11 Safety Information

The power cord must be connected to a properly earth grounded outlet.

Rack Mount Instructions - The following or similar rack-mount instructions are

included with the installation instructions:

(A) Elevated Operating Ambient - If installed in a closed or multi-unit rack assembly,

the operating ambient temperature of the rack environment may be greater than

room ambient. Therefore, consideration should be given to installing the equipment

in an environment compatible with the maximum ambient temperature (Tma)

specified by the manufacturer.

B) Reduced Air Flow - Installation of the equipment in a rack should be such that the

amount of air flow required for safe operation of the equipment is not compromised.

C) Mechanical Loading - Mounting of the equipment in the rack should be such that a

hazardous condition is not achieved due to uneven mechanical loading.

D) Circuit Overloading - Consideration should be given to the connection of the

equipment to the supply circuit and the effect that overloading of the circuits might

have on overcurrent protection and supply wiring. Appropriate consideration of

equipment nameplate ratings should be used when addressing this concern.

E) Reliable Earthing - Reliable earthing of rack-mounted equipment should be

maintained. Particular attention should be given to supply connections other than

direct connections to the branch circuit (e.g. use of power strips).

The socket-outlet shall be installed near the equipment and shall be easily accessible.

Do not disable the power cord grounding plug. The grounding plug is an important

safety feature

Caution: Double pole, neutral fusing. Disconnect mains before servicing.

Plug the power cord made by metals and polymers into a grounded (earthed)

electrical outlet that is easily accessible at all times.

This equipment is intended to be used in a restricted access location and be used by a

qualified person.

This equipment is not suitable for use in locations where children are likely to be

present.

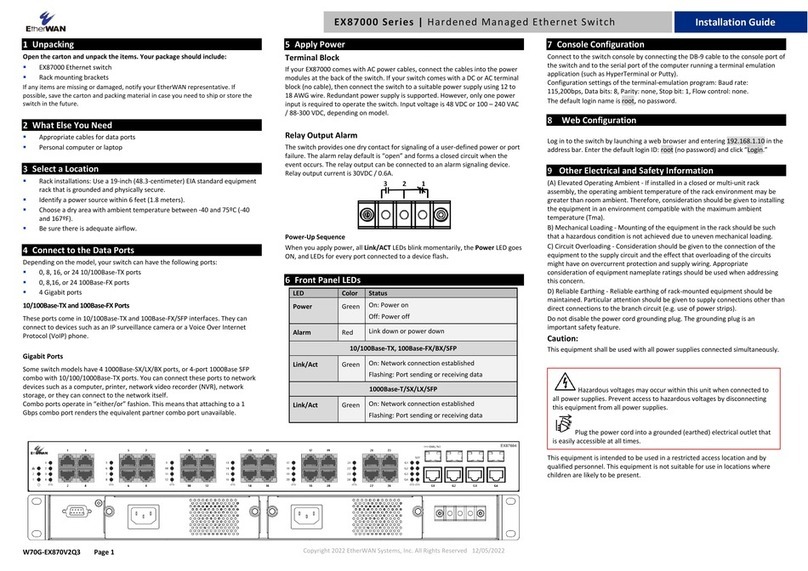

RCR series AC Inlet

The power cord shall be IEC 60227 certified, rated 0.75 mm2x 3C or UL recognized

minimum 18AWG, suitable for the application and subject to country's national codes

and regulations.

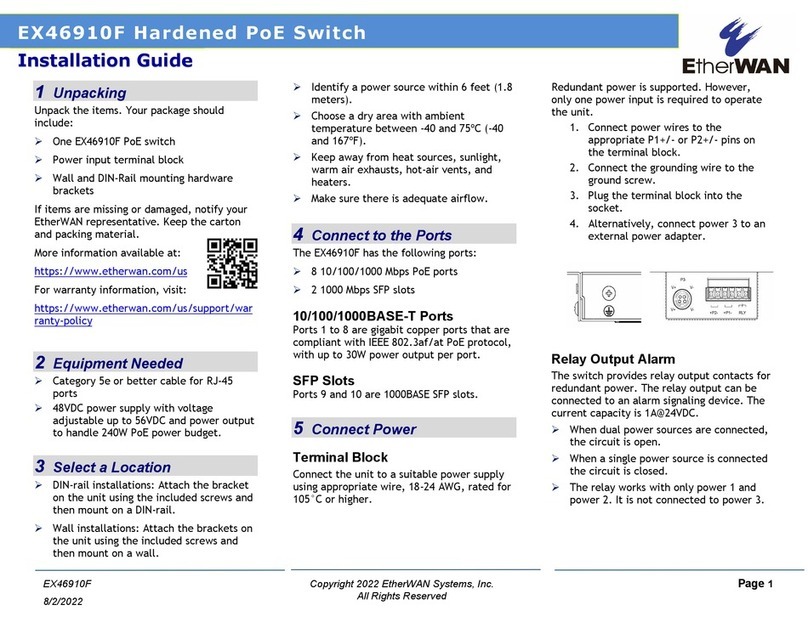

FWR series terminal block:

All power connection wiring by a qualified electrician in accordance with National

Electrical Code, ANSI/NFPA 70 and Canadian Electrical Code, Part I, CSA C22.1. An IEC

certified or UL listed single-phase double pole type circuit-breaker, rated maximum

20A, shall be installed between mains circuit and equipment. For supply connections

use copper conductors, wires suitable for at least 105°C.

Thumbscrews should be tightened with a tool after both initial installation subsequent

access to the panel.

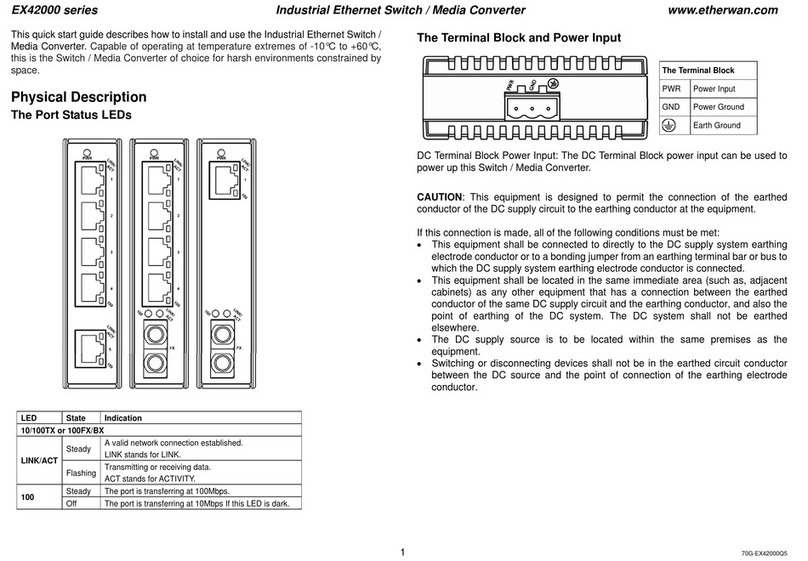

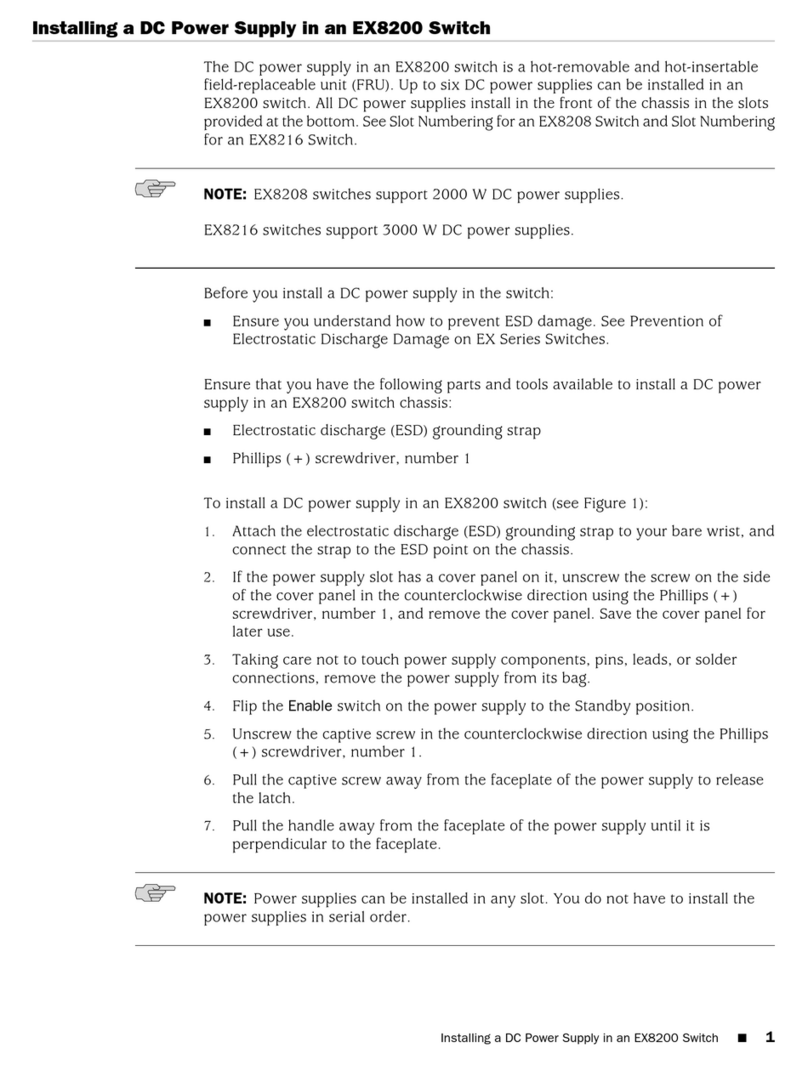

Caution: This equipment has a connection between the earthed conductor of the DC

supply circuit and the earthing conductor. All of the following installation conditions

must be met.

⚫This equipment shall be connected directly to the DC supply system earthing

electrode conductor or to a bonding jumper from an earthing terminal bar or

bus to which the DC supply system earthing electrode is connected.

⚫This equipment shall be located in the same immediate area (such as adjacent

cabinets) as any other equipment that has a connection between the earthed

conductor of the same DC supply circuit and the earthing conductor, and also

the point of earthing of the DC system. The DC system shall not be earthed

elsewhere.

⚫The DC supply source is to be located within the same premises as this

equipment.

⚫There shall be no switching or disconnecting devices in the earthed circuit

conductor between the DC source and the point of connection on the earthing

electrode conductor.

Note: This equipment must use UL recognized Laser Class 1 optical transceiver.

This equipment is intended to be used in a restricted access location and be used by a

qualified person.

This equipment is not suitable for use in locations where children are likely to be

present.

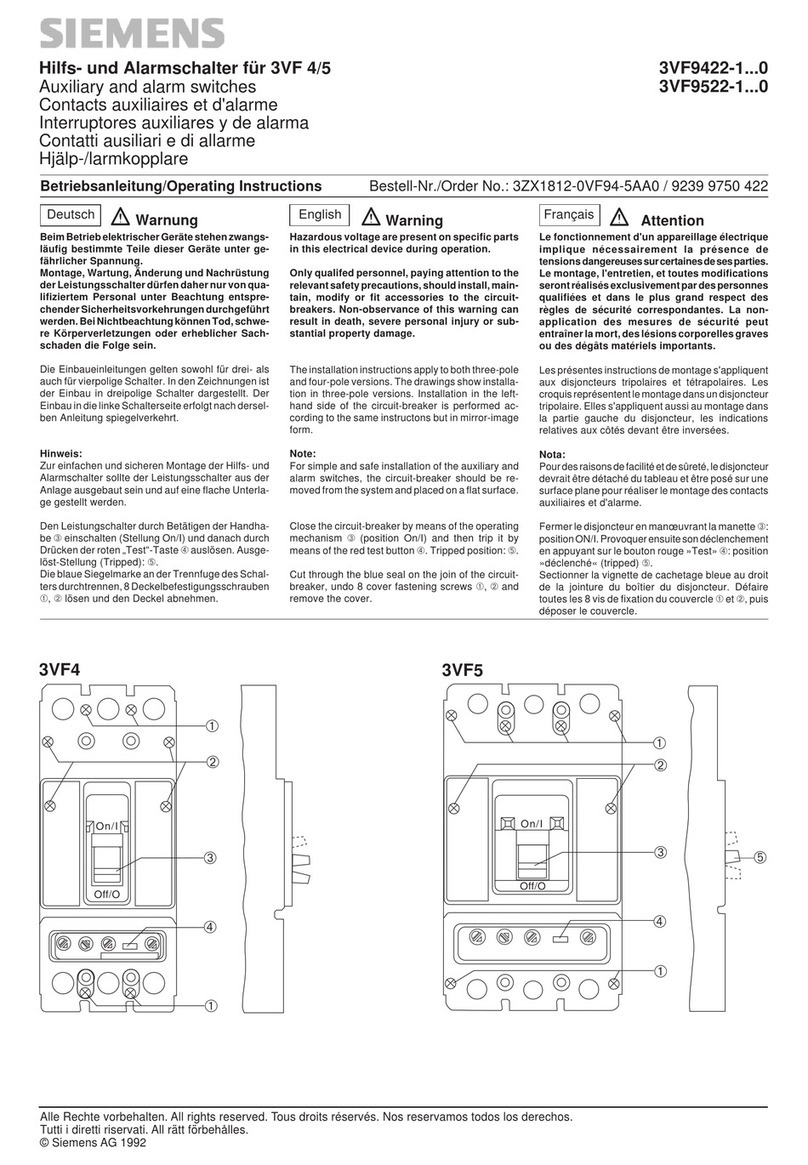

SAFETY INFORMATION

Caution

Read these instructions carefully before connecting the system to the power source.

Keep these instructions for later reference.

⚫Protect the power cord from being walked on or pinched.

⚫To reduce the risk of electrical shock, do not open the equipment. For safety

reasons, may only be opened by qualified service personnel.

⚫Protect equipment from humidity.

⚫Disconnect equipment from power supply before cleaning. Do not use any liquid

or aerosol cleaner. Use only dampened cloth.

⚫Equipment should be placed on a reliable surface. A drop or fall could cause

damage.

⚫If the equipment is not used for long time, disconnect the equipment from power

supply to avoid being damaged by transient over voltage.

⚫This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that

may cause undesired operation.

⚫Max operated altitude is 2000m.

⚫Do not dispose of electrical appliances as unsorted municipal waste. Use separate

collection facilities.

Contact your local government for information regarding the collection systems

available.

If electrical appliances are disposed of in landfills or dumps, hazardous

substances can leak into the groundwater and get into the food chain, damaging

health and well-being.

When replacing old appliances with new ones, the retailer is legally obligated to

take back your old appliance for disposal free of charge.

Les matériels sont destinés à être installés dans des EMPLACEMENTS À ACCÈS

RESTREINT.

Power wiring information:

The rating of the power wire used must be at least 105°C.

USE COPPER CONDUCTORS ONLY.

If the equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment may be impaired.

WARNING –Explosion hazard. Do not disconnect the terminal block while the circuit is

live or unless the area is known to be free of ignitable concentrations.

For repair or maintenance needs, contact EtherWAN directly.

Informations de câblage d'alimentation:

Le calibre du fil d'alimentation utilisé doit être d'au moins 105°C.

DESTINÉ À ÊTRE UTILISÉ AVEC DES CONDUCTEURS EN CUIVRE SEULEMENT.

Si la méthode d'utilisation de l'équipement diffère de celle décrite par le fabricant,

la protection assurée par l'équipement risque d'être altérée.

Contactez-nous pour l'entretien ou la reparation.

Manufacturer information:

ETHERWAN SYSTEMS, INC.

33F, No. 93, Sec. 1, Xintai 5th Rd., Xizhi Dist., New Taipei City, 221

Taiwan