Instruction Manual Supplement

D104211X012

DVC6005 Digital Valve Controllers

August 2017

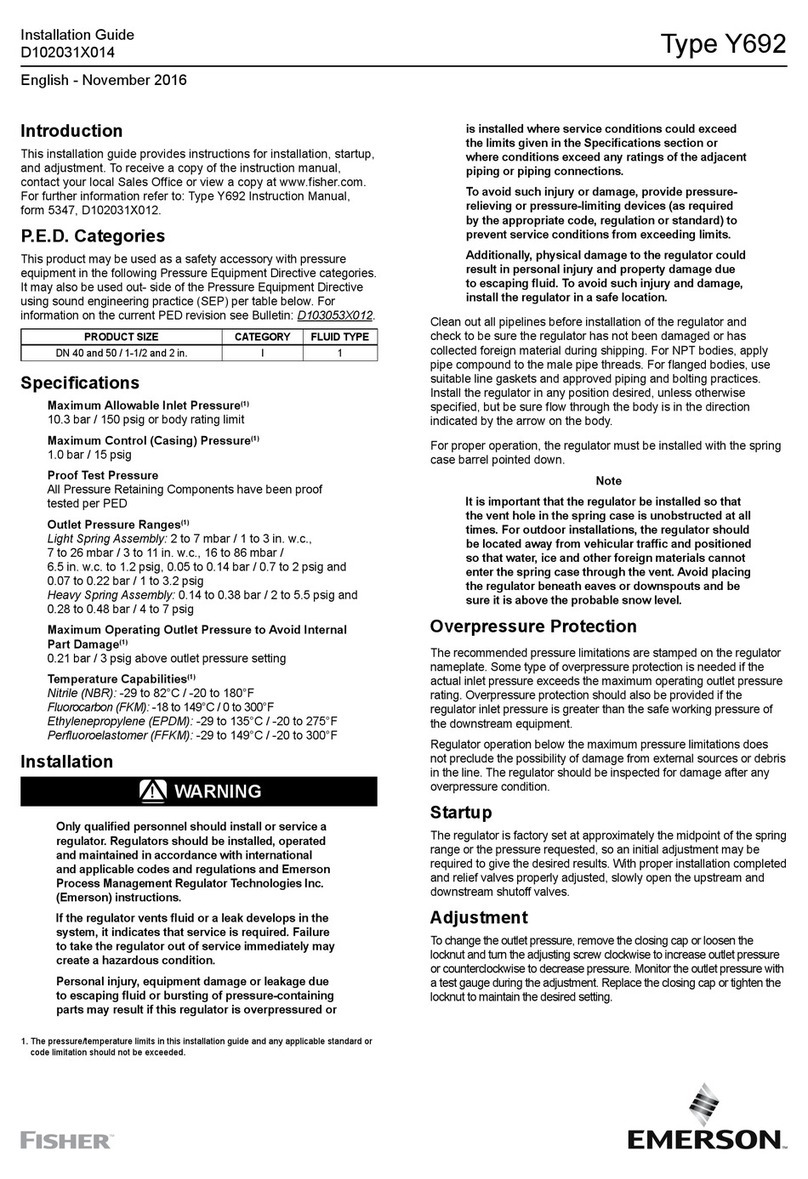

10

THE ENTITY CONCEPT ALLOWS INTERCONNECTION OF INTRINSICALLY SAFE APPARATUS TO ASSOCIATED APPARATUS NOT

SPECIFICALLY EXAMINED IN SUCH COMBINATION. THE CRITERIA FOR INTERCONNECTION IS THAT THE VOLTAGE (Vmax or Ui), THE

CURRENT (Imax or Ii), AND THE POWER (Pmax or Pi) OF THE INTRINSICALLY SAFE APPARATUS MUST BE EQUAL TO OR GREATER THAN

THE VOLTAGE (Voc or Uo), AND THE CURRENT (Isc or Io), AND THE POWER (Po) DEFINED BY THE ASSOCIATED APPARATUS. IN

ADDITION, THE SUM OF THE MAX UNPROTECTED CAPACITANCE (Ci) AND MAX UNPROTECTED INDUCTANCE (Li), INCLUDING THE

INTERCONNECTING CABLING CAPACITANCE (Ccable) AND CABLING INDUCTANCE (Lcable) MUST BE LESS THAN THE ALLOWABLE

CAPACITANCE (Ca) AND INDUCTANCE (La) DEFINED BY THE ASSOCIATED APPARATUS. IF THE ABOVE CRITERIA IS MET, THEN THE

COMBINATION MAY BE CONNECTED.

Vmax or Ui .Voc or Uo Imax or Ii .Isc or Io Pmax or Pi .Po Ci + Ccable ≤Ca Li + Lcable ≤La

THE FISCO CONCEPT ALLOWS INTERCONNECTION OF INTRINSICALLY SAFE APPARATUS TO ASSOCIATED APPARATUS NOT

SPECIFICALLY EXAMINED IN SUCH COMBINATION. THE CRITERIA FOR THE INTERCONNECTION IS THAT THE VOLTAGE (Vmax or Ui),

CURRENT (Imax or Ii), AND POWER (Pmax or Pi), WHICH AN INTRINSICALLY SAFE APPARATUS CAN RECEIVE AND REMAIN

INTRINSICALLY SAFE, CONSIDERING FAULTS, MUST BE EQUAL TO OR GREATER THAN THE VOLTAGE (Voc or Uo), CURRENT (Isc or Io),

AND POWER (Po) LEVELS WHICH CAN BE DELIVERED BY THE ASSOCIATED APPARATUS, CONSIDERING FAULTS AND APPLICABLE

FACTORS. IN ADDITION THE MAXIMUM UNPROTECTED CAPACITANCE (Ci) AND INDUCTANCE (Li) OF EACH APPARATUS (OTHER THAN

THE TERMINATION) CONNECTED TO THE FIELDBUS MUST BE LESS THAN OR EQUAL TO 5 nF AND 10 uH RESPECTIVELY.

IN EACH SEGMENT ONLY ONE ACTIVE DEVICE, NORMALLY THE ASSOCIATED APPARATUS, IS ALLOWED TO PROVIDE THE NECESSARY

ENERGY FOR THE FIELDBUS SYSTEM. THE VOLTAGE (Uo or Voc or Vt) OF THE ASSOCIATED APPARATUS HAS TO BE LIMITED TO THE

RANGE OF 9 V TO 17.5 VDC. ALL OTHER EQUIPMENT CONNECTED TO THE BUS CABLE HAS TO BE PASSIVE, MEANING THAT THEY ARE NOT

ALLOWED TO PROVIDE ENERGY TO THE SYSTEM, EXCEPT FOR A LEAKAGE CURRENT OF 50 uA FOR EACH CONNECTED DEVICE.

SEPARATELY POWERED EQUIPMENT NEEDS A GALVANIC ISOLATION TO ASSURE THAT THE INTRINSICALLY SAFE FIELDBUS CIRCUIT

REMAINS PASSIVE.

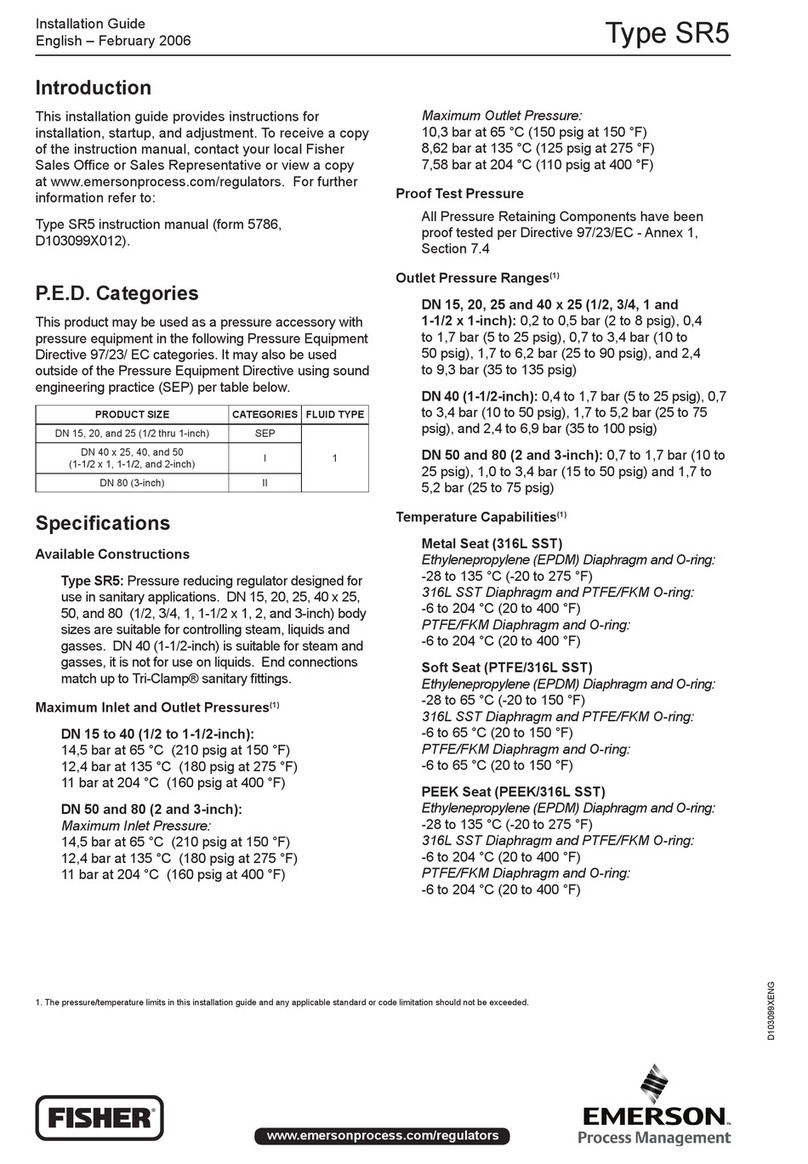

THE CABLE USED TO CONNECT THE DEVICES NEEDS TO HAVE THE PARAMETERS IN THE FOLLOWING RANGE:

LOOP RESISTANCE R': 15 TO 150 ohms/km

INDUCTANCE PER UNIT LENGTH L: 0.4 TO 1 mH/km

CAPACITANCE PER UNIT LENGTH C': 80 TO 200 nF/km

C' = C' LINE/LINE + 0.5' LINE/SCREEN, IF BOTH LINES ARE FLOATING OR

C' = C' LINE/LINE + C' LINE/SCREEN, IF THE SCREEN IS CONNECTED TO ONE LINE.

LENGTH OF SPLICE: < 1 m (T‐BOX MUST ONLY CONTAIN TERMINAL CONNECTIONS WITH NO ENERGY STORAGE CAPABILITY)

LENGTH OF SPUR CABLE: < 30 M

LENGTH OF TRUNK CABLE: < 1 km

AT EACH END OF THE TRUNK CABLE AN APPROVED INFALLIBLE TERMINATION WITH THE FOLLOWING PARAMETERS IS SUITABLE:

R = 90 TO 100 ohms AND C = 0 TO 2.2 uF

NOTE, A BUILT‐IN TERMINATOR IS INCLUDED IN THE FIELD SIDE AND A SELECTABLE TERMINATOR IS AVAILABLE ON THE HOST SIDE.

THE NUMBER OF PASSIVE DEVICES CONNECTED TO THE BUS SEGMENT IS NOT LIMITED IN THE FISCO CONCEPT FOR INTRINSICALLY SAFE

REASONS. IF THE ABOVE RULES ARE RESPECTED, UP TO A TOTAL LENGTH OF 1000 m (SUM OF THE LENGTH OF THE TRUNK CABLE AND

ALL SPUR CABLES), THE INDUCTANCE AND CAPACITANCE OF THE CABLE WILL NOT IMPAIR THE INTRINSIC SAFETY OF THE

INSTALLATION.

INSTALLATION MUST BE IN ACCORDANCE WITH THE NATIONAL WIRING PRACTICES OF THE COUNTRY IN USE.

LOOPS MUST BE CONNECTED ACCORDING TO THE BARRIER MANUFACTURER'S INSTRUCTIONS.

IF HAND‐HELD COMMUNICATOR OR MULTIPLEXER IS USED, IT MUST BE ATEX APPROVED WITH ENTITY PARAMETERS AND

INSTALLED PER THE MANUFACTURER'S CONTROL DRAWINGS.

GE60771 Sheet 2, Rev. C

Figure 5. Notes for ATEX Loop Schematics

Emerson Automation Solutions

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Cernay, 68700 France

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

E2016, 2017 Fisher Controls International LLC. All rights reserved.

[list trademarks in order that they appear in document] are marks owned by one of the companies in the Emerson Automation Solutions business unit of

Emerson Electric Co. Emerson Automation Solutions, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other

marks are the property of their respective owners.

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.