EVCO S.p.A. Vcolor 379 | Installer manual ver. 1.0 | Code 144VC379E104

Page 3 o 42

Contents

1 INTRODUCTION .................................. 4

1.1 Product description ............................. 4

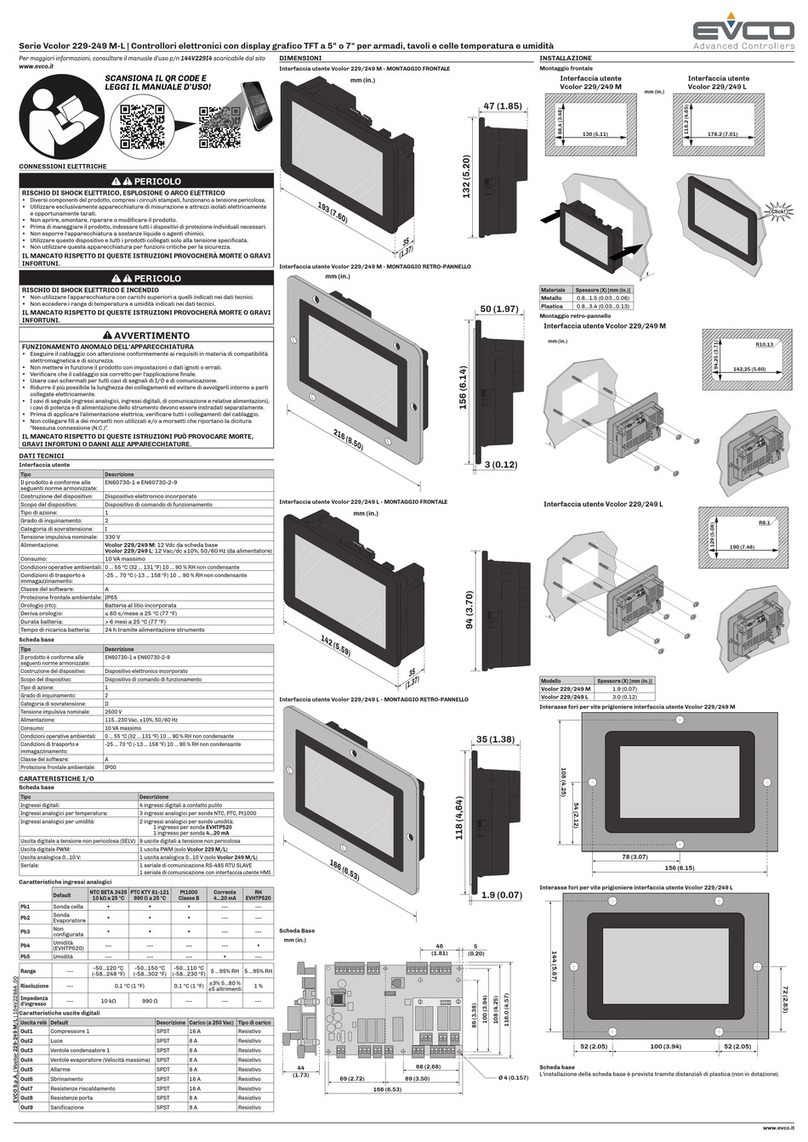

1.2 Models available and technical eatures . 5

2 MEASUREMENTS AND INSTALLATION.... 8

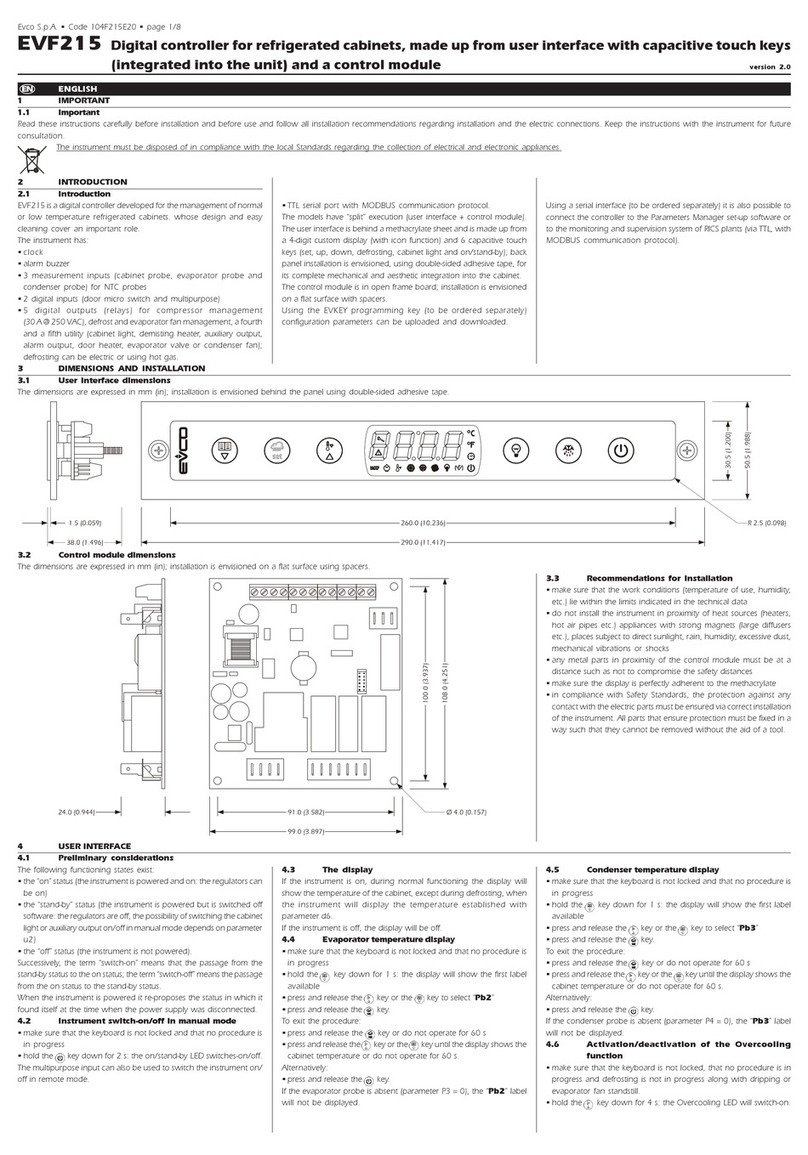

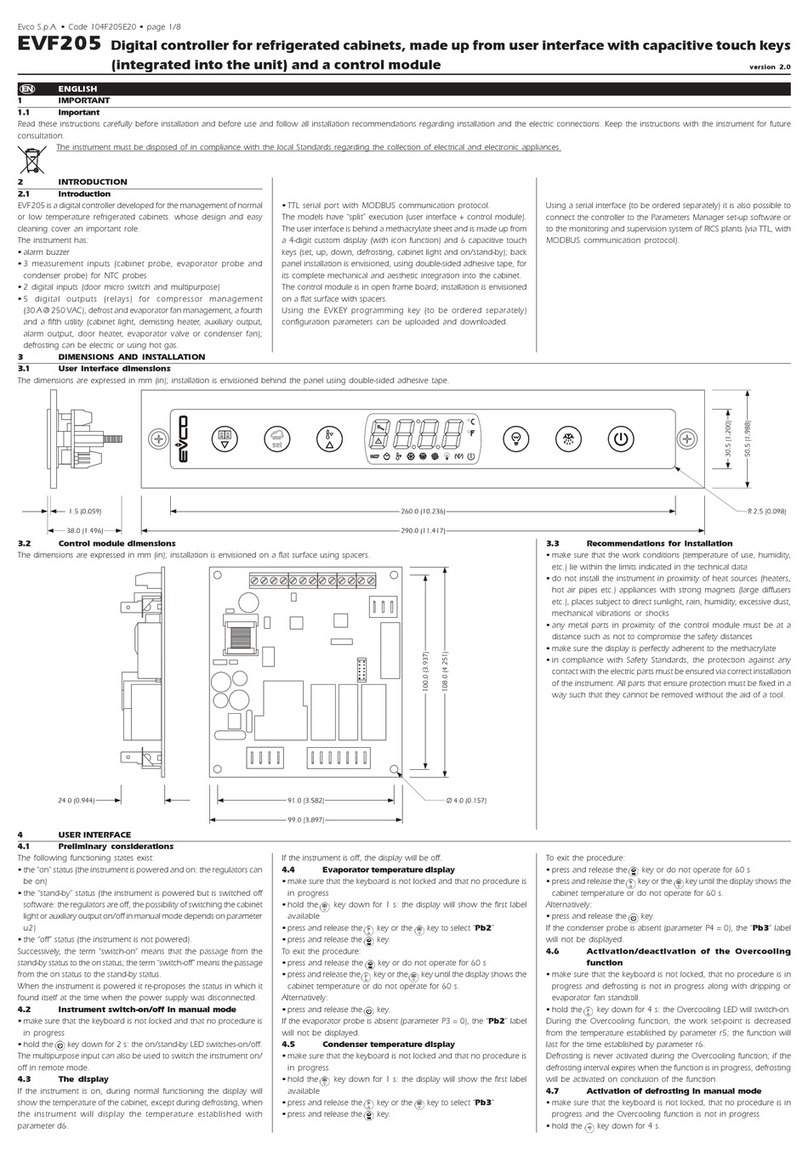

2.1 Format eatures .................................. 8

2.2 Control module measurements and

installation ......................................... 8

2.3 User inter ace measurements ............... 8

2.4 User inter ace installation .................. 10

2.5 Installation precautions ..................... 10

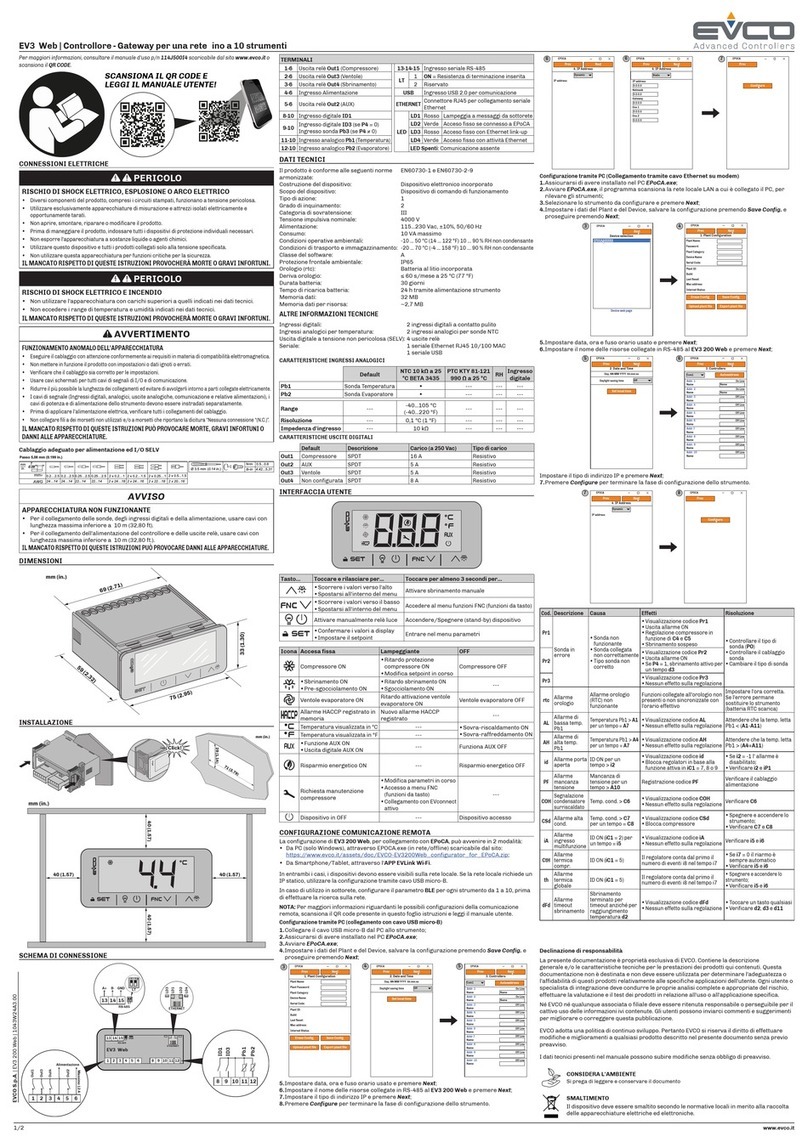

3 ELECTRICAL CONNECTION ................. 11

3.1 Vcolor 379M electrical connection ....... 11

3.2 Vcolor 379L electrical connection ........ 12

3.3 Precautions or electrical connection ... 13

4 FIRST-TIME USE ............................... 14

4.1 First-time use .................................. 14

5 USER INTERFACE ............................. 15

5.1 Initial in ormation ............................. 15

5.2 Splash screen .................................. 15

5.3 STAND-BY screen ............................. 15

5.4 ON screen ....................................... 15

5.5 Recipe book ..................................... 17

5.6 Locked display ................................. 17

6 “WEEKLY PROGRAMMED SWITCH-ON"

FUNCTION ....................................... 18

6.1 Initial in ormation ............................. 18

6.2 Setting and activating the unction ..... 18

7 MANAGING LOADS ........................... 19

7.1 Initial in ormation ............................. 19

7.2 Temperature regulation ..................... 19

7.3 Rotary plate management ................. 20

7.4 Buzzer management ......................... 20

7.5 Electronics compartment an .............. 21

7.6 Stand-by/on relay management ......... 21

7.7 Sound relay management .................. 21

7.8 Type 1 or 2 burner block reset (only or

gas ovens) ....................................... 21

8 CONFIGURATION .............................. 21

8.1 Initial in ormation ............................. 21

8.2 List o alarms ................................... 21

8.3 Internal values ................................. 21

8.4 Display cleaning ............................... 21

8.5 Setting the date and time .................. 21

8.6 Languages ....................................... 22

8.7 USB ................................................ 22

8.8 Service ............................................ 22

9 LIST OF CONFIGURATION

PARAMETERS ................................... 23

10 ALARM MANAGEMENT ....................... 29

11 CONNECTIVITY ................................. 31

11.1 Initial in ormation ............................. 31

11.2 EPoCA cloud plat orm ........................ 32

12 USING THE USB PORT ....................... 33

12.1 Initial in ormation ............................. 33

12.2 Uploading the recipe settings ............. 33

12.3 Downloading the recipe settings ......... 33

12.4 Uploading the settings in the con iguration

parameters ...................................... 33

12.5 Downloading the settings in the

con iguration parameters ................... 33

12.6 Uploading CSV iles to personalise the

graphics, recipes and languages ......... 33

13 ACCESSORIES .................................. 34

13.1 EVCO Inverter .................................. 34

13.2 Sa ety trans ormer ............................ 34

13.3 Non-optoisolated RS-485/USB serial

inter ace .......................................... 34

13.4 USB plug or panel installation ............ 35

13.5 Connecting cables ............................. 35

13.6 Buzzer expansion.............................. 35

13.7 4GB USB lash drive .......................... 35

13.8 EVlinking Wi-Fi RS-485 module .......... 36

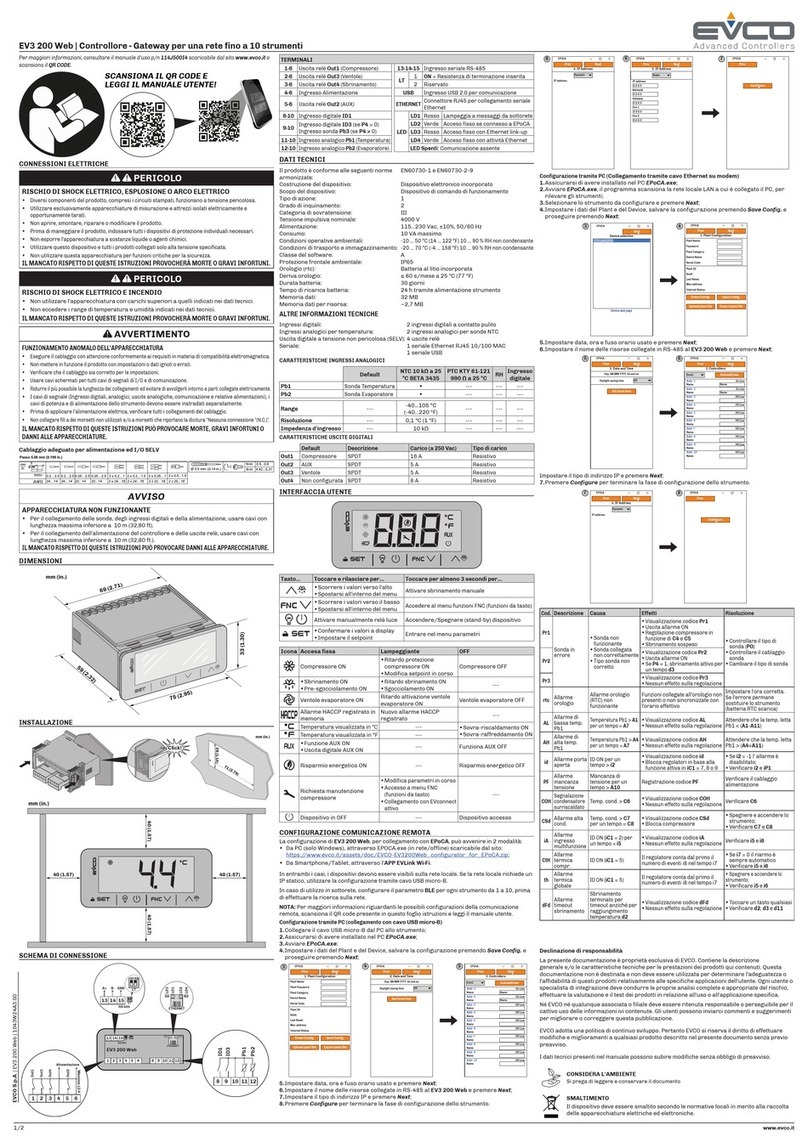

13.9 EV3 Web gateway ............................. 36

14 TECHNICAL SPECIFICATIONS ............. 37

14.1 Technical data .................................. 37