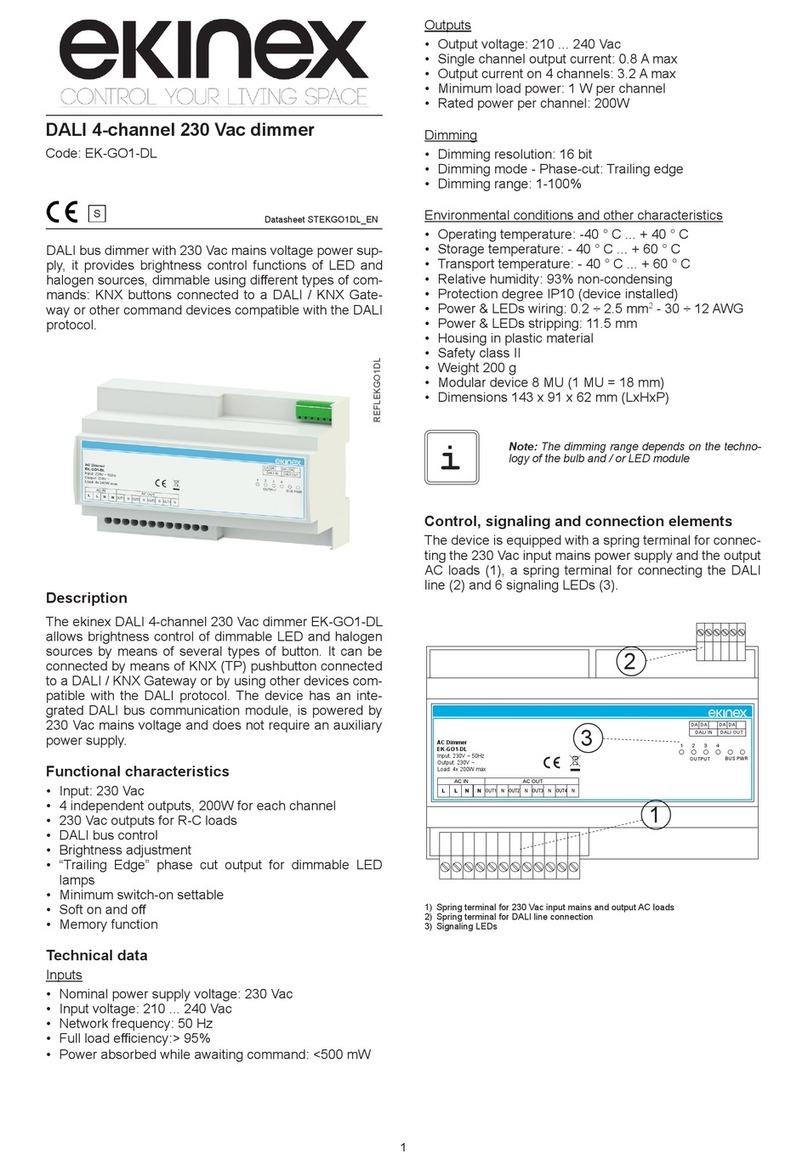

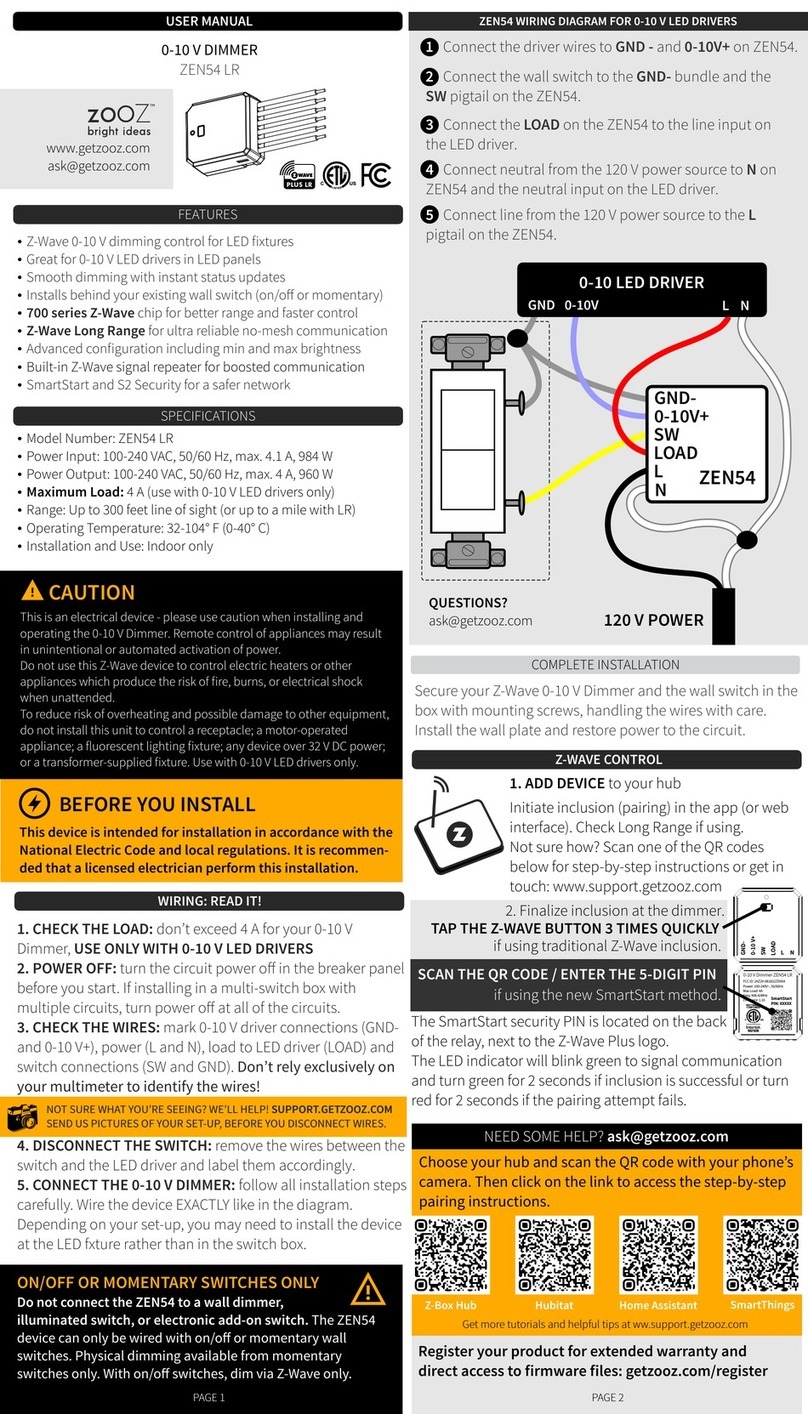

DALI bus line and command connections

The connection to the DALI bus line and the local com-

mands is done via the screw terminal, located on the front

of the device in the upper part.

The length of the connection cables between the local

commands (N.O. Pushbutton, 0-10V, 1-10V, Potentiome-

ter or other) and the product must be less than 10m; the

cables must be dimensioned correctly and they should be

isolated from every wiring or parts at voltage not SELV.

Use double insulated shielded and twisted cables.

The length and type of the connection cables to the DALI

bus must be compliant with the protocol specication and

with the present regulations and they should be isolated

from every wiring or parts at voltage not SELV. Use dou-

ble insulated shielded and twisted cables.

All the devices and the control signal connected to the

DALI bus and to the local command (N.O. Pushbutton,

0-10V, 1-10V, Potentiometer or other) must be SELV (the

devices connected must be SELV or supply a SELV si-

gnal).

Characteristics of the DALI terminal block

• Screw tightening of the conductors

• Command & bus wiring: 1.5 mm2solid – 1 mm2stran-

ded – 30 - 14 AWG

• Command & bus stripping: 6 mm

• Conductor stripping recommended approx. 10 mm

• Maximum length of the connection between dimmer-

driver and control device < 10 m

• Length of connection cables < 10 m

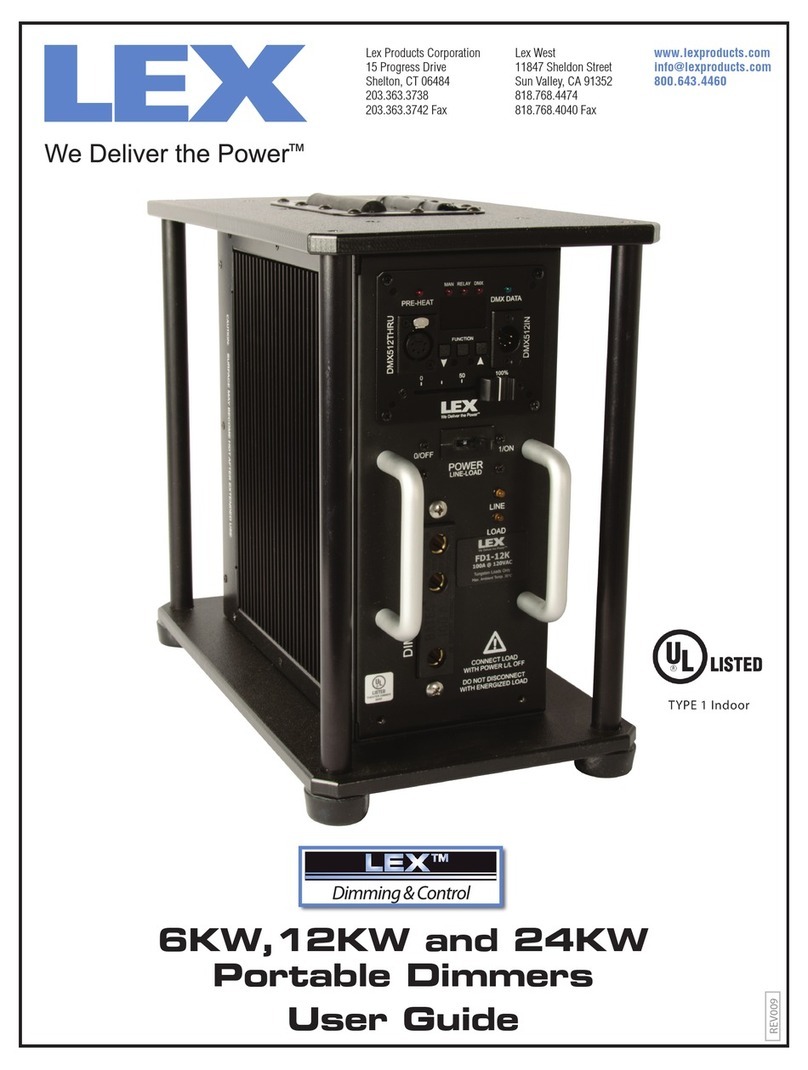

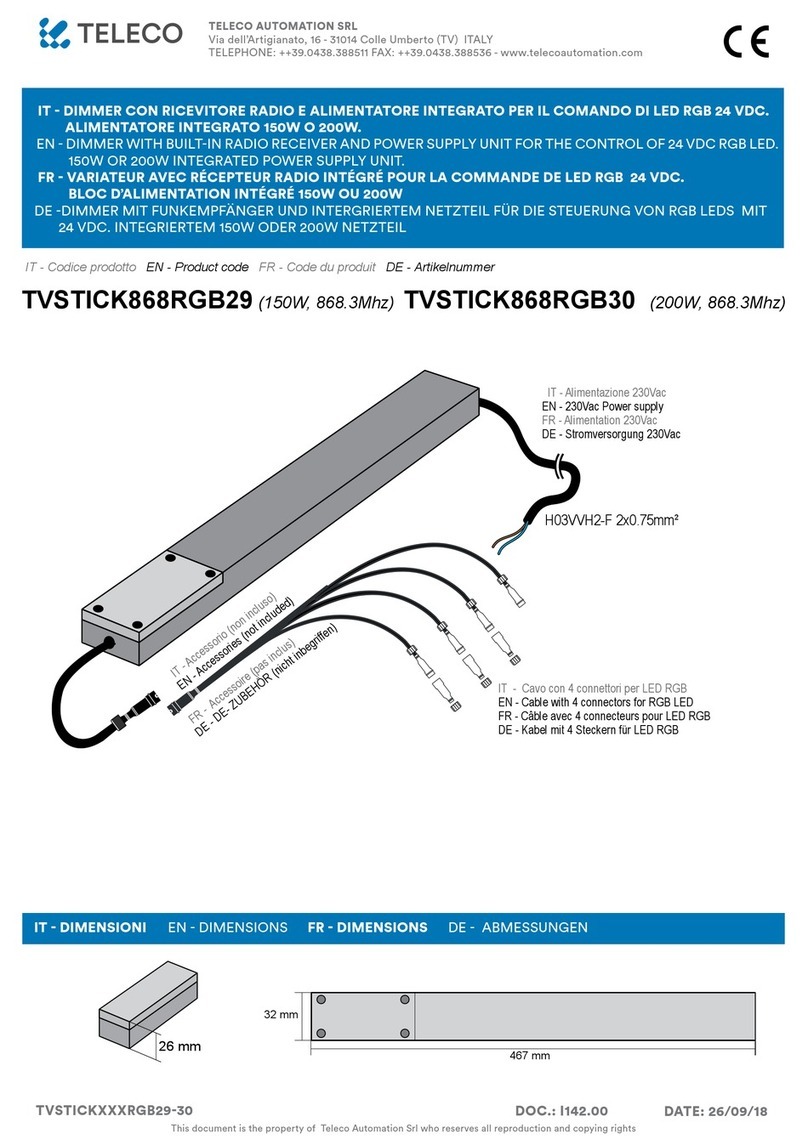

Connection of power supply and LEDs

For the power supply use SELV power suppliers with li-

mited current, short circuit protection only and the power

must be correctly dimensioned. In case of usage of a po-

wer supplier with ground terminals, all points of the pro-

tective earth (PE = Protection Earth) must be connected

to a valid and certied protection earth.

The connection cables between the power source “low

voltage” and the product must be correctly dimensioned

and they should be isolated from every wiring or parts at

not-SELV voltage. Use double insulated cables.

The power supply must be dimensioned according to

the load connected to the device. If the power supply is

oversized with respect to the maximum absorbed current,

then insert a protection against over-current between the