EVCO S.p.A. EVXV 800 range | Installer manual ver. 1.2 | Code 144XV800E124

page 3 of

Index

1

INTRODUCTION ................................................................................................................................... 5

1.1

Introduction ........................................................................................................................................ 5

1.2

Summary table of the main features and the models available ................................................................... 7

2

DESCRIPTION .................................................................................................................................... 10

2.1

Description of EVXV802 and EVXV812 .................................................................................................. 10

2.2

Description of EVXV805 and EVXV815 .................................................................................................. 11

3

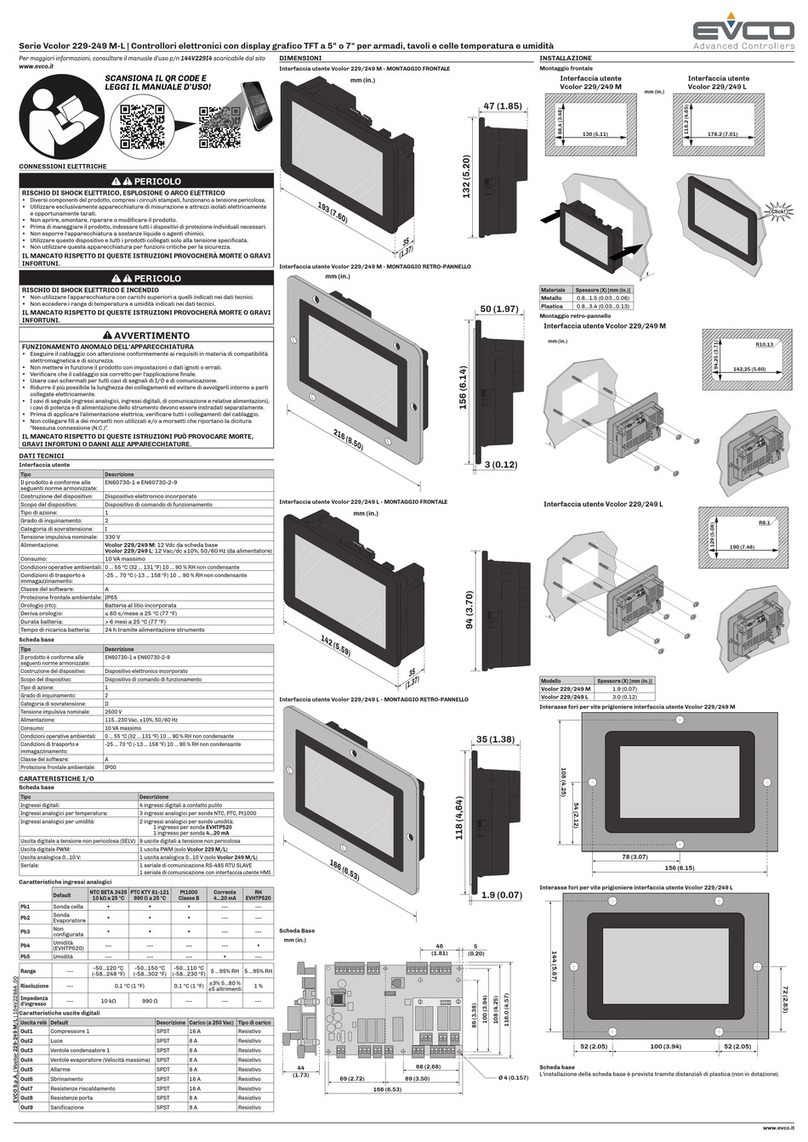

DIMENSIONS AND INSTALLATION ........................................................................................................ 12

3.1

Dimensions of EVXV802 and EVXV812 .................................................................................................. 12

3.2

Dimensions of EVXV805 and EVXV815 .................................................................................................. 12

3.3

Installation ........................................................................................................................................ 13

3.4

Installation warnings .......................................................................................................................... 13

4

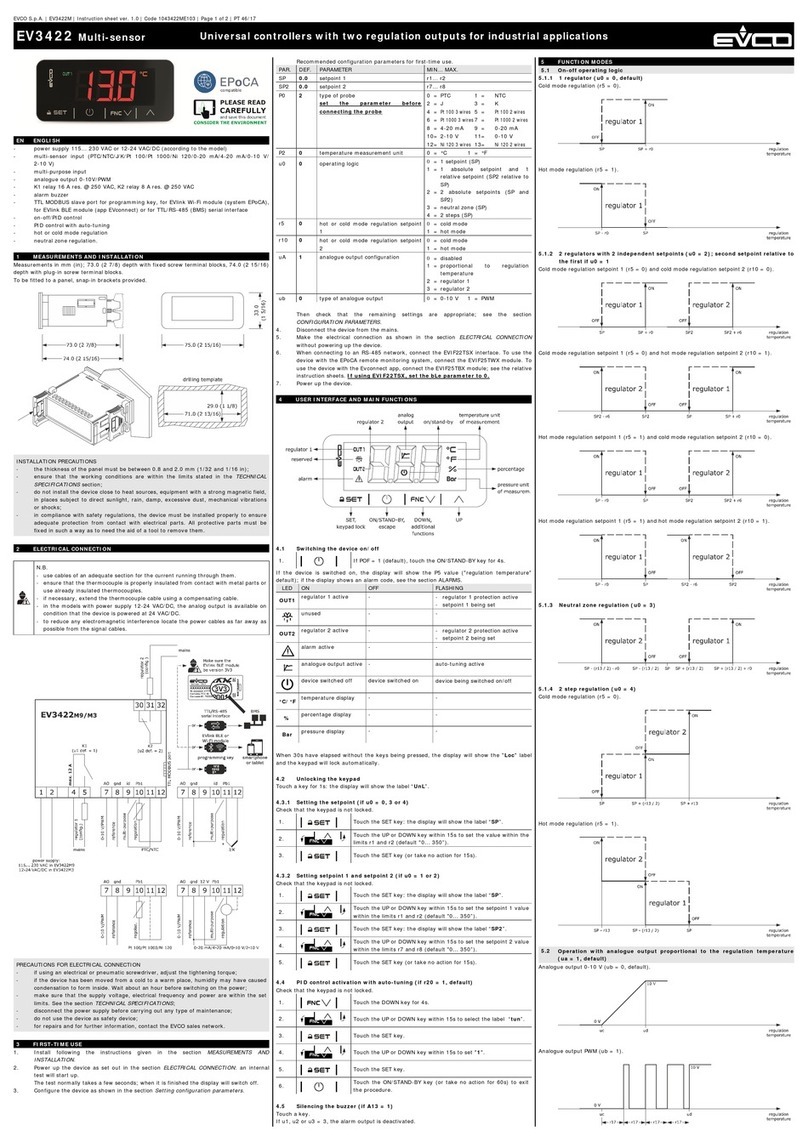

ELECTRIC CONNECTION ...................................................................................................................... 14

4.1

EVXV802 and EVXV812 electric connection ............................................................................................ 14

4.2

EVXV805 and EVXV815 electric connection ............................................................................................ 15

4.3

Warnings for the electric connection ..................................................................................................... 1

5

USER INTERFACE ............................................................................................................................... 17

5.1

Foreword .......................................................................................................................................... 17

5.2

Switching the device on/off ................................................................................................................. 17

5.3

The display ........................................................................................................................................ 17

5.4

Cabinet temperature display ................................................................................................................ 17

5.5

Display of the temperature detected by the needle probe ........................................................................ 18

5.

Evaporator temperature display ........................................................................................................... 18

5.7

Condenser temperature display............................................................................................................ 18

5.8

Defrosting activation in manual mode ................................................................................................... 19

5.9

Switching the cabinet light on/off in manual mode (in EVXV805 and EVXV815 models only) ........................ 19

5.10

Locking/unlocking the keyboard ....................................................................................................... 19

5.11

Silencing the buzzer ....................................................................................................................... 20

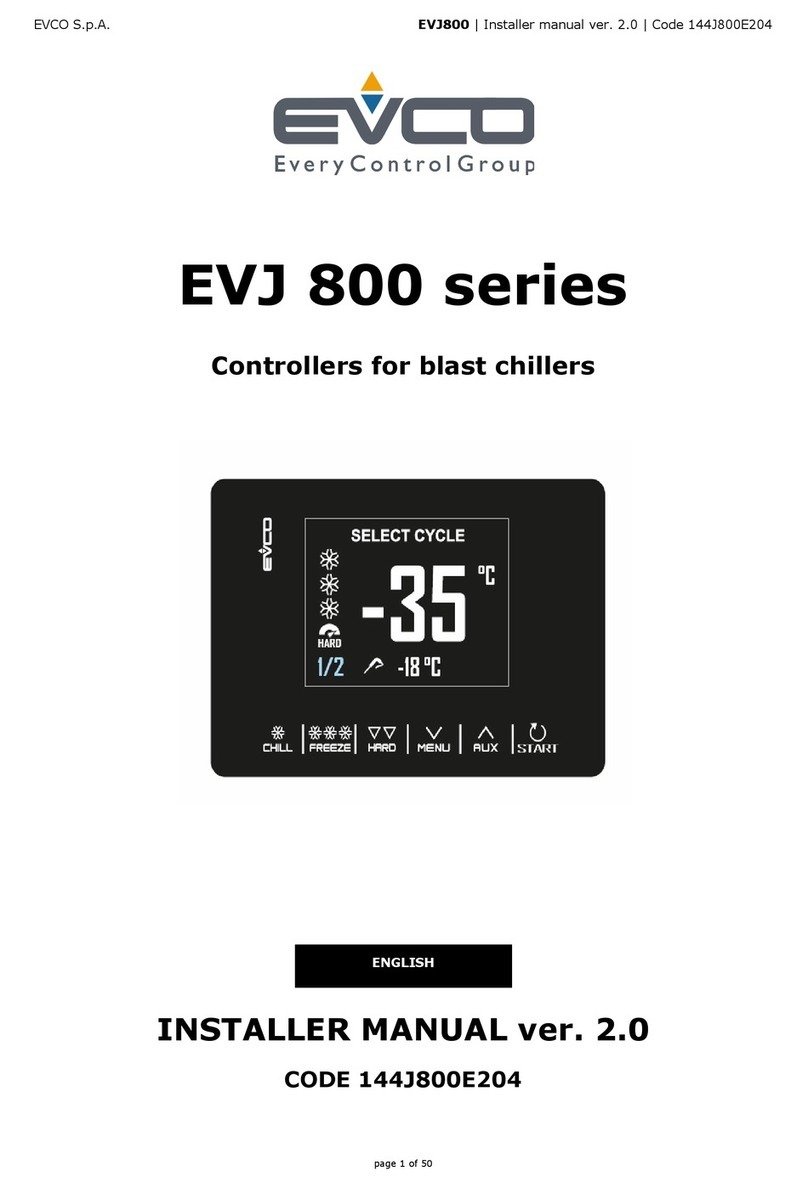

OPERATION ....................................................................................................................................... 21

.1

Foreword .......................................................................................................................................... 21

.2

Blast chilling and storage .................................................................................................................... 21

.3

Hard blast chilling and storage ............................................................................................................. 22

.4

Deep freezing and storage .................................................................................................................. 24

.5

Soft deep freezing and storage ............................................................................................................ 25

.

Pre-cooling start-up ............................................................................................................................ 27

.7

Management of the test regarding correct insertion of the needle probe .................................................... 27

.8

Switching the UV light on for sterilisation cycle (in EVX805 and EVX815 models only) ................................. 28

.9

Needle probe heating (in EVX805 and EVX815 models only) .................................................................... 28

7

“HACCP” FUNCTION (EVXV812 AND EVXV815 MODELS ONLY) ................................................................. 29

7.1

Foreword .......................................................................................................................................... 29

7.2

Displaying information relative to the HACCP alarms .............................................................................. 29

7.3

Deleting the information relative to the HACCP alarms ............................................................................ 30

8

COMPRESSOR OPERATING HOURS COUNT ............................................................................................ 31

8.1

Displaying compressor operating hours ................................................................................................. 31

8.2

Deleting the compressor operating hours .............................................................................................. 31

9

CONFIGURATION ............................................................................................................................... 32

9.1

Setting the real date and time (in EVXV812 and EVXV815 models only) .................................................... 32

9.2

Setting the configuration parameters .................................................................................................... 32