Introduction

2

Dear users!

Centrifuge CM-50 is easy to use and reliable in operation. We ask you to carefully read the

user manual and observe all the requirements of the maintenance and operation this will

ensure a long and flawless exploitation of the device.

General information

CM-50 is a unique high-speed centrifuge designed to separate solutions into fractions.

The device is used in analytical chemistry, microbiology, virology, clinical biochemistry, etc.

Microprocessor control system provides smoothness of rotor rotation start, task enterring and

parameter reflection on the displays (time, braking level, rotor rotation speed in RPM or RCF

units), blocking of lid during work, sound alarm and signals, sleep mode and automatic lid

unblocking at the end of work. Built-in temperature and imbalance sensors protect the unit

from overheating and dangerous imbalance.

Technical specifications

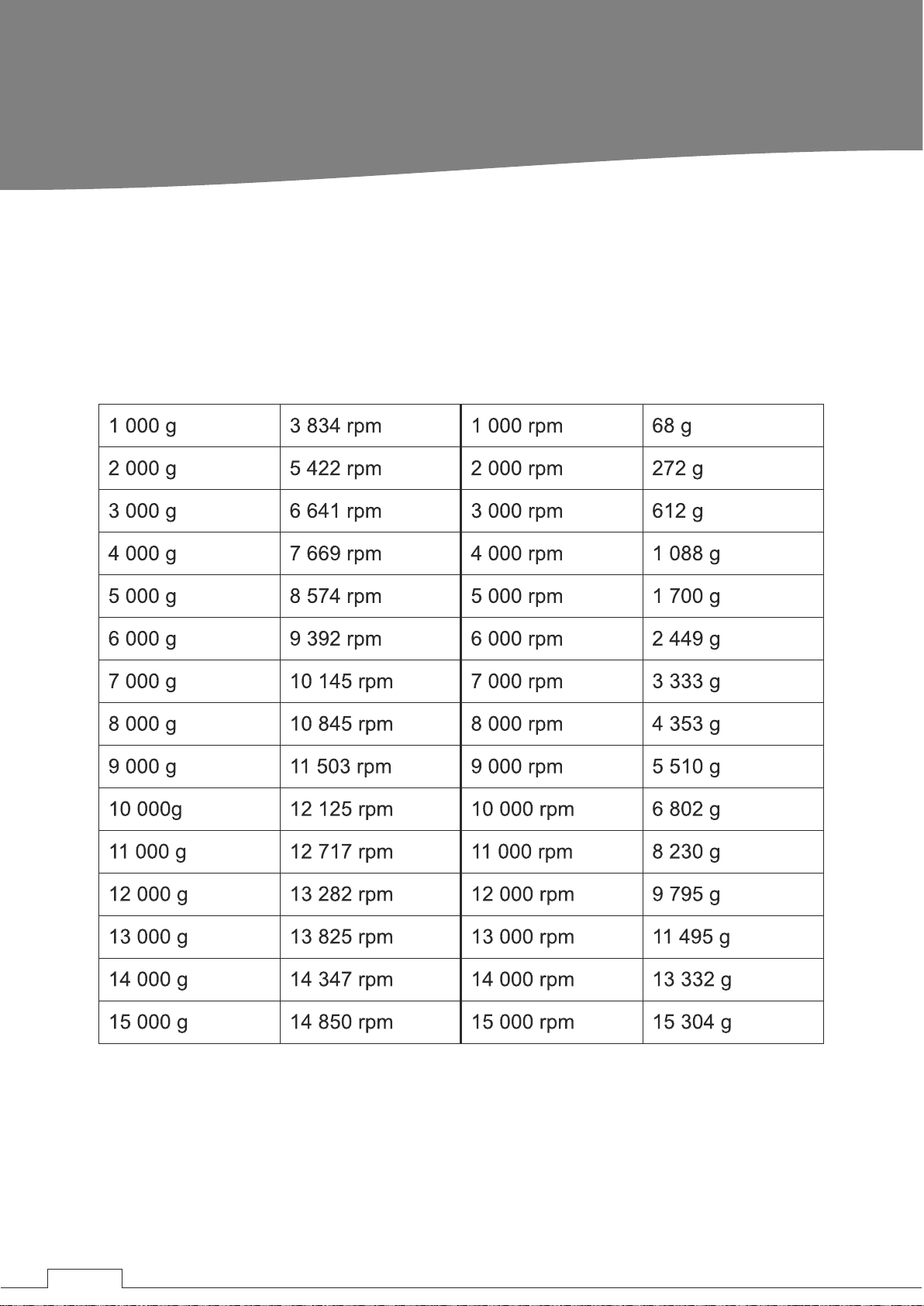

Rotorrotationspeed,RPM 1000-15000

Speedstepselection,RPM 1000

Centrifugalforce,RCF 1000-15000

Centrifugal force step selection, RCF 1000

Timer settings, min 0.1-99

Number of braking levels 5

Total possible imbalance of test tubes, gr 1

Environmental temperature, 4-40

Relativeairmoistureat20 % 80

Power supply adapter, 24V-3.75A

Powerconsumption,W notmorethan90

Size of the device (length x width x height), mm 200?180?145

Weight 3.1

Delivery package

Item Quantity

Centrifuge..............................................................................................................................1

Rotornut..............................................................................................................................1

Rotorkey.............................................................................................................................1

Powersupplyadapter24V-3,75A 90W.....................................................................................1

Powercord.................................................................................................................................1

User manual..............................................................................................................................1

Packaging..................................................................................................................................1

ºC

ºC,