EVCO S.p. . c-pro 3 OEM HRV | pplication handbook ver. 4.0 | Code 144CP3OHE404

page 3 of 138

Index

1

INTRODUCTION ....................................................................................................................................................................................................... 6

1.1

Preliminary notes ................................................................................................................................................................................... 6

1.2

Models available, technical features and purchase codes ............................................................................................................................. 7

2

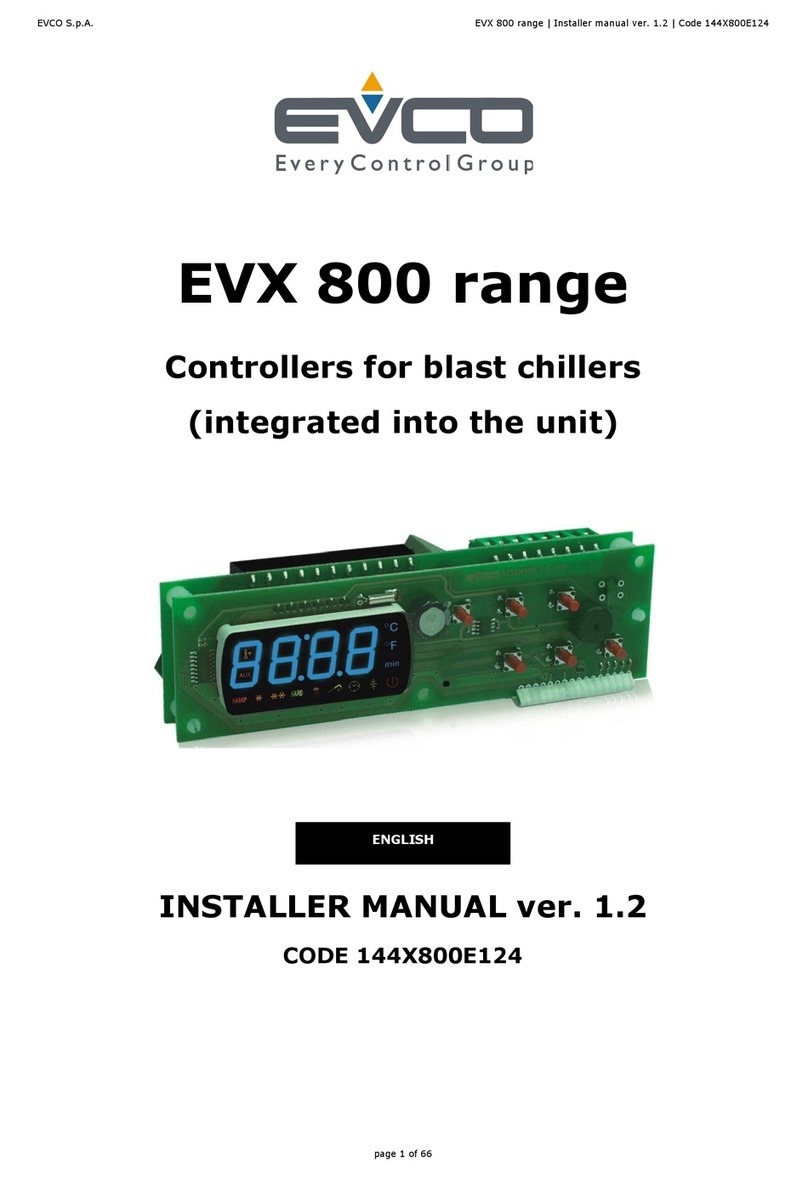

DESCRIPTION ......................................................................................................................................................................................................... 13

2.1

Description of c-pro 3 OEM HRV .............................................................................................................................................................. 13

2.2

Description of EVJ LCD and EPJ LCD ........................................................................................................................................................ 14

2.3

Description of EPJgraph ......................................................................................................................................................................... 15

2.4

Description of EPcolor S ......................................................................................................................................................................... 16

2.5

Description of EVD EXP .......................................................................................................................................................................... 17

3

DIMENSIONS ND INST LL TION ............................................................................................................................................................................. 18

3.1

c-pro 3 OEM HRV dimensions and installation ........................................................................................................................................... 18

3.2

Description and installation of EVJ LCD and EPJ LCD .................................................................................................................................. 19

3.3

Dimensions and installation of EPJgraph .................................................................................................................................................. 20

3.4

Dimensions and installation of EPcolor S .................................................................................................................................................. 21

3.5

Dimensions and installation of EVD EXP ................................................................................................................................................... 22

4

ELECTRIC CONNECTION ........................................................................................................................................................................................... 23

4.1

c-pro 3 OEM HRV connectors .................................................................................................................................................................. 23

4.2

EVJ LCD connectors .............................................................................................................................................................................. 25

4.3

EPJ LCD connectors ............................................................................................................................................................................... 26

4.4

EPJgraph connectors ............................................................................................................................................................................. 27

4.5

EPcolor S connectors ............................................................................................................................................................................. 28

4.6

EVD EXP connectors .............................................................................................................................................................................. 30

4.7

Termination of RS-485 MODBUS and C N networks .................................................................................................................................. 31

4.8

Example of electrical connection of a c-pro 3 OEM HRV controller ............................................................................................................... 33

4.9

Example of electrical connection of an EVJ LCD user interface .................................................................................................................... 33

4.10

Example of electrical connection of an EPJ LCD user interface ..................................................................................................................... 35

4.11

Example of electrical connection of an EPJgraph ....................................................................................................................................... 36

4.12

Example of electrical connection of an EPcolor S ....................................................................................................................................... 38

4.13

Example of electrical connection of an EVD EXP I/O expansion ................................................................................................................... 40

5

USER INTERF CE .................................................................................................................................................................................................... 41

5.1

EPJgraph keypad and display ................................................................................................................................................................. 41

5.2

List of pages ........................................................................................................................................................................................ 42

5.3

Passwords ............................................................................................................................................................................................ 43

5.4

Main page ............................................................................................................................................................................................ 43

5.5

Meaning of display icons on c-pro 3 OEM HRV and on EVJLCD and EPJ LCD interfaces ................................................................................... 44

5.6

EPJgraph and EPcolor user interface ........................................................................................................................................................ 45

5.7

c-pro 3 OEM HRV display and EVJ LCD and EPJ LCD user interfaces............................................................................................................. 46

5.8

General menu ...................................................................................................................................................................................... 55

5.9

User menu ........................................................................................................................................................................................... 55

5.10

Servicer menu ...................................................................................................................................................................................... 55

5.11

Installer menu ...................................................................................................................................................................................... 56

5.12

Manufacturer menu ............................................................................................................................................................................... 56

5.13

RTC menu ............................................................................................................................................................................................ 57

5.14

larms menu ........................................................................................................................................................................................ 57

5.15

larm history menu............................................................................................................................................................................... 57

5.16

Menu save/restore/parameters imp. exp. ................................................................................................................................................. 57

5.17

Info menu ............................................................................................................................................................................................ 57

6

LIST OF P R METERS .............................................................................................................................................................................................. 58

6.1

List of configuration parameters ............................................................................................................................................................. 58

6.2

I/O Table I ( nalogue Inputs) parameters .............................................................................................................................................. 81

6.3

I/O Table DI (Digital Inputs) parameters ................................................................................................................................................. 83

6.4

I/O Table DO (Digital Outputs) parameters .............................................................................................................................................. 84

6.5

I/O Table O ( nalogue Outputs) parameters........................................................................................................................................... 85

7

djustments ........................................................................................................................................................................................................... 88

7.1

Machine status ..................................................................................................................................................................................... 88

7.2

OFF by alarm status .............................................................................................................................................................................. 88

7.3

Operating mode control ......................................................................................................................................................................... 88

7.4

Set real time clock ................................................................................................................................................................................ 89

7.5

System set-up ...................................................................................................................................................................................... 89

7.6

Initial page set-up ................................................................................................................................................................................ 90

7.7

Fans set-up .......................................................................................................................................................................................... 90

7.8

Coil 1 set-up ........................................................................................................................................................................................ 91

7.9

Coil 2 set-up ........................................................................................................................................................................................ 93

7.10

Electric coil set-up ................................................................................................................................................................................ 93

7.11

Pre-heating coil set-up .......................................................................................................................................................................... 95