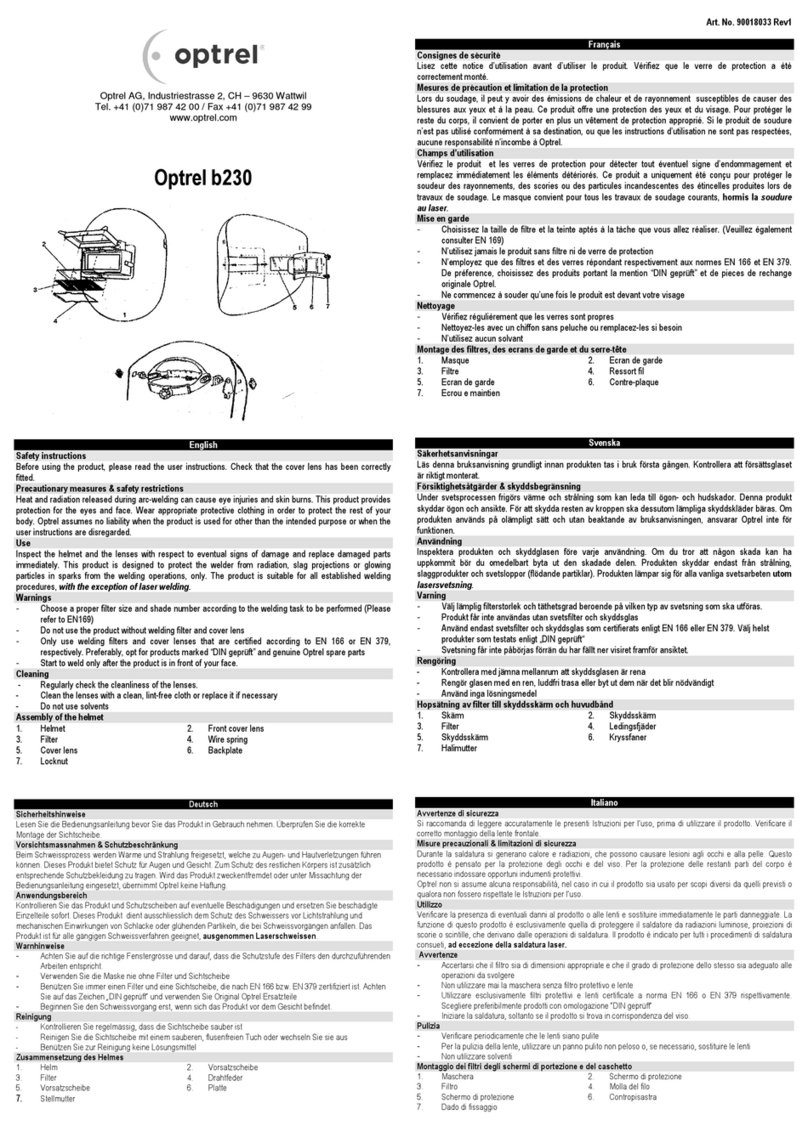

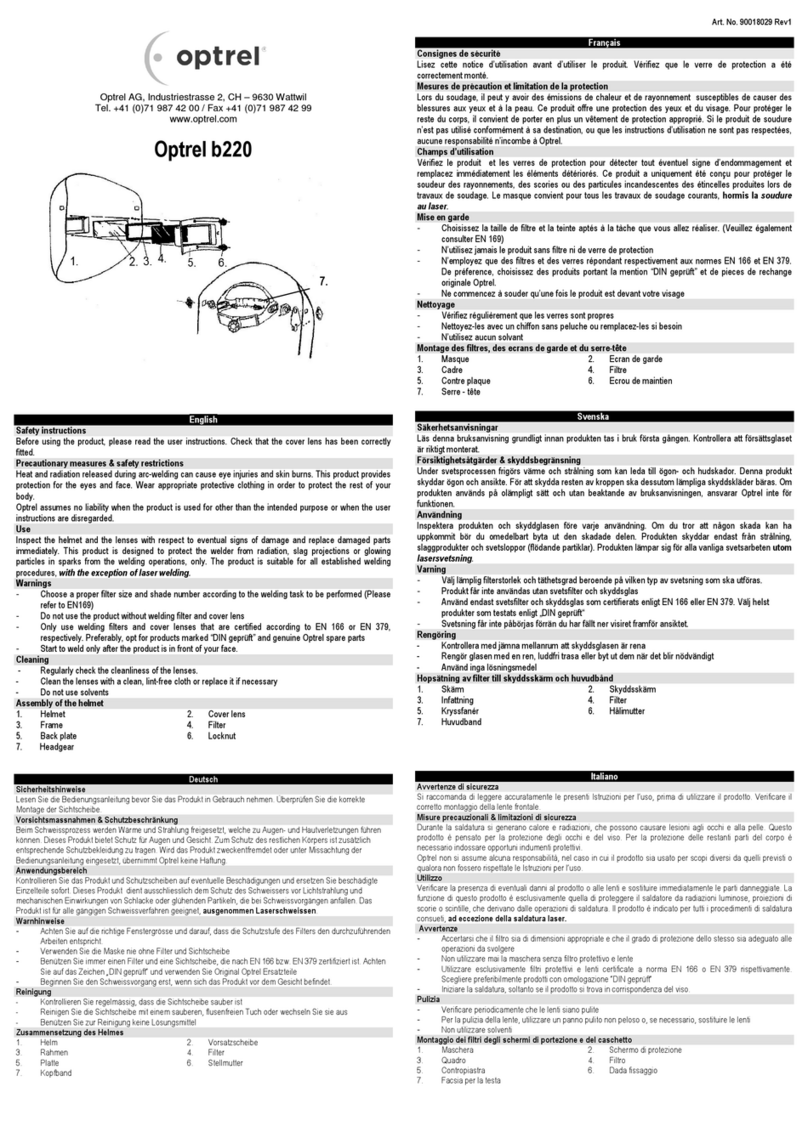

Classe optique

Schutzstufentabelle EN169

Shade level chart EN169

Tableau des niveaux de protection EN169

Tabella dei livelli di protezione EN169

Process 1.5

6

10 15 30 40 60 70 100

125

150 175

200

225 250

300

350 400

450 500

600

8910 11 12 13 14

Fe

910 11 12 13 14

Al

10 11 12 13 14

8910 11 12 13

CO

89

10 11 12 13

9

11

12 13

456789

10 11 12

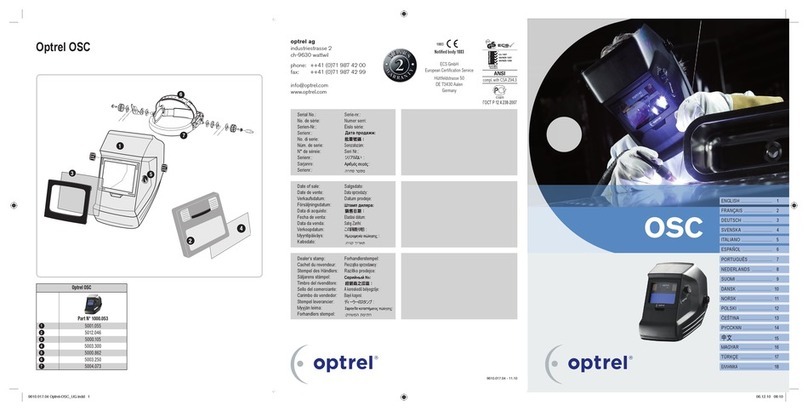

angebrachte Kennzeichnung bedeutet:

indicates:

I

protezione per saldatore contiene i

seguenti dati:

2.5

/

8-12

OS / 1 / 1 / 1 / 2 EN379 CE

2.5

/

8-12

OS / 1 / 1 / 1 / 2 EN379

CE

2.5 / 8-12 OS / 1 / 1 / 1 / 2 EN379 CE 2.5 / 8-12 OS / 1 / 1 / 1 / 2 EN3 79 CE

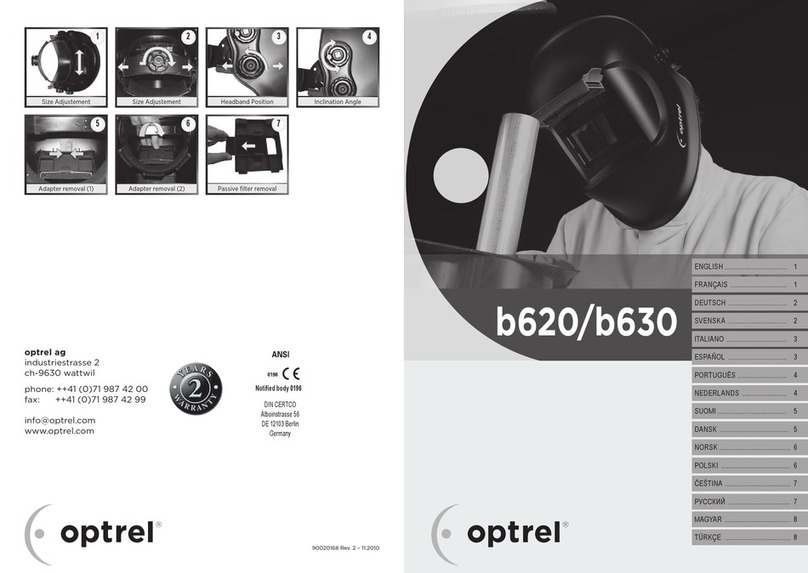

Kennzeichnung

Helmschale:

Marking helmet shell:

Marquages

masque

:

Marcaggi

maschera:

OS

175

B

CE

OS

175

B

CE

OS

175

B

CE

OS

175

B

CE

Kennzeichnung

Vorsatzscheibe

(EN166):

Marking

safety

cover

plate

(EN166):

Marquages Marcaggi

écran

de

protection

extérieur

(EN166)

vetro di protezione esterno (EN166):

OS

1

B

CE

OS

1

B

CE

OS

1

B

CE

OS

1

B

CE

Kennzeichnung

Innere

Schutztscheibe

(EN166):

Marking

inside

cover

lens

(EN166):

Marquages Marcaggi

écran de protection interieur (EN166)

vetro di protezione interno(EN166):

OS

F

CE

OS

F

CE

OS

F

CE

OS

F

CE

Hersteller

Niedrige Stossenergie

Optische Klasse

der Norm

Hersteller

Optische Klasse

Homogenität

Blickwinkelabhängigkeit

Nummer der Norm

Light

shade

Optical class

Manufacturer

of the standard

Manufacturer

Optical Class

Homogeneity

dependence

de protection à l' état clair

Échelon de protection à l' état foncé

Classe ottica

della

norma

di protezione in stato chiaro

Grado di protezione in stato scuro

dipendenza