Epilog Laser Zing User manual

Other Epilog Laser Engraver manuals

Epilog Laser

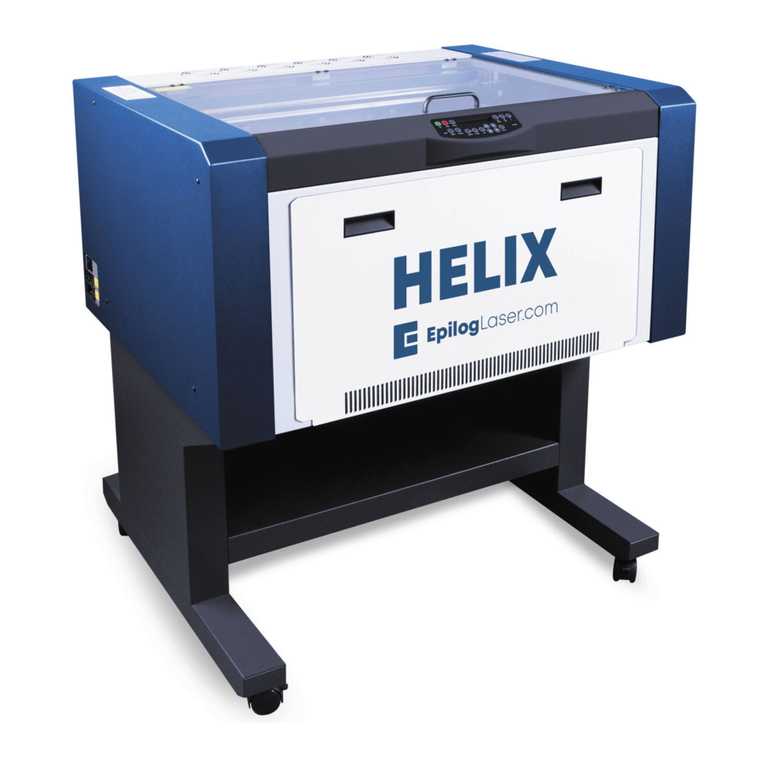

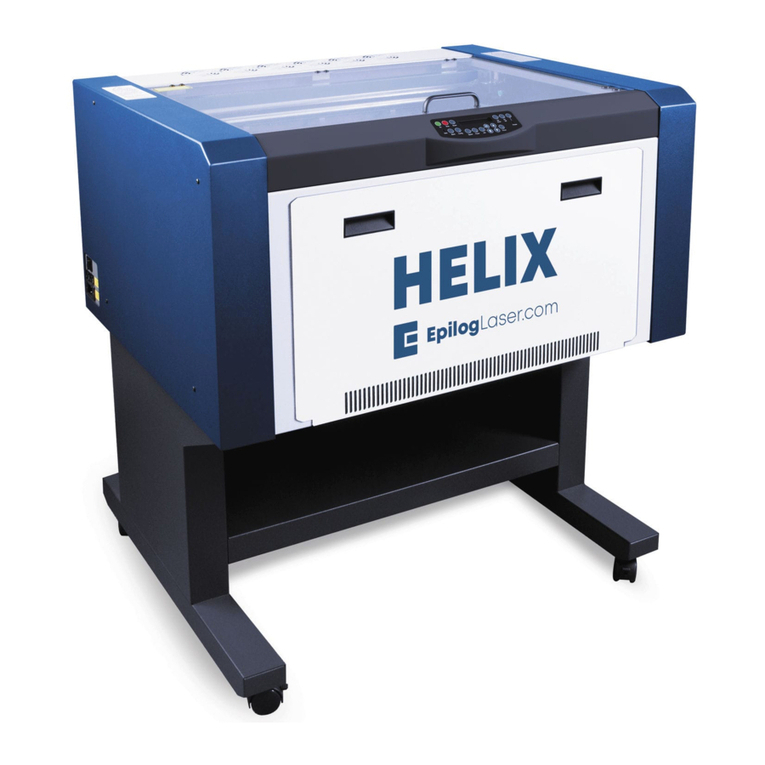

Epilog Laser Helix User manual

Epilog Laser

Epilog Laser MINI User manual

Epilog Laser

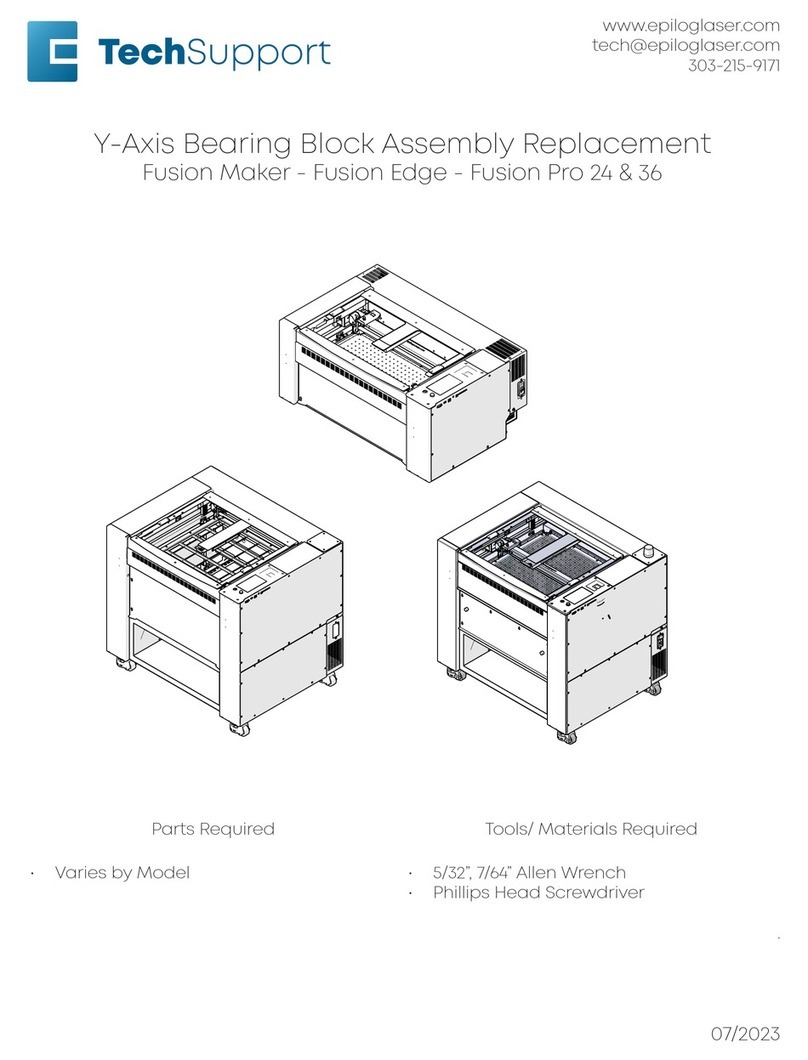

Epilog Laser Fusion Pro 32 User manual

Epilog Laser

Epilog Laser LEGEND 24EX 6000 User manual

Epilog Laser

Epilog Laser MINI 18 User manual

Epilog Laser

Epilog Laser Fusion User manual

Epilog Laser

Epilog Laser MINI User manual

Epilog Laser

Epilog Laser FiberMark User manual

Epilog Laser

Epilog Laser Fusion M2 32 User manual

Epilog Laser

Epilog Laser Fusion User manual

Epilog Laser

Epilog Laser Mini Series User manual

Epilog Laser

Epilog Laser FiberMark User manual

Epilog Laser

Epilog Laser FiberMark User manual

Epilog Laser

Epilog Laser Fusion Use and care manual

Epilog Laser

Epilog Laser Fusion User manual

Epilog Laser

Epilog Laser MINI User manual

Epilog Laser

Epilog Laser Fusion Pro 32 User manual

Epilog Laser

Epilog Laser Zing User manual

Epilog Laser

Epilog Laser Zing User manual

Epilog Laser

Epilog Laser FiberMark Fusion 13000 User manual