Elite Greenhouses 8'5" Wide Thyme User manual

Other Elite Greenhouses Greenhouse Kit manuals

Elite Greenhouses

Elite Greenhouses 5' 3" WIDE DELTA User manual

Elite Greenhouses

Elite Greenhouses 2'3'' Wide Easy Grow User manual

Elite Greenhouses

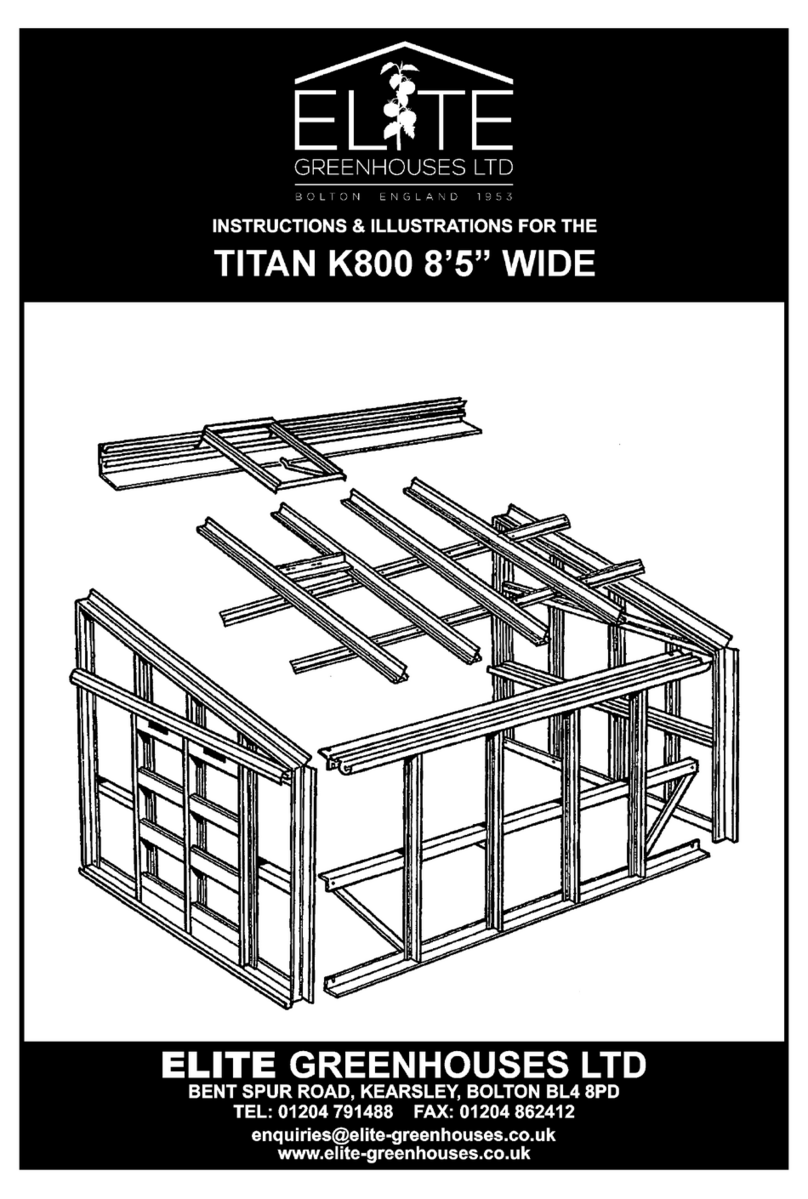

Elite Greenhouses TITAN K800 User manual

Elite Greenhouses

Elite Greenhouses TITAN 1000 User manual

Elite Greenhouses

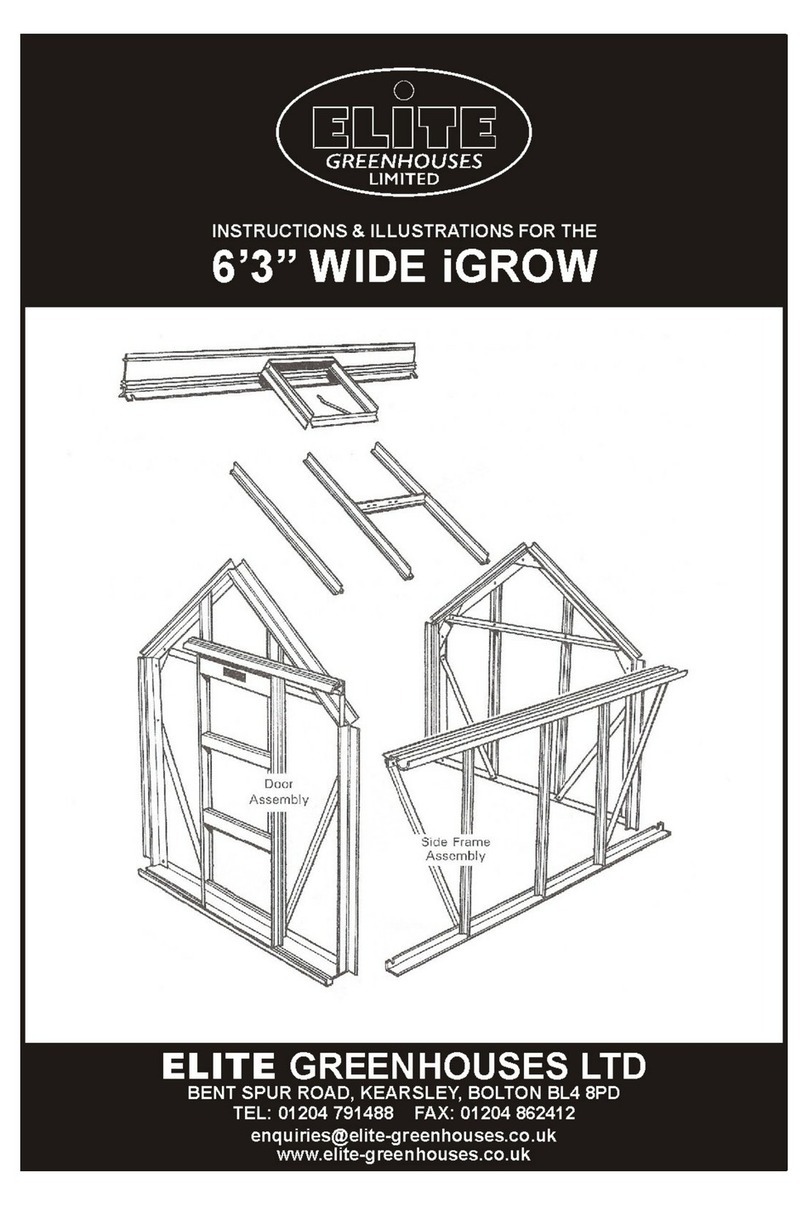

Elite Greenhouses iGrow User manual

Elite Greenhouses

Elite Greenhouses 7'5" WIDE TITAN User manual

Elite Greenhouses

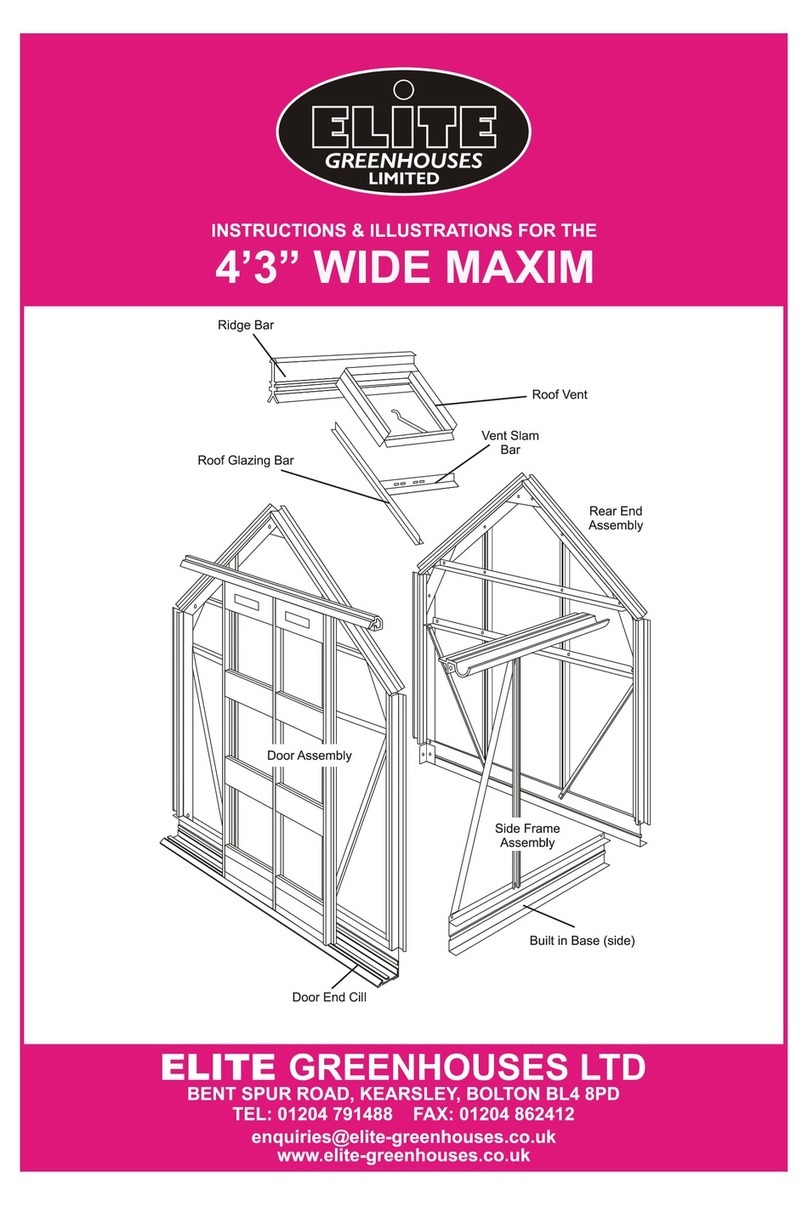

Elite Greenhouses WIDE MAXIM User manual

Elite Greenhouses

Elite Greenhouses STREAMLINE Series User manual

Elite Greenhouses

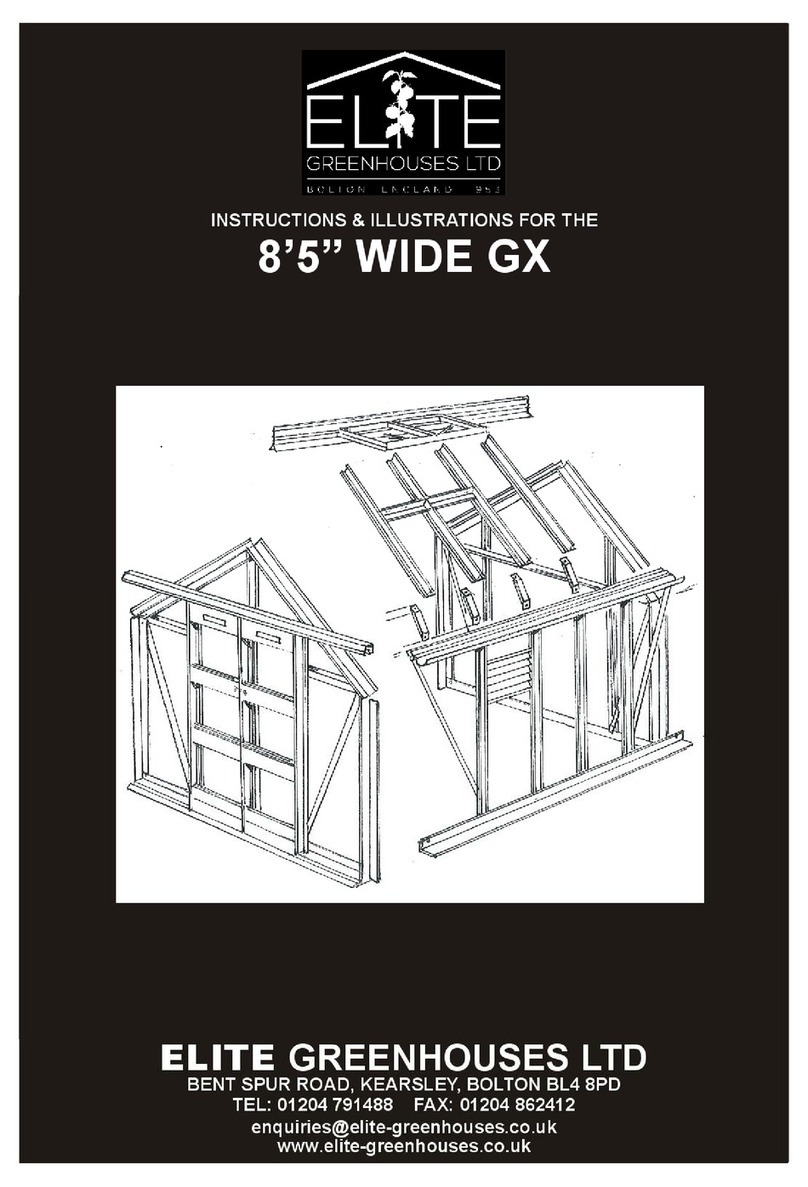

Elite Greenhouses GX800 User manual

Elite Greenhouses

Elite Greenhouses 6'3" WIDE CRAFTSMAN User manual

Elite Greenhouses

Elite Greenhouses 6'5" WIDE TITAN User manual

Elite Greenhouses

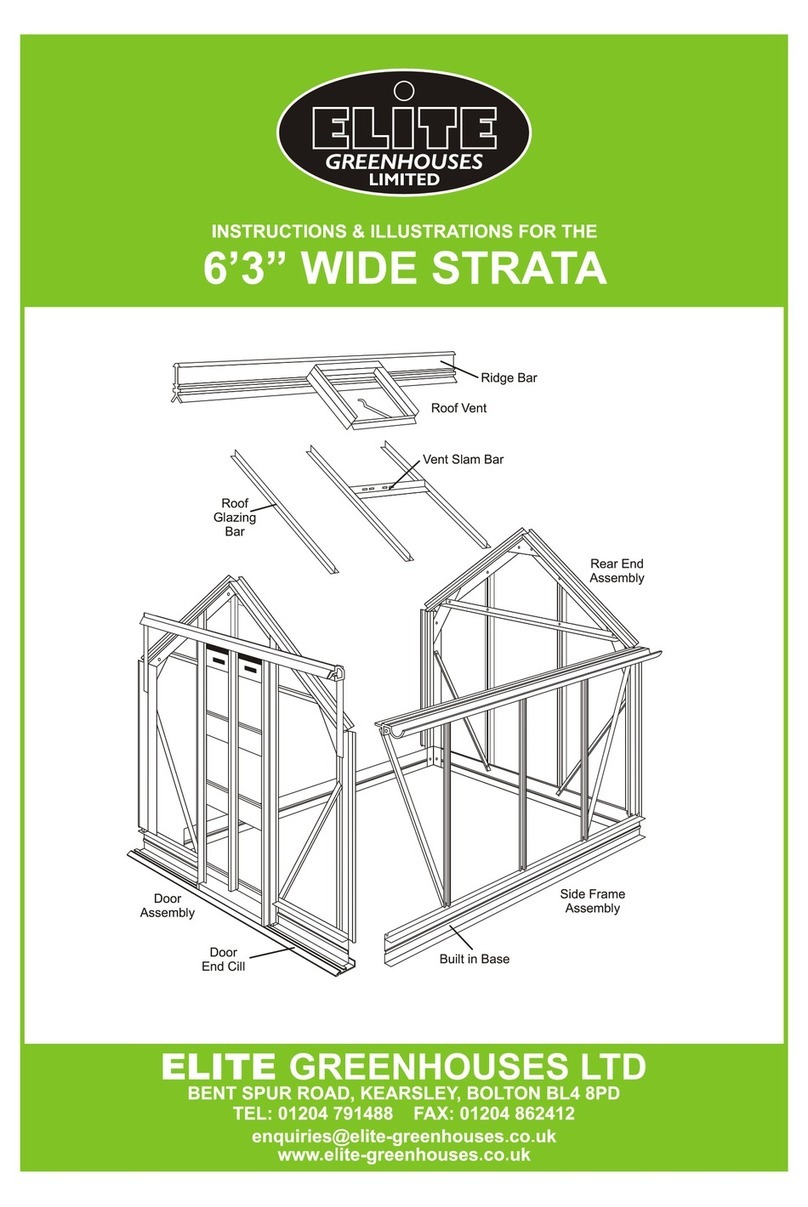

Elite Greenhouses STRATA User manual

Elite Greenhouses

Elite Greenhouses 6'3" WIDE THYME User manual

Elite Greenhouses

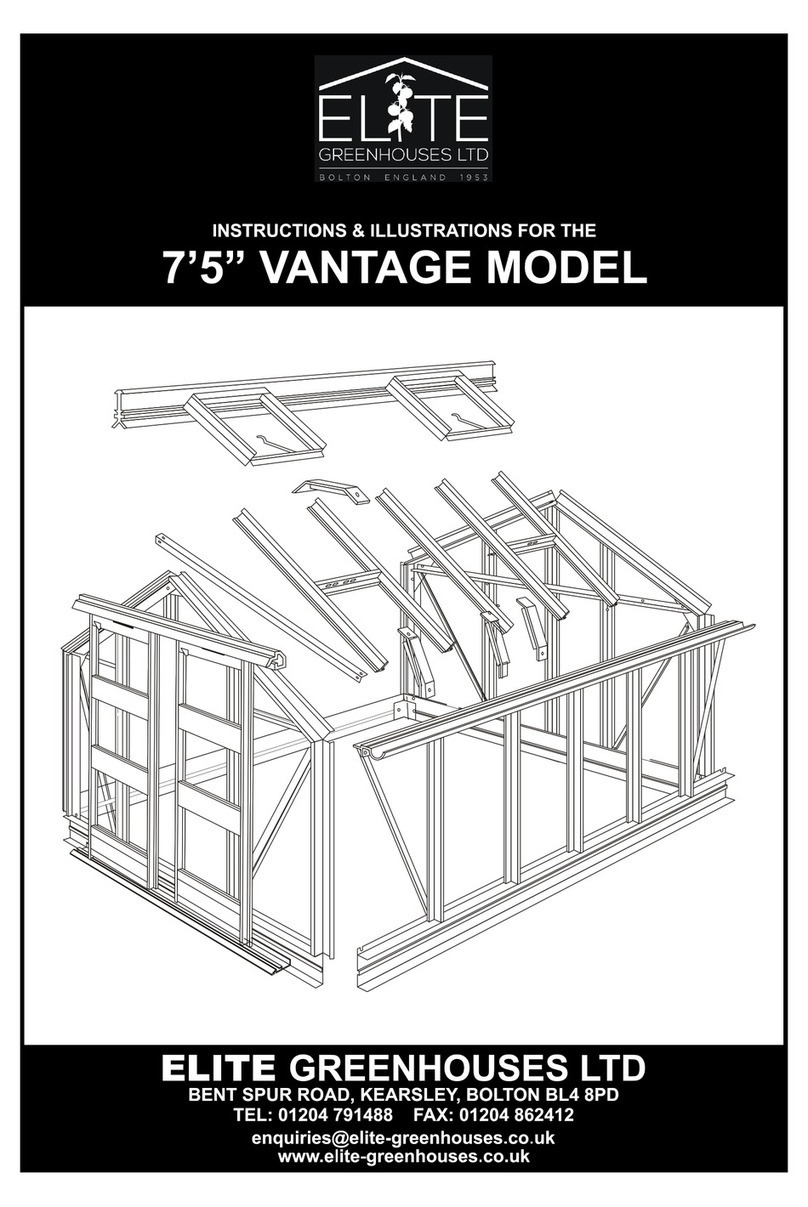

Elite Greenhouses 7'5'' VANTAGE User manual

Elite Greenhouses

Elite Greenhouses 6'3" WIDE HIGH EAVE User manual

Elite Greenhouses

Elite Greenhouses TITAN 1200 User manual

Popular Greenhouse Kit manuals by other brands

Vitavia

Vitavia GAIA JUMBO Assembly instructions

Palram

Palram Harmony 6'x4' Assembly instructions

ClearSpan

ClearSpan Storage Master 104598 instruction manual

Sproutwell

Sproutwell GRANGE - 5 Assembly instructions

STC

STC Easy Grow 6x12 Greenhouse Assembly instructions

Growhouse

Growhouse Lean To 6 x 8 Erection and Glazing Instructions