Proline Promag H 300

2 Endress+Hauser

Table of contents

Document information ....................... 4

Symbols used ................................ 4

Function and system design ................... 5

Measuring principle ............................ 5

Measuring system ............................. 6

Equipment architecture ......................... 7

Safety ..................................... 7

Input ..................................... 8

Measured variable ............................. 8

Measuring range .............................. 8

Operable flow range ........................... 10

Input signal ................................ 10

Output .................................. 11

Output and input variants ....................... 11

Output signal ............................... 12

Signal on alarm .............................. 15

Ex connection data ........................... 17

Low flow cut off ............................. 18

Galvanic isolation ............................ 18

Protocol-specific data .......................... 18

Power supply ............................. 24

Terminal assignment .......................... 24

Device plugs available .......................... 25

Pin assignment, device plug ...................... 25

Supply voltage .............................. 25

Power consumption ........................... 26

Current consumption .......................... 26

Power supply failure .......................... 26

Electrical connection .......................... 26

Potential equalization ......................... 32

Terminals ................................. 34

Cable entries ............................... 34

Cable specification ............................ 34

Performance characteristics .................. 36

Reference operating conditions ................... 36

Maximum measured error ....................... 36

Repeatability ............................... 37

Temperature measurement response time ............ 37

Influence of ambient temperature ................. 37

Installation ............................... 38

Mounting location ............................ 38

Orientation ................................ 39

Inlet and outlet runs .......................... 39

Adapters .................................. 39

Special mounting instructions .................... 40

Environment .............................. 40

Ambient temperature range ..................... 40

Storage temperature .......................... 41

Degree of protection .......................... 41

Vibration resistance ........................... 41

Shock resistance ............................. 41

Impact resistance ............................ 41

Mechanical load ............................. 41

Interior cleaning ............................. 41

Electromagnetic compatibility (EMC) ............... 41

Process .................................. 41

Medium temperature range ...................... 41

Conductivity ................................ 42

Pressure-temperature ratings .................... 42

Pressure tightness ............................ 48

Flow limit ................................. 48

Pressure loss ............................... 48

System pressure ............................. 48

Vibrations ................................. 48

Mechanical construction .................... 49

Dimensions in SI units ......................... 49

Dimensions in US units ......................... 66

Weight ................................... 77

Measuring tube specification ..................... 78

Materials .................................. 78

Fitted electrodes ............................. 80

Process connections ........................... 80

Surface roughness ............................ 80

Operability ............................... 80

Operating concept ............................ 80

Languages ................................. 81

Local operation .............................. 81

Remote operation ............................ 82

Service interface ............................. 85

Supported operating tools ....................... 86

HistoROM data management ..................... 86

Certificates and approvals ................... 88

CE mark ................................... 88

C-Tick symbol ............................... 88

Ex approval ................................ 88

Sanitary compatibility ......................... 89

Functional safety ............................. 89

HART certification ............................ 89

FOUNDATION Fieldbus certification ................ 89

Certification PROFIBUS ......................... 89

Modbus RS485 certification ..................... 89

Radio approval .............................. 89

Other standards and guidelines ................... 89

Ordering information ....................... 90

Application packages ....................... 90

Diagnostics functions .......................... 90

Heartbeat Technology ......................... 91

Cleaning .................................. 91

Accessories ............................... 91

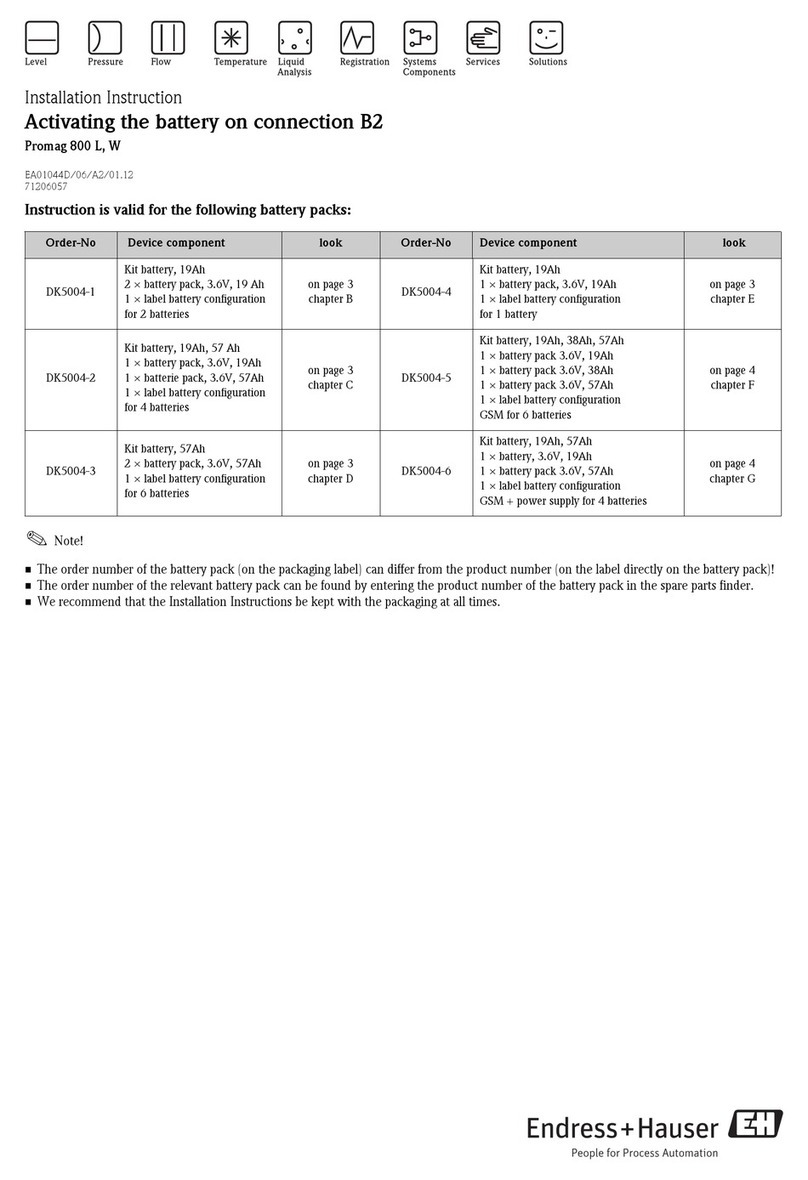

Device-specific accessories ...................... 91