12

ENGLISH

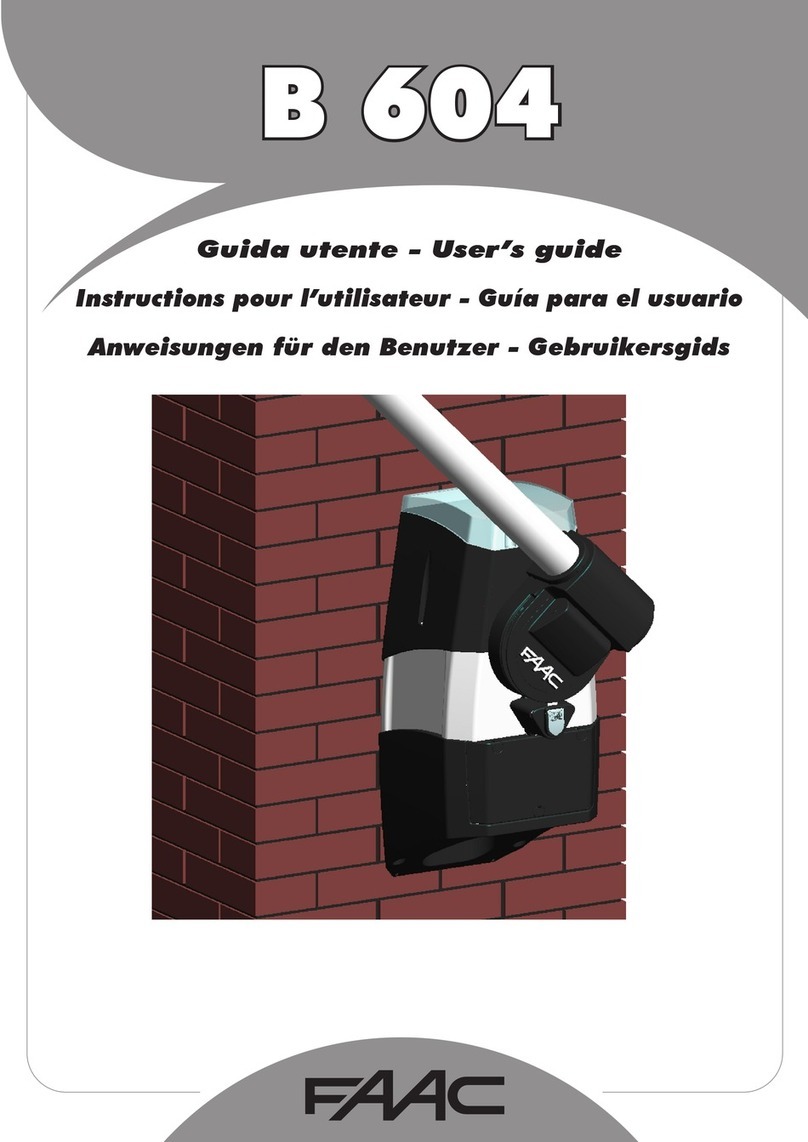

Position the rear plug of the release housing (Fig. 32 ref. a)

Open, on the front plug, the pre-perforated facility for the type of

installed rod, see Fig. 33 and fasten it to the release housing.

Explain, to the end-user, the correct use and operation of the

automated system.

Hand the “USER’S GUIDE” to the user and compile the enclosed

maintenance register.

6. MANUAL OPERATION

In the event of a power cut or malfunction of the automated

system, the beam can be moved manually as follows:

Insert the personalised key and take the beam to its “STOP”

position rotating it anti-clockwise until it stops, Fig. 34.

The key acts on a safety microswitch which positions the

control unit in STOP position, avoiding dangerous situations

during the release manoeuvre or during maintenance of

the automated system.

When the key is in STOP position, power to the automated

system is not cut off.

Open the release cover, Fig. 35.

Pull the release lever until it stops, (Fig. 36 ref. a)

Move the rod manually, Fig. 37.

7. RESTORING NORMAL OPERATION MODE

To prevent an involuntary pulse from putting the automated

system into operation, power down the system before re-

storing normal operation.

Lower the release lever.

Close the release cover.

Move the rod manually up to the point where manual move-

ment is no longer possible.

Take the key back to the “OPERATION” position, turning it

clockwise until it stops.

Remove the key and re-power up the system.

Following the manual manoeuvre, the first cycle could

occur without the programmed slow downs, run a couple

of cycles to check if the memory stored cycle is correctly

restored.

•

•

•

•

1.

1.

2.

3.

1.

2.

3.

4.

5.

8. AVAILABLE ACCESSORIES

The following accessories are available for the B 604 automated

system.

battery Kit

With the battery kit application, some manoeuvres can be carried

out in the event of a power cut.

The number of possible manoeuvres depends on the time

since power was cut, on the condition of the batteries, on

the number of accessories connected to the control unit,

on ambient temperature, and on the general conditions of

the automated system.

Installation procedure for the battery kit:

Cut power to the system.

Open the central compartment.

Position the batter kit on the left of the

transformer, see Fig.38.

Connect the battery kit cables to the

control unit, following the connection

lay-out shown in the control unit instruc-

tions.

Close the central compartment and restore

mains power.

balancing Kit

The length of the rods can be reduced with the balancing kit.

The table below shows the minimum lengths obtainable by using

the balancing kit:

TYPE OF ROD STANDARD L m min. L m

Telescopic rod 3.15 2.30

Fixed rod 4 2.80

Rod with lights 3 2.40

Rod with rubber edge 3 2.20

The rod lengths cannot be reduced beyond the value shown

in the table.

9. MAINTENANCE

To ensure correct long-term operation and a constant level of

safety, we advise you to generally control the system at least

every 6 months. In the “User’s Guide” booklet, there is a form for

recording jobs.

If the rod has to be removed for maintenance jobs, follow the

installation instructions in reverse order.

The rod can be removed only if it is in vertical position. Re-

moving the rod when in horizontal position could cause

dangerous situations.

10. REPAIRS

The User must not in any way attempt to repair or to take direct

action and must solely contact qualified FAAC personnel or

FAAC service centres.

10.1. REPLACEMENT OF FLASHING LAMP

Procedure for replacing the lamp of the integrated flashing light:

Make sure that the rod is in horizontal position.

Cut power to the system.

Remove the top housing, unscrewing the securing screws.

Replace the lamp (use lamp: E14 24V Max. 15W).

Re-position the top housing.

Power up the system.

1.

2.

3.

4.

1.

2.

3.

4.

5.

6.

Fig. 32Fig. 32 Fig. 33Fig. 33

Fig. 34Fig. 34 Fig. 35Fig. 35

Fig. 36Fig. 36 Fig. 37Fig. 37

Fig. 38Fig. 38