Elmi DOS-20L User manual

User manual

Digital orbital shaker DOS-20L

ELMI Ltd.

21-133 Aizkraukles Str.

Riga, LV-1006, Latvia

T.: +371 67558743

T.: +37167551934

E: [email protected]om

W: www.elmi-tech.com

1

Page

Content............................................................................................................................... 1

Introduction..............................................................................................................................2

Technical specifications ...........................................................................................................2

Delivery package.....................................................................................................................2

Safety.......................................................................................................................................3

Preparation to use....................................................................................................................3

The device...............................................................................................................................4

Control description...................................................................................................................5

Using the device(mainmenu) ..................................................................................................6

Orbitalrotationmode................................................................................................................7

Auto reversemode...................................................................................................................7

Reciprocal mode......................................................................................................................8

Vibration mode........................................................................................................................8

Programming menu ............................................................................................................9-10

Additional modes...................................................................................................................11

Disinfection and cleaning .......................................................................................................12

Transportation and storage....................................................................................................12

Warranty statements..............................................................................................................12

Certificate of approval............................................................................................................13

Certificate of sale...................................................................................................................13

2

Dear user!

Congratulations, you have acquired an ELMI shaker - product of advanced technology and

high quality!

DOS-20L shaker is easy to use and reliable in operation. We ask you to carefully read the user

manual and observe all maintenance and operation requirements, as this will ensure long and

flawless use of the device.

The shaker is designed to mix up components in different kind of test tubes, flat bottom laboratory

dishes, flasks, Petri dishes, etc.

Technical specifications

Sizeofworkingplatform,mm 415х295

Speed of rotation, RPM 10-300

Amplitude of platform movement, mm 20

Maximumload,kg 7

Working modes 4

Type of platform movement orbital

Timer 1 minute –9 hours 59minutes

Environmental temperature, °C +4 up to +45

Relative moisture of atmosphere (at 20°C temperature) not more than 80%

Voltageand frequency 110-220 V, 50-60Hz

Powersupplyadapter: 24VDC –1A

Maximal power consumption, W 24

Size of the device, mm 415х365x100

Net weight,kg 8,8

Delivery package

Item Quantity

Shaker............................................................................................................................................1

Powersupply adapter.....................................................................................................................1

Magnetic clips................................................................................................................................8

Usermanual...................................................................................................................................1

Packaging ......................................................................................................................................1

3

General safety

•Use only as directed in the operating instructions provided.

•The unit should not be used if it has encountered a physical shock or has beendropped.

•The unit must be stored and transported in a horizontal position (see package label).

•After transport or storage allow the unit to dry out (2-3 hrs.) before connecting to mainspower.

•Use only original accessories provided by the manufacturer and ordered

specifically for this model.

Electrical safety

•Connect to the mains only with a voltage corresponding to that on the serial number label.

•Ensure that the switch and plug are easily accessible during use.

•Do not plug the unit into the main outlet without grounding, and do not use extension lead without

grounding.

•Before moving the unit, disconnect it from the mains. Toturn off the unit, disconnect the power plug

from the mains outlet.

•It is the user's responsibility to carry out appropriate decontamination if hazardous material is spilt on

or inside the equipment. If liquid is split inside the unit, disconnect it from the mains and have it

checked by a competent person. During operation

•Do not block the platform movement.

•Do not leave the operating unit unattended.

•Do not operate the unit in environments with aggressive or explosive chemicalmixtures.

•Do not operate the unit if it is faulty or been incorrectly installed.

•For indoor use only.

•Before using any cleaning or decontamination method except those recommended by the manufacturer,

check with the manufacturer that the proposed method will not damage the equipment.

•Do not make modifications to the unit.

Biological safety

•It is the user's responsibility to carry out appropriate decontamination if hazardous material is spilt

on or inside the equipment.

Preparation to use

•Unpack the device. Please keep the packaging material for transportation or storagepurposes.

•If the machine was stored at a temperature below 0°C, make sure that it is kept at room

temperature for at least two hours before turning it on.

•Place the shaker onto a level, horizontal surface.

•Examine the power adapter and appearance of device for damage.

•Connect the power cord to the centrifuge, insert the adapter in to the socket and press network

switch at ( I ) symbol. Display will light up on the control panel.

•Check the platform. Try rotating it by hand. There should be no noise or obstacles to smooth

running.

•Check the surrounding of device. Safety distance of 30cm must be observed around the device

during operation.

•Check for other signs of damage or malfunction.

ATTENTION! If there is any apparent damage or malfunction, DO NOT TURN ON the shaker

without consulting a specialist.

4

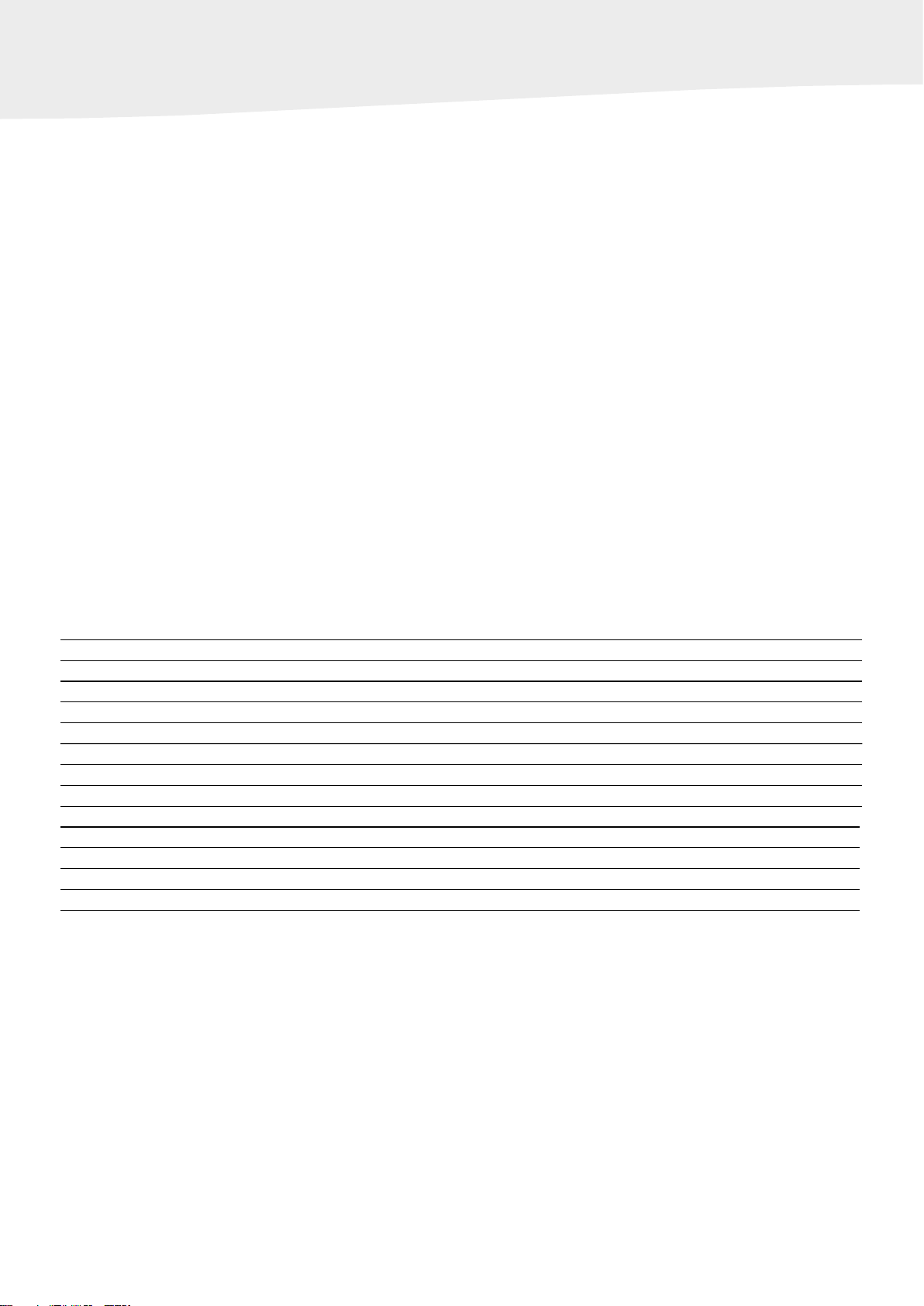

1 - Network switch

2 - Power plug

3 - Working platform

4 - Casing

5 - Control panel

3

4

1

2

5

5

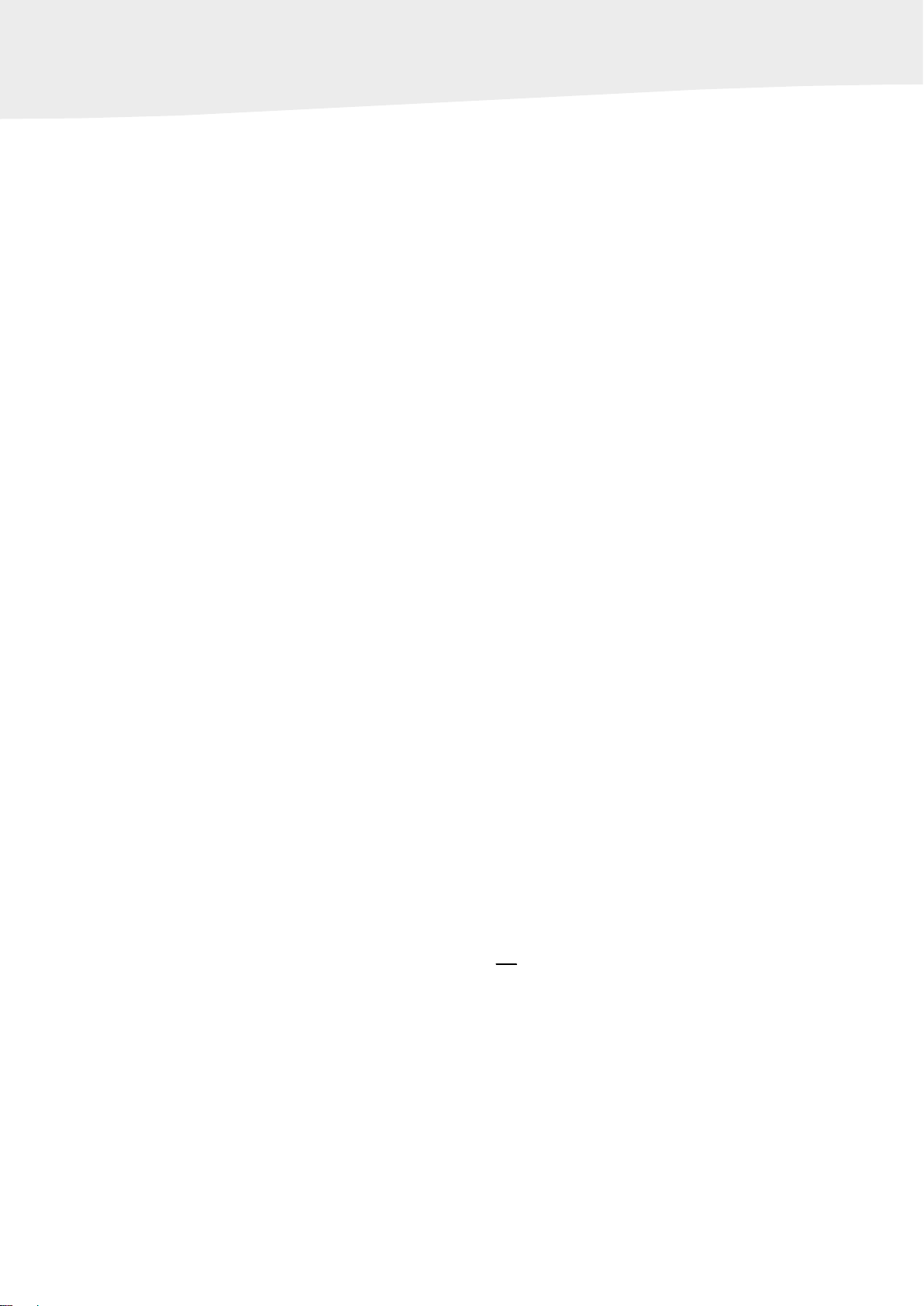

Control panel

Up and down navigation keys

Left, right navigation keys

and increasing, decreasing parameter value keys

Entering and exiting key in programming mode

to set the step parameter

Start/Stop key

Setting key to manage the interface of device

Entering and exiting key to cycle programming mode

6

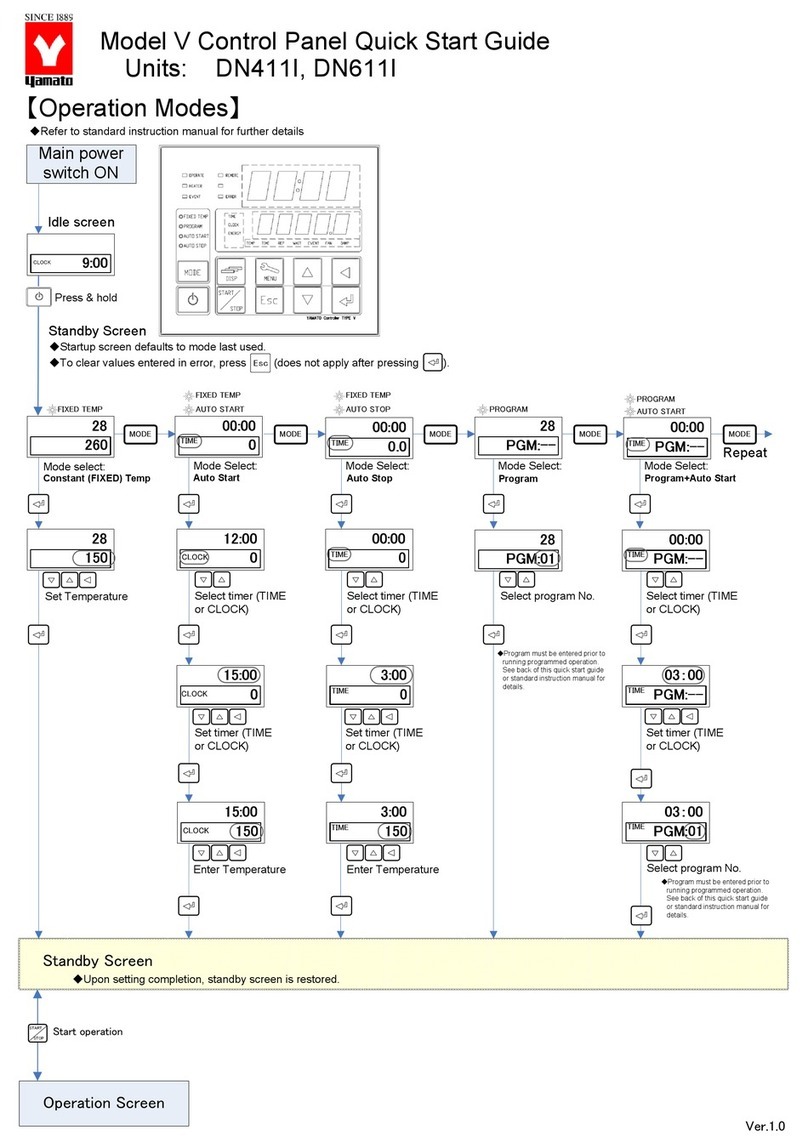

Main menu

In the main menu you can choose and set the needed

working mode.

Choosing the working mode

The shaker has 4 working modes:

1) Orbital rotation

2) Auto reverse

3) Reciprocal

4) Vibration

To choose a mode go to the lowest level of the main menu and

select the desired mode using the right or left navigation keys.

Adjusting the parameters of the mode

Using the navigation keys, select the desired mode and

set required values for each parameter.

Press and hold the left or right navigation key to quickly

change the value of a parameter.

7

Orbital rotation mode

Orbital rotation - clockwise classic platform motion mode

with adjustable speed and time parameters.

mode parameters:

TIMER: 1 minute - 99:59 minutes - continuous mode.

PRM: 15 - 300.

Auto reverse mode

Auto reverse mode - platform orbital motion mode with set and equal numbers of

clockwise and counter-clockwise turns.

Adjustable RPM, time and the number of one-way rotations.

Options:

TIMER: 1 minute - 99.59 minutes - continuous mode.

PRM: 15 RPM - 300 RPM.

TURNS: 5 - 25.

8

Reciprocal mode

Reciprocal mode - provides changing direction motion with the choice

of rotation angle of the platform,

at a predetermined RPM and operating time.

Options:

TIMER: 1 minute - 99.59 minutes - continuos mode.

RPM: 07 - 20.

Angle: 10 ° - 360 °

Vibration mode

Vibration mode - reciprocating type of movement of the platform

imitating shake.

Ability to customize the speed settings, time and amplitude of the shake-up.

Options:

TIMER: 1 minute - 99.59 minutes - continuos mode.

PRM: 07 - 20.

Amplitude: 1mm - 2mm

9

Programming menu

You can create a custom program using the programming

menu. Create multiple steps to combine the various

shaker working modes.

To enter and exit the programming menu use the “Cycles

mode” key.

Creating program

program step

working mode type indicator

number of cycles

total program time

You can set the number of repeat cycles on the bottom line of

the programming menu. Ranges are from 1 to 99, or continuos

mode can be used. Create a custom cycle program by adding

four steps and a number of program repeat cycles as required.

All settings are made using the navigation keys. Enter and

exit the programming menu using "ENTER" key.

When setting the programming, you can assign the

desired operating mode:

1) Orbital rotation mode

2) Auto reverse mode

3) Reciprocal mode

4) Vibration mode

5) Pause

6) Disable step

The number of repeat cycles can be set in the bottom line

of programming main menu, ranges are from 1 to 99,

plus continuos mode.

10

Cycles: 1

Total timer: 000:08:00

Example of custom program

Enter the Cycle programming menu

1 Select the 1st step and press “ENTER” key.

1.1 Go to the step menu’s bottom line, select orbital rotation mode;

set the time for 5 minutes, RPM to 100 and press “ENTER”.

2 Select the 2nd step and press “ENTER” key.

2.1 Go to the step menu’s bottom line and select the pause mode;

set the time to 1 minute and press “ENTER” key.

3 Select the 3rd step and press “ENTER” key.

3.1 Go to the step menu’s bottom line and select orbital rotation

mode; set the time to 2 minutes, RPM to 200, and press“ENTER”.

4 Select the 4th step and press “ENTER” key.

4.1 Go to the step menu’s bottom line and select the “NO

OPERATION” mode and press “ENTER”.

5 Go to the program menu bottom line and set the cycle value to 1.

The program is ready! Press start button to run the program.

11

Simplified menu

If you wish to use the device just as an orbital shaker and other modes are

not needed, you can enable the simplified menu by holding the “PROGRAM”

key and switching the network switch off and on again.

To return to the advanced menu, repeat the operation.

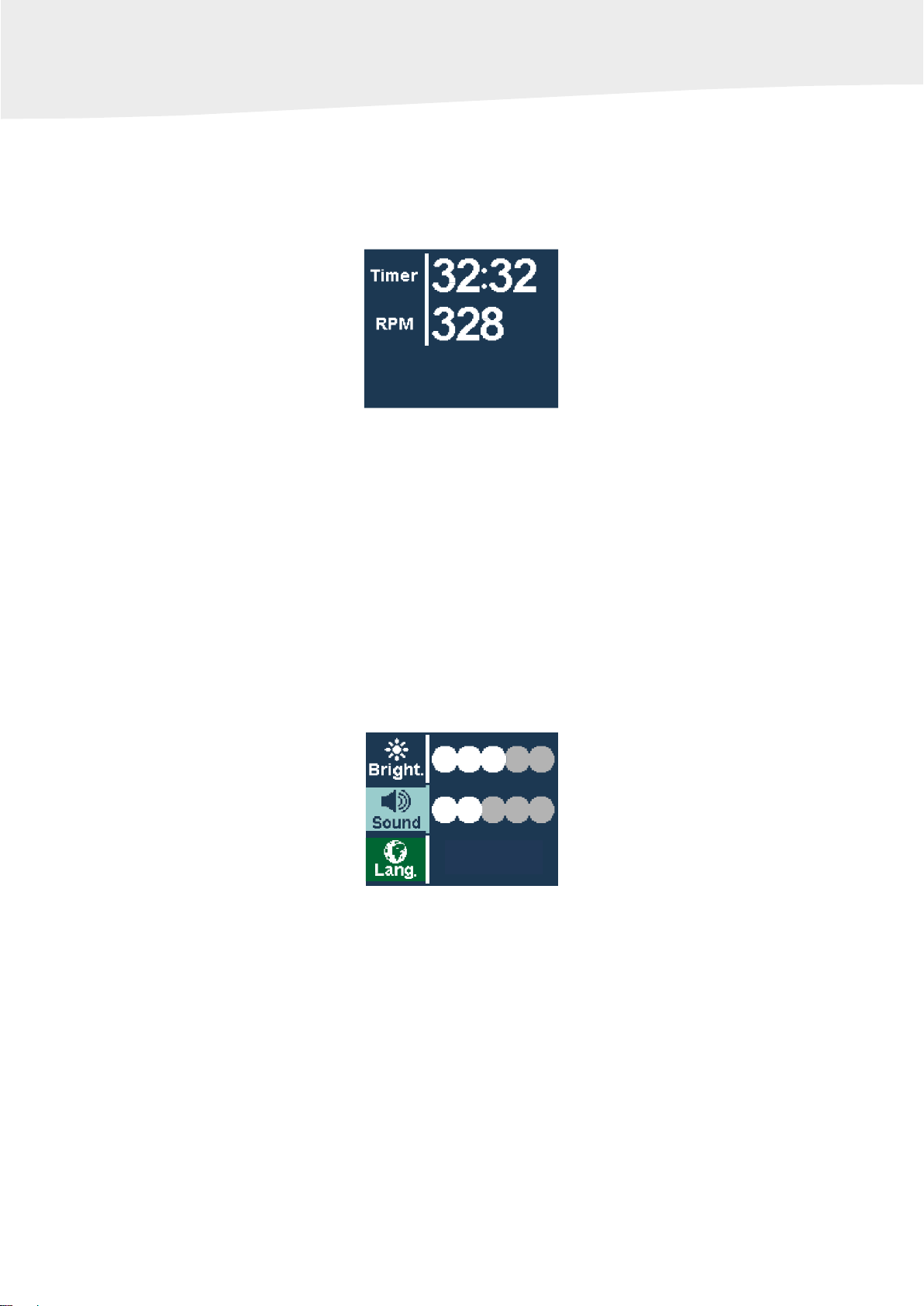

Interface adjustment menu

In the interface menu you can adjust the display

brightness, sound volume, and select the interface

language.

All settings are made using the navigation keys. To enter

and exit the menu use the "SETTINGS" key.

English

12

Disinfection and cleaning

Shaker and accessories must be cleaned once a week to avoid corrosion and changes to

material. Disconnect the device from mains power supply and clean it separately. The platform,

accessories and exterior of the shaker should be cleaned with a moist cloth. Only use neutral

agents to clean these parts. To disinfect, use an alcohol-based disinfectant

(70% isopropanol/water mixture). If corrosive, toxic or radioactive liquids or pathogenic bacteria

are spilled on the platform, shaker must be decontaminated thoroughly.

Transportation and storage

To ensure safety during transportation, the equipment should be packed in the original

manufacturer’s packaging or similar packaging substitute.

Equipment can be transported in any kind of closed transport; make sure that equipment is tightly

fixed and transported accordingly to transportation regulations. Equipment should be stored in

original manufacturers packaging in dry room with humidity not more than 80% and temperature

range of +10°C up to +40°C. It is not recommended to store the equipment more than 36 month.

Warranty statements

•Warranty applies to 24-month period from the date of purchasing.

•Malfunctions that occur due to a fault of the manufacturer, during warranty period, are

repaired free of charge.

•Warranty is not valid in the following cases:

- If the serial number label of the manufacturer is damaged.

- If damage occurs as a result of incorrect operation, transportation or storage.

•These documents are necessary if applying for warranty repair:

- User manual with serial number of the machine.

- Officially signed report, describing the reasons and circumstances of theequipment

malfunctions.

•Warranty repair can be performed only if the equipment is delivered in theoriginal

manufacturers packaging or equally safe packaging.

•Before returning for warranty repair ensure that the device is fully cleaned, decontaminated

and does not present any kind of health risk to our staff.

•If the above warranty requirements are not met, repair charges are applied to thecustomer.

•For all further questions concerning usage and maintenance, please contact the manufacturer

or product vendor.

13

Certificate of approval

Shaker DOS-20L N has been inspected for the technical conditions and

meets all regulations necessary for this class of device.

Quality control person .

(name) (signature)

Date of manufacture .

Place for stamp.

Certificate of sale

Organization .

Address .

Phone .

Vendor .

(name) (signature)

Date of sale .

Manufacturers' address.

21-133 Aizkraukles Str., Riga LV-1006

Tel: (+371) 6755 8743

Tel: (+371) 6755 1934

WWW: www.elmi-tech.com

Table of contents

Other Elmi Laboratory Equipment manuals