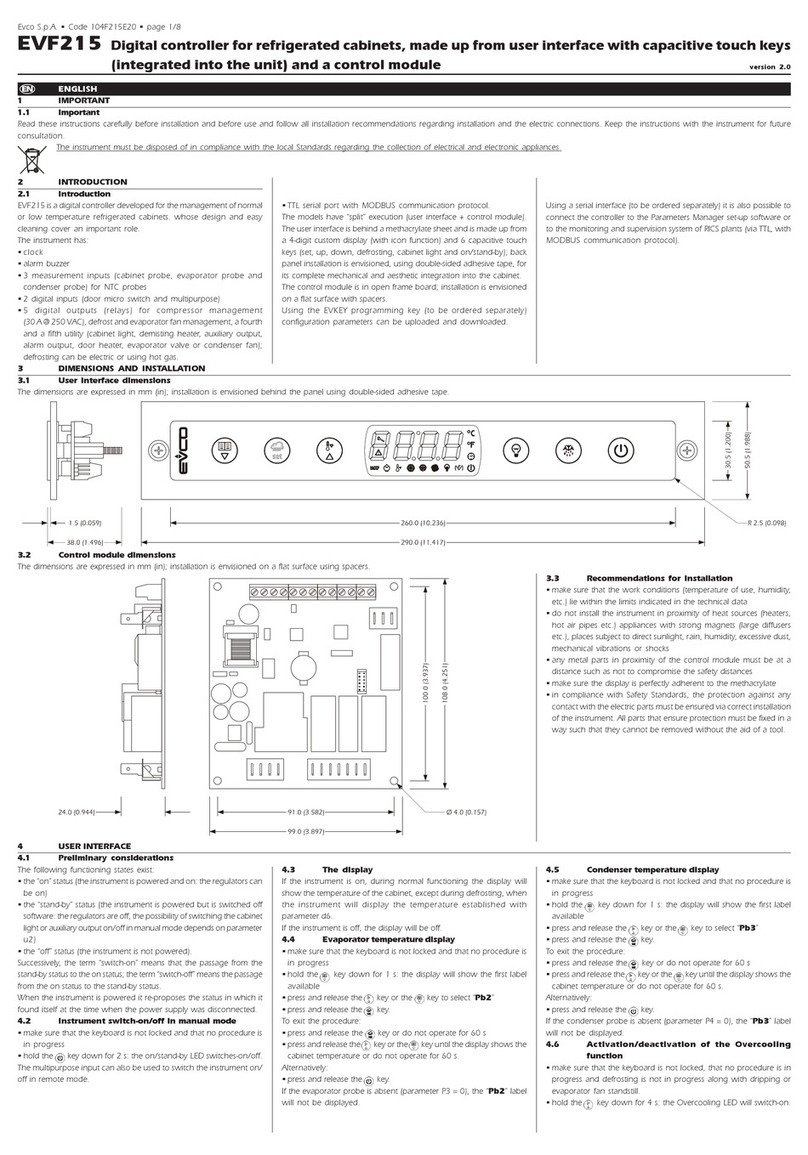

EVCO S.p.A. | EVJ 200 | Instruction sheet ver. 2.0 | Code 104J200I203 | Pa e 2 of 4 | PT 18/17

2.

Touch the UP or DOWN key within 15s to select a label.

LAB.

DESCRIPTION

S view HACCP alarm information

r S

delete HACCP alarm information

3.

Touch the SET key.

4.

Touch the UP or DOWN key to select an alarm code (to select

label “ S”) or to set “149” (to select label “r S”).

COD.

DESCRIPTION

A low temperature alarm

AH

hi h temperature alarm

id

open door alarm (if i4 = 1)

PF

power failure alarm (available in EVJ213, EVJ214, EVJ214N7VXXRXV, EVJ215,

EVJ234 and EVJ235 or in EVJ203, EVJ204, EVJ205, EVJ224 and EVJ225 with

interface EVIF25TBX connected)

5. Touch the SET key.

6.

Touch the ON/STAND-BY key (or do not operate for 60s) to exit

the procedure.

Example of alarm information (e. . a hi h temperature alarm).

8.0

critical value (calculated cabinet/product temperature)

was 8.0 °C/°F

Sta

(available in EVJ213, EVJ214, EVJ214N7VXXRXV, EVJ215, EVJ234

and EVJ235 or in EVJ203, EVJ204, EVJ205, EVJ224 and EVJ225 with

interface EVIF25TBX connected)

y15

alarm si nalled in 2015

n03

alarm si nalled in March

d26

alarm si nalled on 26 March 2015

h16

alarm si nalled at 16:00

n30

alarm si nalled at 16:30

dur

h01

alarm lasted 1h

n15

alarm lasted 1h 15min

5.5 View/delete compressor functioning hours

Check that the keypad isn’t locked.

1.

Touch the DOWN key for 1s.

2.

Touch the UP or DOWN key within 15s to select a label.

LAB.

DESCRIPTION

CH1

view compressor functionin hundreds of hours

CH2 view second compressor functionin hundreds of hours (if u1c... u5c = 1)

rCH delete compressor and second compressor functionin hours

3. Touch the SET key.

4.

Touch the UP or DOWN key to set “149” (to select rCH).

5.

Touch the SET key.

6.

Touch the ON/STAND-BY key (or do not operate for 60s) to exit

the procedure.

5.6 View the temperature detected by the probes

Check that the keypad isn’t locked.

1.

Touch the DOWN key for 1s.

2.

Touch the UP or DOWN key within 15s to select a label.

LAB.

DESCRIPTION

Pb1 cabinet temperature (if P4 = 0, 1 or 2)

inlet air temperature (if P4 = 3)

Pb2

evaporator temperature (if P3 = 1 or 2)

Pb3

auxiliary temperature (if P4 = 1, 2 or 3)

Pb4 calculated product temperature (CPT; if P4 = 3)

3. Touch the SET key.

4.

Touch the ON/STAND-BY key (or do not operate for 60s) to exit

the procedure.

6

DATA- OGGER MODU E on SD CARD (not available in

EVJ224 and EVJ225)

6.1 Initial information

The data-lo er module makes it possible to write information about the device on an SD card

(in CSV format ), in HACCP or service mode.

Data-lo er module confi uration parameters.

PAR.

DEF.

PARAMETER

MIN... MAX.

Sd0

30

SD card writin interval in HACCP

mode

1... 30 min

Sd1

1

SD card writin interval in service

mode

1... 30 min

Sd2 60 service mode duration 1... 240 min

Sd3 0 enable critical temperature recordin 0 = no 1 = yes

Sd4 1 enable cabinet temperature recordin 0 = no 1 = yes

Sd5 1 decimal separator type 0 = comma 1 = point

6.2 Writing in HACCP mode

Writin in HACCP mode is always activated, it enerates a daily file and a monthly file.

Information written in HACCP mode.

- cabinet temperature (if Sd4 = 1, default “no”)

- critical temperature (if Sd3 = 1, default “no”)

- device switched on/off

- defrost activated/completed

- ener y savin activated/deactivated

- alarm activated/restored

- power supply restored

The date and time is written for each piece of information.

6.3 Writing in service mode

Writin in service mode must be manually activated.

Information written in service mode.

- temperature detected by all probes

- enable/disable probes

- device switched on/off

- functions on/off

- defrost activated/completed

- ener y savin activated/deactivated

- alarm activated/restored

- power supply restored

The date and time is written for each piece of information.

6.4 Activate/deactivate writing in service mode

Check that the keypad isn’t locked.

1.

Touch the DOWN key for 1s.

2.

Touch the UP or DOWN key within 15s to select the label “SEr”.

3.

Touch the SET key.

4.

Touch the UP or DOWN key within 15s to set “1” (activate

writin ) or “0” (deactivate writin ).

5.

Touch the ON/STAND-BY key (or do not operate for 60s) to exit

the procedure.

6.5 File names

Example of a daily file name written in HACCP mode (e. . the file “log001_2015_03_26.csv”).

001 the device address is 1 (parameter LA)

2015 the file was written in 2015

03 the file was written in March

26 the file was written on 26 March 2015

Example of a monthly file name written in HACCP mode (e. . the file “log001_2015_m03.csv”).

001 the device address is 1 (parameter LA)

2015 the file was written in 2015

m03

the file was written in March 2015

Example of a file name written in service mode (e. . the file “log001_2015_0001.csv”).

001 the device address is 1 (parameter LA)

2015 the file was written in 2015

0001 sequence number

6.6 View data-logger module alarms

Check that the keypad isn’t locked.

1.

Touch the DOWN key for 1s.

2.

Touch the UP or DOWN key within 15s to select the label “Err”.

3.

Touch the SET key.

4.

Touch the UP or DOWN key within 15s to see the alarm code.

LAB. DESCRIPTION

FU

no space left on SD card alarm

Sd

SD card not inserted or not reco nised alarm

5.

Touch the ON/STAND-BY key (or do not operate for 60s) to exit

the procedure.

7 SETTINGS

7.1 Setting configuration parameters

1.

Touch the SET key for 4s: the display will show the label “PA”.

2.

Touch the SET key.

3.

Touch the UP or DOWN key within 15s to set the PAS value

(default “-19”).

4.

Touch the SET key (or do not operate for 15s): the display will

show the label “SP”.

5.

Touch the UP or DOWN key to select a parameter.

6.

Touch the SET key.

7.

Touch the UP or DOWN key within 15s to set the value.

8.

Touch the SET key (or do not operate for 15s).

9.

Touch the SET key for 4s (or do not operate for 60s) to exit the

procedure.

7.2 Set the date, time and day of the week (available in EVJ213, EVJ214,

EVJ214N7VXXRXV, EVJ215, EVJ234 and EVJ235 or in EVJ203, EVJ204, EVJ205,

EVJ224 and EVJ225 with interface EVIF25TBX connected)

N.B.

- If the device is connected to the interface EVIF25TBX, do not disconnect the device

from the mains within two minutes since the settin of the time and day of the

week.

- If the device communicates with the APP EVconnect, the date, time and day of the

week will automatically be set by the smartphone or tablet.

Check that the keypad isn’t locked.

1.

Touch the DOWN key for 1s.

2.

Touch the UP or DOWN key within 15s to select the label “rtc”.

3.

Touch the SET key: the display will show the label “y” followed

by the last two fi ures of the year.

4.

Touch the UP or DOWN key within 15s to set the year.

5. Repeat actions 3 and 4 to set the next labels.

LAB.

MEANING OF THE NUMBERS FOLLOWING THE LABEL

n month (01… 12)

d day (01… 31)

h time (00… 23)

n

minutes (00… 59)

6.

Touch the SET key: the display will show the label for the day of

the week.

7.

Touch the UP or DOWN key within 15s to set the day of the

week.

LAB.

DESCRIPTION

Mon Monday

tuE Tuesday

UEd Wednesday

thu

Thursday

Fri Friday

Sat Saturday

Sun Sunday

8. Touch the SET key: the device will exit the procedure.

9.

Touch the ON/STAND-BY key to exit the procedure beforehand.

7.3 Reset the factory settings

N.B.

Check that the factory settin s are appropriate; see the section CONFI URATION

PARAMETERS.

1.

Touch the SET key for 4s: the display will show the label “PA”.

2.

Touch the SET key.

3.

Touch the UP or DOWN key within 15s to set “149”.

4.

Touch the SET key (or do not operate for 15s): the display will

show the label “dEF”.

5.

Touch the SET key.

6.

Touch the UP or DOWN key within 15s to set “1”.

7.

Touch the SET key (or do not operate for 15s).

8. Interrupt the power supply to the device.

9.

Touch the SET key for 2s before action 6 to exit the procedure

beforehand.

8 CONFIGURATION PARAMETERS

N. PAR. DEF. SETPOINT MIN... MAX.

1 SP 0.0 setpoint r1... r2

N. PAR. DEF. ANALOGUE INPUTS MIN... MAX.

2

CA1

0.0

cabinet probe offset

-25... 25 °C/°F

if P4 = 3, air in probe offset

3 CA2 0.0 evaporator probe offset -25... 25 °C/°F

4 CA3 0.0 auxiliary probe offset -25... 25 °C/°F

5 P0 1 probe type 0 = PTC 1 = NTC

6 P1 1 enable °C decimal point 0 = no 1 = yes

7

P2

0

temperature unit of

measurement

0 = °C 1 = °F

8

P3

1

evaporator probe function

0 = disabled

1 = defrost + fan

2 = fan

9

P4

0

confi urable input function

(option 4 only available in

EVJ224, EVJ225, EVJ234 and

EVJ235)

0 = di ital input

1 = condenser probe

2 =

critical temperature probe

3 = air out probe

4 = evaporator 2 probe

if P4 = 3, re ulation temperature

= product temperature (CPT)

10

P5

0

value displayed

0 = re ulation temperature

1 = setpoint

2 = evaporator temperature

3 = auxiliary temperature

4 = air in temperature

11

P7

50

inlet air wei ht for calculated

product temperature (CPT)

0... 100 %

CPT = {[(P7 x (inlet air T)] +

[(100 - P7) x (outlet air T)] :

100}

12

P8 5 display refresh time 0... 250 s : 10

N.

PAR.

DEF.

REGULATION

MIN... MAX.

13

r0

2.0

setpoint differential

1... 15 °C/°F

if u1c... u5c 1, proportional

band

14

r1 -40 minimum setpoint -99 °C/°F... r2

15

r2 50.0

maximum setpoint r1... 199 °C/°F

16

r3 0 enable setpoint block

0 = no 1 = yes

17

r4 0.0 setpoint offset in ener y savin 0... 99 °C/°F

18

r5

0

coolin or heatin operation

0 = coolin

1 = heatin

19

r6

0.0

setpoint offset in

overcoolin /overheatin

0... 99 °C/°F

20

r7 0 overcoolin /overheatin duration 0... 240 min

21

r12

1

position of the r0 differential

0 = asymmetric

1 = symmetric

N. PAR. DEF. COMPRESSOR MIN... MAX.

22

C0

0

compressor on delay after

power-on

0... 240 min

23

C1

5

delay between 2 compressor

switch-ons

0... 240 min

24

C2 3 compressor off minimum time 0... 240 min

25

C3 0 compressor on minimum time 0... 240 s

26

C4

10

compressor off time durin

cabinet probe alarm

0... 240 min

27

C5

10

compressor on time durin

cabinet probe alarm

0... 240 min

28

C6

80.0

threshold for hi h condensation

warnin

0... 199 °C/°F

differential = 2 °C/4 °F

29

C7

90.0

threshold for hi h condensation

alarm

0... 199 °C/°F

30

C8 1 hi h condensation alarm delay 0... 15 min

31

C10

0

compressor hours for service

0... 999 h x 100

0 = disabled

32

C11 10 compressor 2 on delay 0... 240 s

33

C12

2

compressor hours wei ht for

balancin hours and switch-ons

(BHC) - (only available in

EVJ224, EVJ225, EVJ234 and

EVJ235)

0... 10

BHC = {[C12 x (compressor

hours)] + [C13 x

(compressor switch-ons)]}

34

C13

1

compressor hours switch-ons for

balancin hours and switch-ons

(BHC) - (only available in

EVJ224, EVJ225, EVJ234 and

EVJ235)

0... 10

BHC = {[C12 x (compressor

hours)] + [C13 x

(compressor switch-ons)]}

35

C14

1

tie between compressors (only

available in EVJ224, EVJ225,

EVJ234 and EVJ235)

0 = accordin to C11

1 = accordin to r0

N. PAR. DEF. DEFROST (if r5 = 0) MIN... MAX.

36

d0

8

automatic defrost interval

0... 99 h

0 = only manual

if d8 = 3, maximum interval

37

d1

0

defrost type

0 = electric

1 = hot as

2 = compressor stopped

38

d2 2.0 threshold for defrost end -99... 99 °C/°F

39

d3

30

defrost duration

0... 99 min

se P3 = 1, maximum duration

40

d4 0 enable defrost at power-on 0 = no 1 = yes

41

d5 0 defrost dealy after power-on 0... 99 min

42

d6

1

value displayed durin defrost

0 = re ulation temperature

1 = display locked

2 = dEF label

43

d7 2 drippin time 0... 15 min

44

d8

0

defrost interval countin mode

0 = device on hours

1 = compressor on hours

2 = hours evaporator

temperature < d9

3 = adaptive (if P4 = 4,

device on hours)

4 = real time

45

d9

0.0

evaporation threshold for

automatic defrost interval

countin

-99... 99 °C/°F

46

d11 0 enable defrost timeout alarm 0 = no 1 = yes

47

d15

0

compressor on consecutive time

for hot as defrost

0... 99 min

48

d16

0

pre-drippin time for hot as

defrost

0... 99 min

49

d18

40

adaptive defrost interval

0... 999 min

if compressor on + evapora-

tor temperature < d22

0 = only manual

50

d19

3.0

threshold for adaptive defrost

(relative to optimal evaporation

temperature)

0... 40 °C/°F

optimal evaporation

temperature - d19

51

d20

180

compressor on consecutive time

for defrost

0... 999 min

0 = disabled

52

d21

200

compressor on consecutive time

for defrost after power-on and

overcoolin

0... 500 min

if (re ulation temperature -

setpoint) > 10°C/20 °F

0 = disabled

53

d22

-2.0

evaporation threshold for

adaptive defrost interval countin

(relative to optimal evaporation

temperature)

-10... 10 °C/°F

optimal evaporation

temperature + d22

54

d25

0

enable air out probe for defrost

durin evaporator probe alarm

0 = no 1 = yes

55

d26

6

defrost interval durin

evaporator probe alarm

0... 99 h

0 = only manual

if d25 = 1

N.

PAR.

DEF.

ALARMS

MIN... MAX.

56

A0

0

select value for hi h/low

temperature alarms

0 = re ulation temperature

1 = evaporator temperature

57

A1

0.0

threshold for low temperature

alarm

-99... 99 °C/°F

58

A2

0

low temperature alarm type

0 = disabled

1 = relative to setpoint

2 = absolute